Effect of Flux Rate Variation at Fixed V/III Ratio on Semi-Polar (11

Abstract

:1. Introduction

2. Experimental Methods

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Nakamura, S.; Pearton, S.; Fasol, G. Physics of Gallium Nitride and Related Compounds. In The Blue Laser Diode; Springer: Berlin, Heidelberg, 2000; pp. 29–45. [Google Scholar] [CrossRef]

- Akasaki, I.; Amano, H. Crystal growth and conductivity control of group III nitride semiconductors and their application to short wavelength light emitters. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 1997, 36, 5393–5408. [Google Scholar] [CrossRef]

- Zhang, Z.; Kushimoto, M.; Sakai, T.; Sugiyama, N.; Schowalter, L.J.; Sasaoka, C.; Amano, H. A 271 8 nm deep-ultraviolet laser diode for room temperature operation. Appl. Phys. Express 2019, 12, 124003. [Google Scholar] [CrossRef]

- Nakamura, S.; Senoh, M.; Nagahama, S.I.; Iwasa, N.; Yamada, T.; Matsushita, T.; Kiyoku, H.; Sugimoto, Y. InGaN-based multi-quantum-well-structure laser diodes. Jpn. J. Appl. Phys. Part 2 Lett. 1996, 35, L74–L76. [Google Scholar] [CrossRef]

- Nakamura, S.; Mukai, T.; Senoh, M. Candela-class high-brightness InGaN/AlGaN double-heterostructure blue-light-emitting diodes. Appl. Phys. Lett. 1994, 64, 1687–1689. [Google Scholar] [CrossRef]

- Zhu, S.; Lin, S.; Li, J.; Yu, Z.; Cao, H.; Yang, C.; Li, J.; Zhao, L. Influence of quantum confined Stark effect and carrier localization effect on modulation bandwidth for GaN-based LEDs. Appl. Phys. Lett. 2017, 111, 171105. [Google Scholar] [CrossRef]

- Ling, S.C.; Lu, T.C.; Chang, S.P.; Chen, J.R.; Kuo, H.C.; Wang, S.C. Low efficiency droop in blue-green m-plane InGaN/GaN light emitting diodes. Appl. Phys. Lett. 2010, 96, 231101. [Google Scholar] [CrossRef] [Green Version]

- Kioupakis, E.; Rinke, P.; Delaney, K.T.; Van De Walle, C.G. Indirect Auger recombination as a cause of efficiency droop in nitride light-emitting diodes. Appl. Phys. Lett. 2011, 98, 161107. [Google Scholar] [CrossRef] [Green Version]

- Song, K.M.; Kim, J.M.; Kang, B.K.; Yoon, D.H.; Kang, S.; Lee, S.W.; Lee, S.N. Characteristics of indium incorporation in InGaN/GaN multiple quantum wells grown on a-plane and c-plane GaN. Appl. Phys. Lett. 2012, 100, 212103. [Google Scholar] [CrossRef]

- Speck, J.S.; Chichibu, S.F. Nonpolar and semipolar Group III nitride-based materials. MRS Bull. 2009, 34, 304–309. [Google Scholar] [CrossRef]

- Waltereit, P.; Brandt, O.; Trampert, A.; Grahn, H.T.; Monniger, J.; Ramsteiner, M.; Relche, M.; Ploog, K.H. Nirtride semiconductors free of electrostatic fields for efficient white light-emitting diodes. Nature 2000, 406, 865–868. [Google Scholar] [CrossRef]

- Sato, H.; Chung, R.B.; Hirasawa, H.; Fellows, N.; Masui, H.; Wu, F.; Saito, M.; Fujito, K.; Speck, J.S.; Denbaars, S.P.; et al. Optical properties of yellow light-emitting diodes grown on semipolar (112) bulk GaN substrates. Appl. Phys. Lett. 2008, 92, 221110. [Google Scholar] [CrossRef]

- Wernicke, T.; Schade, L.; Netzel, C.; Rass, J.; Hoffmann, V.; Ploch, S.; Knauer, A.; Weyers, M.; Schwarz, U.; Kneissl, M. Indium incorporation and emission wavelength of polar, nonpolar and semipolar InGaN quantum wells. Semicond. Sci. Technol. 2012, 27, 2. [Google Scholar] [CrossRef]

- Dasilva, Y.A.R.; Chauvat, M.P.; Ruterana, P.; Lahourcade, L.; Monroy, E.; Nataf, G. Defect structure in heteroepitaxial semipolar (112) (Ga, Al)N. J. Phys. Condens. Matter 2010, 22, 355802. [Google Scholar] [CrossRef] [PubMed]

- Ruterana, P.; Chauvat, M.P.; Arroyo Rojas Dasilva, Y.; Lei, H.; Lahourcade, L.; Monroy, E. Extended defects in nitride layers, influence on the quantum wells and quantum dots. In Gallium Nitride Materials and Devices V; SPIE: Bellingham, DC, USA, 2010; Volume 7602, p. 760212. [Google Scholar]

- Zhu, T.; Johnston, C.F.; Kappers, M.J.; Oliver, R.A. Microstructural, optical, and electrical characterization of semipolar (112) gallium nitride grown by epitaxial lateral overgrowth. J. Appl. Phys. 2010, 108, 083521. [Google Scholar] [CrossRef]

- Xing, K.; Tseng, C.; Wang, L.; Chi, P.; Wang, J.; Chen, P.; Liang, H. Semi-polar (112) GaN epitaxial films with significantly reduced defect densities grown on m-plane sapphire using a sequence of two in situ SiNx interlayers. Appl. Phys. Lett. 2019, 114, 131105. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, L.; Yang, S.; Li, H.; Wei, H.; Han, D.; Wang, Z. Anisotropic structural and optical properties of semi-polar (112) GaN grown on m-plane sapphire using double AlN buffer layers. Sci. Rep. 2016, 6, 20787. [Google Scholar] [CrossRef] [Green Version]

- Tendille, F.; De Mierry, P.; Vennéguès, P.; Chenot, S.; Teisseire, M. Defect reduction method in (112) semipolar GaN grown on patterned sapphire substrate by MOCVD: Toward heteroepitaxial semipolar GaN free of basal stacking faults. J. Cryst. Growth 2014, 404, 177–183. [Google Scholar] [CrossRef]

- Xu, S.R.; Zhang, J.C.; Cao, Y.R.; Zhou, X.W.; Xue, J.S.; Lin, Z.Y.; Ma, J.C.; Bao, F.; Hao, Y. Improvements in (112) semipolar GaN crystal quality by graded superlattices. Thin Solid Films 2012, 520, 1909–1912. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, G.; Meng, Y.; Li, H.; Yang, S.; Wang, Z. Comparative Investigation of Semipolar (112) GaN Layers on m -Plane Sapphire with Different Nucleation Layers. J. Nanosci. Nanotechnol. 2018, 18, 7446–7450. [Google Scholar] [CrossRef]

- Grinys, T.; Drunga, T.; Badokas, K.; Dargis, R.; Clark, A.; Malinauskas, T. Growth conditions of semi and non-polar GaN on Si with Er2O3 buffer layer. J. Alloys Compd. 2017, 725, 739–743. [Google Scholar] [CrossRef]

- Sun, Q.; Leung, B.; Yerino, C.D.; Zhang, Y.; Han, J. Improving microstructural quality of semipolar (112) GaN on m -plane sapphire by a two-step growth process. Appl. Phys. Lett. 2009, 95, 231904. [Google Scholar] [CrossRef]

- Liu, J.M.; Zhang, J.; Lin, W.Y.; Ye, M.X.; Feng, X.X.; Zhang, D.Y.; Steve, D.; Xu, C.K.; Liu, B.L. Effect of pressure on the semipolar GaN (111) growth mode on patterned Si substrates. Chin. Phys. B 2015, 24, 5. [Google Scholar] [CrossRef]

- Pristovsek, M.; Han, Y.; Zhu, T.; Frentrup, M.; Kappers, M.J.; Humphreys, C.J.; Kozlowski, G.; Maaskant, P.; Corbett, B. Low defect large area semi-polar (11[Formula: See text]2) GaN grown on patterned (113) silicon. Phys. Status Solidi B Basic Solid State Phys. PSS 2014, 252, 1104–1108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jung, C.; Jang, J.; Hwang, J.; Jeong, J.; Kim, J.; Lee, K.; Nam, O. Defect reduction in (112) semipolar GaN with embedded InN islands on m-plane sapphire. J. Cryst. Growth 2013, 370, 26–29. [Google Scholar] [CrossRef]

- Kriouche, N.; Venénguès, P.; Nemoz, M.; Nataf, G.; De Mierry, P. Stacking faults blocking process in (112) semipolar GaN growth on sapphire using asymmetric lateral epitaxy. J. Cryst. Growth 2010, 312, 2625–2630. [Google Scholar] [CrossRef]

- Omar, A.Z.; Shuhaimi Bin Abu Bakar, A.; Makinudin, A.H.A.; Khudus, M.I.M.A.; Azman, A.; Kamarundzaman, A.; Supangat, A. Effect of low NH3 flux towards high quality semi-polar (112) GaN on m-plane sapphire via MOCVD. Superlattices Microstruct. 2018, 117, 207–214. [Google Scholar] [CrossRef]

- Li, Z.; Jiu, L.; Gong, Y.; Wang, L.; Zhang, Y.; Bai, J.; Wang, T. Semi-polar (112) AlGaN on overgrown GaN on micro-rod templates: Simultaneous management of crystal quality improvement and cracking issue. Appl. Phys. Lett. 2017, 110, 082103. [Google Scholar] [CrossRef] [Green Version]

- Hsu, H.C.; Su, Y.K.; Huang, S.J.; Wang, Y.J.; Wu, C.Y.; Chou, M.C. Direct growth of a-plane GaN on r-plane sapphire by metal organic chemical vapor deposition. Jpn. J. Appl. Phys. 2010, 49, 04DH05. [Google Scholar] [CrossRef]

- Kamarudzaman, A.; Bin Abu Bakar, A.S.; Azman, A.; Omar, A.Z.; Supangat, A.; Talik, N.A. Positioning of periodic AlN/GaN multilayers: Effect on crystalline quality of a-plane GaN. Mater. Sci. Semicond. Process. 2020, 105, 104700. [Google Scholar] [CrossRef]

- Sun, Q.; Kong, B.H.; Yerino, C.D.; Ko, T.S.; Leung, B.; Cho, H.K.; Han, J. Morphological and microstructural evolution in the two-step growth of nonpolar a-plane GaN on r-plane sapphire. J. Appl. Phys. 2009, 106, 123519. [Google Scholar] [CrossRef]

- Sun, Q.; Yerino, C.D.; Ko, T.S.; Cho, Y.S.; Lee, I.H.; Han, J.; Coltrin, M.E. Understanding nonpolar GaN growth through kinetic Wulff plots. J. Appl. Phys. 2008, 104, 093523. [Google Scholar] [CrossRef]

- Leung, B.; Sun, Q.; Yerino, C.D.; Han, J.; Coltrin, M.E. Using the kinetic Wulff plot to design and control nonpolar and semipolar GaN heteroepitaxy. Semicond. Sci. Technol. 2012, 27, 024005. [Google Scholar] [CrossRef]

- Hu, N.; Dinh, D.V.; Pristovsek, M.; Honda, Y.; Amano, H. How to obtain metal-polar untwinned high-quality (103) GaN on m-plane sapphire. J. Cryst. Growth 2018, 507, 205–208. [Google Scholar] [CrossRef]

- Dinh, D.V.; Skuridina, D.; Solopow, S.; Frentrup, M.; Pristovsek, M.; Vogt, P.; Kneissl, M.; Ivaldi, F.; Kret, S.; Szczepaska, A. Growth and characterizations of semipolar (112) InN. J. Appl. Phys. 2012, 112, 013530. [Google Scholar] [CrossRef]

- Dinh, D.V.; Conroy, M.; Zubialevich, V.Z.; Petkov, N.; Holmes, J.D.; Parbrook, P.J. Single phase (112) AlN grown on (100) sapphire by metalorganic vapour phase epitaxy. J. Cryst. Growth 2015, 414, 94–99. [Google Scholar] [CrossRef]

- Young, E.C.; Wu, F.; Romanov, A.E.; Tyagi, A.; Gallinat, C.S.; DenBaars, S.P.; Nakamura, S.; Speck, J.S. Lattice tilt and misfit dislocations in (112) semipolar GaN heteroepitaxy. Appl. Phys. Express 2010, 3, 011004. [Google Scholar] [CrossRef]

- Tyagi, A.; Wu, F.; Young, E.C.; Chakraborty, A.; Ohta, H.; Bhat, R.; Fujito, K.; Denbaars, S.P.; Nakamura, S.; Speck, J.S. Partial strain relaxation via misfit dislocation generation at heterointerfaces in (Al,In)GaN epitaxial layers grown on semipolar (112) GaN free standing substrates. Appl. Phys. Lett. 2009, 95, 251905. [Google Scholar] [CrossRef]

- Jiang, T.; Xu, S.; Zhang, J.; Li, P.; Huang, J.; Niu, M.; Meng, X.; Chen, Z.; Zhu, J.; Zhao, Y.; et al. Temperature dependence of the Raman-active modes in the semipolar (112) plane GaN Film. J. Appl. Phys. 2016, 120, 245706. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, X.; Wang, S.; Wang, Y.; Luan, H.; Dai, Q.; Wu, Z.; Zhao, J.; Cui, Y. Effects of Si-doping on structural, electrical, and optical properties of polar and non-polar AlGaN epi-layers. Superlattices Microstruct. 2016, 96, 1–7. [Google Scholar] [CrossRef]

- Ploch, S.; Wernicke, T.; Dinh, D.V.; Pristovsek, M.; Kneissl, M. Surface diffusion and layer morphology of ((112)) GaN grown by metal-organic vapor phase epitaxy. J. Appl. Phys. 2012, 111, 33526. [Google Scholar] [CrossRef]

- Wernicke, T.; Kneissl, M. III-Nitride Semiconductors and Their Modern Devices; Gil, B., Ed.; OUP Oxford: Oxford, UK, 2014; p. 253. [Google Scholar]

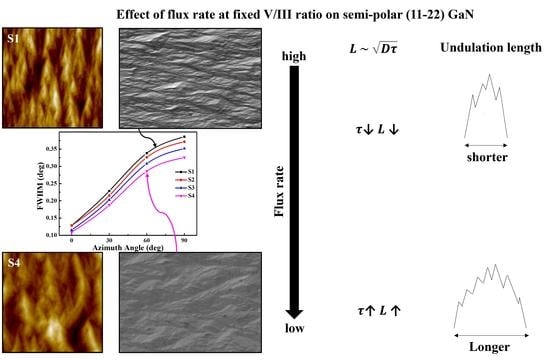

| Sample | TMG Flux Rate (sccm) | Ammonia (NH3) Flux Rate (slm) | V/III Ratio | Growth Rate (µm/h) | Growth Time (min) |

|---|---|---|---|---|---|

| S1 | 33.6 | 0.40 | 118 | 4.82 | 57 |

| S2 | 29.5 | 0.35 | 118 | 4.06 | 68 |

| S3 | 25.3 | 0.30 | 118 | 3.42 | 81 |

| S4 | 21.1 | 0.25 | 118 | 2.94 | 98 |

| Sample | S1 | S2 | S3 | S4 |

|---|---|---|---|---|

| 00] | 1.36 | 1.23 | 1.20 | 1.00 |

| Rms Roughness (nm) | 22.33 | 25.81 | 29.66 | 40.41 |

| Sample | TMG Flux Rate (sccm) | Ammonia (NH3) Flux Rate (slm) | FWHM of φ at 0° (arcsec) | FWHM of φ at 90° (arcsec) | RMS (nm) |

|---|---|---|---|---|---|

| R1 | 21.5 | 1.3 | 613 | 1312 | 17.36 |

| R2 | 16.6 | 1.0 | 500 | 1184 | 32.18 |

| R3 | 11.6 | 0.7 | 480 | 1005 | 55.37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ooi, C.S.; Shuhaimi, A.; Tan, G.; Al-Zuhairi, O.; Abd Majid, W.H.

Effect of Flux Rate Variation at Fixed V/III Ratio on Semi-Polar (11

Ooi CS, Shuhaimi A, Tan G, Al-Zuhairi O, Abd Majid WH.

Effect of Flux Rate Variation at Fixed V/III Ratio on Semi-Polar (11

Ooi, Chong Seng, Ahmad Shuhaimi, Gary Tan, Omar Al-Zuhairi, and Wan Haliza Abd Majid.

2022. "Effect of Flux Rate Variation at Fixed V/III Ratio on Semi-Polar (11