1. Introduction

In the synthesis of metal oxides by corrosion/oxidation processes, many metals such as steel, nickel, titanium, zirconium alloys, silver, and aluminum-based alloys are well known as oxide-passivated metals, with titanium being an essential corrosion-resistant metal that may be used in high-strength applications [

1,

2]. Titanium is used in aerospace applications, medical implants, marine hardware, and high-purity titanium for use in electronics [

3]. However, to enhance strength in titanium, titanium composites must be produced at high temperatures (~1000 °C), which could limit their use [

1]. Titanium may be replaced for applications that require corrosion gradually, depending on the environmental conditions; therefore, due to their non-toxicity and classification as a non-carcinogen [

4], aluminum is the most widely used non-ferrous metal because of its non-ignition, mechanical strength, and it being the most cost-effective material to recycle.

Aluminum is the third most abundant element after oxygen and silicon and is the most abundant metal in the earth. This metal is chemically reactive, highly conductive, and non-magnetic [

5]. To produce aluminum, it must be converted in aluminum oxide by the Bayer process from bauxite, the main ore of aluminum, where small crystals of aluminum hydroxide are collected to serve as seeding agents where granular particles may be converted by heating. Other manner to produce aluminum is when the alumina (Al

2O

3), found in nature as the corundum mineral, is converted to metal by Hall–Heroult process. Both process types are highly energy-consuming. The aluminum has major uses in transportation, building and construction, machinery and equipment, packaging, as well as for electricity-related uses [

3,

6].

Nowadays, several challenges in aluminum production must be taken into account. The major challenge is the greenhouse gas emissions. These gases result from electrical consumption from the perfluorocarbons and by-products (sulfur dioxide) during processing into the smelters where released sulfur dioxide is one of the primary precursors of acid rain, and where high concentrations of toxic ions are a primary factor that disturbs root growth and its function in acidic soils [

7]. Because only 5% of energy is required for recycling aluminum in comparison with that used to produce aluminum from ore [

3], today recycling of beverage cans may be a crucial task where they can be effortlessly recovered to be useful as sustainable functional device [

8]. However, to manufacture aluminum-based functional devices, it must be gradually oxidized as a function of its ionizing activity where initially a free aluminum atom has a radii of 1.43 Å, but when it is oxidized their three outermost electrons participate in the chemical compounds, which are removed, then the radii of aluminum shrinks to 0.53 Å to be a six-coordinated atom [

9]. Further, owing to its low heat retention, relatively high thermal conductivity (30 Wm

−1K

−1), and large band gap (~4.2 eV), the extended use of aluminum oxide in electronics is currently used in electrically insulated substrates for the integrated circuits, as a tunnel barrier for the fabrication of nanoscale transistors, and as dielectric in insulating barriers of capacitors [

10].

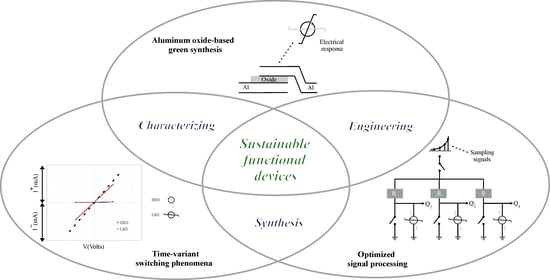

The work presents the synthesis of aluminum oxide assisted by the corrosion/oxidation process. Experimental procedure for synthesis of aluminum oxide will be detailed in

Section 2. Electrical conduction in aluminum oxide-based structures will be covered in

Section 3. Theoretic prototypes which show that electrical conduction in disordered aluminum oxide might play an important role for the optimized signal processing in electronics. This will be presented in

Section 4. Finally, conclusion about this research is presented in

Section 5.

2. Synthesis Process for Aluminum Oxide

Aluminum sheets of alloy 3004-H19 (Al-Mg-Mn series) recovered from useless beverage cans of an average thickness of 0.2 mm have been used here to synthesis of aluminum oxide. Before, aluminum sheets were cut in foils of cross-section area 2 cm × 2 cm. Because the sheets are internally coated with a highly electronegative thin-passivation oxide layer of 4 nm of thickness and electrode potential of −1.66 V including epoxy resin to avoid chemical reactions [

5], and also externally coated by printed shells, these must be removed on both sides of such these aluminum foils with mechanical polishing using silicon carbide (SiC) abrasive of fine particle size to achieve a controllable chemical attack on it. Next, cleaning process was realized with a home-used organic solvent known as thinner and successively dried in air atmosphere. In the synthesis of aluminum oxide, the following three stages are involved: (1) Chemical attack into a solution in concentration at 40% for etching PCBs well known as ferric chloride (FeCl

3). (2) Removing excess of solution from the attacked surface. (3) Immersing the attacked foils inside a sterilizing solution well employed in home wound treatment where concentration of hydrogen peroxide (H

2O

2) is 18 g/L suitable to ensure an oxygen source.

Before, the FeCl

3 solution must be activated with water to be used as electrolyte. Thus, 2.5 mL of FeCl

3 is mixed with 2.5 mL of water to get 1:1 ratio. A corrosion process occurs in the aluminum foils when a chemical attack is done during 30 sec by immersion. In this first stage, the reaction mechanism for corrosion can be written as

The species was dissolved in the solution activated with water are Fe

+(OH)

− and H

+Cl

−, which indicated that the presence of H

+ acts as reducing agent on the aluminum surface [

5,

11]. Subsequently, the chemical attack resulted in a disordered aluminum layer. Once the foils were immersed in the previous stage, some residues of FeCl

2 remain added.

In the third stage, chemically attacked foils were immersed into H

2O

2 in aqueous solution at different immersion times as indicated in

Table 1. In accordance with the following reaction mechanism, a disordered aluminum-oxide that grew on the recycled aluminum sheets took place as

In the third stage, the presence of two H

+ ions acted as reducing agents on the aluminum surface [

11]. The ionic species dissolved, such as Fe

+Cl

− and H

+Cl

−, will determine the oxidation degree, where the O

− ions transferred toward the surface reacted with Al

+3 ions to produce aluminum oxide of appearance opaque gray.

The X-ray diffraction with XPERT-PRO diffractometer system of CuK

α radiation (λ = 0.1541 nm) was employed to evaluate the formation of aluminum oxide. For this analysis, X-ray diffraction patterns were analyzed using the PANalytical evaluation software in the 2θ scanning range from 20

o to 90°.

Figure 1 shows the diffraction peaks for three samples of aluminum oxide labeled as AS-1, AS-2, and AS-3. As a reference, the diffraction pattern for an aluminum sheet recuperated from unusable beverage cans is shown. The samples resulted to be polycrystalline with rhombohedra (corundum) lattice. Several peaks appear which correspond to crystallographic planes for the preferred α-Al

2O

3 phase. Displacement in the X-ray diffraction patterns between peaks position of each aluminum-oxide layer and peaks position of recycled aluminum sheet were observed, ensuring the presence of elastic strain during the stages involved in the synthesis stages induced by disordered array of aluminum and oxygen ions into the aluminum-oxide lattice.

Because of the existence of elastic strain in aluminum-oxide layers, the minimum thickness for carrier conduction in the absence of scattering events must be estimated by Scherrer relation t ~ λ[є

2θ cos θ]

−1, where the average elastic strain is є

2θ = (d − d

0) d

−1 with d as the measure plane spacing and d

0 as the unstrained plane spacing [

12]. In

Table 1, the estimated thickness for the samples is given where their significant plane is corresponding to the area under (202) reflection peak.

The importance of obtaining the t parameter is that it lets us know how much disordered oxide occurs when the aluminum oxide grows as a function of the aluminum-surface corrosion, which will result in the aluminum atoms being visualized as layers of hexagonal close-packed oxygen atoms with small aluminum atoms in two-thirds of the octahedral coordinated holes between the oxygen atoms [

13], such that oxide behaves like to a defective oxide [

14,

15,

16].

It is well know that aluminum cans are alloyed to improve their physical properties using non-heat-treatable forming process, for example, mechanical hardness and corrosion resistance in Al-Mg-Mn series when these are exposed to temperature changes. The alloying metals in aluminum cans typically are 5% magnesium, 1% manganese, 0.1% chromium, as well as iron and silicon in a few percent per weight [

17]. Therefore, the X-ray diffraction analysis in

Figure 1 confirms that the recycled aluminum sheets are corresponding with above 90% aluminum in accordance with the peak-assignment cards, which guarantee that the structure properties for the aluminum oxide previously synthesized do not depend on the alloying metals.

3. Electrical Conduction in Aluminum Oxide-Based Structures

This section discusses how is the electrical conduction in aluminum-oxide layers (samples) synthesized with emphasis on knowledge of their conduction properties. Before, these samples must be cut with an area of 0.5 cm × 0.5 cm and inserted between two electrodes, as shown in the aluminum oxide-based structure of

Figure 2a. Electrical conduction measurements are performed and evaluated by current-voltage plots at room temperature using a digital storage oscilloscope (Tektronix, TDS1012C). A function generator (Matrix, MFG-8250A) is used to produce the sine wave at low frequency (f = 100 Hz) with magnitude scanned from −10 V to 10 V, which is connected between the bottom and upper aluminum electrodes of an area 1 cm

2, to ensure the bipolar-biased condition. These large-area electrodes acting as contacts were mechanically fixed to avoid surface deteriorating.

The operation in aluminum oxide-based structure has been confirmed with the practical circuit of

Figure 2b. To adjust the electrical current flow through this circuit when each samples was tested, graphite-based devices dependent on their distributed resistance and assembled on SiC sheets as substrates were used as resistors [

18]. To assess practical-circuit performance; an empirical technique well known as a transfer function for the analysis of the linear systems in control theory, is used here to correlate the current–voltage characteristics and internal states of each sample, where a relationship describing the charge carriers conduction under operation understands the ratio of the output variable to the input variable [

19].

To extract electrical signals from the practical circuit, a sine wave was connected in series with the scheme of

Figure 2a and with 100 Ω and 56 Ω load resistors, respectively. The sine wave was measured directly as CHX input oscilloscope signal, and the equivalent electrical current flow was monitored by determining the voltage across of the load resistors as CHY input oscilloscope signal as shown in

Figure 2b.

Figure 3a–c displays the current–voltage plots of each aluminum oxide-based structure tested with each one samples enlisted in

Table 1. As a reference, an electrical response of a recycled aluminum sheet connected in series with a 100 Ω load resistor has been included as dotted line from

Figure 3a to

Figure 3c to emphasize that the electrical conduction is dependent on internal states proximate to the interface between each sample and electrode aluminum; hence, an electrical symbol for the aluminum oxide-based structure is also proposed in

Figure 2b to differentiate the internal states revealed in

Figure 3. A phenomenological description related to the activation of each internal state is given below:

3.1. High-Resistance State

Because the aluminum ions are missing in the aluminum-oxide layer, it is disordered, which means that lattice defects occur. Therefore, the oxide must exhibit properties sensitive not only to stress states, but also to other variables including aluminum vacancies, variation in oxide composition, thickness, etc. In order to know how electrical conduction is caused by the electric field applied in the practical circuit, current–voltage plots help to reveal that the Ohmic conduction observed will be strongly depended on attractive electrostatic forces, F

a, where aluminum and oxygen ions are being well polarized as shown in

Figure 4a, until the injected carriers from the aluminum electrodes can be collected by these vacancies, which act as trapping sites when temperature increases from the interface.

3.2. Low-Resistance State

By increasing in the electric field and temperature through each aluminum-oxide layer in the practical circuit, the electrons trapped in aluminum vacancies are favored and as a consequence aluminum and oxygen ions will depolarize as a function of repulsive electrostatic forces, F

r, as shown in

Figure 4b, causing the structure to change in resistance with moderate conduction being influenced by the capability of the trapping sites to be occupied.

The effect of increasing thermal activation will be also dependent on high energy of injected electrons, such that a constant conduction is maintained.

The physical description previously made discloses that both compressive (−) and tensile (+) states from X-ray diffraction and charge carries conduction from electrical conduction could be responsible for the change in resistance of each sample, where carrier activation energy between 2eV to 4 eV, in accordance to the measured voltage transition in current–voltage plots, assumes at what voltage magnitude a change in resistance could occur, whose magnitude will differ as a function of the synthesis process in each one of the aluminum-oxide layers, and it must take place when the electron density reaches a critical quantity triggered by an time-variant electrical current.

The resulting current–voltage plots were found to be rather peculiar; the operating properties such as R

OFF/R

ON ratio, switching speed, retention time, and endurance [

20], being defined for switching-mode conduction, were estimated here from the current–voltage plots and collected in

Table 2. These collected data only reflect the degree to which the aluminum oxide-based structures were tested. It should be noted that due to the activation energy were not sufficiently high to dielectric breakdown in the samples; therefore, in

Figure 3a, it can be assumed that the oxide was enhanced with aluminum vacancies being equivalent to an aluminum-rich oxide layer, which resulted that R

OFF/R

ON ratio was moderately high and the switching speed was lower, but retention and endurance were a short time. In contrast,

Figure 3b,c assumes that the oxide is poorer with a reduced number of aluminum vacancies whose composition is equivalent to an oxygen-rich oxide layer, which results in both retention and endurance being extended time (>1 h), switching speed above 100 µsec, and R

OFF/R

ON ratio being lower.