Theoretical Study on the Dynamic Characteristics of Marine Stern Bearing Considering Cavitation and Bending Deformation Effects of the Shaft

Abstract

:1. Introduction

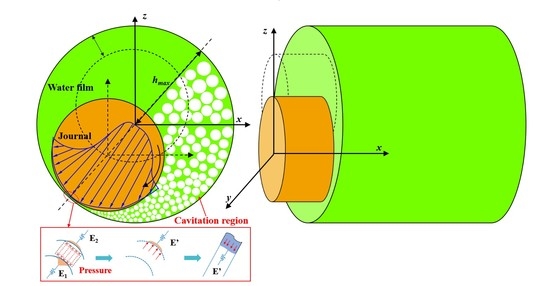

2. Theory Modelling

2.1. Characteristics of Journal Bearing

2.2. Bearing Forces

2.3. Attitude Angle

2.4. Film Thickness Considering Bending Deformation of Journal

2.5. Determining the Bending Deformation of Journal

2.6. The Deformation of Bearing

2.7. The Pressure in Cavitation Zone

2.8. Calculation of the Dynamic Coefficients

2.9. Finite Perturbation Method (FPM)

3. Numerical Procedure

- (1)

- Input the parameters of the stern bearing, initial film pressure, asperities contact forces and deformation of bearing. The assumption condition for the shaft center is given, and then the deformation of the shaft under external loads (the concentrated load of the propeller) is calculated;

- (2)

- Calculating the water film shape according to the current journal position through Equation (20) and adding the value of bearing deformation into ;

- (3)

- Obtain the hydrodynamic pressure distribution by implementing the universal cavitation algorithm; Calculate the asperities contact forces;

- (4)

- The trajectory position is acquired by the integral for the balance loads, hydrodynamic pressure and asperity contact force. In addition, the over-relaxation Newton–Raphson method is employed to accelerate convergence;

- (5)

- For the deformation of the shaft under external loads, film pressure and asperity contact force and bearing deformation, the calculation needs to be resolved until they meet the convergence criterion:

- (6)

- In order to determine the bearing force of each perturbation position, step (2)~(5) is recalculated by perturbing the position and velocity of the journal;

- (7)

- According to Equations (38)–(45), the dynamic coefficients are acquired.

4. Results and Discussion

4.1. Validation

4.2. The Equivalent Stiffness

4.3. The Natural Frequency Analysis

5. Conclusions

- (1)

- For equivalent stiffness, due to the increase in hydrodynamic effect, it is more affected by the speed, especially at low speeds;

- (2)

- For natural frequency, there is a critical speed between 130 rpm and 150 rpm, which makes the natural frequency strike the maximum value because of the comprehensive influencing factors (external loads, tangential forces, large centrifugal forces and gyroscopic moment).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| IFPM | infinitesimal perturbation method |

| FPM | finite perturbation method |

Nomenclature

| liquid bulk-modulus | deformation of bearing | ||

| liquid density | Young’s modulus of journal | ||

| density ratio | Young’s modulus of bearing | ||

| film pressure | the elastic modulus for journal material | ||

| external load | the bubble point pressure | ||

| attitude angle | density of vapor phase | ||

| the length of the shaft | density of liquid phase | ||

| the angle of journal misalignment | velocity of the sound in the pure vapor | ||

| the external force | velocity of the sound in the pure liquid | ||

| eccentricity | asperity contact forces | ||

| composite Young’s modulus of bearing and journal | cavitation region range | ||

| the inertial moment of cross-section of shaft | starting angle of cavitation area | ||

| film thickness of water | product of density and velocity in x direction |

References

- Holmes, R. The vibration of a rigid shaft on short sleeve bearings. J. Mech. Eng. Sci. 1960, 2, 337–341. [Google Scholar] [CrossRef]

- Sternlicht, B. Elastic and damping properties of cylindrical journal bearings. J. Basic Eng. 1959, 91, 101–109. [Google Scholar] [CrossRef]

- Lund, J.W.; Sternlicht, B. Rotor-bearing dynamics with emphasis on attenuation. J. Basic Eng. 1962, 84, 491–502. [Google Scholar] [CrossRef]

- Lund, J.W. Calculation of stiffness and damping properties of gas bearings. J. Lubr. Technol. 1968, 90, 793–803. [Google Scholar] [CrossRef]

- Reinhardt, E.; Lund, J.W. The influence of fluid inertia on the dynamic properties of journal bearings. J. Lubr. Technol. 1975, 97, 159–165. [Google Scholar] [CrossRef]

- Someya, T. Journal-Bearing Databook; Springer: Berlin, Germany, 1989. [Google Scholar]

- Wang, L.H.; Tieu, A.K. A study on the static and dynamic characteristics of journal bearing. In Research Report Tribology; University of Wollongong: Wollongong, Australia, 1989. [Google Scholar]

- Choy, F.K.; Braun, M.J.; Hu, Y. Nonlinear effects in a plain journal bearing, Part I: Analytical study. J. Tribol. 1991, 113, 555–562. [Google Scholar] [CrossRef]

- Choy, F.K.; Braun, M.J.; Hu, Y. Nonlinear transient and frequency response analysis of a hydrodynamic journal bearing. J. Tribol.-Trans. ASME 1992, 114, 448–454. [Google Scholar] [CrossRef]

- Rho, B.H.; Kim, K.W. A study of nonlinear frequency response analysis of hydrodynamic journal bearings with external disturbances. Tribol. Trans. 2002, 45, 117–121. [Google Scholar] [CrossRef]

- Lin, Q.Y.; Wei, Z.Y.; Wang, N.; Chen, W. Analysis on the lubrication performances of journal bearing system using computational fluid dynamics and fluid-structure interaction considering thermal influence and cavitation. Tribol. Int. 2013, 64, 8–15. [Google Scholar] [CrossRef]

- Vijayaraghavan, D.; Keith, T.G. Analysis of a finite grooved misaligned journal bearing considering cavitation and starvation effects. J. Tribol. 1990, 112, 60–67. [Google Scholar] [CrossRef]

- Bouyer, J.; Fillon, M. An experimental analysis of misalignment effects on hydrodynamic plain journal bearing performances. J. Tribol. 2002, 124, 313–319. [Google Scholar] [CrossRef]

- Sun, J.; Gui, C.L. Hydrodynamic lubrication analysis of journal bearing considering misalignment caused by shaft deformation. Tribol. Int. 2004, 37, 841–848. [Google Scholar] [CrossRef]

- Hirani, H.; Verma, M. Tribological study of elastomeric bearings for marine propeller shaft system. Tribol. Int. 2009, 42, 378–390. [Google Scholar] [CrossRef]

- Bou-Said, J.F.; Huebner, K.H. Application of finite element methods to lubrication: An engineering approach. J. Lubr. Tech. 1972, 94, 313–321. [Google Scholar]

- San Andres, L.S. Effect of shaft misalignment on the dynamic force response of annular pressure seals. Tribol. Trans. 1993, 36, 173–182. [Google Scholar] [CrossRef]

- Qiu, Z.L. A Theoretical and Experimental Study on Dynamic Characteristics of Journal Bearings. Ph.D. Thesis, University of Wollongong, Wollongong, Australia, 1995. [Google Scholar]

- Feng, H.; Jiang, S.; Ji, A. Investigations of the static and dynamic characteristics of water-lubricated hydrodynamic journal bearing considering turbulent, thermohydrodynamic and misaligned effects. Tribol. Int. 2019, 130, 245–260. [Google Scholar] [CrossRef]

- Hanawa, N.; Kuniyoshi, M.; Miyatake, M.; Yoshimoto, S. Static characteristics of a water-lubricated hydrostatic thrust bearing with a porous land region and a capillary restrictor. Precis. Eng. 2017, 50, 293–307. [Google Scholar] [CrossRef]

- Lin, X.; Wang, R.; Zhang, S.; Jiang, S. Study on dynamic characteristics for high speed water-lubricated spiral groove thrust bearing considering cavitating effect. Tribol. Int. 2020, 143, 106022. [Google Scholar] [CrossRef]

- Liang, X.; Yan, X.; Ouyang, W.; Wood, R.J.K.; Liu, Z. Thermo-Elasto-Hydrodynamic analysis and optimization of rubber-supported water-lubricated thrust bearings with polymer coated pads. Tribol. Int. 2019, 138, 365–379. [Google Scholar] [CrossRef]

- Dowson, D.; Taylor, C.M. Fundamental Aspects of Cavitation in Bearings. IMECHE 1974, 7, 15–26. [Google Scholar]

- Brewe, D.E.; Ball, J.H.; Khonsari, M.M. Current Research in Cavitating Fluid Films; STLE Special Publication SP-28; NASA: Washington, DC, USA, 1990; Volume 21, pp. 56–61.

- Brewe, D.E. Theoretical modeling of the vapor cavitation in dynamincally loaded journal bearings. J. Tribol.-Trans. ASME 1986, 108, 628–637. [Google Scholar] [CrossRef]

- Floberg, L. Cavitation Boundary Conditions with Regard to the Number of Streamers and Tensile Strength of the Liquid. IMECHE 1974, 17, 31–36. [Google Scholar]

- Elrod, H.G.; Adams, M. A Computer Program for Cavitation and Starvation Problems. IMECHE 1974, 1, 37–42. [Google Scholar]

- Elrod, H.G. A Cavitation Algorithm. J. Lubr. Technol. 1981, 103, 350–354. [Google Scholar] [CrossRef]

- Vijayaraghavan, D.; Keith, T.G. Development and evaluation of a cavitation algorithm. Tribol. Trans. 1989, 103, 225–233. [Google Scholar] [CrossRef]

- Priestner, C.; Allmaier, H.; Priebsch, H.H.; Forstner, C. Refined simulation of friction power loss in crank shaft slider bearings considering wear in the mixed lubrication regime. Tribol. Int. 2012, 46, 200–207. [Google Scholar] [CrossRef]

- Hearn, E.J. Mechanics of Materials 1; Butterworth-Heinemann: Oxford, UK, 1997; Volume 14, pp. 26–31. [Google Scholar]

- Choi, J.; Kim, S.S.; Rhim, S.S.; Choi, J.H. Numerical modeling of journal bearing considering both elastohydrodynamic lubrication and multi-flexible-body dynamics. Int. J. Auto. Tech-KOR 2012, 13, 255–261. [Google Scholar] [CrossRef]

- Batada, G.; Chupin, L. Compressiable fluid model for hydrodynamic lubrication cavitation. J. Tribol. 2013, 135, 041702-1–041702-13. [Google Scholar] [CrossRef]

- Su, H. Determining the value of pressure in the cavitation zone for steady-state journal bearing. Chin. Mech. Eng. 2007, 5, 88–89. [Google Scholar]

- Chouchane, M.; Naimi, S.; Ligier, J.L. Stability analysis of hydrodynamic bearings with a central circumferential feeding groove. In Proceedings of the 13th World Congress in Mechanism and Machine Science, Guanajuato, Mexico, 19–23 June 2011. [Google Scholar]

- Patir, N.; Cheng, H.S. Application of average flow model to lubrication between rough sliding surfaces. J. Lubr. Technol. 1979, 101, 220–230. [Google Scholar] [CrossRef]

- He, T.; Zou, D.; Lu, X.; Guo, Y.; Wang, Z.; Li, W. Mixed-lubrication analysis of marine stern tube bearing considering bending deformation of stern shaft and cavitation. Tribol. Int. 2014, 73, 108–116. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, X.; Zhu, W. Theoretical and experimental exploration into the fluid structure coupling dynamic behaviors towards water-lubricated bearing with axial asymmetric grooves. Mech. Syst. Signal Process. 2022, 168, 108624. [Google Scholar] [CrossRef]

- Xie, Z.; Zhu, W. Theoretical and experimental exploration on the micro asperity contact load ratios and lubrication regimes transition for water-lubricated stern tube bearing. Tribol. Int. 2021, 164, 107105. [Google Scholar] [CrossRef]

- Zhou, H.J.; Lv, B.L.; Wang, D.H. Research and analysis of gyroscopic vibration dynamic response of shafting based on an Improved Fourier Series Method. J. Ship Mech. 2012, 16, 962–970. [Google Scholar]

- Kuang, F.; Zhou, X.; Liu, Z.; Huang, J.; Liu, X.; Qian, K.; Gryllias, K. Computer-vision-based research on friction vibration and coupling of frictional and torsional vibrations in water-lubricated bearing-shaft system. Tribol. Int. 2020, 150, 106336. [Google Scholar] [CrossRef]

- Xu, J.; Jiao, C.; Zou, D.; Ta, N.; Rao, Z. Study on the dynamic behavior of herringbone gear structure of marine propulsion system powered by double-cylinder turbines. China Technol. Sci. 2022, 65, 611–630. [Google Scholar] [CrossRef]

| Loading Condition | ||

|---|---|---|

Concentrated load P at end | (23) | |

Concentrated load P at point a | (24) | |

| Item | Value |

|---|---|

| Radius of Bearing (m) | 0.05 |

| Radial Clearance (mm) | 0.1455 |

| Ratio of Bearing Length and Bearing Diameter | 1.333 |

| Eccentricity ratio | 0.61 |

| Angular Velocity (rad/s) | 48.1 |

| Lubrication Supply Pressure (Pa) | 0 |

| Cavitation Pressure (Pa) | −72,139.79 |

| Shaft Segment No. | Middle Shaft | Stern Shaft | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Length (m) | 2.9 | 3.6 | 1.55 | 3.45 | 2.05 | |

| Diameter of shaft (cm) | 39 | 39 | 49.8 | 49.8 | 49.8 | |

| Young’s Modulus of shaft(N/m2) | 2.1 × 1011 | |||||

| Density of shaft (kg/m3) | 7850 | |||||

| Poisson Ratio of shaft | 0.3 | |||||

| Bearing material (bearing 1, bearing 2 and bearing 3) | Aluminium alloy PTFE | |||||

| Radial clearance(m) | Bearing 1 | 0.6 × 10−3 | ||||

| Bearing 2 | 0.6 × 10−3 | |||||

| Bearing 3 | 0.4 × 10−3 | |||||

| Roughness of shaft (m) | 4.3 × 10−6 | |||||

| Roughness of bearing (m) | 4.3 × 10−6 | |||||

| Shaft to Bearing contact friction coefficient | 0.1 | |||||

| Kinematic viscosity of lubricant (N·s/cm2) | 0.15 × 10−6 | |||||

| Ratio of density rp | 2.31 × 10−5 | |||||

| Density of the liquid phase of lubricant (kg/m3) | 890 | |||||

| Sound velocity of the sound in the pure vapor (m/s) | 343 | |||||

| Sound velocity of the sound in the pure liquid (m/s) | 1450 | |||||

| Frequency Ratios | Natural Frequency (r/min) | ||||

|---|---|---|---|---|---|

| Results by Ref. [34] | Different Operating Speed Considering Lubrication | ||||

| 90 rpm | 110 rpm | 130 rpm | 150 rpm | ||

| h = 1 | 1022.59 | 950.33 | 963.22 | 969.23 | 969.15 |

| h = 1/4 | 890.87 | 845.36 | 853.69 | 857.46 | 857.15 |

| h = 0 | 849.89 | 811.17 | 818.31 | 821.55 | 821.29 |

| h = −1/4 | 811.84 | 778.66 | 784.84 | 787.64 | 787.46 |

| h = −1 | 709.71 | 693.80 | 698.07 | 700.05 | 700.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, T.; Xie, Z.; Ke, Z.; Dai, L.; Liu, Y.; Ma, C.; Jiao, J. Theoretical Study on the Dynamic Characteristics of Marine Stern Bearing Considering Cavitation and Bending Deformation Effects of the Shaft. Lubricants 2022, 10, 242. https://doi.org/10.3390/lubricants10100242

He T, Xie Z, Ke Z, Dai L, Liu Y, Ma C, Jiao J. Theoretical Study on the Dynamic Characteristics of Marine Stern Bearing Considering Cavitation and Bending Deformation Effects of the Shaft. Lubricants. 2022; 10(10):242. https://doi.org/10.3390/lubricants10100242

Chicago/Turabian StyleHe, Tao, Zhongliang Xie, Zhiwu Ke, Lu Dai, Yong Liu, Can Ma, and Jian Jiao. 2022. "Theoretical Study on the Dynamic Characteristics of Marine Stern Bearing Considering Cavitation and Bending Deformation Effects of the Shaft" Lubricants 10, no. 10: 242. https://doi.org/10.3390/lubricants10100242