Laser-Synthesized 2D-MoS2 Nanostructured Photoconductors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrate Preparation

2.2. Precursor Film Preparation

2.3. Laser Irradition

2.4. Characterization

2.5. Photodetector Device Fabrication

3. Results and Discussion

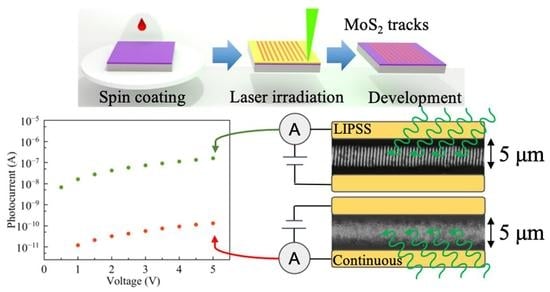

3.1. Linear LIPSS and Formation of Nanoribbons

3.2. 2D LIPSS

3.3. Nanostructured Photodetectors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Manzeli, S.; Ovchinnikov, D.; Pasquier, D.; Yazyev, O.V.; Kis, A. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2017, 2, 1–15. [Google Scholar] [CrossRef]

- Wen, X.; Gong, Z.; Li, D. Nonlinear optics of two-dimensional transition metal dichalcogenides. InfoMat 2019, 1, 317–337. [Google Scholar] [CrossRef] [Green Version]

- Scharf, B.; Xu, G.; Matos-Abiague, A.; Žutić, I. Magnetic proximity effects in transition metal dichalcogenides: Converting excitons. Phys. Rev. Lett. 2017, 119, 127403. [Google Scholar] [CrossRef] [Green Version]

- Hsu, Y.T.; Vaezi, A.; Fischer, M.H.; Kim, E.A. Topological superconductivity in monolayer transition metal dichalcogenides. Nat. Commun. 2017, 8, 14985. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, S.A.; Bhatia, R.; Kim, S.W. Synthesis, properties and potential applications of two-dimensional transition metal dichalcogenides. Nano Converg. 2015, 2, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Abbas, O.A.; Lewis, A.H.; Aspiotis, N.; Huang, C.C.; Zeimpekis, I.; Hewak, D.W.; Sazio, P.; Mailis, S. Laser printed two-dimensional transition metal dichalcogenides. Sci. Rep. 2021, 11, 5211. [Google Scholar] [CrossRef] [PubMed]

- Averchenko, A.V.; Salimon, I.A.; Zharkova, E.V.; Lipovskikh, S.; Somov, P.; Abbas, O.A.; Lagoudakis, P.G.; Mailis, S. Laser-enabled localized synthesis of Mo1-xWxS2 alloys with tunable composition. Mater. Today Adv. 2023, 17, 100351. [Google Scholar]

- Liu, K.-K.; Zhang, W.; Lee, Y.-H.; Lin, Y.-C.; Chang, M.-T.; Su, C.-Y.; Chang, C.-S.; Li, H.; Shi, Y.; Zhang, H.; et al. Growth of large-area and highly crystalline MoS2 thin layers on insulating substrates. Nano Lett. 2012, 12, 1538–1544. [Google Scholar] [CrossRef] [Green Version]

- Abbas, O.A.; Zeimpekis, I.; Wang, H.; Lewis, A.H.; Sessions, N.P.; Ebert, M.; Aspiotis, N.; Huang, C.-C.; Hewak, D.; Mailis, S.; et al. Solution-based synthesis of few-layer WS2 large area continuous films for electronic applications. Sci. Rep. 2020, 10, 1696. [Google Scholar] [CrossRef] [Green Version]

- Rahman, S.; Lu, Y. Nano-engineering and nano-manufacturing in 2D materials: Marvels of nanotechnology. Nanoscale Horiz. 2022, 7, 849–872. [Google Scholar] [CrossRef] [PubMed]

- Daus, A.; Vaziri, S.; Chen, V.; Köroğlu, Ç.; Grady, R.W.; Bailey, C.S.; Lee, H.R.; Shauble, K.; Brenner, K.; Pop, E. High-performance flexible nanoscale transistors based on transition metal dichalcogenides. Nat. Electron. 2021, 4, 495–501. [Google Scholar] [CrossRef]

- Kim, K.S.; Ji, Y.J.; Kim, K.H.; Choi, S.; Kang, D.-H.; Heo, K.; Cho, S.; Yim, S.; Lee, S.; Park, J.-H.; et al. Ultrasensitive MoS2 photodetector by serial nano-bridge multi-heterojunction. Nat. Commun. 2019, 10, 4701. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bonse, J.; Gräf, S. Maxwell meets Marangoni—A review of theories on laser-induced periodic surface structures. Laser Photonics Rev. 2020, 14, 2000215. [Google Scholar] [CrossRef]

- Durbach, S.; Kilian, H.; Hampp, N. Laser-driven Self-organized Evolution of 1D-and 2D-Nanostructures from Metal Thin-films on Silicon: Influence of Alloying and Oxidation. Appl. Surf. Sci. 2023, 622, 156927. [Google Scholar] [CrossRef]

- Mezera, M.; van Drongelen, M.; Römer, G.R.B.E. Laser-Induced Periodic Surface Structures (LIPSS) on polymers processed with picosecond laser pulses. J. Laser Micro Nanoeng. 2018, 13, 105–116. [Google Scholar]

- Dostovalov, A.V.; Derrien, T.J.Y.; Lizunov, S.A.; Přeučil, F.; Okotrub, K.A.; Mocek, T.; Korolkov, V.P.; Babin, A.B.; Bulgakova, N.M. LIPSS on thin metallic films: New in-sights from multiplicity of laser-excited electromagnetic modes and efficiency of metal oxidation. Appl. Surf. Sci. 2019, 491, 650–658. [Google Scholar] [CrossRef] [Green Version]

- Salimon, I.A.; Averchenko, A.V.; Lipovskikh, S.A.; Skryleva, E.A.; Novikov, A.V.; Lagoudakis, P.G.; Mailis, S. UV laser-induced nanostructured porous oxide in GaAs crystals. Solid State Sci. 2022, 128, 106887. [Google Scholar] [CrossRef]

- Brito, J.L.; Ilija, M.; Hernández, P. Thermal and reductive decomposition of ammonium thiomolybdates. Thermochim. Acta 1995, 256, 325–338. [Google Scholar] [CrossRef]

- Huynh, T.T.D.; Semmar, N. Dependence of ablation threshold and LIPSS formation on copper thin films by accumulative UV picosecond laser shots. Appl. Phys. A 2014, 116, 1429–1435. [Google Scholar] [CrossRef]

- Mastellone, M.; Bellucci, A.; Girolami, M.; Serpente, V.; Polini, R.; Orlando, S.; Santagata, A.; Sani, E.; Hitzel, F.; Trucchi, D.M. Deep-subwavelength 2D periodic surface nanostructures on diamond by double-pulse femtosecond laser irradiation. Nano Lett. 2021, 21, 4477–4483. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Nogales, A.; Ezquerra, T.A.; Rebollar, E. Influence of substrate and film thick-ness on polymer LIPSS formation. Appl. Surf. Sci. 2017, 394, 125–131. [Google Scholar] [CrossRef] [Green Version]

- Fraggelakis, F.; Mincuzzi, G.; Lopez, J.; Manek-Hönninger, I.; Kling, R. Controlling 2D laser nano structuring over large area with double femtosecond pulses. App. Surf. Sci. 2019, 470, 677–686. [Google Scholar] [CrossRef]

- Wang, M.; Li, D.; Liu, K.; Guo, Q.; Wang, S.; Li, X. Nonlinear optical imaging, precise layer thinning, and phase engineering in MoTe2 with femtosecond laser. ACS Nano 2020, 14, 11169–11177. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Chi, D. Dispersive growth and laser-induced rippling of large-area singlelayer MoS2 nanosheets by CVD on c-plane sapphire substrate. Sci. Rep. 2015, 5, 11756. [Google Scholar] [CrossRef] [Green Version]

- Durbach, S.; Krauss, F.T.; Hoffmann, M.; Lehmann, V.; Reinhardt, H.; Sundermeyer, J.; Hampp, N. Laser-Driven One-and Two-Dimensional Subwavelength Periodic Pat-terning of Thin Films Made of a Metal–Organic MoS2 Precursor. ACS Nano 2022, 16, 10412–10421. [Google Scholar] [CrossRef]

- Park, H.; Lee, J.; Han, G.; AlMutairi, A.; Kim, Y.H.; Lee, J.; Kim, Y.-M.; Kim, Y.-J.; Yoon, Y.; Kim, S. Nano-patterning on multilayer MoS2 via block copolymer lithography for highly sensitive and responsive phototransistors. Commun. Mater. 2021, 2, 94. [Google Scholar] [CrossRef]

- George, A.; Fistul, M.V.; Gruenewald, M.; Kaiser, D.; Lehnert, T.; Mupparapu, R.; Neumann, C.; Hübner, U.; Schaal, M.; Masurkar, N.; et al. Giant persistent photoconductivity in monolayer MoS2 field-effect transistors. NPJ 2D Mater. Appl. 2021, 5, 15. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Genovese, L.; Foller, T.; Giubileo, F.; Luongo, G.; Croin, L.; Liang, S.-G.; Ang, L.K.; Schleberger, M. Electrical transport and persistent photoconductivity in monolayer MoS2 phototransistors. Nanotechnology 2017, 28, 214002. [Google Scholar] [CrossRef] [Green Version]

- Chandan Sarkar, S.; Angadi, B. Defects induced persistent photoconductivity in monolayer MoS2. Appl. Phys. Lett. 2021, 118, 172105. [Google Scholar] [CrossRef]

- Rose, A. Performance of photoconductors. Proc. IRE 1955, 43, 1850–1869. [Google Scholar] [CrossRef]

| Power (µW) | 650 nm Excitation | |

|---|---|---|

| (s) | (s) | |

| 0.48 | 99 | 1055 |

| 3.3 | 107 | 1104 |

| 4.8 | 112 | 1134 |

| 6.0 | 134 | 1228 |

| 10.0 | 108 | 936 |

| 13.2 | 135 | 1148 |

| 20.8 | 101 | 1082 |

| Power (µW) | 450 nm Excitation | |

|---|---|---|

| (s) | (s) | |

| 0.52 | 210 | 1639 |

| 1.44 | 151 | 1349 |

| 3.3 | 112 | 1063 |

| 5.3 | 100 | 931 |

| 6.2 | 95 | 831 |

| 7.0 | 50 | 469 |

| 11.0 | 45 | 457 |

| 13.2 | 32 | 343 |

| 22.0 | 40 | 409 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salimon, I.A.; Zharkova, E.V.; Averchenko, A.V.; Kumar, J.; Somov, P.; Abbas, O.A.; Lagoudakis, P.G.; Mailis, S. Laser-Synthesized 2D-MoS2 Nanostructured Photoconductors. Micromachines 2023, 14, 1036. https://doi.org/10.3390/mi14051036

Salimon IA, Zharkova EV, Averchenko AV, Kumar J, Somov P, Abbas OA, Lagoudakis PG, Mailis S. Laser-Synthesized 2D-MoS2 Nanostructured Photoconductors. Micromachines. 2023; 14(5):1036. https://doi.org/10.3390/mi14051036

Chicago/Turabian StyleSalimon, Igor A., Ekaterina V. Zharkova, Aleksandr V. Averchenko, Jatin Kumar, Pavel Somov, Omar A. Abbas, Pavlos G. Lagoudakis, and Sakellaris Mailis. 2023. "Laser-Synthesized 2D-MoS2 Nanostructured Photoconductors" Micromachines 14, no. 5: 1036. https://doi.org/10.3390/mi14051036