1. Introduction

Precision positioning platforms have been widely used in bioengineering [

1,

2,

3], precision optics [

4,

5,

6], atomic force microscopes [

7,

8], aerospace [

9] and other engineering fields [

10,

11,

12]. They are playing an increasingly significant role in micro-nano operations. Conventional mechanisms can usually be divided into rigid mechanisms and compliant mechanisms. With the continuous development of science and technology, rigid mechanisms can no longer meet the current needs of high precision and rapid response on specific occasions due to their limitations, such as friction and clearance [

13]. On the contrary, the compliant mechanisms with the advantages of no friction, no clearance, and high precision have become a research focus in the field of micro-nano operations in the past few years [

14,

15]. In micro-nano operations, electromagnetic actuators, electrostatic actuators, electrothermal actuators, and piezoelectric ceramic actuators are usually used to drive the platforms [

16]. As one kind of the most popular actuators, piezoelectric ceramic actuators are widely used in precision platforms for their merits of high resolution, fast response speed, and large driving force [

17,

18]. The traditional compliant precision positioning platforms can be divided into a single degree of freedom platforms [

19] and multi-degree of freedom platforms [

20,

21]. With the development of the micro-nano field, it is difficult for the single degree of freedom platforms to meet the requirements of current precise operation. Therefore, the research of high-performance multi-degree of freedom precision positioning platforms has become the research focus in these years [

22,

23].

The XYZ-platform is an important type of precise positioning platform, which is required in some space operations [

24,

25]. The spatial XYZ-platforms have been widely researched in the past few decades. For example, Lv et al. [

26] introduced an innovative design based on a three-dimensional (3D) motion device, which can produce precise and fast micro-displacement. Zhu et al. [

24] adopted the orthogonal arrangement of a three-chain parallel mechanism to achieve the low coupling and high natural frequency of XYZ-axis. Xu et al. [

27] also designed an XYZ precise positioning platform by using the orthogonal arrangement of three chains and introduced a multistage lever amplification mechanism in each chain to amplify the output displacement. Zhang et al. [

28] amplified the stroke of XYZ platform for more than 30 times than the input displacement through the bridge lever compound amplification mechanism. It should be noted that most of these Spatial XYZ platforms consist of three orthogonal chains along the XYZ directions, which generally leads to their bigger overall sizes [

29,

30]. Furthermore, the bigger size will also cause other problems such as greater mass, which has a negative impact on the natural frequency of the platform.

To reduce the size of the platform, Ling et al. [

31] placed a piezoelectric ceramic actuator and two-stage amplification mechanism in the center of the planar mechanism. Zhang et al. [

20] adopted the zigzag beams and using the differential moving principle (DMP) to realize XYZ movement with compact structure size. Ghafarian et al. [

32] designed a circular small-size XYZ precision positioning platform with three bridge-type mechanisms arranged in a 120-degree plane and inclined blocks with semicircular notch hinges. Wang et al. [

33] design a near-plane structure, the high natural frequency XYZ platform adopted the wedge structure in each of the three chains. These platforms have been reduced the size in different ways. However, they can not achieve a large stroke in all three degrees of freedom simultaneously. Moreover, they can only achieve two degrees of freedom bi-directional motion at most.

The Z-shaped flexure hinge is originally proposed by Guan et al. [

34], which is used as a driver. It can change the direction of motion in a compact structure and amplify the stroke in the output direction. Subsequently, some researchers have also designed various platforms using Z-shaped flexure hinges. Liu et al. [

35] placed a piezoelectric ceramic actuator at the output end of the Z-shaped flexure hinges in a special structure to achieve the movement of the XYZ axis. Xie et al. [

36] used three actuators and the symmetrical Z-shaped flexure hinges structure to achieve 3DOF movement in a planar mechanism. With the rapid development of micro-nano operations, it is more difficult for the traditional platform only moving in one-direction to meet some cases which require positive and negative directions relative to its origin. Therefore, bi-directional motion platforms have been designed by some researchers. Choi et al. [

37] designed a XY bi-directional motion platform for micro-nano operations. Zhu et al. [

38] designed a 2DOF platform for tool cutting by using Z-shaped flexure hinges; it can realize a bi-directional cutting function on the X axis. In this paper, by using the compact structure of Z-shaped flexure hinges and their functions of displacement amplification and direction change, 3DOF bi-directional motion is realized in a nearly plane structure, and the platform has a large stroke along the Z axis.

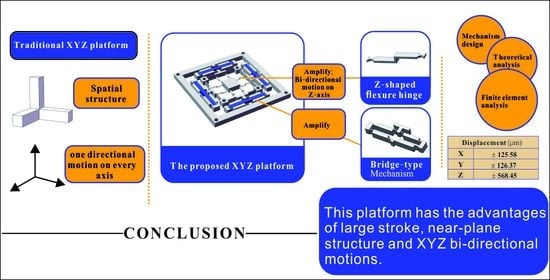

To sum up, the main problem existing in the current XYZ precision positioning platforms is the mismatch between the platform size and the stroke. In particular, they can not simultaneously realize a larger stroke while reducing the size along the Z axis. Furthermore, most of the platforms cannot generate positive and negative bi-directional movement relative to the origin. To solve these problems, in this paper, a 3DOF XYZ bi-directional motion platform based on Z-shaped flexure hinges is presented. In this platform, the reverse arrangement of Z-shaped flexure hinges on the X-axis and Y-axis is introduced to acquire a near-plane structure, small size, large stroke and bi-directional motion in every degrees of freedom.

The rest of the paper is organized as follows:

Section 2 introduces the structure design and principle of the platform; in

Section 3, Z-shaped flexure hinges are analyzed, and the static and dynamic analysis of the platform is carried out;

Section 4 carries on the finite element simulation to the platform to verify the rationality of the theoretical analysis; finally,

Section 5 is the summary of the whole paper.

2. Design of the XYZ Bi-Directional Motion Platform

In this paper, it is essential to rationally use and arrange the Z-shaped flexure hinges in order to realize XYZ bi-directional motion. The Z-shaped flexure hinges can change the direction of movement and amplify the output displacement by bending deformation.

Figure 1 shows the working principle of Z-shaped flexure hinges. The rigid body is laid out in the middle, and symmetrical Z-shaped flexure hinges are arranged on both sides of the rigid body. Z-shaped flexure hinges would produce deformation because of bending when force or displacement to both ends is imposed. The direction of bending deformation is related to the layout of the Z-shaped flexure hinges. As shown in

Figure 2, when a pair of Z-shaped flexure hinges with opposite directions are arranged on the X-axis and Y-axis, respectively, the moving platform in the middle can move up or down on the Z-axis relative to the origin.

The structure design of the XYZ bi-directional motion platform is shown in

Figure 3. The bridge-type amplification mechanisms in each of the four branched chains are used to enlarge the input displacements. The leaf-shaped flexure guide hinges are designed at the output end of the bridge mechanism to decouple the input and output. The Z-shaped flexure hinges are connected in series with the bridge-type mechanism and the leaf-shaped flexure guide hinges, and they are finally connected to the moving platform. The bridge-type mechanism, leaf-shaped flexure guide beams, and Z-shaped flexure hinges on each side form a branch chain, and the four chains form the precise positioning platform of the 4-PP configuration. It is worth noting that the four chains are not entirely symmetrical because the Z-shaped flexure hinges arranged in the X-axis and Y-axis are opposite.

In order to generate XYZ bi-direction movement, a pair of identical piezoelectric ceramic actuators (PCA) are arranged on the X-axis and Y-axis, respectively, as shown in

Figure 3. According to the famous DMP, the difference between the driving forces of the two coaxial actuators will induce the motion of the platform along the X-axis or Y-axis [

39]. The pair of actuators on the X-axis can motivate the platform to move in both positive and negative directions on the X-axis as well as a positive direction on the Z-axis. The pair of actuators on the Y-axis can motivate the platform to move in both positive and negative directions on the Y-axis as well as the negative direction on the Z-axis. In this way, it is feasible to achieve XYZ bi-directional motions with a nearly planar structure.

4. Finite Element Analysis and Discussion

The finite element analysis (FEA) is carried out by using ANSYS to test the performance of the proposed platform. In FEA, Al7075-T6 is chosen as the material of the platform, and its main properties are shown in

Table 3. The reasons for use Al 7075-T6 are due to its low density and larger

ratio value, which make it have the merit of light weight and higher elasticity. In addition,

denotes the yield stress,

E denotes the Young’s modulus. In addition, the platform adopts the automatic meshing method in ANSYS, and the size of the mesh is 0.5 mm.

Figure 10a shows the meshing of the platform. In addition,

Figure 10b shows the maximum stress of 440 MPa and it is lower than 505 MPa, which is the yield stress of Al 7075-T6. The maximum stress occurs when input displacement of 40 μm is applied to each side of the bridge-type mechanisms on the X direction. It appears on the semicircular notched hinges which connect the Z-shaped flexure hinges and the moving platform.

Firstly, the statics simulation of the platform is carried out in this section.

Figure 11 shows the total deformation along the XYZ axis. If the platform needs to move along the X or Y axis, input displacement is supposed to be applied on one of the bridge-type mechanisms along the X or Y axis; meanwhile, the maximum input displacement is 20 μm. As shown in

Figure 11a–d, an input displacement of 20 μm is applied to only one of the bridge-type mechanisms along the X axis or Y axis. In addition, the probe function is used in ANSYS to detect the displacements of each degree of freedom. The maximum displacements of the moving platform are 125.34 μm and −125.81 μm in positive and negative directions along the X-axis, respectively. The maximum displacements are 126.19 μm and −126.54 μm in positive and negative directions along the Y-axis. As shown in

Figure 11e,f, if the platform needs to move along the Z-axis, input displacements should be applied on both sides of the bridge-type mechanisms on the X or Y axis. Meanwhile, both sides of the the maximum input displacements are 40 μm. The maximum positive and negative displacements on the Z-axis are 566.03 μm and −570.86 μm, respectively.

Figure 12 shows the relation between the input displacement and output displacement, which is calculated by theoretical analysis and FEA, respectively.

denotes the output displacement of the left bridge-type mechanism,

denotes the output displacement of the moving platform along the X-axis, and

denotes the output displacement of the moving platform along the Z-axis. It can be seen from

Figure 12b that the amplification of the bridge-type mechanism is less than the case of

Figure 12a. It is because the bridge-type mechanism is subjected to bigger external force when both of the actuators along the X-axis are driven, which will reduce their displacements. The first six modes of the platform are simulated by using ANSYS. As shown in

Figure 13, the first three natural frequencies are 247.3 Hz, 270.2 Hz and 271.7 Hz, respectively, which can meet the demands of this platform.

The input stiffness and output stiffness are simulated by FEA and the comparisons between theoretical analysis and simulation results are shown in

Table 4. The error of the input stiffness between the FEA and analytical model is only 8.07%. The error of output stiffness on the X-axis, Y-axis and Z-axis are 5.67%, 3.73% and 12.74 %. These errors are small enough to show that the theoretical analysis is right. The error of the output stiffness on the Z-axis is the largest compared to that on the X-axis and the Y-axis. It is mainly because the compliance matrix method does not take the large deformation of the hinges into consideration and the displacement on the Z-axis is larger than that on the X-axis and Y-axis. In total, the simulations show that the proposed 3DOF XYZ bi-directional platform is effective.

Table 5 shows the comparisons between the developed platform and several typical XYZ-platforms at a similar size. It can be found that the size on the Z-axis of this platform is the smallest (except for Xie [

36]) at a similar size on X and Y axes. In addition, this platform can provide a large stroke on the Z-axis of 1 mm (including both the positive and negative directions). In addition, the platform in this paper can generate positive and negative bi-directional motion relative to the origin at each degree of freedom of XYZ.

5. Conclusions

A new 3DOF XYZ precision positioning platform based on Z-shaped flexure hinges is firstly presented in this paper. The platform can achieve bi-directional movement on the X, Y, and Z-axis relative to the origin using four piezoelectric ceramic actuators. Bridge-type mechanisms and Z-shaped flexure hinges are adopted to acquire a large stroke especially on the Z-axis of the platform. Subsequently, the static analysis of the platform is carried out by using energy method, compliance matrix, force balance principle and energy conservation. Finally, simulations by FEA are carried out to verify the analytical models and the developed stage. The errors of both the input stiffness and output stiffness are less than 12.74%. The simulation results show that the average stroke of the platform along the X, Y, and Z-axis are μm, μm, μm, respectively. Its first three natural frequencies are 247.3 Hz, 270.2 Hz, 271.7 Hz, respectively. In a word, the developed platform in this paper has the merits of compact structure, large stroke and bi-directional motion on all the X, Y, and Z-axes. However, the proposed platform also faces some challenges such as being relatively difficult to manufacture, having a high cost and being difficult to control for four actuators. In the future, we will optimize the design of the Z-shaped flexure hinge and process a platform prototype for experiments.

Table 6 shows a nomenclature table for some parameters.