1. Introduction

A twisted hybrid aligned [

1], hybrid twisted nematic (HTN) [

2], hybrid aligned nematic using strong and weak polar anchoring surfaces [

3], or reverse twisted nematic (RTN) [

4,

5,

6,

7] liquid crystal displays (LCDs) have been proposed to reduce the driving voltage. An HTN that uses strong and weak polar anchoring surfaces was numerically analyzed [

8]. Long-pitched supertwisted nematic (LPSTN) LCDs have been reported [

9] in the development of RTN-LCDs. In addition, the doping of metallic nanoparticles in the LC system [

10], or ferroelectric barium titanate nanoparticles in alignment layer [

11] provide low power consumption in the display devices.

The RTN and LPSTN structures were separately formed controlling the chiral pitch to the cell thickness (p/d) ratio [

9]. These structures were changed from a splay twisted (ST) structure (

Figure 1a), which includes a chiral reagent causing the twist distortion opposite to that determined by the rubbing directions and were formed by the application of voltage over Fredericks transition threshold voltage to the ST structure. The twist of the liquid crystal is basically determined by the angle of the director in the vicinity of the alignment layer depending on the rubbing direction of the alignment layers of the upper and lower substrates. The director of twisted nematic and STN structures, which include a chiral reagent causing the twist distortion that determined by the rubbing directions, rotates in the direction of Azimuth angle. In addition, the STN has a steeper transmittance change than the TN. On the contrary, splay-twisted nemantic structures which include a chiral reagent causing the twist distortion opposite to that determined by the rubbing directions, which rotate in the direction of Azimuth and Polar angles. The RTN and LPSTN structures that include a chiral reagent with the twist distortion opposite to that determined by the rubbing directions have a metastable state and can be maintained when a specific voltage is applied after application of the saturation voltage. This voltage is referred to as the sustain voltage. The ST structure changes to RTN or LPSTN structures as the director near the center of the LC cell is rotated in the opposite direction, as the Gibbs free energy increases with the voltage. This phenomenon can be explained by assuming that the stress of the LC structure generated by the splayed structure with an electric voltage can be released because the reversely twisted structure (no splay deformation) is more stable than the splayed structure [

5,

12,

13]. The RTN structure appears when the p/d ratio is more than three. Moreover, our group has developed a stabilization method for the RTN structure by UV irradiation using reactive mesogens (RMs) with application from 1.25 to 1.5 V [

14]. The driving voltage for the RTN-LCD is reduced compared with the TN-LCD (

Figure 1). When the p/d ratio is 2.78, the STN structure appears [

9]. In the case that the rubbing directions are twisted at 90° by application of high voltage to avoid ST structure, it changes into the RTN structure [

5] and, at the same time, the STN structure in which LC material is twisted at 270° could be formed by twisting in the direction opposite to the RTN. These RTN and STN do not contain splayed structures. The p/d value approaches 1.5, which is necessary for the LC to twist 270°; therefore, the ST structure is formed when the voltage is 0 V. Application of a voltage higher than the threshold voltage causes the energy of the ST structure to increase, so that the STN structure is obtained without the splay structure. STN has an increased twist angle from 180° up to 270° [

15,

16,

17], which is known to increase the steepness of the transmittance–voltage curve (V-T curve). In

Figure 1, the V-T curve of LPSTN is shown as blue open triangles [

9]. When the p/d ratio is 2.14, the RTN structure appears by application of a high voltage (metastable state 2 (ii) in

Figure 1d), while the typical STN (p/d ratio is 1.5) does not change to RTN. Our group has termed this non-typical STN (p/d ratio more than 1.5) LPSTN.

In this study, we focus on the effect of thermal energy and attempt to cause transformation by heat instead of voltage to maintain the structure by application of a low voltage because, by reducing the applied voltage, RTN-LCDs of high transmittance without applied voltage can be obtained. Transformation from the ST state to the RTN state occurred at a temperature slightly below the nematic–isotropic (NI) point with the application of 1.0 V. Furthermore, the electro–optical properties and Gibbs free energy were calculated for each structure and compared with the obtained results. The Gibbs free energy is calculated by Frank–Oseen free energy density

and the energy per unit volume by electric field

is given by:

where

K11,

K22 and

K33 are elastic constants for different director deformations: splay, twist and bend, respectively,

is constant and describes the chiral pitches

of the helix, and

is eigenvector [

18].

is given by:

where

is the dielectric tensor of the liquid crystal, and

is the electric field. The Gibbs free energy

can be expressed by:

2. Materials and Methods

The LC material MLC-2173 (US048) (Merck & Co. Inc., Darmstadt, Germany) had a left-handed pitch of 15.0 µm and MJ141067 (US048) had 5 wt% RM in MLC-2173 (US048). Two LC were mixed to be 1 wt% RM. The MLC-2173 has positive dielectric anisotropy (20.8). The polyimide material for the alignment layers was produced by mixing PIA-X768-01X and PIA-X359-01X (Chisso Petrochemical Corp., Tokyo, Japan) in a 15:85 ratio. The pretilt angle of the alignment layer was confirmed to be 6° with a pretilt analysis system (PAS-301, Elsicon Inc., Newark, NJ, USA). The cell thicknesses were set at 5.0 and 5.4 µm using silica bead spacers. The rubbing directions were set to form a right-handed twist of the LC material without a chiral reagent from the upper to the lower substrate. A splayed twisted structure was formed when left-handed LC materials were injected into the cell. The temperature was controlled with a high-precision temperature controller (mK1000, Instec Inc., Boulder, CO, USA) and UV light was irradiated to cure the RM with a UV lamp (LUV-6, AS ONE Co., Osaka, Japan). The electro-optical properties (applied voltage dependence of the transmittance and response time) were measured using OPTIPRO-standard (Shintech Inc., Yamaguchi, Japan). The optical axis of one polarizer was set parallel to one of the rubbing directions in a crossed nicols setting. The elastic constant was measured with an elastic constant measurement system (EC-1, Toyo Corp., Tokyo, Japan). Simulations of the electro-optical properties and Gibbs free energy were performed using LCD Master (Shintech Inc.) software under various conditions, such as pretilt angle, cell thickness, and chiral pitch. The LCDs were driven by a 1 kHz square wave.

3. Results and Discussions

The transition from ST to RTN was confirmed by polarized optical microscopy (POM) measurements under a crossed nicols condition. The clearing point for this LC is 353 K.

Figure 2 shows the lowest sustain voltage for each cell thickness as a function of temperature. These voltages started to decrease near 343 K. Transition to the isotropic phase occurred with application of 1.0 V at 354.7 and 356.5 K for the cell thicknesses of 5.0 and 5.4 µm, respectively. The chiral pitch extended up to 16.8 µm at high temperature, as shown in

Figure 3. The chiral pitch was once saturated near 343 K; however, it extended up to 16.8 µm at high temperature, as shown in

Figure 3. The change of the molecular conformation of chiral reagent could occur at high temperature. The change of the pitch dependence on temperature could be explained by the change of the molecular conformation [

19]. Therefore, the disturbance of the chiral pitch on temperature could be explained by the large change of the conformation of the chiral reagent. Although the reason is not stated, there are reports that the chiral pitch changed twice at high temperatures [

20].

The ST structure changed to the RTN structure with application of 1.2 V (transition voltage) at 356 K. A decrease in the voltage to 0.5 or 0 V resulted in a transition of the RTN structure to the ST structure via the STN state in

Figure 4a,b. Transition speed to STN is faster than that to ST. At this time, the STN structure changed to the RTN structure with application of 1.0 V, while the ST structure was maintained. After a relatively long time of applying a voltage lower than 1.0 V, the structure becomes the ST structure (

Figure 4c). It is necessary to apply 1.2 V to transform the ST structure into the RTN structure, while 1.0 V is required for a transition from the STN to RTN structure (

Figure 4d). Therefore, there is a higher potential barrier between ST and RTN than that between STN and RTN.

These RTN-LCDs were irradiated with UV light for 1 h, while 1.0 V was applied at 356 K, after confirmation of the RTN structure with POM. After UV irradiation, the RTN structure was maintained at high temperature; however, the LPSTN structure was formed at room temperature when the cell thickness was 5.4 µm.

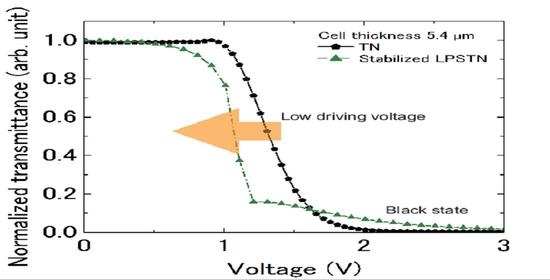

Figure 5 (green solid triangles) shows V-T curves for the LPSTN structure. On the other hand, when the cell thickness was 5.0 µm, the RTN structure at high temperature relaxed to the ST structure at room temperature even after UV irradiation. The driving voltage increased in the order of RTN-LCD < LPSTN-LCD < TN-LCD. When the V-T curves of STN-LCD were calculated (LCD Master) for cell thicknesses of 5.0–6.2 µm with a chiral pitch of 15 µm, a pretilt of 6° and a twist angle of 270°, the driving voltage was high as a function of thickness (

Figure 6).

Figure 7 shows V-T curves calculated for various chiral pitches of 10–25 µm with a chiral pitch of 15 µm, a pretilt of 6°, a twist angle of 270°, and a cell thickness of 5.4 µm. A longer chiral pitch results in a lower driving voltage; however, if the pitch is too long (chiral pitch is 25 µm), then the transmittance slowly decreases as a function of the voltage. Although the transmittance of LPSTN did not decrease to zero at 1.2 V in

Figure 5, the steepness of transmittance increased compared with the TN or RTN. In addition, the transmittance decreased to zero in simulation in the case of the cell thickness of 5.4 μm and chiral pitch of 20 μm. Therefore, we thought that a black state at low driving voltage can be realized by controlling condition of LCD.

The transmittance and the change of azimuth angle dependence on voltage were calculated for LPSTN using LCD Master for a cell thickness of 5.4 µm and a chiral pitch of 15 µm, and the results are shown in

Figure 8 and

Figure 9. The transmittance decreased similar to that for STN LCDs until 1.06 V and then dropped slowly from 1.07 V. The twist of the azimuth angle was 270° up to 1.06 V and then changed to 90°, which is not simple rotation. The LC molecules near the alignment layer twist left-handed where z/d implies the normalized thickness is from 0.0 to 0.4 and from 0.6 to 1.0 and those near the center of the cell twist right-handed at more than 90°. This phenomenon is an intrinsic twist for the RTN structure. Consequently, the LPSTN structure changed into an RTN structure with application over a certain voltage.

The chiral pitch is known to cause length increase, and the decrease in physical properties (e.g., the dielectric constant anisotropy, and the elastic constant) under heating. The chiral pitch was elongated to 16.8 μm (

Figure 3) and the physical properties changed (

Table 1) at 353 K. The physical properties at 353 K were estimated from multiplying nominal values at room temperature (298 K) by the ratio of measured values at 298 K to measured values at 353 K. The tilt angle in the vicinity of the alignment layer may be lower than that in the previous study [

14], because the sustain voltage is low. The pretilt angle for LCDs has been reported to be controllable by polymer matrix formation in the vicinity of the alignment layers by application of an electric voltage [

14,

21,

22].

The pretilt angle was assumed 15° because the RTN structure was maintained by UV irradiation with application of 1 V, while the pretilt angle is 6.0° for MLC-2173 without chiral dopant and RM at room temperature. The Gibbs free energy for RTN and LPSTN was calculated for the difference of (i) the physical properties (

Figure 10a,b), and (ii) the pretilt angles under the condition (i) (

Figure 10c,d).

At the beginning, the Gibbs free energy of the RTN and LPSTN structure at high temperature decreased at 0 V compared with the Gibbs free energy of those structures at room temperature (

Figure 10a,b). Additionally, these energies then slowly decreased as a function of voltage. The transition voltage from LPSTN structure (blue inverted triangles) to RTN structure (green triangles) under the physical properties at 353 K was lower than the transition voltage from LPSTN structure (black squares) to RTN structure (red circles) at 298 K. Secondly, the transition voltage from LPSTN structure (sky blue diamonds) to RTN structure (purple left-pointing triangles) was lower than the transition voltage from LPSTN structure (blue inverted triangles) to RTN structure (green triangles) in

Figure 10c,d. For application of 1.0 V, the RTN structure was stable because the LPSTN structure changed to the RTN structure, even if the pretilt angle was kept low.

For the RTN structure with the application of 1 V at 356 K experimentally, two routes are conceivable for the process of decreasing the voltage from 1 to 0 V; (i) the RTN remaining (green triangles in

Figure 11) or (ii) the RTN changing to the LPSTN at 0.95 V (blue inverted triangles in

Figure 11). The LPSTN structure was observed to change to the RTN structure with the application of 1.0 V at 356 K in

Figure 4. Therefore, the RTN structure when polymerized with the application of 1 V at 356 K was the RTN structure that was changed from the LPSTN. After being polymerized, the LPSTN structure was stable at room temperature.

A notable point of the STN-LCD is that their sharper threshold properties can realize a larger number of pixels in the case of passive matrix LCDs. For multiple-line addressing of passive matrix LCDs, the sharpness of the threshold property can be expressed by:

where

Vsat is the saturation voltage and

Vth is the threshold voltage. A sharper threshold property means that

approaches one more closely. The maximum number of scanning electrodes of passive matrix addressing

Nmax, can be expressed using

[

23].

In the case where approaches one, the possible number of scanning electrodes increases. For this reason, high-resolution LCDs can be achieved using the sharp threshold property of the STN mode. However, because the STN mode uses the change in the retardation of liquid crystals, it has a problem in that the transmitted light is colored. An LPSTN LCD possesses the STN structure without an applied voltage and exhibits the sharp threshold property. However, when voltage larger than the threshold voltage is applied, it changes to the RTN-LCD structure and shows the black state without color. Therefore, an LPSTN can realize the sharp threshold property of the STN mode and the black state without the color of the TN mode.

The change from LPSTN to RTN occurs because the RTN and LPSTN states are considered topologically equivalent. The LPSTN mode showing low driving voltage and a realizing black state could be an improved alternative candidate for STN-LCDs.