Hardness, Young’s Modulus and Elastic Recovery in Magnetron Sputtered Amorphous AlMgB14 Films

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Optical Properties

3.2. Nanoindentation

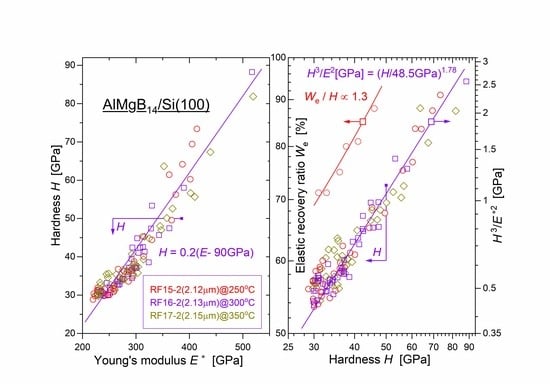

3.3. Hardness and Young’s Modulus

3.4. Plastic and Elastic Parts of the Indentation Work

4. Conclusions

5. Patents

Funding

Conflicts of Interest

Appendix A

References

- Matkovich, V.I.; Economy, J. Structure of MgAlB14 and a brief critique of structural relationships in higher borides. Acta Crystallogr. B 1970, 26, 616–621. [Google Scholar] [CrossRef]

- Cook, B.A.; Harringa, J.L.; Lewis, T.L.; Russel, A.M. A new class of ultra-hard materials based on AlMgB14. Scrip. Mater. 2000, 42, 597–602. [Google Scholar]

- Higashi, I.; Kobayashi, M.; Okada, S.; Hamano, K.; Lundström, T. Boron-rich crystals in Al-M-B (M = Li, Be, Mg) systems grown from high-temperature aluminum solutions. J. Cryst. Growth 1993, 128, 1113–1119. [Google Scholar] [CrossRef]

- Tian, Y.; Bastawros, A.F.; Lo, C.C.H.; Constant, A.P.; Russell, A.M.; Cook, B.A. Superhard self-lubricating AlMgB14 films for microelectromechanical devices. Appl. Phys. Lett. 2003, 83, 2781–2783. [Google Scholar] [CrossRef] [Green Version]

- Grishin, A.M.; Khartsev, S.I.; Böhlmark, J.; Ahlgren, M. Ultra-hard AlMgB14 coatings fabricated by RF magnetron sputtering from a stoichiometric target. JETP Lett. 2014, 100, 680–687. [Google Scholar]

- Hunold, O.; Chen, Y.-T.; Music, D.; Persson, P.O.Å.; Primetzhofer, D.; Baben, M.; Achenbach, J.-O.; Keuter, P.; Schneider, J.M. Correlative theoretical and experimental investigation of the formation of AlYB14 and competing phases. J. Appl. Phys. 2016, 119, 085307. [Google Scholar] [CrossRef] [Green Version]

- Hunold, O.; Keuter, P.; Bliem, P.; Music, D.; Wittmers, F.; Ravensburg, A.L.; Primetzhofer, D.; Schneider, J.M. Elastic properties of amorphous T0.75Y0.75B14 (T = Sc, Ti, V, Y, Zr, Nb) and the effect of O incorporation on bonding, density and elasticity (T’ = Ti, Zr). J. Phys. Cond. Matter 2017, 29, 085404. [Google Scholar]

- Roberts, D.J.; Zhao, J.; Munir, Z.A. Mechanism of reactive sintering of MgAlB14 by pulse electric current. Int. J. Refract. Met. Hard Mater. 2009, 27, 556–563. [Google Scholar] [CrossRef]

- Swanepoel, R. Determination of the thickness and optical constants of amorphous silicon. J. Phys. E Sci. Instrum. 1983, 16, 1214–1222. [Google Scholar] [CrossRef]

- Werheit, H.; Filipov, V.; Kuhlmann, U.; Schwarz, U.; Armbrüster, M.; Leithe-Jasper, A.; Tanaka, T.; Higashi, I.; Lundström, T.; Gurin, V.N.; et al. Raman effect in icosahedral boron-rich solids. Sci. Technol. Adv. Mater. 2010, 11, 023001. [Google Scholar]

- Goubeau, J.; Hummel, D. Die Schwingungsspektren verschiedener Borsauerstoffverbindungen. Z. Physik. Chem. N. F. 1959, 20, 15–33. [Google Scholar] [CrossRef]

- Choudhary, R.B.; Pande, P.P. Lubrication potential of boron compounds: An overview. Lubr. Sci. 2002, 14, 211–222. [Google Scholar] [CrossRef]

- Kleiner, K. Material Slicker than Teflon Discovered by Accident. NewScientist, Technology, 21 November 2008. Available online: https://www.newscientist.com/article/dn16102-material-slicker-than-teflon-discovered-by-accident/ (accessed on 16 September 2020).

- Music, D.; Kreissig, U.; Chirita, V.; Schneider, J.M.; Helmersson, U. Elastic modulus of amorphous boron suboxide thin films studied by theoretical and experimental methods. J. Appl. Phys. 2003, 93, 940–944. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Anders, A.; Brown, I.G. Nanoindentation and nanoscratching of hard carbon coatings for magnetic discs. Mater. Res. Soc. Symp. Proc. 1995, 383, 447–452. [Google Scholar] [CrossRef] [Green Version]

- Bhushan, B.; Li, X. Micromechanical and tribological characterization of doped single-crystal silicon and polysilicon films for microelectromechanical systems devices. J. Mater. Res. 1997, 12, 54–63. [Google Scholar] [CrossRef]

- Ueda, M.; Lepienski, C.M.; Rangel, E.C.; Cruz, N.C.; Dias, F.G. Nanohardness and contact angle of Si wafers implanted with N and C and Al alloy with N by plasma ion implantation. Surf. Coat. Technol. 2002, 156, 190–194. [Google Scholar] [CrossRef]

- Hopcroft, M.A.; Nix, W.D.; Kenny, T.W. What is the Young’s modulus of silicon? J. Microelectromech. Syst. 2010, 19, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Musil, J. Hard and superhard nanocomposite coatings. Surf. Coat. Technol. 2000, 125, 322–330. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relations between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technology 2002, 154, 304–313. [Google Scholar] [CrossRef]

- Musil, J.; Jirout, M. Toughness of hard nanostructured ceramic thin films. Surf. Coat. Technol. 2007, 201, 5148–5152. [Google Scholar] [CrossRef]

- Grishin, A.M. Abrasion resistant low friction and ultra-hard magnetron sputtered AlMgB14 coatings. Mater. Res. Express 2016, 3, 046402. [Google Scholar] [CrossRef]

- Putrolaynen, V.V.; Grishin, A.M.; Rigoev, I.V. Anti-Scratch AlMgB14 Gorilla® Glass Coating. Tech. Phys. Lett. 2017, 43, 871–874. [Google Scholar] [CrossRef]

- Putrolaynen, V.V.; Grishin, A.M.; Rigoev, I.V. Method for Fabrication of Wear Resistant Aluminum Magnesium Boride Coating. Patent RU 2677810, 7 March 2017. [Google Scholar]

- Putrolaynen, V.V.; Grishin, A.M.; Rigoev, I.V. Method for Fabrication of Transparent Wear Resistant Aluminum Magnesium Boride Coating on the Surface of Transparent Glassy Wares. Patent RU 2680548, 28 December 2017. [Google Scholar]

- Corning® 1737 AMLCD Glass Substrates. Material Information. Available online: http://www.vinkarola.com/pdf/Corning%20Glass%201737%20Properties.pdf (accessed on 16 September 2020).

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grishin, A.M. Hardness, Young’s Modulus and Elastic Recovery in Magnetron Sputtered Amorphous AlMgB14 Films. Crystals 2020, 10, 823. https://doi.org/10.3390/cryst10090823

Grishin AM. Hardness, Young’s Modulus and Elastic Recovery in Magnetron Sputtered Amorphous AlMgB14 Films. Crystals. 2020; 10(9):823. https://doi.org/10.3390/cryst10090823

Chicago/Turabian StyleGrishin, Alexander M. 2020. "Hardness, Young’s Modulus and Elastic Recovery in Magnetron Sputtered Amorphous AlMgB14 Films" Crystals 10, no. 9: 823. https://doi.org/10.3390/cryst10090823