State-of-the-Art in Sustainable Machining of Different Materials Using Nano Minimum Quality Lubrication (NMQL)

Abstract

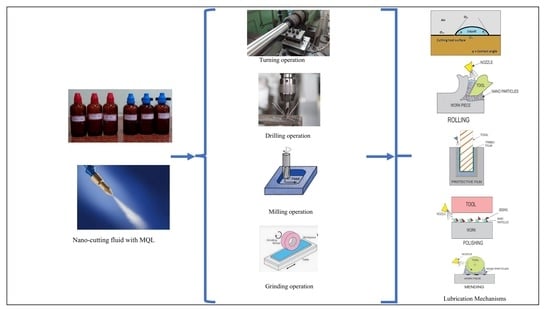

:1. Introduction

2. Minimum Quality Lubrication

3. Experimental Study

3.1. Nanofluid-Assisted MQL Turning

3.1.1. Turning on Steel

3.1.2. Turning on Nickel Alloys

3.1.3. Turning on Titanium Alloys

3.1.4. Turning on Cobalt Alloys

| Ref. No. | Work/Tool Material | Base Fluid | Nano Particles/ Size in nm | Cutting Parameters | MQLParameters | Effects(Reduction of Responses) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vc (m/min) | f (mm/rev) | d (mm) | Pressure (Bar) | Flow Rate (mL/Min) | |||||

| [37] | AISI1040steelØ70 mm and 300 mm L/Cemented carbide | Vegetable oil + water emulsion | Al2O3/45 | 96.7 | 0.1 | 1 | 4 | 50 | 1% conc.—cutting force, flank wear and surface roughness. |

| [38] | AISI-1040 steel Ø70 mm and 300 mm L/Carbide | Vegetable oil | TiO2/ <100 | 96.7 | 0.1 | 1 | 5 | 50 | 1% conc. TiO2-tool wear, surface roughness and cutting force by 50, 30, and 30% compared to other environments |

| [39] | AISI D2 steel Ø40 mm and 180 mm L/Tungsten carbide | SAE20W40 mineral oil | MWCNT/ <100 | 51–123 | 0.1–0.2 | - | 5–7 | - | 0.2 wt.%—surface roughness and cutting temperature |

| [40] | AISI 304 stainless steelØ70 mm and 300 L- | Water emulsion | MWCNT/ <100 | 40 | 0.08 | 0.6 | 4 | 0.83 | 1% conc.—cutting temperature and surface roughness at lower value of cutting parameters |

| [41] | Austempered ductile iron/Carbide | Ecolubric E200 vegetable oil | Al2O3/ 20 | 120 | 0.2 | 0.5 | 5 | 40 | 4 vol.% con.—tool wear |

| [42] | H 11 steel Ø20 mm and 100 mm L/Carbide | Ethylene glycol | Cu/ 50 | 209 | 0.1 | 1 | 3 | 7 | 0.2 wt.% con.—surface roughness and flank wear by 40% and 60% |

| [43] | AISI-H13 steelØ50 mm and 250 mm L/Tungsten carbide | Coconut oil with additives + Mineral oil | CaF2 and MoS2/ <100 | 90 | 0.28 | 0.5 | 5 | 0.58 | 0.3 wt.%. con. MoS2 (HN-GCF) 1:16-co-efficient of friction, surface roughness and tool wear |

| [44] | AISI-4340 steel Ø24 mm and 100 mm L/Tungsten-coated carbide | Ethylene glycol | MWCNT/ <70 | 75 | 0.04 | 1 | 5 | 2.33 | 0.2% conc.—surface roughness and cutting force |

| [45] | AISI 4340 steel Ø50 mm and 700 mm L/Cermet | Radiator coolant | Al2O3/ <50 | 80 | 0.05 | 0.4 | 7 | 2.5 | tool wear, cutting force and serrations on chips |

| [45] | EN24 steelØ20 mm and 100 mm L/Carbide | Ethylene glycol | Cu/ 20–50 | 157 | 0.2 | 0.2 | 3 | 10 | 0.4 wt.% con.—surface roughness and flank wear |

| [46] | AISI-D3 steel Ø20 mm and 145 mm L/Tungsten carbide | Ethylene glycol | Graphene/ <100 | 31.4–94.2 | 0.03–0.13 | 0.75–1.5 | 2 | 8 | 0.8 wt.% con.—surface roughness and cutting temperature to 50% compared to other |

| [47] | 90CrSi steel Ø40 mm/Tungsten carbide | Soya bean oil + water emulsion | Al2O3 and MoS2/ 30 | 81.7–119.4 | 0.1 | 0.15 | - | - | Al2O3—thrust force and surface roughness whereas MoS2-Cutting and feed forces |

| [48] | AISI-304 steel/Cemented carbide | Vegetable oil + distilled water + detergent | Al2O3-MWCNT/ 45 | 60–120 | 0.08–0.16 | 0.6–1.2 | 4 | 2.5 | 1.25% conc. hybrid Al-MWCNT (90:10)—cutting forces and surface roughness |

| [49] | AISI-52100 steel/Carbide | Blaser cutting oil in DI | Al2O3, Al2O3-Graphene/ 45 and 10–16 | 90 | 0.1 | 0.5 | 6 | 5 | 0.75% conc. Al-graphene (85:15)—cutting power, machine tool power, surface roughness and specific energy consumption |

| [50] | AISI-1080 Steel, Ø40 mm and 300 mm L/Ti-AlN | Coconut oil | CuO-Al2O3/ 50–100 and 30 | 180 | 0.1 | 0.5 | - | - | CuO-Al2O3 (50:50)—surface roughness |

| [51] | Inconel-600 alloyØ20 mm and 100 mm L/Carbide | vegetable oil-coolube 2210EP | Al2O3/ <100 | 40–60 | 0.08–0.16 | 0.4–1.2 | 5 | 1.66 | 6 vol.% con.—tool wear, cutting force, temperature and surface roughness compared to dry and pure MQL |

| [52] | Nicrofer-C263 Ø42 mm and 250 mmL/Cemented tungsten carbide | Max Mist ST2020 | Al2O3/<100 | 36–54.75 | 0.09–0.12 | 0.75–0.9 | 5 | 1 | 1 vol.% con.—surface roughness, cutting force and cutting temperature compared to dry and pure MQL |

| [53] | Nimonic90 Ø60 mm and 300 mm L/Tungsten Carbide | Water | Al2O3 and Ag/ 40 and 10 | 60 | 0.12 | 0.5 | 4 | 1–4.16 | Al2O3 125 mL/h—tool wear, chip thickness and friction co-efficient |

| [54] | Inocel-617 Ø32 mm and 300 mm L/PVD (AlTiN) | Coconut oil | Al2O3/ <100 | 40–100 | 0.14–0.2 | 0.5 | 4 | 20 | 0.25% con.—tool wear, cutting force surface roughness and serrations on chips |

| [55] | Inconel-718 (ASTMSB 637)/Tungsten carbide | Ecolubric E200 vegetable oil | Al2O3 and MWCNT/ 20 and 13–20 | 40–60 | 0.2–0.4 | 0.2 | 5 | 0.66 | 4% con. MWCNT—cutting force and cutting temperature |

| [56] | Inconel-625 Ø70 mm and 300 mm L/PVD TiNcementedcabide | Plantocut 10 SR | h-BN/ 70 | 40 | 0.075 | 0.8 | 8 | 0.83 | 1%vol. con.—tool wear, cutting temperature and surface roughness |

| [57] | Inconel-800 Ø50 mm and 120 mm L/Cubicboron nitride | Sunflower oil | Al2O3, MoS2 and Graphite/40 | 200–300 | 0.1–0.2 | 0.25–0.75 | 5 | 0.5 | 3 wt.% con. graphite-cutting forces, tool wear and surface roughness compared to others |

| [58] | Hastelloy-X/PVD (TiAlN) and CVD (Al2O3) | Coconut oil | h-BN/ 30-1 00 | 40–100 | 0.14–0.2 | 0.5 | 4 | 0.125 | 0.25 vol.% con with PVD-coated tool-tool wear, cutting force and surface roughness |

| [59] | Titanium (grade-2) Ø52 mm and 150 mm L/Cubic boron nitride | Vegetable oil | Al2O3, MoS2 and Graphite/ 40 | 215 | 0.1 | 1 | 5 | 0.5 | Graphite—cutting forces, tool wear and surface roughness compared to Al2O3 and MoS2 |

| [59] | Ti-6Al-4V (Titanium grade5) Ø30 mm and150 mm L/CNMG 12408 | soya bean oil | Graphene/ <100 | 100–200 | 0.1–0.2 | 0.2–0.4 | - | 16.66 | Graphene—flank wear, surface roughness and cutting temperature compared to dry and pure MQL environments |

| [64] | Ti-6 Al-4V(UNSR56400)/Carbide | Ecolubric E200 | MWCNT/ 13–20 | 120–220 | 0.1–0.2 | 0.2 | 5 | 0.66 | 2% conc.—power consumption and tool wear by 11.5% and 45% compared to base fluid MQL |

| [65] | Titanium grade2 Ø16 mm and 130 mm L/tungsten carbide | Ethylene glycol | Ag/ 20 | 85.4 | 0.03 | 1.5 | 3 | 10 | 0.4 wt.% con.—tool wear, surface roughness and cutting temperature |

| [66] | Ti-6 Al-4V Ø30 mm and 200 mm L/carbide | Jojoba oil and LRT 30 | MoS2/ 80–100 | 80 | 0.16 | 4 | 6 | 1 | 0.1 wt.% of MoS2 in jojoba oil—tool wear, cutting force, surface roughness |

| [67] | Ti-6Al-4V Ø80 mm and 300 mm L/laser textured carbide | Sun flower oil + deionized water | Al2O3/ 40 | 60–120 | 0.1–0.2 | 1 | 4–7 | 1.16–1.66 | Sun flower oil + deionized water in the ratio 1:10 with MQL improved the machining performance compared to dry and nano MQL |

| [69] | Ti-6Al-4V (Ø50 mm and 250 mm L)/CNGA-120408 T01020-WG | Blaser-distilled water base fluid | CuO-MWCNT/ 5–10 and 10–30 | 80–120 | 0.08–0.12 | 1 | 4.5 | 2.5 | 24% con. CuO- MWCNT (90:10)—tool wear, surface roughness, cutting temperature and power |

| [70] | Haynes-25 (L = 100 mm)/carbide | Blasar vegetable oil in water | Al2O3-Graphene/ 45 | 30–60 | 0.08–0.16 | 1 | 6 | 5 | (85:15) Al-graphene—cutting energy, carbon emission and cost per part. |

3.2. Nanofluid-Assisted MQL Milling

3.2.1. Milling on Steel

3.2.2. Milling on Cast Iron

3.2.3. Milling on Aluminum Alloys

3.2.4. Milling on Nickel Alloys

3.2.5. Milling on Titanium Alloys

| Ref. No. | Work/Tool Material | Base Fluid | Nano Particles/ Size in nm | Cutting Parameters | MQL Parameters | Effects(Reduction of Responses) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vc (m/min) | f (mm/rev) | d (mm) | Pressure (bar) | Flow Rate (mL/Min) | |||||

| [71] | AISI-1045 steel (203.2,127 and 203.2)/TIAlN-coated carbide insert (Ø25 mm) | UNIST Coolube 2210 (vegetable oil) | Graphene platelets/ 10 thick | 274–353 | 0.5–0.7 | A = 1 and R = 0.6 | 5.5 | 1.5 | 0.1 wt. % con.—tool wear and friction co-efficient |

| [72] | AISI-1050 and AISI-P21 steel (100 × 100 × 80 mm3)/Carbide TiN+TiAlN (Ø20 mm) | Vegetable cutting oil | MWCNT/ 24–40 | 157 | 0.1 | A = 0.8 and R = 20 | 4 | 1 | 0.5 wt. % con.—surface roughness and tool wear compared to dry and wet milling |

| [73] | AISI-420martensitic steel (400 × 250 × 4 mm3)/Tungsten carbide end mill (Ø32 mm) | Eraoil KT/2000 | MoS2/<60 | 99 | 0.18 | 0.5 | 5 | 0.33–0.66 | 1% wt. con.—tool wear and surface roughness compared to other cutting environments |

| [74] | AISI-430 ferritic steel (400 × 250 × 6 mm3)/Tungsten carbide end mill and TiN-coated Tungsten carbide tool (Ø32 mm) | Eraoil KT/2000 | Graphene/<100 | 100 | 0.18 | 0.5 | 5 | 0.33–0.66 | TiN-coated tool and 0.5 wt.% con.—cutting temperature and burs on surface of work |

| [75] | AISI-304 stainless steel (210 × 105 × 110 mm3)/Coated Carbide (Ø35 mm) | Polyethylene glycol 300 (PEG300) | GO nano sheets, SiO2 and GO- SiO2/ 5–10 thick and 20–30 dia. | 100 | 0.12 | A = 1 and R = 5 | 3.5 | 0.25 | GO/SiO2(0.02:0.50) con.—achieved significant tribological characteristics and milling performance compared to all other |

| [76] | AISI-304 austenitic stainless steel (210 × 105 × 110 mm3)/Coated Carbide (Ø35 mm) | LB-2000 vegetable oil | Graphene/ 5–10 and ≤10 μm. dia. | 100 | 0.1 | A = 1 and R = 5 | 3 | 0.166 | 0.06 wt.% con. at -6 kv.—tool wear and surface roughness effectively compared to base EMQL |

| [77] | AISI-304 steel (200 × 150 × 50 mm3)/coated (Al,TiN) carbide insert | Soya bean oil | MWCNT/ 15-Oct | 100–160 | 0.075–0.15 | 0.3–0.6 | 6 | 1.25 | 1% wt. con.—surface roughness significantly compared to dry, flood, and pure MQL |

| [78] | AISI-4340 steel (250 mm × 100 mm × 20 mm)/cutter with Tungsten carbide insert (Ø16 mm) | Servocut -S oil + water | Boric acid, Graphite and Boric acid/Graphite/<100 | 251–376 | 0.1–0.13 | 0.5 | 5 | 2.5 | 10 wt.% con.—cutting forces and surface roughness compared to others |

| [79] | AISI-O2 Steel (150 × 80 × 80 mm3)/Carbide (Ø25 mm) | Ethylene glycol | h-BN/<100 | 100 | 0.05 | A = 0.5 and R = 15 | 5 | 0.83 | 2 wt.% con.—tool wear, surface roughness, and cutting force |

| [80] | SKD 11 tool steel (90 × 48 × 50 mm3)/submicron carbide insert (Ø50 mm) | Emulsion-based cutting fluid | MoS2/30 | 90–110 | 0.012 | 0.12 | 6 | 0.5 | 0.5 wt.% con.—surface roughness |

| [81] | SKH-9 Steel/double edge micro end mill(Ø300µm) | Oil | MWCNT and Graphene/ 12 and 60 | 37.69–56.54 | 0.002–0.004 | 0.1 | 1–3 | 0.25–0.58 | 1 wt.% con.—micro milling force, temperature and tool wear compared to other techniques employed |

| [82] | EN-GSJ 700–02 cast iron (70 × 160 × 40 mm3)/coated carbide cutting inserts (Ø32 mm) | ERALUBETM BIO CF 350 | MoS2/90 | 300 | 0.2 | A = 1 and R = 10 | 3–5 | 2.6–5.16 | 0.5 wt.% con.—surface roughness, traces of abrasive and adhesive wear of tool |

| [83] | AA6061-T6 (50 × 50 × 200 mm3)/HSS tool (Ø10 mm) | ECOCUT SSN 322 mineral oil | SiO2/ 15 | 157 | 0.02 | 5 | 200 | 2 | 0.2 wt.% con.—cutting force, specific energy and power during machining |

| [84] | AA6061-T6 alloy/Tungsten cobalt (6%) insert | De-ionized water | TiO2/ 40 | 5200–5600 rpm | 0.09 | 2.25 | 6 | 0.65 | 2.5 wt.% con.—Higher adhesion and edge chipping |

| [85] | AA6061-T6 (100 × 100 × 20 mm3)/Coated tungsten carbide | Ethylene Glycol | TiO2- ZnO/ 21 and 10–30 | 3000–6800 rpm | - | 0.35–1.3 | - | 0.6–2.4 | TiO2- ZnO (80:20) 0.1 vol.%—tool wear and surface roughness compared to dry and pure MQL |

| [86] | AA7075-T6 alloy (152 × 103 × 80 mm3)/High speed steel (Ø10 mm) | ethylene glycol | Ag and Borax/ <100 | 64–135 | 0.029–0.171 | - | 5 | 0.83 | Reduced the surface roughness significantly but failed in reducing cutting force |

| [87] | Inconel-690/Uncoated carbide tool (Ø6 mm) | Palm oil | Al2O3/ 30 | 140 | 0.2 | 1 | 8 | 2 | 2.5 wt.% con.—specific cutting energy, surface roughness, cutting temperature and tool wear compared to other medium |

| [88] | Inconel-X750 alloy (100 × 150 × 17.3 mm3)/Coated carbide TiAlN | Vegetable oil | h-BN, MoS2 and graphite/ 80 | 45 | 0.10 | 0.5 | 8 | 0.83 | 0.5 wt.% con.—cutting force, temperature, and surface roughness |

| [89] | Nickel alloy X-750/uncoated SiAlON CC cutting tool | Belgin oil cuttex syn.5 | h-BN/ 65–75 | 500–700 rpm | 0.025–0.075 | A = 0.5 and R = 15 | 8 | 0.83 | 0.5 vol.% con.—flank wear, surface roughness, cutting force, and temperature |

| [90] | HastelloyC276 (150 × 100 × 15 mm3)/coated carbide inserts (Ø32 mm) | Vegetable oil | Al2O3/ 18 | 60–90 | 0.1–0.2 | - | 8 | 1.6 | 1 wt.% con.—significant improvement in surface roughness and tool wear |

| [91] | Ti-6Al-4V (30 × 30 × 5 mm3)/tungsten carbide end mill (Ø500 μm) | Neo-01 vegetable oil | Diamond/ | 70.6 | 0.005 | 0.1 | 1.5 | 0.16 | 0.1 wt.% con.—milling forces, surface roughness, tool wear, and co-efficient of friction |

| [92] | Titanium TC4 alloy (80 × 30 × 15 mm3)/coated carbide end mill (Ø6 mm) | LB2000 vegetable oil-based cutting fluid | Graphene/ 5 | 15 | 0.0.16 | 0.1 | 6 | 1 | 0.1 wt.% con.—surface roughness, milling forces, temperature, and tool wear |

| [93] | Ti-6Al-4V (40 × 30 × 30 mm3) | Cotton seed oil | Al2O3, MoS2, SiO2, CNTs, SiC and graphite/ 70 | 1200 rpm | 0.41 | A = 0.25 and R = 10 | 4 | 1,41 | 1.5 wt.% spherical shaped nanoparticles Al2O3 and SiO2 had improved the lubricating performance of base fluid compared to other nano fluids. |

| [94] | Ti-6Al-4V (50 × 50 × 100 mm3)/Coated cemented carbide (Ø10 mm) | Fatty acid ester | h-BN/ 80–100 | 56–73 | 0.01–0.059 | 0.68–2.31 | 3 | 0.31–0.66 | 24.75%. con.—cutting forces and surface roughness compared to pure MQL |

| [95] | Ti-6Al-4V/Carbide milling tool (Ø10 mm) | Blaso cut oil emulsion | Al2O3-MWCNT/ 30 | 67.5–130 | 0.012–0.024 | A = 0.25–0.45 and R = 1.6–3.6 | 4 | 2 | 1 vol.% Al2O3-MWCNT (90:10) con.—surface roughness, energy consumption and enhanced the metal removal rate |

3.3. Nanofluid-Assisted MQL Drilling

3.3.1. Drilling on Steel

3.3.2. Drilling on Titanium Alloy

3.3.3. Drilling on Aluminum Alloy

3.3.4. Drilling on Compacted Graphite Iron

| Ref. No. | Work/Tool Material | Base Fluid | Nano Particles/ Size in nm | Cutting Parameters | MQL Parameters | Effects (Reduction of Responses) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vc (m/min) | f (mm/s) | d (mm) | Pressure (bar) | Flow Rate (mL/Min) | |||||

| [96] | AISI-P20 steel (150 × 150 × 40 mm3)/TiAlN-coated carbide (Ø8.5 mm) | Soluble coconut oil | CuO/<50 | 50–150 | 0.01 | 6 | 0.166 | 0.5 wt.% con.—tool wear | |

| [97] | AISI-4140 steel (130 × 180 × 5 mm3)/carbide drill (Ø10 mm) | ethylene glycol | Cu/70 | 61–123 | 0.02–0.05 | 4 | 10 | 0.2 wt.% con.—surface roughness and flank wear by 71% and 53% compared to CC and coconut oil cutting environment | |

| [98] | AISI-314 stainless steel (30 mm thick)/M35 HSS drill (Ø8 mm) | Sun flower oil | Graphene/ 10 | 7.91 | 0.125 | 6 | 2 | 1.5 wt.% con.—thrust force, torque, surface roughness, and co-efficient of friction, wear rate compared to pure MQL | |

| [99] | Hardox-500 (150 × 100 × 15 mm3)/carbide drill with TiAlCN coating | Rice bran oil and Water-based emulsion | Al2O3/ 30 | 15–25 | 0.02–0.06 | 6 | 0.5 | 1 wt.% con.—surface roughness and thrust force followed by better tool life and surface micro structure of work. | |

| [100] | Ti-6Al-4V (30 × 30 × 5 mm3)/Uncoated tungsten carbide (Ø300 µm) | Palm oil | Dimond/ 35 and 80 | 56.52 | 0.0001–0.0008 | 0.4 | 3 | 0.125 | 0.4 wt.% con.—tool wear, torque, and force |

| [101] | Ni-Ti alloy (94 × 70 × 10 mm3)/TiAlN-coated Tungsten carbide drill (Ø6 mm) | sol-cut oil | Al2O3/ <50 | 10–30 | 0.02 | - | - | 0.83 | 0.4 wt.% con.—cutting force, surface roughness and tool wear at low cutting speed but failed in achieving the same at high cutting speed |

| [102] | Aluminum 6061 alloy/Uncoated carbide drill of (Ø200 µm) | Paraffin and vegetable oil | Dimond/ 30 | 37.68 | 0.00083 | 0.4 | - | - | Paraffin diamond nano fluid of 1 vol.% con.—torque and thrust force and achieved no burrs compare to other cutting environments |

| [103] | Aluminium-6063 (25 mm thick)/HSS drill (Ø6 mm) | Soya bean oil | Al2O3/ 20 | 30–53.7 | 0.037 | - | 4.8 | 3.33 | 1.5 wt.% con.—thrust force, torque, tool wear and surface roughness compared to dry, flood, and pure MQL |

| [104] | Aluminium-6061-T6 alloy plate (20 mm thick)/HSS drill (9, 10 and 11 mm) | Canola oil | MoS2/ 30 | 28.26–69.08 | 0.02 | - | 10 | 0.5 | 3 wt.% con.—power, force, tool wear and surface roughness compared to other cutting environments. |

| [105] | AA 5052 (150 × 200 × 5 mm3)/Tungsten carbide drill | Ethylene glycol | Cu/ 50 | 60–210 | 150 mm/min | - | 4 | 8 | 0.2 wt.% con.—surface roughness, flank wear and cutting temperature significantly |

| [106] | Compacted Graphite Iron (CGI)/WC-CO twist type drill (Ø6.35 mm) | Misty Blue TM | WS2 and h-BN/ <100 | 50 | 0.1 | - | 6.8 | 0.2 | 0.1 wt.% con. of WS2 and h-BNnano particles improved the tribological properties by enhancing the lubricating performance of base fluid |

3.4. Nanofluid-Assisted MQL Grinding

3.4.1. Grinding on Steel

3.4.2. Grinding on Nickel Alloys

3.4.3. Grinding on Cast Iron

3.4.4. Grinding on Ceramics

3.4.5. Grinding on Composites

| Ref. No | Work/Tool Material | Base Fluid | Nano Particles/ Size in nm | Cutting Parameters | MQL Parameters | Effects (Reduction of Responses) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vc (m/min) | f (mm/rev) | d (mm) | Pressure (bar) | Flow Rate (mL/Min) | |||||

| [107] | SK-41C tool steel Width = 2 mm and length = 20 mm/Shank Diameter Φ3 mm, Tool Diameter Φ1.0 mm | Paraffin oil | Diamond/ 30 and 150 | 251.2 | 0.0015 | 0.005 | 3.9 | 0.125 | 2 wt.% con. and 30 nm size—grinding forces and surface roughness compared to other cutting environments |

| [108] | 45 steel/corundum wheel of (300 × 20 × 76.2 mm) | Paraffin, palm oil, rapeseed oil and soya bean oil | MoS2/50 | 1800 | 50 | 0.01 | 6 | 0.833 | 6 wt.% MoS2 con.—co-efficient of friction, specific energy of grinding and surface roughness of the work |

| [109] | AISI-52100 (70 × 50 × 10 mm3)/A60K5V8 wheel with ϕ200 mm, width: 25 mm Bore (Ø50 mm) | Deionized water | MWCNT/50 | 1500 | 100–166 | 0.01–0.02 | 4 | 0.83–5.8 | 0.81 wt.% con.—best retention of grit sharpness and best dissipation of heat from grinding zone |

| [110] | AISI-52100 (70 × 50 × 10 mm3)/Vitrified alumina wheel | Sunflower oil and synthetic soluble oil | MWCNT/ 40 | 1500 | 83.3–100 | 0.005–0.2 | 3 | 0.83–5.8 | 1 wt.% con.—given more superior cooling and lubrication, wettability and tribological characteristics than all other cutting conditions |

| [111] | AISI-52100 hardened steel (Ø 55 and 15 mm)/Norton e 5SG46-JVS (177 15) | Paraffin (mineral oil) and soya bean (vegetable oil) | MoS2/40 | 2100 | 83.3 | 0.015 | 4 | 5 | UAG with MoS2- grinding forces, G-ratio, and surface quality |

| [112] | AISI-1045 steel (60 × 20 × 10 mm3)/Vitrified Alumina (WA46K5V) (Ø250 mm and 32 mm width) | Canola emulsion | CuO/<50 | 1800 | 83.3–250 | 0.01–0.04 | 4 | 0.83 | 0.15–0.35 vol.% con.—grinding forces, G-ratio, temperature, and surface roughness compared to dry and flood cooling condition |

| [113] | AISI-202 stainless steel (80 × 45 × 8 mm3) | Rapeseed vegetable oil | MoS2/ 50–100 | 3720 | 66 | 0.015 | 4.13–6.2 | 1–2 | 1 wt.% con.—surface roughness, grinding forces and temperature compared to other cutting environments |

| [114] | GH4169 Inconel-718 Ni-based alloy/corundum wheel of (300 × 20 × 76.2 mm) | Synthetic lipids | MoS2 and CNT/ 30 | 1800 | 50 | 0.01 | 6 | 0.83 | 8 wt.%—G-ratio and surface roughness. |

| [115] | GH4169 Inconel-718 Ni-based alloy (40 × 30 × 30 mm3)/corundum wheel of (300 × 20 × 76.2 mm) | Bluebe#LB-1 and plant oil (synthetic lipids) | Al2O3-SiC/ 30, 50 and 70 | 1800 | 50 | 0.02 | 6 | 0.83 | 30:70 nano particles size ratio attained good surface finish, largest wetting area, high cross section co-efficient and best morphology of abrasive dust compared to other combinations |

| [116] | Inconel-718/Alumina AA80 K5 V8 | Groundnut oil, palm oil | Al2O3/<100 | 1680 | 35 | 0.02 | 4–6 | 1 | 0.5 wt.% concentrated palm oil-based nano fluid—surface roughness, G-ratio, grinding energy and co-efficient of friction |

| [117] | Ni-Cr alloy/Alumina AA80 K5 V8 (wheel width-13 mm) | Sunflower oil and rice bran oil | CuO/<100 | 1680 | 35 | 0.02 | 4–6 | 1.66 | 0.5 and 1 wt.% con.—surface roughness and grinding energy |

| [118] | Ductile Cast-iron (QT400–18) (32 × 12 × 12 mm3)/CBN grinding wheel (300 × 20 × 76.2 mm) | Soya bean oil | CNT/20 | 1800 | 50 | 0.01 | 6 | 0.583 | 2 wt.% con.—surface roughness and achieved highest G-ratio compared to pure MQL flood and dry grinding environments |

| [119] | YG8 Tungsten carbide (42 × 8 × 4 mm3)/1A1 (200 × 15 × 51) K120 N D181 C75 | Paraffin oil and sun flower oil | Al2O3, graphite and MoS2/ <100 | 1800 | 166.6 | 0.02 | 2 | 1.5 | MoS2 in mineral oil—cutting force and energy when compared to all other cutting fluids |

| [120] | SiC reinforced (1,2 and 3 wt.%) Al-matrix composite (20 mm dia. and 300 mm length)/Aluminium oxide grinding wheel | Cashew nut-based vegetable oil | TiO2/ 20 | 565–942 | 62.8 | 0.01–0.03 | - | - | grinding force and temperature compared to pure oils MQL |

| [121] | Carbon fiber-reinforced polymer/Diamond grinding wheel | Palm Oil | CNT/ 50 | 2400 | 30 | 0.02 | 6 | 1 | surface roughness compared to dry and pure MQL |

| [122] | Ti6Al4V-EI (150 × 80 × 20 mm3)/Cubic boron nitride (150 × 12 × 31.75 mm) | synthetic fluid, canola oil, soyabean oil and olive oil | MoS2, Graphite and Graphene/ 8 | 1320 | 50 | 0.01 | 5 | 0.83 | Canola -Graphene 1.5 wt.% con.—grinding forces, surface roughness and specific energy greatly compared to other combinations adopted |

3.5. Mechanisms Involved in NMQL Machining

4. Cryogenic MQL

5. Conclusions

- Due to the efficient penetration of oil-mist in the contact zone, MQL has shown a significant reduction in the friction coefficient.

- A hybrid cryogenic MQL cooling/lubrication technique for end milling Ti-6Al-4V is developed, which has shown superior performance compared to cryogenic-LN2, MQL, and dry cutting conditions. The cryogenic LN2 showed better performance than MQL in terms of cutting temperature.

- During precision machining of in situ TiB2/7075 composite, the supercritical CO2 (scCO2) jet yielded a coefficient of friction (COF) as low as 0.1 and recorded an increment in tool life by 198.08% compared with dry conditions.

- In the turning process, cryogenic cooling was found better in tool-chip interface temperature, tool life, tool wear, and chip morphology. In contrast, nanofluid showed better results regarding average surface roughness and surface topography.

- Cryogenic cooling has a profound effect on controlling the tool-wear rate and the progressive tool-wear in the machining of NiTi shape memory alloys.

- To get better results from the MQL setup, the designs of the aerosol-supply channels, tool geometry, tool materials, and tool body design (back tapers, reliefs, undercuts and supporting elements) should be optimized for MQL.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Vc = cutting speed (m/min) |

| f = feed (mm/rev) |

| d = depth of cut (mm) |

| L = machining length (mm) |

| Fz = cutting force (N) |

| Fy = thrust force (N) |

| Fx = feed force (N) |

| VB = flank wear of insert (mm) |

| Eq. = Equations |

| nps = Nanoparticles |

| SEM = Scanning electron microscope |

| XRD = X-ray diffraction |

| RSM = Response surface methodology |

| ANOVA = Analysis of variation |

| TiO2 = Titanium oxide |

| Al2O3 = Alumina |

| MWCNT = Multi-walled carbon nanotubes |

| MoS2 = Molybdenum disulphide |

| h-BN = Hexagonal boron nitride |

| SiO2 = Silicon oxide |

| WS2 = Tungsten sulfide |

References

- Nouari, M. Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 2003, 255, 1359–1368. [Google Scholar] [CrossRef]

- Baradie, M.A. Cutting fluids: Part I. characterization. J. Mater. Process. Technol. 1996, 56, 786–797. [Google Scholar] [CrossRef]

- Chiffre, D.L.; Belluco, W. Comparison of methods for cutting fluid performance testing. CIRP Ann. Manuf. Technol. 2000, 49, 57–60. [Google Scholar] [CrossRef]

- Avallone, E.A.; Baumeister, T. Marks’ Standard Handbook for Mechanical Engineers, 10th ed.; McGraw Hill: New York, NY, USA, 1996. [Google Scholar]

- Courbon, C.; Kramar, D.; Krajnik, P.; Pusavec, F.; Rech, J.; Kopac, J. Investigation of machining performance in high-pressure jet assisted turning of Inconel 718: An experimental study. Int. J. Mach. Tools Manuf. 2009, 49, 1114–1125. [Google Scholar] [CrossRef]

- Klocke, F.; Eisenblätter, G. Dry cutting. CIRP Ann. Manuf. Technol. 1997, 46, 519–522. [Google Scholar] [CrossRef]

- Kurgin, S.; Dasch, J.M.; Simon, D.L.; Barbe, G.C.; Zou, Q. Evaluation of the convective heat transfer coefficient for minimum quantity lubrication (MQL). Ind. Lubr. Tribol. 2012, 64, 376–386. [Google Scholar] [CrossRef]

- Weinert, K.; Inasaki, I.; Sutherland, J.W.; Wakabayashi, T. Dry machining, and minimum quantity lubrication. CIRP Ann. Manuf. Technol. 2004, 53, 511–537. [Google Scholar] [CrossRef]

- Fratila, D. Sustainable manufacturing through environmentally-friendly machining. In Green Manufacturing Processes and Systems; Davim, J.P., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1–21. [Google Scholar]

- López de Lacalle, L.N.; Angulo, C.; Lamikiz, A.; Sánchez, J.A. Experimental and numerical investigation of the effect of spray cutting fluids in high speed milling. J. Mater. Process. Technol. 2006, 172, 11–15. [Google Scholar] [CrossRef]

- Li, K.M.; Liang, S.Y. Performance profiling of minimum quantity lubrication in machining. Int. J. Adv. Manuf. Technol. 2007, 35, 226–233. [Google Scholar] [CrossRef]

- Saidur, R.; Leong, K.Y.; Mohammad, H.A. A review on applications and challenges of nanofluids. Renew. Sustain. Energy Rev. 2011, 15, 1646–1668. [Google Scholar] [CrossRef]

- Kakaç, S.; Pramuanjaroenkij, A. Review of convective heat transfer enhancement with nanofluids. Int. J. Heat Mass Transf. 2009, 52, 3187–3196. [Google Scholar] [CrossRef]

- Daungthongsuk, W.; Wongwises, S. A critical review of convective heat transfer of nanofluids. Renew. Sustain. Energy Rev. 2005, 9, 1. [Google Scholar] [CrossRef]

- Wen, D.; Lin, G.; Vafaei, S.; Zhang, K. Review of nanofluids for heat transfer applications. Particuology 2009, 7, 141–150. [Google Scholar] [CrossRef]

- Chen, H.; Ding, Y. Heat transfer and rheological behaviour of nanofluids—A review. Adv. Transp. Phenom. 2009, 1, 135–177. [Google Scholar]

- Eastman, J.A.; Choi, S.U.S.; Li, S.; Yu, W.; Thompson, L.J. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl. Phys. Lett. 2001, 78, 718–720. [Google Scholar] [CrossRef]

- Liu, M.S.; Lin, M.C.C.; Tsai, C.Y.; Wang, C.C. Enhancement of thermal conductivity with Cu for nanofluids using chemical reduction method. Int. J. Heat Mass Transf. 2006, 49, 3028–3033. [Google Scholar] [CrossRef]

- Yoo, D.H.; Hong, K.S.; Yang, H.S. Study of thermal conductivity of nanofluids for the application of heat transfer fluids. Thermochim. Acta 2007, 455, 66–69. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Zhang, Z.G.; Yu, W.; Lockwood, F.E.; Grulke, E.A. Anomalous thermal conductivity enhancement in nanotube suspensions. Appl. Phys. Lett. 2001, 79, 2252–2254. [Google Scholar] [CrossRef]

- Yang, Y. Carbon Nanofluids for Lubricant Application. Ph.D. Thesis, University of Kentucky, Lexington, KY, USA, 2006. [Google Scholar]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; Lópezde Lacalle, L.N.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Amigo, F.J.; Urbikain, G.; Pereira, O.; Fernández-Lucio, P.; Fernández-Valdivielso, A.; Lópezde Lacalle, L.N. Combination of high feed turning with cryogenic cooling on Haynes 263 and Inconel 718 superalloys. J. Manuf. Process. 2020, 58, 208–222. [Google Scholar] [CrossRef]

- Vallim, P.J.H.; Clemente, Z.; Castanha, R.F.; Santo Pereira, A.E.; Campos, E.V.R.; Assalin, M.R.; Maurer-Morelli, C.V.; Fraceto, L.F.; Salgadod Castro, V.L.S. Chitosan nanoparticles containing the insecticide dimethoate: A new approach in the reduction of harmful ecotoxicological effects. NanoImpact 2022, 27, 100408. [Google Scholar] [CrossRef]

- Stephen, B.J.; Sharma, M.M.; Jain, D.; Singh, A. Biogenic synthesized nanoparticles a boon to human health. Mater. Today Proc. 2021, 43, 3211–3213. [Google Scholar] [CrossRef]

- Jaswal, T.; Gupta, J. A review on the toxicity of silver nanoparticles on human health. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; López de Lacalle, L.N.; Rodríguez, A.; Pereira, O. In pursuit of sustainable cutting fluid strategy for machining Ti-6Al-4V using life cycle analysis. Sustain. Mater. Technol. 2021, 29, e00301. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Lozano, J.A.; Carou, D.; Pimenov, D.Y.; Królczyk, G.; Khan, A.M.; Dhar, N.R. Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V. J. Clean. Prod. 2019, 210, 121–133. [Google Scholar] [CrossRef]

- Agrawal, C.; Khanna, N.; Kumar, M.K.; Kaynak, Y. Sustainability assessment of in-house developed environment-friendly hybrid techniques for turning Ti-6Al-4V. Sustain. Mater. Technol. 2020, 26, e00220. [Google Scholar] [CrossRef]

- Gupta, K.M.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M. Ecological, economical and technological perspectives based sustainability assessment in hybrid-cooling assisted machining of Ti-6Al-4V alloy. Sustain. Mater. Technol. 2020, 26, e00218. [Google Scholar]

- Dote, T.; Mali, R.; Katiyar, J.K.; Gupta, T.V.K. Multi-response optimization of cutting parameters in MQL assisted turning of Haynes 25 alloy with Taguchi based grey relational analysis, J. J. Eng. Res. 2022, 10 (2B), 142–157. [Google Scholar]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Process. 2021, 62, 179–201. [Google Scholar] [CrossRef]

- Shah, P.; Bhat, P.; Khanna, N. Life cycle assessment of drilling Inconel 718 using cryogenic cutting fluids while considering sustainability parameters. Sustain. Energy Technol. Assess. 2021, 43, 100950. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Joksch, S. (Eds.) Metalworking Fluids (MWFs) for Cutting and Grinding—Fundamentals and Recent Advances; Woodhead: Cambridge, UK, 2012. [Google Scholar]

- Marksberry, P.W.; Jawahir, I.S. A comprehensive tool-wear/tool-life performance model in the evaluation of NDM (near dry machining) for sustainable manufacturing. Int. J. Mach. Tools Manuf. 2008, 48, 878–886. [Google Scholar] [CrossRef]

- Sharma, A.K.; Katiyar, J.K.; Bhaumik, S.; Roy, S. Influence of Alumina/MWCNT Hybrid Nanoparticle Additives on Tribological Properties of lubricant in Turning Operation. Friction 2018, 7, 153–168. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.K.; Tiwari, A.K.; Singh, R.K.; Dixit, A.R. Tribological Investigation of TiO2 Nanoparticle based Cutting Fluid in Machining under Minimum Quantity Lubrication (MQL). Mater. Today Proc. 2016, 3, 2155–2162. [Google Scholar] [CrossRef]

- Sharma, P.; Sidhu, B.S.; Sharma, J. Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. J. Clean. Prod. 2015, 108, 72–79. [Google Scholar] [CrossRef]

- Singh, R.K.; Sharma, A.K.; Mandal, B.V.; Gaurav, K.; Sharma, A.; Kumar, A.; Dixit, A.R.; Mandal, A.; Das, A.K. Effect of multi-walled carbon nanotubes based nanofluid on surface roughness and cutting temperature in turning operation using minimum quantity lubrication. IOP Conf. Ser. Mater. Sci. Eng. 2017, 377, 1. [Google Scholar] [CrossRef]

- Eltaggaz, A.A.; Hegab, H.A.; Deiab, I.M.; Kishawy, H.A. On using Nano-Cutting Fluid When Maching Austempered Ductile Iron (ADI). In Proceedings of the 27th CANCAM, Victoria, BC, Canada, 29 May–1 June 2017. [Google Scholar]

- Ganesan, K.; Babu, M.N.; Santhanakumar, M.; Muthukrishnan, N. Experimental investigation of copper nanofluid based minimum quantity lubrication in turning of H 11 steel. J Braz. Soc. Mech. Sci. Eng. 2018, 40, 160. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suvin, P.S.; Kailas, S.V.; Sankar, M.R. Thermal, Rheological, Wettability and Hard Machining Performance of MoS2 and CaF2 based Minimum Quantity Hybrid Nano-Green Cutting Fluids. J. Mater. Process. Technol. 2018, 266, 125–139. [Google Scholar] [CrossRef]

- Patole, P.B.; Kulkarni, V.V. Optimization of Process Parameters based on Surface Roughness and Cutting Force in MQL Turning of AISI 4340 using Nano Fluid. Mater. Today Proc. 2018, 5, 104–112. [Google Scholar] [CrossRef]

- Das, A.; Patel, S.K.; Biswal, B.B.; Sahoo, N.; Pradhan, A. Performance evaluation of various cutting fluids using MQL technique in hard turning of AISI 4340 alloy steel. Measurement 2020, 150, 107079. [Google Scholar] [CrossRef]

- Babu, M.N.; Anandan, V.; Muthukrishnan, N. Analysis of EN24 steel in turning process with copper nanofluids under minimum quantity lubrication. J Braz. Soc. Mech. Sci. Eng. 2019, 41, 101. [Google Scholar]

- Babu, M.N.; Anandan, V.; Muthukrishnan, N.; Arivalagar, A.A.; Babu, M.D. Evaluation of Graphene based nanofluids with minimum quantity lubrication in turning of AISI D3 steel. SN Appl. Sci. 2019, 1, 1202. [Google Scholar]

- Duc, T.M.; Long, T.T.; Chien, T.Q. Performance Evaluation of MQL Parameters Using Al2O3 and MoS2 Nanofluids in Hard Turning 90CrSi Steel. Lubricants 2019, 7, 40. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R.; Singh, R.K. Measurement of machining forces and surface roughness in turning of AISI 304 steel using alumina-MWCNT hybrid nanoparticles enriched cutting fluid. Measurement 2020, 150, 107078. [Google Scholar] [CrossRef]

- Khan, A.M.; Gupta, M.K.; Hegab, H.; Jamil, M.; Mia, M.; He, N.; Song, Q.; Liu, Z.; Pruncu, C.I. Energy-based cost integrated modelling and sustainability assessment of Al-GnP hybrid nanofluid assisted turning of AISI52100 steel. J. Clean. Prod. 2020, 257, 120502. [Google Scholar] [CrossRef]

- Kumar, M.S.; Krishna, V.M. An Investigation on Turning AISI 1018 Steel with Hybrid Bio-degradable Nano fluid/MQL Incorporated with Combinations of CuO-Al2O3 Nanoparticles. Mater. Today Proc. 2020, 24, 1577–1584. [Google Scholar] [CrossRef]

- Vasu, V.; Reddy, G.P.K. Effect of minimum quantity lubrication with Al2O3 nanoparticles on surface roughness, tool wear and temperature dissipation in machining Inconel 600 alloy. Proc. Inst. Mech. Eng. N J. Nanomater. Nanoeng. Nanosyst. 2011, 225, 3–16. [Google Scholar] [CrossRef]

- Bose, P.S.C.; Rao CS, P.; Jawale, K. Role of MQL and nanofluids on the machining of Nicrofer C263. In Proceedings of the 5th International & 26th All India Manufacturing Technology, Design and Research Conference, (AIMTDR 2014), Guwahati, India, 12–14 December 2014. [Google Scholar]

- Chetan; Behera, B.C.; Ghosh, S.; Rao, P.V. Application of nanofluids during minimum quantity lubrication: A case study in turning process. Tribol. Int. 2016, 101, 234–246. [Google Scholar] [CrossRef]

- Venkatesan, K.; Mathew, A.T.; Devendiran, S.; Ghazaly, N.M.; Sanjith, S.; Raghul, R. Machinability study and multi-response optimization of cutting force, Surface roughness and tool wear on CNC turned Inconel-617 super alloy using Al2O3 Nanofluids in Coconut oil. Procedia Manuf. 2019, 30, 396–403. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Soliman, M.; Kishawy, H.A. Effects of nano-cutting fluids on tool performance and chip morphology during machining Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 3449–3458. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Sarıkaya, M.; Kıvak, T.; Şirin, Ş. The effect of adding h-BN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning Ni-based Inconel 625. Tribol. Int. 2019, 134, 443–456. [Google Scholar] [CrossRef]

- Gupta, M.K.; Jamil, M.; Wang, X.; Song, Q.; Liu, Z.; Mia, M.; Hega, H.; Khan, A.M.; Collado, A.G.; Pruncu, C.I.; et al. Performance Evaluation of Vegetable Oil-Based Nano-Cutting Fluids in Environmentally Friendly Machining of Inconel-800 Alloy. Materials 2019, 12, 2792. [Google Scholar] [CrossRef]

- Venkatesan, K.; Devendiran, S.; Purusotham, K.N.; Praveen, V.S. Study of machinability performance of Hastelloy-X for nanofluids, dry with coated tools. Mater. Manuf. Process. 2020, 35, 751–761. [Google Scholar] [CrossRef]

- Fernández-Valdivielso, A.; López de Lacalle, L.N.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. Part C 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

- Jadhav, P.S.; Mohanty, C.P. Performance assessment of energy efficient and eco-friendly turning of Nimonic C-263: A comparative study on MQL and cryogenic machining. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2021, 236, 1125–1140. [Google Scholar] [CrossRef]

- Marques, A.; Reddy Narala, S.K.; Machado, A.R.; Gunda, R.K.; Josyula, S.K.; Da Silva, R.B.; Da Silva, M.B. Performance assessment of MQSL: Minimum quantity solid lubricant during turning of Inconel 718. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2015, 231, 1144–1159. [Google Scholar] [CrossRef]

- Gupta, M.K.; Sood PKSharma, V.S. Optimization of machining parameters and cutting fluids during nano-fluid based minimum quantity lubrication turning of titanium alloy by using evolutionary techniques. J. Clean. Prod. 2016, 135, 1276–1288. [Google Scholar] [CrossRef]

- Katta, S.; Chaitanya; Shanker, R. Experimental Investigations of Graphene Nanoparticle-Based Cutting Fluid during Turning of Titanium Alloy (Grade 5) with Minimum Quantity Lubrication. J Adv. Res. Manuf. Mater. Sci. Met. Eng. 2018, 5, 22–30. [Google Scholar]

- Hegab, H.; Umer, U.; Deiab, I.; Kishway, H. Performance evaluation of Ti–6Al–4V machining using nano-cutting fluids under minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2018, 95, 4229–4241. [Google Scholar] [CrossRef]

- Anandan, V.; Babu, M.N.; Krishnan, N.M.; Babu, M.D. Performance of silver nanofluids with minimum quantity lubrication in turning on titanium: A phase to green manufacturing. J Braz. Soc. Mech. Sci. Eng. 2020, 42, 198. [Google Scholar] [CrossRef]

- Gaurav, G.; Sharma, A.; Dangayach, G.S.; Meena, M.L. Assessment of jojoba as a pure and nano-fluid base oil in minimum quantity lubrication (MQL) hard-turning of Ti–6Al–4V: A step towards sustainable machining. J. Clean. Prod. 2020, 272, 122553. [Google Scholar] [CrossRef]

- Mishra, S.K.; Ghosh, S.; Aravindan, S. Machining performance evaluation of Ti6Al4V alloy with laser textured tools under MQL and nano-MQL environments. J. Manuf. Process. 2020, 53, 174–189. [Google Scholar] [CrossRef]

- Jamil, M.; He, N.; Li, L.; Khan, A.M. Clean manufacturing of Ti-6Al-4V under CO2-snow and hybrid nanofluids. Procedia Manuf. 2020, 48, 131–140. [Google Scholar] [CrossRef]

- Khan, A.M.; Jamil, M.; Mia, M.; He, N.; Zhao, W.; Gong, L. Sustainability-based performance evaluation of hybrid nanofluid assisted machining. J. Clean. Prod. 2020, 257, 120541. [Google Scholar] [CrossRef]

- Park, K.H.; Ewald, B.; Kwon, P.Y. Effect of Nano-Enhanced Lubricant in Minimum Quantity Lubrication Balling Milling. J. Tribol. 2011, 133, 031803. [Google Scholar] [CrossRef]

- Huang, W.T.; Wu, D.H.; Lin, S.P.; Chen, J.T. Robust Design of Using MWCNTs in Minimum Quantity Lubrication. Appl. Mech. Mater. 2014, 670–671, 11–21. [Google Scholar] [CrossRef]

- Uysal, A.; Demirena, F.; Altana, E. Applying Minimum Quantity Lubrication (MQL) Method on Milling of Martensitic Stainless Steel by Using Nano MoS2 Reinforced Vegetable Cutting Fluid. Procedia Soc. Behav. Sci. 2015, 195, 2742–2747. [Google Scholar] [CrossRef]

- Uysal, A. An experimental study on cutting temperature and burr in milling of ferritic stainless steel under MQL using nano Graphene reinforced cutting fluid. Adv. Mater. Proc. 2017, 2, 560–563. [Google Scholar] [CrossRef]

- Lv, T.; Huang, S.; Hu, X. Tribological and machining characteristics of a minimum quantity lubrication (MQL) technology using GO/SiC hybrid nanoparticle water-based lubricants as cutting fluids. Int. J Adv. Manuf. Technol. 2018, 96, 2931–2942. [Google Scholar] [CrossRef]

- Lv, T.; Huang, S.; Liu, E.; Ma, Y.; Xu, X. Tribological and machining characteristics of an electrostatic minimum quantity lubrication (EMQL) technology using Graphene nano-lubricants as cutting fluids. J. Manuf. Process. 2018, 34, 225–237. [Google Scholar] [CrossRef]

- Singh, P.; Dureja, J.S.; Singh, H.; Bhatti, M.S. Performance evaluation of coated carbide tool during face milling of AISI 304 under different cutting environments. Mater. Res. Express. 2019, 6, 5. [Google Scholar]

- Muaz, M.; Choudhury, S.K. Experimental investigations, and multi-objective optimization of MQL-assisted milling process for finishing of AISI 4340 steel. Measurement 2019, 138, 557–569. [Google Scholar]

- Kursuncu, B. Use of nano hexagonal boron nitride (h-BN) added cutting fluid in milling of hard to cut materials. Eur. J. Tech. 2019, 9, 330–337. [Google Scholar]

- Dong, P.Q.; Duc, T.M.; Long, T.T. Performance Evaluation of MQCL Hard Milling of SKD 11 Tool Steel Using MoS2 Nanofluid. Metals 2019, 9, 658. [Google Scholar]

- Huang, W.T.; Chou, F.I.; Tsai, J.T.; Chou, J.H. Application of Graphene Nanofluid/Ultrasonic Atomization MQL System in Micro milling and Development of Optimal Predictive Model for SKH-9 High-Speed Steel Using Fuzzy-Logic-Based Multi-objective Design. Int. J. Fuzzy Syst. 2020, 22, 2101–2118. [Google Scholar]

- Çelik, B.; Kaçal, A. Experimental Investigation on Nano MoS2 Application in Milling of EN-GSJ 700-02 Cast Iron with Minimum Quantity Lubrication (MQL). J. Sci. Ind. Res. 2020, 79, 479–483. [Google Scholar]

- Sarhan, A.A.D.; Sayuti, M.; Hamdi, M. Reduction of power and lubricant oil consumption in milling process using a new SiO2 nano lubrication system. Int. J. Adv. Manuf. Technol. 2012, 63, 505–512. [Google Scholar]

- Najiha, M.S.; Rahmanet, M.M.; Kadirgama, K. Performance of water-based TiO2 nanofluid during the minimum quantity lubrication machining of aluminium alloy, AA6061-T6. J Clean. Prod. 2016, 135, 1623–1636. [Google Scholar]

- Sahid, N.S.M.; Rahmanet, M.M.; Kadirgama, K.; Ramasamy, D.; Maleque, M.A.; Noor, M.M. Experimental investigation on the performance of the TiO2 and ZnO hybrid nanocoolant in ethylene glycol mixture towards AA6061-T6 machining. Int. J. Automot. Eng. 2017, 14, 3913–3926. [Google Scholar]

- Cetin, M.H.; Kilincarslanb, S.K. Effects of cutting fluids with nano-silver and borax additives on milling performance of aluminium alloys. J. Manuf. Process. 2020, 50, 170–182. [Google Scholar]

- Sen, B.; Mia, M.; Gupta, M.K.; Rahman, M.A.; Mandal, U.K.; Mondal, S.P. Influence of Al2O3 and palm oil–mixed nano-fluid on machining performances of Inconel-690: IF-THEN rules–based FIS model in eco-benign milling. Int. J. Adv. Manuf. Technol. 2019, 103, 3389–3403. [Google Scholar]

- Şirin, Ş.; Kıvak, T. Performances of different eco-friendly nano fluid lubricants in the milling of Inconel X-750 superalloy. Tribol. Int. 2019, 137, 180–192. [Google Scholar] [CrossRef]

- Günan, F.; Kıvak, T.; Yıldırım, Ç.V.; Sarıkaya, M. Performance evaluation of MQL with AL2O3 mixed nanofluids prepared at different concentrations in milling of Hastelloy C276 alloy. J. Mater. Res. Technol. 2020, 9, 10386–10400. [Google Scholar] [CrossRef]

- Şirin, Ş.; Sarıkaya, M.; Yıldırım, Ç.V.; Kıvak, T. Machinability performance of nickel alloy X-750 with SiAlON ceramic cutting tool under dry, MQL and hBN mixed nanofluid-MQL. Tribol. Int. 2020, 153, 106673. [Google Scholar]

- Kim, J.S.; Kim, J.W.; Lee, S.W. Experimental characterization on micro-end milling of titanium alloy using nanofluid minimum quantity lubrication with chilly gas. Int. J. Adv. Manuf. Technol. 2017, 91, 2741–2749. [Google Scholar]

- Li, M.; Yu, T.; Zhang, R. MQL milling of TC4 alloy by dispersing Graphene into vegetable oil-based cutting fluid. Int. J. Adv. Manuf. Technol. 2018, 99, 1735–1753. [Google Scholar] [CrossRef]

- Bai, X.; Li, C.; Dong, L.; Yin, Q. Experimental evaluation of the lubrication performances of different nanofluids for minimum quantity lubrication (MQL) in milling Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 101, 2621–2632. [Google Scholar] [CrossRef]

- Osman, K.A.; Yılmaz, V.; Ünver, H.Ö.; Şeker, U.; Kılıç; S. Slot milling of titanium alloy with hexagonal boron nitride and minimum quantity lubrication and multi-objective process optimization for energy efficiency. J. Clean. Prod. 2020, 258, 120739. [Google Scholar] [CrossRef]

- Jamil MKhan, A.M.; Hegab, H. Milling of Ti–6Al–4V under hybrid Al2O3-MWCNT nanofluids considering energy consumption, surface quality, and tool wear: A sustainable machining. Int. J. Adv. Manuf. Technol. 2020, 107, 4141–4157. [Google Scholar] [CrossRef]

- Jamil, N.A.M.; Azmi, A.I.; Fairuz, M.A. Coated carbide drill performance under soluble coconut oil lubricant and nanoparticle enhanced MQL in drilling AISI P20. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012111. [Google Scholar] [CrossRef]

- Muthuvel, S.; Babu, M.N.; Muthukrishnan, N. Copper nanofluids under minimum quantity lubrication during drilling of AISI 4140 steel. Aust. J. Mech. Eng. 2020, 18, S151–S164. [Google Scholar] [CrossRef]

- Pal, A.; Chatha, S.S.; Sidhu, H.S. Experimental investigation on the performance of MQL drilling of AISI 321 stainless steel using nano-Graphene enhanced vegetable-oil-based cutting fluid. Tribol. Int. 2020, 151, 106508. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Thanh, D.V. Evaluation of minimum quantity lubrication and minimum quantity cooling lubrication performance in hard drilling of Hardox 500 steel using Al2O3 nanofluid. Adv. Mech. Eng. 2020, 12, 1–12. [Google Scholar] [CrossRef]

- Nam, J.; Lee, S.W. Machinability of titanium alloy (Ti-6Al-4V) in environmentally-friendly micro-drilling process with nanofluid minimum quantity lubrication using nano diamond particles. Int. J. Précis. Eng. Manuf.-Green Technol. 2018, 5, 29–35. [Google Scholar] [CrossRef]

- Rosnana, R.; Murada, M.N.; Azmib, A.I.; Shyhac, I. Effects of minimal quantity lubricants reinforced with nano-particles on the performance of carbide drills for drilling nickel-titanium alloys. Tribol. Int. 2019, 136, 58–66. [Google Scholar] [CrossRef]

- Nam, J.S.; Lee, P.H.; Lee, S.W. Experimental characterization of micro-drilling process using nano fluid minimum quantity lubrication. Int. J. Mach. Tools Manuf. 2011, 51, 649–652. [Google Scholar] [CrossRef]

- Chatha, S.S.; Pal, A.; Singh, T. Performance evaluation of aluminium 6063 drilling under the influence of nanofluid minimum quantity lubrication. J. Clean. Prod. 2016, 137, 537–545. [Google Scholar] [CrossRef]

- Singh, G.; Sharma, V.S.; Gupta, M.K. Sustainable drilling of aluminium 6061-T6 alloy by using nano-fluids and Ranque-Hilsch vortex tube assisted by MQL: An optimisation approach. Int. J. Mach. Mach. Mater. 2018, 20, 3. [Google Scholar] [CrossRef]

- Babu, M.N.; Muthukrishnan, N. Experimental analysis in drilling of AA 5052 using copper nanofluids under minimum quantity lubrication. Aust. J. Mech. Eng. 2020, 18, S15–S24. [Google Scholar] [CrossRef]

- Abad, M.D.; Veldhuis, S.C. Inorganic Nanoparticles as a Lubricant Additive for MQL Machining. In Proceedings of the 1st International Conference on Virtual Machining Process Technology, Montreal, QC, Canada, 28 May–1 June 2012. [Google Scholar]

- Lee, P.; Nam, T.S.; Li, C.; Lee, S.W. Environmentally-Friendly Nano-fluid Minimum Quantity Lubrication (MQL) Meso-scale Grinding Process Using Nano-diamond Particles. In Proceedings of the International Conference on Manufacturing Automation, Hong Kong, 13–15 December 2010; pp. 44–49. [Google Scholar]

- Zhang, Y.; Li, C.; Jia, D.; Zhang, D.; Zhang, X. Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J. Clean. Prod. 2015, 87, 930–940. [Google Scholar] [CrossRef]

- Kumar, K.M.; Ghosh, A. Synthesis of MWCNT nanofluid and evaluation of its potential besides soluble oil as micro cooling-lubrication medium in SQL grinding. Int. J. Adv. Manuf. Technol. 2016, 77, 1955–1964. [Google Scholar]

- Kumar, K.M.; Ghosh, A. Assessment of cooling-lubrication and wettability characteristics of nano-engineered sunflower oil as cutting fluid and its impact on SQCL grinding performance. J. Mater. Process. Technol. 2016, 237, 55–64. [Google Scholar]

- Molaie, M.M.; Akbari, J.; Movahhedyet, M.R. Ultrasonic assisted grinding process with minimum quantity lubrication using oil-based nanofluids. J. Clean. Prod. 2016, 129, 212–222. [Google Scholar] [CrossRef]

- Shabgard, M.; Seyedzavvar, M.; Mohammadpourfard, M. Experimental investigation into lubrication properties and mechanism of vegetable-based CuO nanofluid in MQL grinding. Int. J. Adv. Manuf. Technol. 2017, 92, 3807–3823. [Google Scholar] [CrossRef]

- Pal, A.; Chatha, S.S.; Singh, K. Performance evaluation of minimum quantity lubrication technique in grinding of AISI 202 stainless steel using nano-MoS2 with vegetable-based cutting fluid. Int J. Adv. Manuf. Technol. 2020, 110, 125–137. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Jia, D.; Li, B.; Wang, Y.; Yang, M.; Hou, Y.; Zhang, X. Experimental study on the effect of nanoparticle concentration on the lubricating property of nanofluids for MQL grinding of Ni-based alloy. J. Mater. Process. Technol. 2016, 232, 100–115. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Zhang, Y.; Wang, Y.; Li, B.; Yang, M.; Guo, S.; Liu, G.; Zhang, N. Lubricating property of MQL grinding of Al2O3/SiC mixed nanofluid with different particle sizes and microtopography analysis by cross-correlation. Precis. Eng. 2017, 47, 532–545. [Google Scholar] [CrossRef]

- Virdi, R.L.; Chatha, S.S.; Singh, H. Experiment evaluation of grinding properties under Al2O3 nanofluids in minimum quantity lubrication. Mater. Res. Express 2019, 6, 096574. [Google Scholar] [CrossRef]

- Virdi, R.L.; Chatha, S.S.; Singh, H. Processing Characteristics of Different Vegetable Oil-based Nanofluid MQL for Grinding of Ni-Cr Alloy. Adv. Mater. Process. Technol. 2022, 8, 210–223. [Google Scholar] [CrossRef]

- Gao, T.; Li, C.; Jia, D.; Zhang, Y.; Yang, M.; Wang, X.; Cao, H.; Li, R.; Ali, H.M.; Xu, X.; et al. Surface morphology assessment of CFRP transverse grinding using CNT nanofluid minimum quantity lubrication. J. Clean. Prod. 2020, 277, 123328. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Emami, M.; Sadeghi, M.H. An experimental investigation on the effects of minimum quantity nano lubricant application in grinding process of Tungsten carbide. J. Manuf. Process. 2018, 35, 244–253. [Google Scholar] [CrossRef]

- Nandakumar, A.; Rajmohan, T.; Vijayabhaskar, S. Experimental Evaluation of the Lubrication Performance in MQL Grinding of Nano SiC Reinforced Al Matrix Composites. Silicon 2019, 11, 2987–2999. [Google Scholar] [CrossRef]

- Li, C.; Zhang, D.; Jia, D.; Wang, S.; Hou, Y. Experimental evaluation on tribological properties of nano-particle jet MQL grinding. Int. J. Surf. Sci. Eng. 2015, 9, 159–175. [Google Scholar] [CrossRef]

- Singh, H.; Sharma, V.S.; Singh, S.; Dogra, M. Nanofluids assisted environmental friendly lubricating strategies for the surface grinding of titanium alloy: Ti6Al4V-ELI. J. Manuf. Process. 2019, 39, 241–249. [Google Scholar] [CrossRef]

- Liu, G.; Li, X.; Qin, B.; Xing, D.; Guo, Y.; Fan, R. Investigation of the Mending Effect and Mechanism of Copper Nano-Particles on a Tribologically Stressed Surface. Tribol. Lett. 2004, 17, 961–966. [Google Scholar] [CrossRef]

- Samykano, M.; Mohan, R.S.; Aravamudhan, S. Structure and Morphology of Electrodeposited Nickel Nanowires at an Electrode Distance of 20 mm. Structure 2015, 1, 23704. [Google Scholar]

- Samykano, M.; Mohan, R.S.; Aravamudhan, S. Effect of Current Density and Magnetic Field on the Growth and Morphology of Nickel Nanowires. MEMS Nanotechnol. 2015, 8, 75–83. [Google Scholar]

- Yan, T.; Ingrassia, L.P.; Kumar, R.; Turos, M.; Canestrari, F.; Lu, X.; Marasteanu, M. Evaluation of Graphite Nanoplatelets Influence on the Lubrication Properties of Asphalt Binders. Materials 2020, 13, 772. [Google Scholar] [CrossRef]

- Singh, V.; Sharma, A.K.; Sahu, R.K.; Katiyar, J.K. Novel Application of Graphite-Talc Hybrid Nanoparticle Enriched Cutting Fluid in Turning Operation. J. Manuf. Process. 2021, 62, 378–387. [Google Scholar] [CrossRef]

- Singh, V.; Sharma, A.K.; Sahu, R.K.; Katiyar, J.K. State of the Art on Sustainable Manufacturing using Mono/Hybrid Nano-cutting Fluids with Minimum Quantity Lubrication. Mater. Manuf. Process. 2022, 37, 603–639. [Google Scholar] [CrossRef]

- Lee, K.; Hwang, Y.; Cheong, S.; Choi, Y.; Kwon, L.; Lee, J.; Kim, S.H. Understanding the role of nanoparticles in nano-oil lubrication. Tribol. Lett. 2009, 35, 127–131. [Google Scholar] [CrossRef]

- González, H.; Pereira, O.; López de Lacalle, L.N.; Calleja, A.; Ayesta, I.; Muñoa, J. Flank-Milling of Integral Blade Rotors Made in Ti6Al4V Using Cryo CO2 and Minimum Quantity Lubrication. J. Manuf. Sci. Eng. 2021, 143, 091011. [Google Scholar] [CrossRef]

- Ihsan, A.S.; Stephen, A.S.; Newman, T. Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy. J. Manuf. Process. 2019, 43, 229–243. [Google Scholar]

- Jamil, M.; Zhao, W.; He, N.; Gupta, M.K.; Sarikaya, M.; Khan, A.M.; Siengchin, S.; Pimenov, D.Y. Sustainable milling of Ti–6Al–4V: A trade-off between energy efficiency, carbon emissions and machining characteristics under MQL and cryogenic environment. J. Clean. Prod. 2021, 281, 125374. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Kıvak, T.; Sarıkaya, M.; Şirin, Ş. Evaluation of tool wear, surface roughness/topography and chip morphology when machining of Ni-based alloy 625 under MQL, cryogenic cooling and CryoMQL. J. Mater. Res. Technol. 2020, 9, 2079–2092. [Google Scholar] [CrossRef]

- Nagaraj, A.; Uysa, A.; Jawahir, I.S. An Investigation of Process Performance when Drilling Carbon Fiber Reinforced Polymer (CFRP) Composite under Dry, Cryogenic and MQL Environments. Procedia Manuf. 2020, 43, 551–558. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; Chetan. Comparative analysis of dry, flood, MQL and cryogenic CO2 techniques during the machining of 15-5-PH SS alloy. Tribol. Int. 2020, 146, 106196. [Google Scholar] [CrossRef]

- Chen, J.; Yu, W.; Zuo, Z.; Li, Y.; Chenb, D.; An, Q.; Wang, H.; Chen, M. Tribological properties and tool wear in milling of in-situ TiB2/7075 Al composite under various cryogenic MQL conditions. Tribol. Int. 2021, 160, 107021. [Google Scholar] [CrossRef]

- Chetan; Ghosh, S.; Rao, P.V. Comparison between sustainable cryogenic techniques and nano-MQL cooling mode in turning of nickel-based alloy. J. Clean. Prod. 2019, 231, 1036–1049. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V. Investigation of hard turning performance of eco-friendly cooling strategies: Cryogenic cooling and nanofluid based MQL. Tribol. Int. 2020, 144, 106127. [Google Scholar] [CrossRef]

- Kaynak, Y.; Karaca, H.E.; Noebe Jawahir, R.D.I.S. Tool-wear analysis in cryogenic machining of NiTi shape memory alloys: A comparison of tool-wear performance with dry and MQL machining. Wear 2013, 306, 51–63. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, A.; Sharma, A.K.; Katiyar, J.K. State-of-the-Art in Sustainable Machining of Different Materials Using Nano Minimum Quality Lubrication (NMQL). Lubricants 2023, 11, 64. https://doi.org/10.3390/lubricants11020064

Kumar A, Sharma AK, Katiyar JK. State-of-the-Art in Sustainable Machining of Different Materials Using Nano Minimum Quality Lubrication (NMQL). Lubricants. 2023; 11(2):64. https://doi.org/10.3390/lubricants11020064

Chicago/Turabian StyleKumar, Avinash, Anuj Kumar Sharma, and Jitendra Kumar Katiyar. 2023. "State-of-the-Art in Sustainable Machining of Different Materials Using Nano Minimum Quality Lubrication (NMQL)" Lubricants 11, no. 2: 64. https://doi.org/10.3390/lubricants11020064