Effects of Machining Parameters of C45 Steel Applying Vegetable Lubricant with Minimum Quantity Cooling Lubrication (MQCL)

Abstract

:1. Introduction

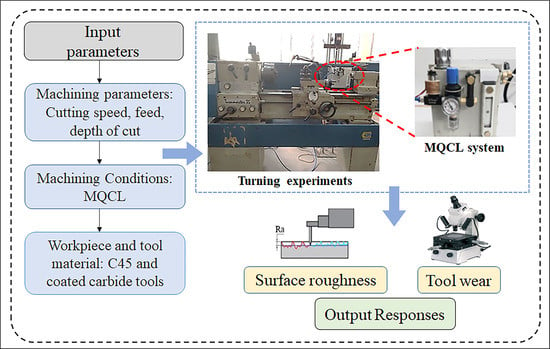

2. Material and Processes

2.1. Materials

2.2. Experimental Method

2.3. Experimental Design Using the Taguchi Method

3. Results and Discussions

3.1. Analysis Using the Taguchi Methods

3.2. S/N Ratio Analysis for Surface Roughness (Ra)

3.3. Regression Analysis for Surface Roughness

3.4. S/N Ratio Analysis for Tool Wear

3.5. Regression Analysis for Tool Wear

3.6. Confirmation Tests

3.7. Efficiency of Vegetable-Based Lubricant MQCL

4. Conclusions

- Three distinct levels of cutting speed, feed rate, and depth of cut were used to build the L9 orthogonal array. Results of studies corresponding to the L9 orthogonal array were obtained for surface roughness, and tool wear S/N ratios. The highest S/N ratio value was chosen, which produced the ideal cutting settings;

- The optimum cutting condition yielded a maximum S/N ratio of −0.11219 for surface roughness. The cutting parameters were 100 m/min for cutting speed, 0.180 mm/rev for the feed rate, and 0.150 mm for depth of cut (2-1-3 orthogonal array). Optimum cutting conditions for tool wear corresponding to a maximum 17.0774 S/N value were 80 m/min for cutting speed, 0.180 mm/rev for feed rate, and 0.125 mm for depth of cut (1-1-2 orthogonal array);

- The effects of cutting parameters related to Ra and tool wear were also examined using the model summary. The results showed that cutting speed, feed rate, and depth of cut varied surface roughness by 1.9%, 78.3%, and 14.04%. For tool wear, the cutting speed, feed rate, and depth of cut have effects of 43.8%, 37.9%, and 6.3%, respectively;

- The probability plots and main effect plots demonstrated the considerable impact of chosen machining parameters on tool wear and surface roughness in the MQCL environment;

- Vegetable oil contains a significant number of nonpolar methyl groups in its fatty acid chain. Thus, between the molecules, a dispersion force exists. As a result, two molecules are drawn to one another. Vegetable oil droplets often have a high viscosity at higher cutting temperatures and remain in the cutting zone for a longer period, enabling a superior lubrication effect during machining. Considering the biodegradable nature of vegetable oil, the application of vegetable oil-based MQL can be considered a feasible alternative for improving machinability without affecting environmental resources.

5. Future Scope of Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Said, L.B.; Kolsi, L.; Ghachem, K.; Almeshaal, M.; Maatki, C. Application of nanofluids as cutting fluids in machining operations: A brief review. Appl. Nanosci. 2022, 13, 4247–4278. [Google Scholar] [CrossRef]

- Xavior, M.A.; Adithan, M. Determining the influence of cutting fluids on tool wear and surface roughness during turning of AISI 304 austenitic stainless steel. J. Mater. Process. Technol. 2009, 209, 900–909. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, A.K.; Katiyar, J.K.; Kumar, A.; Sharma, A.K.; Katiyar, J.K. State-of-the-Art in Sustainable Machining of Different Materials Using Nano Minimum Quality Lubrication (NMQL). Lubricants 2023, 11, 64. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B. Cutting tool wear prediction in machining operations, a review. J. New Technol. Mater. 2022, 12, 15–26. [Google Scholar]

- Knight, W.A.; Boothroyd, G. Fundamentals of Metal Machining and Machine Tools, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2005; p. 602. [Google Scholar]

- Agrawal, A.; Goel, S.; Rashid, W.; Price, M. Prediction of surface roughness during hard turning of AISI 4340 steel (69 HRC). Appl. Soft Comput. 2015, 30, 279–286. [Google Scholar] [CrossRef] [Green Version]

- Khare, S.K.; Agarwal, S. Optimization of Machining Parameters in Turning of AISI 4340 Steel under Cryogenic Condition using Taguchi Technique. Procedia CIRP 2017, 63, 610–614. [Google Scholar] [CrossRef]

- Rapeti, P.; Pasam, V.K.; Gurram, K.M.; Revuru, R.S. Performance evaluation of vegetable oil-based nano cutting fluids in machining using grey relational analysis-A step towards sustainable manufacturing. J. Clean Prod. 2018, 172, 2862–2875. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Chen, J.C.; Kirby, E.D. Surface roughness optimization in an end-milling operation using the Taguchi design method. J. Mater. Process. Technol. 2007, 184, 233–239. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Elaziz, M.A.; Das, S.R.; Muthuramalingam, T.; Lu, S. A new optimized predictive model based on political optimizer for eco-friendly MQL-turning of AISI 4340 alloy with nano-lubricants. J. Manuf. Process. 2021, 67, 562–578. [Google Scholar] [CrossRef]

- Akkuş, H.; Asilturk, Đ. Predicting Surface Roughness of AISI 4140 Steel in Hard Turning Process through Artificial Neural Network, Fuzzy Logic and Regression Models. Sci. Res. Essays 2011, 6, 2729–2736. [Google Scholar]

- Singh, H.; Kumar, P. Mathematical models of tool life and surface roughness for turning operation through response surface methodology. J. Sci. Ind. Res. 2007, 66, 220–226. [Google Scholar]

- Çelik, Y.H.; Fidan, Ş. Analysis of cutting parameters on tool wear in turning of Ti-6Al-4V alloy by multiple linear regression and genetic expression programming methods. Measurement 2022, 200, 111638. [Google Scholar] [CrossRef]

- Jahanbakhsh, M.; Farid, A.A.; Lotfi, M. Optimal flank wear in turning of Inconel 625 super-alloy using ceramic tool. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 208–216. [Google Scholar] [CrossRef]

- Lalwani, D.I.; Mehta, N.K.; Jain, P.K. Experimental investigations of cutting parameters influence on cutting forces and surface roughness in finish hard turning of MDN250 steel. J. Mater. Process. Technol. 2008, 206, 167–179. [Google Scholar] [CrossRef]

- Nalbant, M.; Gökkaya, H.; Toktaş, I.; Sur, G. The experimental investigation of the effects of uncoated, PVD- and CVD-coated cemented carbide inserts and cutting parameters on surface roughness in CNC turning and its prediction using artificial neural networks. Robot Comput. Integr. Manuf. 2009, 25, 211–223. [Google Scholar] [CrossRef]

- Aslan, E.; Camuşcu, N.; Birgören, B. Design optimization of cutting parameters when turning hardened AISI 4140 steel (63 HRC) with Al2O3 + TiCN mixed ceramic tool. Mater. Des. 2007, 28, 1618–1622. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.J.; Aviña, K.; Ulloa-Castillo, N.A.; Melo-Maximo, D.V. Thermal Transport and Physical Characteristics of Silver-Reinforced Biodegradable Nanolubricant. Sustainability 2023, 15, 8795. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.J.; Aviña, K.; Padilla-Gainza, V.; Akundi, A. Halloysite Reinforced Natural Esters for Energy Applications. Lubricants 2023, 11, 65. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Shaji, S.; Kanakkillam, S.S.; Palma, M.I.M.; Aviña, K. Tribological and Thermal Transport of Ag-Vegetable Nanofluids Prepared by Laser Ablation. Appl. Sci. 2020, 10, 1779. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.A.A.; Hussain, M.; Lodhi, S.K.; Zazoum, B.; Asad, M.; Afzal, A. Green Metalworking Fluids for Sustainable Machining Operations and Other Sustainable Systems: A Review. Metals 2022, 12, 1466. [Google Scholar] [CrossRef]

- Vila, C.; Abellán-Nebot, J.V.; Siller-Carrillo, H.R. Study of Different Cutting Strategies for Sustainable Machining of Hardened Steels. Procedia Eng. 2015, 132, 1120–1127. [Google Scholar] [CrossRef] [Green Version]

- Rahim, E.A.; Ibrahim, M.R.; Rahim, A.A.; Aziz, S.; Mohid, Z. Experimental Investigation of Minimum Quantity Lubrication (MQL) as a Sustainable Cooling Technique. Procedia CIRP. 2015, 26, 351–354. [Google Scholar] [CrossRef] [Green Version]

- Jamil, M.; He, N.; Zhao, W.; Khan, A.M.; Laghari, R.A. Tribology and machinability performance of hybrid Al2O3 -MWCNTs nanofluids-assisted MQL for milling Ti-6Al-4 V. Int. J. Adv. Manuf. Technol. 2022, 119, 2127–2144. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.J.; Edinbarough, I.A. Comparative Cutting Fluid Study on Optimum Grinding Parameters of Ti-6Al-4V Alloy Using Flood, Minimum Quantity Lubrication (MQL), and Nanofluid MQL (NMQL). Lubricants 2023, 11, 250. [Google Scholar] [CrossRef]

- Chetan, H.; Behera, B.C.; Ghosh, S.; Rao, P.V. Application of nanofluids during minimum quantity lubrication: A case study in turning process. Tribol. Int. 2016, 101, 234–246. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.F.; Wang, Y.W. Tool life and cutting forces in end milling Inconel 718 under dry and minimum quantity cooling lubrication cutting conditions. J. Clean Prod. 2012, 32, 81–87. [Google Scholar] [CrossRef]

- Tamang, S.K.; Chandrasekaran, M.; Sahoo, A.K. Sustainable machining: An experimental investigation and optimization of machining Inconel 825 with dry and MQL approach. J. Brazilian Soc. Mech. Sci. Eng. 2018, 40, 374. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Singh, G.; Królczyk, G.; Pimenov, D.Y. An approach to cleaner production for machining hardened steel using different cooling-lubrication conditions. J. Clean Prod. 2018, 187, 1069–1081. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; De Lacalle, L.L. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; de Lacalle LN, L.; Rodríguez, A.; Pereira, O. In pursuit of sustainable cutting fluid strategy for machining Ti-6Al-4V using life cycle analysis. Sustain. Mater. Technol. 2021, 29, e00301. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; De Lacalle, L.L. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- De Lacalle, L.L.; Angulo, C.; Lamikiz, A.; Sanchez, J.A. Experimental and numerical investigation of the effect of spray cutting fluids in high speed milling. J. Mater. Process. Technol. 2006, 172, 11–15. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Rodrigues, J.R.P.; Neves, T.D.E.S.B.; da Silva, M.B.; Martins, K.C.R.; Robeiro, J.D.R.d.S.; Cunha, A.P.A. Study of the application of sunflower oil in the process of drilling ABNT 1045 steel. Acta Scientiarum. Technol. 2014, 36, 257–262. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.M.A.; Mithu, M.A.H.; Dhar, N.R. Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. J. Mater. Process. Technol. 2009, 209, 5573–5583. [Google Scholar] [CrossRef]

- Guo, S.; Li, C.; Zhang, Y.; Wang, Y.; Li, B.; Yang, M.; Zhang, X.; Liu, G. Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based alloy. J. Clean. Prod. 2017, 140, 1060–1076. [Google Scholar] [CrossRef]

- Behera, B.C.; Ghosh, S.; Rao, P.V. Wear behavior of PVD TiN coated carbide inserts during machining of Nimonic 90 and Ti6Al4V superalloys under dry and MQL conditions. Ceram. Int. 2016, 42, 14873–14885. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Krolczyk, G.M.; Mandal, U.K.; Mondal, S.P. Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. Int. J. Precis. Eng. Manuf. -Green Technol. 2021, 8, 249–280. [Google Scholar] [CrossRef] [Green Version]

- Sivaprakasam, T.; Hasan, S.; Thamizhmanii, S.; Saparudin, S.; Hasan, S. Analyses of surface roughness by turning process using Taguchi method Experimental and Simulation of Ultrasonic Vibration Assisted Milling Performance Toward Inconel 718. J. Achiev. Mater. Manuf. Eng. 2007, 20, 503–506. [Google Scholar]

- Saleem, M.Q.; Mehmood, A. Eco-friendly precision turning of superalloy Inconel 718 using MQL based vegetable oils: Tool wear and surface integrity evaluation. J. Manuf. Process. 2022, 73, 112–127. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Güllü, A. Multi-response optimization of minimum quantity lubrication parameters using Taguchi-based grey relational analysis in turning of difficult-to-cut alloy Haynes 25. J. Clean. Prod. 2015, 91, 347–357. [Google Scholar] [CrossRef]

| Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Cutting speed (m/min) | 80 | 100 | 120 |

| Feed rate (mm/rev) | 0.180 | 0.200 | 0.225 |

| Depth of cut (mm) | 0.100 | 0.125 | 0.150 |

| Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Surface Roughness (Ra) (µm) | S/N Ratio for Ra | Tool Wear (mm) | S/N Ratio for Tool Wear | |

|---|---|---|---|---|---|---|---|

| 1 | 120 | 0.180 | 0.100 | 1.15967 | −1.28669 | 0.28 | 11.0568 |

| 2 | 120 | 0.200 | 0.125 | 1.25633 | −1.98207 | 0.25 | 12.0412 |

| 3 | 120 | 0.225 | 0.150 | 1.24533 | −1.90569 | 0.21 | 13.5556 |

| 4 | 100 | 0.200 | 0.100 | 1.19400 | −1.54009 | 0.19 | 14.4249 |

| 5 | 100 | 0.225 | 0.125 | 1.34467 | −2.57231 | 0.18 | 14.8945 |

| 6 | 100 | 0.180 | 0.150 | 1.01300 | −0.11219 | 0.15 | 16.4782 |

| 7 | 80 | 0.225 | 0.100 | 1.37467 | −2.76397 | 0.16 | 15.9176 |

| 8 | 80 | 0.180 | 0.125 | 1.03700 | −0.31558 | 0.14 | 17.0774 |

| 9 | 80 | 0.200 | 0.150 | 1.15900 | −1.28167 | 0.14 | 17.0774 |

| Level | Cutting Speed (m/min) | Feed (mm/rev) | Depth of Cut (mm) |

|---|---|---|---|

| 1 | −1.4537 | −0.5715 | −1.8636 |

| 2 | −1.4082 | −1.6013 | −1.6233 |

| 3 | −1.7248 | −2.4140 | −1.0998 |

| Delta | 0.3166 | 1.8425 | 0.7637 |

| Rank | 3 | 1 | 2 |

| Predictor | Coef. | SE Coef. | T | P |

|---|---|---|---|---|

| Constant | 0.2610 | 0.2069 | 1.26 | 0.263 |

| Cutting speed (m/min) | 0.0007555 | 0.0009048 | 0.83 | 0.442 |

| Feed (mm/rev) | 5.5576 | 0.8026 | 6.92 | 0.001 |

| Depth of cut (mm) | −2.0734 | 0.7238 | −2.86 | 0.035 |

| Source | DoF | SS | MS | F | P |

|---|---|---|---|---|---|

| Regression | 3 | 0.111695 | 0.037232 | 18.95 | 0.004 |

| Residual Error | 5 | 0.009824 | 0.001965 | ||

| Total | 8 | 0.121519 |

| Level | Cutting Speed (m/min) | Feed (mm/rev) | Depth of Cut (mm) |

|---|---|---|---|

| 1 | 16.69 | 14.87 | 13.80 |

| 2 | 15.27 | 14.51 | 14.67 |

| 3 | 12.22 | 14.79 | 15.70 |

| Delta | 4.47 | 0.36 | 1.90 |

| Rank | 1 | 3 | 2 |

| Predictor | Coef. | SE Coef. | T | P |

|---|---|---|---|---|

| Constant | 0.07918 | 0.08844 | 0.90 | 0.412 |

| Cutting speed (m/min) | 0.0025000 | 0.0003868 | 6.46 | 0.001 |

| Feed (mm/rev) | −0.1585 | 0.3431 | −0.46 | 0.664 |

| Depth of cut (mm) | −0.8667 | 0.3095 | −2.80 | 0.038 |

| Source | DoF | SS | MS | F | P |

|---|---|---|---|---|---|

| Regression | 3 | 0.0178933 | 0.0059644 | 16.61 | 0.005 |

| Residual Error | 5 | 0.0017956 | 0.0003591 | ||

| Total | 8 | 0.0196889 |

| Cutting Speed (m/min) | Feed (mm/rev) | Depth of Cut (mm) | Surface Roughness (μm) | Tool Wear (mm) | |||

|---|---|---|---|---|---|---|---|

| Exp. | Pred. | Exp. | Pred. | ||||

| 1 | 120 | 0.200 | 0.125 | 1.25633 | 1.20485 | 0.25 | 0.23 |

| 2 | 80 | 0.225 | 0.100 | 1.37467 | 1.36540 | 0.16 | 0.15 |

| 3 | 90 | 0.190 | 0.130 | 1.32120 | 1.11625 | 0.17 | 0.16 |

| 4 | 110 | 0.195 | 0.140 | 1.17210 | 1.15915 | 0.22 | 0.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makhesana, M.A.; Bagga, P.J.; Patel, K.M.; Taha-Tijerina, J.J. Effects of Machining Parameters of C45 Steel Applying Vegetable Lubricant with Minimum Quantity Cooling Lubrication (MQCL). Lubricants 2023, 11, 332. https://doi.org/10.3390/lubricants11080332

Makhesana MA, Bagga PJ, Patel KM, Taha-Tijerina JJ. Effects of Machining Parameters of C45 Steel Applying Vegetable Lubricant with Minimum Quantity Cooling Lubrication (MQCL). Lubricants. 2023; 11(8):332. https://doi.org/10.3390/lubricants11080332

Chicago/Turabian StyleMakhesana, Mayur A., Prashant J. Bagga, Kaushik M. Patel, and Jose J. Taha-Tijerina. 2023. "Effects of Machining Parameters of C45 Steel Applying Vegetable Lubricant with Minimum Quantity Cooling Lubrication (MQCL)" Lubricants 11, no. 8: 332. https://doi.org/10.3390/lubricants11080332