Evaluation of Bronze Electrode in Electrical Discharge Coating Process for Copper Coating

Abstract

:1. Introduction

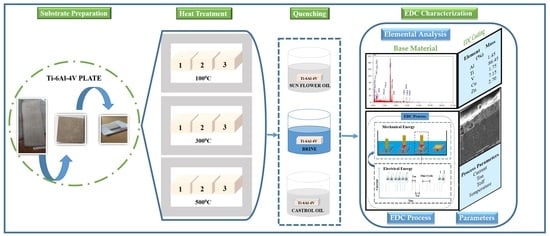

2. Materials and Methods

2.1. Workpiece and Electrode Materials

2.2. Output Process Parameters

2.3. Methods

TOPSIS

3. Experimental Procedure

4. Results

Analysis of Output Parameters

5. Discussion

5.1. Analysis of Surface Integrity before and after Heat Treatment

5.2. Surface Morphology

5.3. Surface Crack Density

5.4. Coating and Base Material Interfacing Analysis

5.5. Elemental Analysis

5.6. Optimization by TOPSIS

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Banu, A.; Ali, M.Y. Ali, Electrical Discharge Machining (EDM): A Review Electrical Discharge Machining (EDM): A Review. Int. J. Eng. Mater. Manuf. 2016, 1, 3–10. [Google Scholar] [CrossRef]

- Faisal, N.; Kumar, K. Optimization of Machine Process Parameters in EDM for EN 31 Using Evolutionary Optimization Techniques. Technologies 2018, 6, 54. [Google Scholar] [CrossRef] [Green Version]

- Shabgard, M.R.; Gholipoor, A.; Baseri, H. A review on recent developments in machining methods based on electrical discharge phenomena. Int. J. Adv. Manuf. Technol. 2016, 87, 2081–2097. [Google Scholar] [CrossRef]

- Descoeudres, A. Characterization of Electrical Discharge Machining Plasmas. EPFL 2006, 3542, 137. [Google Scholar] [CrossRef]

- Liew, P.J.; Yap, C.Y.; Wang, J.; Zhou, T.; Yan, J. Surface modification and functionalization by electrical discharge coating: A comprehensive review. Int. J. Extreme Manuf. 2020, 2, 012004. [Google Scholar] [CrossRef]

- Maddu, J.; Shaik, R.U. A Review on Electrical Discharge Coating (EDC) and its Multi-Optimization Techniques. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1185, 12027. [Google Scholar] [CrossRef]

- Murray, J.; Algodi, S.; Fay, M.; Brown, P.; Clare, A. Formation mechanism of electrical discharge TiC-Fe composite coatings. J. Mater. Process. Technol. 2017, 243, 143–151. [Google Scholar] [CrossRef]

- Krishna, M.E.; Patowari, P.K. Parametric Study of Electric Discharge Coating using Powder Metallurgical Green Compact Electrodes. Mater. Manuf. Process. 2014, 29, 1131–1138. [Google Scholar] [CrossRef]

- Mughal, M.P.; Farooq, M.U.; Mumtaz, J.; Mia, M.; Shareef, M.; Javed, M.; Jamil, M.; Pruncu, C.I. Surface modification for osseointegration of Ti6Al4V ELI using powder mixed sinking EDM. J. Mech. Behav. Biomed. Mater. 2020, 113, 104145. [Google Scholar] [CrossRef]

- Machkale, P.; Dabade, B. Experimental investigation of tungsten and copper carbide coating on AISI 1020 steel using electro discharge coating process. Mater. Today Proc. 2019, 26, 2915–2920. [Google Scholar] [CrossRef]

- Mohanty, S.; Bhushan, B.; Das, A.K.; Dixit, A.R. A study on parametric optimization of Micro-electrical discharge coating process using response surface methodology. Mater. Today Proc. 2020, 38, 325–332. [Google Scholar] [CrossRef]

- Maddu, J.; Karrolla, B.; Shaik, R.U.; Vuppala, S. Comparative Study of Optimization Models for Evaluation of EDM Process Parameters on Ti-6Al-4V. Modelling 2021, 2, 29. [Google Scholar] [CrossRef]

- Sumanth, P.; Reddy, M.V.; Shaik, I.; Maddu, J.R. Parameter Optimization of EDM Characteristics on Ti-6Al-4V Using Different Electrodes. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1185, 012022. [Google Scholar] [CrossRef]

- Norambuena, G.A.; Patel, R.; Karau, M.; Wyles, C.C.; Jannetto, P.J.; Bennet, K.E.; Hanssen, A.D.; Sierra, R.J. Antibacterial and Biocompatible Titanium-Copper Oxide Coating May Be a Potential Strategy to Reduce Periprosthetic Infection: An In Vitro Study. Clin. Orthop. Relat. Res. 2017, 475, 722–732. [Google Scholar] [CrossRef] [Green Version]

- Tyagi, R.; Darmalingam, K.; Patel, V.S.; Das, A.K.; Mandal, A. Mandal, Deposition of WS2 and Cu nanopowder coating using EDC process and its analysis. Mater. Today Proc. 2019, 18, 5170–5176. [Google Scholar] [CrossRef]

- Algodi, S.J.; Murray, J.W.; Brown, P.D.; Clare, A.T. Wear performance of TiC/Fe cermet electrical discharge coatings. Wear 2018, 402–403, 109–123. [Google Scholar] [CrossRef]

- Mussada, E.K.; Patowari, P.K. Post processing of the layer deposited by electric discharge coating. Mater. Manuf. Process. 2017, 32, 442–449. [Google Scholar] [CrossRef]

- Hsu, H.-Y.; Hu, C.-C. Surface quality improvement of EDMed Ti–6Al–4V alloy using plasma etching and TiN coating. Int. J. Adv. Manuf. Technol. 2017, 88, 67–74. [Google Scholar] [CrossRef]

- Maddu, J.; Vuppala, S.; Shaik, R.U. Formation and Statistical Optimization of Electrical Discharge Coatings using Conventional Electrodes. Energies 2021, 14, 5691. [Google Scholar] [CrossRef]

- Algodi, S.J.; Murray, J.W.; Fay, M.W.; Clare, A.T.; Brown, P.D. Electrical discharge coating of nanostructured TiC-Fe cermets on 304 stainless steel. Surf. Coatings Technol. 2016, 307, 639–649. [Google Scholar] [CrossRef]

- Tyagi, R.; Das, A.; Mandal, A. Electrical discharge coating using WS2 and Cu powder mixture for solid lubrication and enhanced tribological performance. Tribol. Int. 2018, 120, 80–92. [Google Scholar] [CrossRef]

- Murray, J.; Cook, R.; Senin, N.; Algodi, S.; Clare, A. Defect-free TiC/Si multi-layer electrical discharge coatings. Mater. Des. 2018, 155, 352–365. [Google Scholar] [CrossRef] [Green Version]

- Bui, V.D.; Mwangi, J.W.; Meinshausen, A.-K.; Mueller, A.J.; Bertrand, J.; Schubert, A. Antibacterial coating of Ti-6Al-4V surfaces using silver nano-powder mixed electrical discharge machining. Surf. Coat. Technol. 2020, 383, 125254. [Google Scholar] [CrossRef]

- Ming, W.; Guo, X.; Xu, Y.; Zhang, G.; Jiang, Z.; Li, Y.; Li, X. Progress in non-traditional machining of amorphous alloys. Ceram. Int. 2023, 49, 1585–1604. [Google Scholar] [CrossRef]

- Kahlin, M.; Ansell, H.; Basu, D.; Kerwin, A.; Newton, L.; Smith, B.; Moverare, J.J. Improved fatigue strength of additively manufactured Ti6Al4V by surface post processing. Int. J. Fatigue 2020, 134, 105497. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, D.; Zhang, Y.; Xue, T.; Huang, Y.; Zhang, G. Fabrication and droplet impact performance of superhydrophobic Ti6Al4V surface by laser induced plasma micro-machining. Appl. Surf. Sci. 2022, 605, 154661. [Google Scholar] [CrossRef]

- Schnell, G.; Duenow, U.; Seitz, H. Effect of Laser Pulse Overlap and Scanning Line Overlap on Femtosecond Laser-Structured Ti6Al4V Surfaces. Materials 2020, 13, 969. [Google Scholar] [CrossRef] [Green Version]

- Zeng, Z.-Y.; Xiao, H.-Q.; Jie, X.-H.; Zhang, Y.-M. Friction and wear behaviors of TiCN coating based on electrical discharge coating. Trans. Nonferrous Met. Soc. China 2015, 25, 3716–3722. [Google Scholar] [CrossRef]

- Jeavudeen, S.; Jailani, H.S.; Murugan, M. Effect of process parameters in the machining of Titanium alloy and high speed steel in powder mixed electrical discharge machining process. Mater. Today Proc. 2020, 27, 615–619. [Google Scholar] [CrossRef]

- Maddu, J.; Karrolla, B.; Shaik, R.U. Experimental optimization of electrical discharge coatings using conventional electrode. Mater. Sci. Eng. B 2022, 286, 116069. [Google Scholar] [CrossRef]

- Kumar, N.; Mandal, N.; Das, A.K. Micro-machining through electrochemical discharge processes: A review. Mater. Manuf. Process. 2020, 35, 363–404. [Google Scholar] [CrossRef]

- Jagadeeswara Rao, M.; Shaik, R.U.; Buschaiah, K. Electrical Discharge Machining: A Comparative Surface Integrity Study for Incoloy-800. Mater. Today Proc. 2020, 22, 3286–3296. [Google Scholar] [CrossRef]

- Mansor, A.F.; Azmi, A.I.; Zain, M.Z.; Jamaluddin, R. Parametric evaluation of electrical discharge coatings on nickel-titanium shape memory alloy in deionized water. Heliyon 2020, 6, e04812. [Google Scholar] [CrossRef] [PubMed]

- ASahu, A.K.; Thomas, J.; Mahapatra, S.S. An intelligent approach to optimize the electrical discharge machining of titanium alloy by simple optimization algorithm. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2021, 235, 371–383. [Google Scholar] [CrossRef]

- Buschaiah, K.; JagadeeswaraRao, M.; Krishnaiah, A. Krishnaiah, Investigation on the Influence of Edm Parameters on Machining Characteristics for Aisi 304. Mater. Today Proc. 2018, 5, 3648–3656. [Google Scholar] [CrossRef]

- Mohanty, S.; Kumar, V.; Das, A.K.; Dixit, A.R. Dixit, Surface modification of Ti-alloy by micro-electrical discharge process using tungsten disulphide powder suspension. J. Manuf. Process. 2018, 37, 28–41. [Google Scholar] [CrossRef]

- Kumar, D.; Mondal, S. Process parameters optimization of AISI M2 steel in EDM using Taguchi based TOPSIS and GRA. Mater. Today Proc. 2019, 26, 2477–2481. [Google Scholar] [CrossRef]

- Meel, R.; Singh, V.; Katyal, P.; Gupta, M. Optimization of process parameters of micro-EDD/EDM for magnesium alloy using Taguchi based GRA and TOPSIS method. Mater. Today Proc. 2021, 51, 269–275. [Google Scholar] [CrossRef]

- Izwan, N.S.L.B.; Feng, Z.; Patel, J.B.; Hung, W.N. Prediction of Material Removal Rate in Die-sinking Electrical Discharge Machining. Procedia Manuf. 2020, 5, 658–668. [Google Scholar] [CrossRef] [Green Version]

- Shaik, R.U.; Karanjai, M.; Joardar, J.; Hebalkar, N.Y.; Borse, P.H. Thermally stable electro catalytic nickel-phosphide film deposition on graphite for HER electrode application. Mater. Sci. Eng. B 2022, 285, 115927. [Google Scholar] [CrossRef]

- Huang, C.H.; Yang, A.B.; Hsu, C.Y. The optimization of micro EDM milling of Ti–6Al–4V using a grey Taguchi method and its improvement by electrode coating. Int. J. Adv. Manuf. Technol. 2018, 96, 3851–3859. [Google Scholar] [CrossRef]

- Maddu, J.; Karrolla, B.; Shaik, R.U.; Burdhuhos-Nergis, D.-P. SWOT Analysis of Electrical Discharge Coatings: A Case Study of Copper Coating on Titanium Alloy. Surfaces 2022, 5, 21. [Google Scholar] [CrossRef]

| Properties | Electrode | Substrate |

|---|---|---|

| Chemical composition | Cu 88% Sn 10% Zn 2% | C 0.08, Fe 0.25, Al 6, V 4, Ti balance |

| Density (kg/m3) | 8770 | 4.42 |

| Melting point (°C) | 1035 | 1878 |

| Specific heat capacity (J/g °C) | 370 | 553 |

| Hardness | 170 | 300 |

| S. No. | Input Process Parameters | Level |

|---|---|---|

| 1 | Current (Amps) | 4 8 12 |

| 2 | Ton (µs) | 280 360 440 |

| 3 | Toff (µs) | 200 300 400 |

| 4 | Temperature (°C) | 100 300 500 |

| Exp. No. | Current (Amp) | Ton (µs) | Toff (µs) | Temp (°C) | Quenching Medium | MDR (Gram/Min) | EWR (Gram/Min) |

|---|---|---|---|---|---|---|---|

| 1 | 4 | 280 | 200 | 100 | Sunflower | 0.00442 | 0.000442 |

| 2 | 4 | 360 | 300 | 300 | Brine | 0.00214 | 0.000852 |

| 3 | 4 | 440 | 400 | 500 | Castor oil | 0.005205 | 0.000682 |

| 4 | 8 | 280 | 300 | 500 | Sunflower | 0.002253 | 0.002775 |

| 5 | 8 | 360 | 400 | 100 | Brine | 0.003148 | 0.003565 |

| 6 | 8 | 440 | 200 | 300 | Castor oil | 0.00506 | 0.00462 |

| 7 | 12 | 280 | 400 | 300 | Sunflower | 0.012278 | 0.012423 |

| 8 | 12 | 360 | 200 | 500 | Brine | 0.001868 | 0.013923 |

| 9 | 12 | 440 | 300 | 100 | Castor oil | 0.000155 | 0.011508 |

| Exp. No. | Avg. HV | Avg. Diameter (Micron) | Avg. Grain Area (Micron Sqr) | Avg. Grain No. | 50X | Grain Structure |

|---|---|---|---|---|---|---|

| 1 | 392.66 | 61.95 | 4865 | 4 |  | |

| 2 | 399.3 | 26.85 | 861.5 | 7 | ||

| 3 | 350.46 | 26.85 | 861.5 | 7 | ||

| 4 | 355.83 | 30.95 | 1220 | 6 | ||

| 5 | 408.3 | 26.85 | 861.5 | 7 | ||

| 6 | 389.5 | 30.95 | 1220 | 6 | ||

| 7 | 393.56 | 30.95 | 1220 | 6 | ||

| 8 | 379.1 | 26.85 | 861.5 | 7 | ||

| 9 | 378.96 | 36.8 | 1725 | 6 | ||

| Exp. No. | Avg. HV | Avg. Diameter (Micron) | Avg. Grain Area (Micron Sqr) | Avg. Grain No. | 50X | Grain Structure |

|---|---|---|---|---|---|---|

| 1 | 348.13 | 26.85 | 861.5 | 7 |  | |

| 2 | 398.83 | 26.85 | 861.5 | 7 | ||

| 3 | 360.7 | 30.95 | 1220 | 6 | ||

| 4 | 358.13 | 36.8 | 1725 | 6 | ||

| 5 | 396.166 | 26.85 | 861.5 | 7 | ||

| 6 | 398.76 | 26.85 | 861.5 | 7 | ||

| 7 | 387.73 | 52.1 | 3440 | 5 | ||

| 8 | 359.46 | 36.8 | 1725 | 6 | ||

| 9 | 383.16 | 104.1 | 13750 | 3 | ||

| Exp. No. Units | MDR (Gram/Min) | EWR (Gram/Min) | CT (µm) | SCD (µm2) | Ti % | Al % | Cu % |

|---|---|---|---|---|---|---|---|

| 1 | 0.00442 | 0.00044 | 38.3333 | 0.0000992775 | 86.45 | 1.45 | 7.65 |

| 2 | 0.00214 | 0.00085 | 28.8333 | 120971533.3 | 85.93 | 0.85 | 6.6 |

| 3 | 0.0052 | 0.00068 | 33.5667 | 156621668.1 | 90.21 | 1.39 | 4.72 |

| 4 | 0.00225 | 0.00278 | 27.5333 | 44156787.82 | 91.14 | 1.23 | 3.82 |

| 5 | 0.00315 | 0.00357 | 39.9 | 261218750.4 | 90.41 | 0.38 | 4.82 |

| 6 | 0.00506 | 0.00462 | 40.2 | 194348924 | 91.71 | 1.79 | 5.82 |

| 7 | 0.01228 | 0.01242 | 30.4333 | 188926795.8 | 91.57 | 1.41 | 5.24 |

| 8 | 0.00187 | 0.01392 | 39.8 | 117702032.4 | 92.42 | 1 | 2.11 |

| 9 | 0.00015 | 0.01151 | 31.7 | 121594295.4 | 91.18 | 1.23 | 3.84 |

| Exp. No. | MDR | EWR | AV CT | SCD | Ti | Cu |

|---|---|---|---|---|---|---|

| 1 | 0.00442 | 0.000442 | 38.33333 | 0.0000993 | 86.45 | 7.65 |

| 2 | 0.00214 | 0.000852 | 28.83333 | 121000000 | 85.93 | 6.6 |

| 3 | 0.005205 | 0.000682 | 33.56667 | 157000000 | 90.21 | 4.72 |

| 4 | 0.002252 | 0.002775 | 27.53333 | 44156788 | 91.14 | 3.82 |

| 5 | 0.003147 | 0.003565 | 39.9 | 261000000 | 90.41 | 4.82 |

| 6 | 0.00506 | 0.00462 | 40.2 | 194000000 | 91.71 | 5.82 |

| 7 | 0.012278 | 0.012423 | 30.43333 | 189000000 | 91.57 | 5.24 |

| 8 | 0.001868 | 0.013923 | 39.8 | 118000000 | 92.42 | 2.11 |

| 9 | 0.000155 | 0.011508 | 31.7 | 122000000 | 91.18 | 3.84 |

| Exp. No. | Relative Closeness | Rank |

|---|---|---|

| 1 | 0.370044 | 3 |

| 2 | 0.370065 | 9 |

| 3 | 0.370053 | 5 |

| 4 | 0.370064 | 8 |

| 5 | 0.370041 | 2 |

| 6 | 0.370034 | 1 |

| 7 | 0.370054 | 6 |

| 8 | 0.370046 | 4 |

| 9 | 0.370057 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maddu, J.; Karrolla, B.; Shaik, R.U.; Elahi, H.; Arkanti, K. Evaluation of Bronze Electrode in Electrical Discharge Coating Process for Copper Coating. Micromachines 2023, 14, 136. https://doi.org/10.3390/mi14010136

Maddu J, Karrolla B, Shaik RU, Elahi H, Arkanti K. Evaluation of Bronze Electrode in Electrical Discharge Coating Process for Copper Coating. Micromachines. 2023; 14(1):136. https://doi.org/10.3390/mi14010136

Chicago/Turabian StyleMaddu, JagadeeswaraRao, Buschaiah Karrolla, Riyaaz Uddien Shaik, Hassan Elahi, and Krishnaiah Arkanti. 2023. "Evaluation of Bronze Electrode in Electrical Discharge Coating Process for Copper Coating" Micromachines 14, no. 1: 136. https://doi.org/10.3390/mi14010136