Assessment of Pavement Structural Conditions and Remaining Life Combining Accelerated Pavement Testing and Ground-Penetrating Radar

Abstract

:1. Introduction

- (1)

- To investigate the relationship between pavement temperature and atmospheric temperature in the depth direction.

- (2)

- To analyze the influencing factors of mechanical responses of pavement structure layer and reveal its influencing law.

- (3)

- To explore the establishment of more reliable parameters in FE simulation for fatigue life prediction under more complex conditions.

- (4)

- To reveal the relationship between the pavement structure conditions and remaining life of different structural layers.

2. Materials and Method

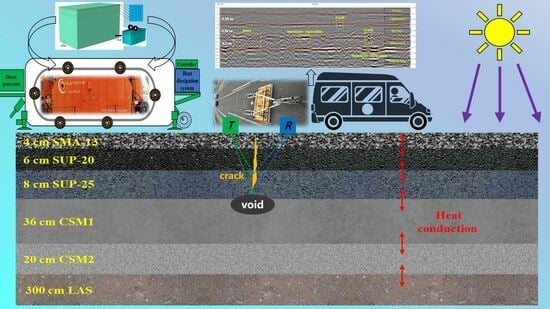

2.1. Field Investigation

2.1.1. Dynamic Modulus Tests

2.1.2. Field Temperature Monitoring

2.1.3. Accelerated Pavement Testing

2.1.4. GPR Investigation

2.2. Numerical Simulation

2.2.1. FE Modelling

2.2.2. Viscoelastic Parameters

2.2.3. Material Parameter Inversion

2.2.4. Fatigue Life Indexes

3. Results and Discussion

3.1. Field Temperature Monitoring

3.2. Dynamic Responses to Different Influencing Factors

3.2.1. Field Temperature

3.2.2. Loading Weight

3.2.3. Loading Speed

3.3. Dynamic Response Prediction

3.4. Finite Element Simulation

3.4.1. Results of Material Parameter Inversion

3.4.2. Prediction Results of Fatigue Failure and Critical Conditions

3.5. Relationship between Pavement Structural Conditions and Remaining Life

- Linear fitting was performed for the data with IPCI less than 10, IPCI greater than 80 and the intermediate segment, respectively. IPCI and RLR showed a roughly negative relationship: when the IPCI was less than 10, the slope k of the line was small (about 0.2). It was significant larger when the IPCI was greater than 10 (between 1.1 to 1.3); however, it became small again after the IPCI was greater than 80.

- With the increase in traffic grade, the IPCI of different structural layers decreased to different degrees, and the IPCI of the base layer decreased more obviously due to load accumulation. On the other hand, the fitting relationship between IPCI and RLR was slightly weakened, which may be because the thickness of pavement structural layers changes under repeated load, thus affecting the calculation result of IPCI.

- Under the same IPCI value, the RLR of the base layer was lower than that of the asphalt surface layer, and this difference was more evident with the increase in traffic grade. This may be due to the increase in the distress ratio, as the performance of the CSM base material decreases significantly, and the modulus attenuation is greater.

4. Conclusions

- (1)

- Temperatures were predicted using a dual sinusoidal model for pavement structures based on the measured atmospheric temperature and structural temperatures. The good linear correlation (coefficient > 0.95) indicates that this model is reliable.

- (2)

- The asphalt surface layer showed a three-way strain increase with increasing temperature and load weight, but a decrease with increasing loading speed. It was excellently correlated with the measured values to predict dynamic responses under multivariate factors.

- (3)

- The material parameter inversion of the asphalt surface layer was proposed by controlling the average error of six strains between the FE-simulated and APT-measured values. Based on the established FE model, key mechanical index values can be analyzed under different conditions, along with the fatigue life of pavement structural layers.

- (4)

- There is a good negative correlation between the IPCI and the RLR of the pavement structure. Therefore, the RLR of the pavement structure can be predicted via GPR detection and quantitative assessment of structure conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, D.; Liu, Z.; Gu, X.; Wu, W.; Chen, Y.; Wang, L. Automatic Detection of Pothole Distress in Asphalt Pavement Using Improved Convolutional Neural Networks. Remote Sens. 2022, 14, 3892. [Google Scholar] [CrossRef]

- Ren, D.Y.; Song, H.; Huang, C.; Xiao, C.; Ai, C.F. Comparative Evaluation of Asphalt Pavement Dynamic Response with Different Bases under Moving Vehicular Loading. J. Test. Eval. 2020, 48, 1823–1836. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.Y.; Ren, H.; Wang, X.; Dong, Q. Three-dimensional finite element analysis for structural parameters of asphalt pavement: A combined laboratory and field accelerated testing approach. Case Stud. Constr. Mat. 2022, 17, e01221. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Ren, H. Rutting prediction of asphalt pavement with semi-rigid base: Numerical modeling on laboratory to accelerated pavement testing. Constr. Build. Mater. 2023, 375, 130903. [Google Scholar] [CrossRef]

- Ingrassia, L.P.; Virgili, A.; Canestrari, F. Effect of geocomposite reinforcement on the performance of thin asphalt pavements: Accelerated pavement testing and laboratory analysis. Case Stud. Constr. Mat. 2020, 12, e00342. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Loulizi, A.; Elseifi, M.; Lahouar, S. The Virginia Smart Road: The impact of pavement instrumentation on understanding pavement performance. J. Assoc. Asph. Pavement 2004, 73, 427–465. [Google Scholar]

- Dessouky, S.H.; Alqadi, I.L.; Yoo, P.J. Full-Depth Flexible Pavement Response to Different Truck Tire Loadings. In Proceedings of the Transportation Research Board Meeting, Washington, DC, USA, 21–25 January 2007. [Google Scholar]

- Bhattacharjee, S.; Mallick, R.B. Effect of temperature on fatigue performance of hot mix asphalt tested under model mobile load simulator. Int. J. Pavement Eng. 2012, 13, 166–180. [Google Scholar] [CrossRef]

- Han, Z.; Sha, A.; Hu, L.; Jiao, L. Modeling to simulate inverted asphalt pavement testing: An emphasis on cracks in the semirigid subbase. Constr. Build. Mater. 2021, 306, 124790. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Zhang, Q.F.; Chen, L.; Du, Z. Mechanical response of hydronic asphalt pavement under temperature-vehicle coupled load: A finite element simulation and accelerated pavement testing study. Constr. Build. Mater. 2021, 272, 121884. [Google Scholar] [CrossRef]

- Greene, J.; Choubane, B.; Upshaw, P. Evaluation of a Heavy Polymer Modified Asphalt Binder Using Accelerated Pavement Testing. In Proceedings of the 4th International Conference on Accelerated Pavement Testing, Davis, CA, USA, 19–21 September 2012. [Google Scholar]

- Blab, R.; Kluger-Eigl, W.; Füssl, J.; Arraigada, M.; Hofko, B. Accelerated Pavement Testing on Slab and Block Pavements using the New Mobile Load Simulator MLS10. In Proceedings of the 4th International Conference on Accelerated Pavement Testing, Davis, CA, USA, 19–21 September 2012. [Google Scholar]

- Jansen, D.; Wacker, B.; Pinkofsky, L. Full-scale accelerated pavement testing with the MLS30 on innovative testing infrastructures. Int. J. Pavement Eng. 2018, 19, 456–465. [Google Scholar] [CrossRef]

- Zhang, H.; Ren, J.; Ji, L.; Wang, L. Mechanical response measurement and simulation of full scale asphalt pavement. J. Harbin Inst. Technol. 2016, 48, 41–48. [Google Scholar]

- Zaumanis, M.; Haritonovs, V. Long term monitoring of full scale pavement test section with eight different asphalt wearing courses. Mater. Struct. 2016, 49, 1817–1828. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X. Performance Evaluation of Full-scale Accelerated Pavement using NDT and Laboratory Tests: A case study in Jiangsu, China. Case Stud. Constr. Mat. 2023, 18, e02083. [Google Scholar] [CrossRef]

- Ling, J.M.; Wei, F.L.; Zhao, H.D.; Tian, Y.; Han, B.Y.; Chen, Z.A. Analysis of airfield composite pavement responses using full-scale accelerated pavement testing and finite element method. Constr. Build. Mater. 2019, 212, 596–606. [Google Scholar] [CrossRef]

- Yang, H.L.; Wang, S.J.; Miao, Y.H.; Wang, L.B.; Sun, F.Y. Effects of accelerated loading on the stress response and rutting of pavements. J. Zhejiang Univ. Sci. A 2021, 22, 514–527. [Google Scholar] [CrossRef]

- Ai, C.F.; Rahman, A.; Xiao, C.; Yang, E.H.; Qiu, Y.J. Analysis of measured strain response of asphalt pavements and relevant prediction models. Int. J. Pavement Eng. 2017, 18, 1089–1097. [Google Scholar] [CrossRef]

- Chun, S.; Kim, K.; Greene, J.; Choubane, B. Evaluation of interlayer bonding condition on structural response characteristics of asphalt pavement using finite element analysis and full-scale field tests. Constr. Build. Mater. 2015, 96, 307–318. [Google Scholar] [CrossRef]

- Ma, X.; Dong, Z.; Chen, F.; Xiang, H.; Cao, C.; Sun, J. Airport asphalt pavement health monitoring system for mechanical model updating and distress evaluation under realistic random aircraft loads. Constr. Build. Mater. 2019, 226, 227–237. [Google Scholar] [CrossRef]

- Li, N.; Zhan, H.; Yu, X.; Tang, W.; Yu, H.; Dong, F. Research on the high temperature performance of asphalt pavement based on field cores with different rutting development levels. Mater. Struct. 2021, 54, 70. [Google Scholar] [CrossRef]

- Gouveia, B.C.S.; Preti, F.; Cattani, L.; Bozzoli, F.; Roberto, A.; Romeo, E.; Tebaldi, G. Numerical and Experimental Analysis of the Raise-Temperature Effect of Quicklime in Cold Recycled Mixtures. J. Mater. Civil. Eng. 2022, 34, 04022283. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Dong, X.; Cui, B.; Hu, D. Mechanism and Performance of Graphene Modified Asphalt: An Experimental Approach Combined with Molecular Dynamic Simulations. Case Stud. Constr. Mat. 2022, 18, e01749. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, L.; Gu, X.; Wang, X.; Dong, Q.; Zhou, Z.; Tang, J. Characteristics, mechanisms, and environmental LCA of WMA containing sasobit: An analysis perspective combing viscosity-temperature regression and interface bonding strength. J. Clean. Prod. 2023, 391, 136255. [Google Scholar] [CrossRef]

- Yang, J.; Fang, Y. Rationality and Applicability of High-Temperature Performance Indexes for Polymer-Modified Asphalts. J. Mater. Civ. Eng. 2021, 33, 04021238. [Google Scholar] [CrossRef]

- Barber, E.S. Calculation of Maximum Pavement Temperatures from Weather Reports. Highw. Res. Board Bull. 1957, 168. Available online: http://onlinepubs.trb.org/Onlinepubs/hrbbulletin/168/168-001.pdf (accessed on 29 June 2023).

- Anupam, K.; Srirangam, S.K.; Scarpas, A.; Kasbergen, C. Influence of Temperature on Tire-Pavement Friction: Analyses. Transp. Res. Rec. 2013, 2369, 114–124. [Google Scholar] [CrossRef]

- Si, W.; Ma, B.; Ren, J.P.; Hu, Y.P.; Zhou, X.Y.; Tian, Y.X.; Li, Y. Temperature responses of asphalt pavement structure constructed with phase change material by applying finite element method. Constr. Build. Mater. 2020, 244, 118088. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Shen, A.Q.; Ma, B.F. Temperature response of asphalt pavement to low temperatures and large temperature differences. Int. J. Pavement Eng. 2020, 21, 49–62. [Google Scholar] [CrossRef]

- Luo, X.; Gu, F.; Lytton, R.L. Kinetics-based aging prediction of asphalt mixtures using field deflection data. Int. J. Pavement Eng. 2019, 20, 287–297. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Yang, H.; Wang, L.; Chen, Y.; Wang, D. Novel YOLOv3 Model With Structure and Hyperparameter Optimization for Detection of Pavement Concealed Cracks in GPR Images. IEEE Trans. Intell. Transp. 2022, 23, 22258–22268. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Chen, J.; Wang, D.; Chen, Y.; Wang, L. Automatic recognition of pavement cracks from combined GPR B-scan and C-scan images using multiscale feature fusion deep neural networks. Autom. Constr. 2023, 146, 104698. [Google Scholar] [CrossRef]

- Liu, Z.; Yeoh, J.K.W.; Gu, X.; Dong, Q.; Chen, Y.; Wu, W.; Wang, L.; Wang, D. Automatic pixel-level detection of vertical cracks in asphalt pavement based on GPR investigation and improved mask R-CNN. Autom. Constr. 2023, 146, 104689. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.Y.; Wu, W.X.; Zou, X.Y.; Dong, Q.; Wang, L.T. GPR-based detection of internal cracks in asphalt pavement: A combination method of DeepAugment data and object detection. Measurement 2022, 197, 111281. [Google Scholar] [CrossRef]

- Long, J.; Luo, Q.; Liu, Z.; Zhu, Z. Road distress detection and maintenance evaluation based on ground penetrating radar. In Advances in Civil Function Structure and Industrial Architecture; CRC Press: Boca Raton, FL, USA, 2022; pp. 474–481. [Google Scholar]

- Wang, L.T.; Gu, X.Y.; Liu, Z.; Wu, W.X.; Wang, D.Y. Automatic detection of asphalt pavement thickness: A method combining GPR images and improved Canny algorithm. Measurement 2022, 196, 111248. [Google Scholar] [CrossRef]

- Dai, Q.; Lee, Y.H.; Sun, H.H.; Qian, J.; Ow, G.; Yusof, M.L.M.; Yucel, A.C. A Deep Learning-Based GPR Forward Solver for Predicting B-Scans of Subsurface Objects. IEEE Geosci. Remote Sens. 2022, 19, 4025805. [Google Scholar] [CrossRef]

- Rasol, M.; Pais, J.C.; Pérez-Gracia, V.; Solla, M.; Fernandes, F.M.; Fontul, S.; Ayala-Cabrera, D.; Schmidt, F.; Assadollahi, H. GPR monitoring for road transport infrastructure: A systematic review and machine learning insights. Constr. Build. Mater. 2022, 324, 126686. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011; Volume JTG E20-2011.

- Liu, Z.; Zhou, Z.; Gu, X.; Sun, L.; Wang, C. Laboratory evaluation of the performance of reclaimed asphalt mixed with composite crumb rubber-modified asphalt: Reconciling relatively high content of RAP and virgin asphalt. Int. J. Pavement Eng. 2023, 24, 2217320. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.Y.; Ren, H.; Zhou, Z.; Wang, X.; Tang, S. Analysis of the dynamic responses of asphalt pavement based on full-scale accelerated testing and finite element simulation. Constr. Build. Mater. 2022, 325, 126429. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Ren, H.; Li, S.; Dong, Q. Permanent Deformation Monitoring and Remaining Life Prediction of Asphalt Pavement Combining Full-Scale Accelerated Pavement Testing and FEM. Struct. Control Health Monit. 2023, 2023, 6932621. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.Y.; Wu, C.Y.; Ren, H.; Zhou, Z.; Tang, S. Studies on the validity of strain sensors for pavement monitoring: A case study for a fiber Bragg grating sensor and resistive sensor. Constr. Build. Mater. 2022, 321, 126085. [Google Scholar] [CrossRef]

- Ren, H.; Gu, X.Y.; Liu, Z. Analysis of Mechanical Responses for Semi-Rigid Base Asphalt Pavement Based on MLS66 Accelerated Loading Test. In Proceedings of the 20th and 21st Joint COTA International Conference of Transportation Professionals—Advanced Transportation, Enhanced Connection, Xi’an, China, 16–20 December 2021; pp. 732–742. [Google Scholar]

- Loría-Salazar, L.G.; Aguiar-Moya, J.P.; Vargas-Nordcbeck, A.; Leiva-Villacorta, F. The Roles of Accelerated Pavement Testing in Pavement Sustainability; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Liu, Z.; Gu, X.; Ren, H. Dynamic response analysis of asphalt pavement with semi-rigid base based on MLS66 accelerated loading test. J. Southeast Univ. 2023, 53, 114–122. [Google Scholar] [CrossRef]

- Liang, X.; Yu, X.; Chen, C.; Jin, Y.; Huang, J. Automatic Classification of Pavement Distress Using 3D Ground-Penetrating Radar and Deep Convolutional Neural Network. IEEE Trans. Intell. Transp. 2022, 23, 22269–22277. [Google Scholar] [CrossRef]

- Hong, X.; Tan, W.; Xiong, C.; Qiu, Z.; Yu, J.; Wang, D.; Wei, X.; Li, W.; Wang, Z. A Fast and Non-Destructive Prediction Model for Remaining Life of Rigid Pavement with or without Asphalt Overlay. Buildings 2022, 12, 868. [Google Scholar] [CrossRef]

- Lin, X.; Li, Q. Study on esidual Life Evaluation Method of Semi-rigid Base Structure of Expressway Asphalt Pavement. J. Highw. Transp. Res. Dev. 2021, 38, 1–8. [Google Scholar] [CrossRef]

- Ge, N.; Li, H.; Yang, B.; Fu, K.; Yu, B.; Zhu, Y. Mechanical responses analysis and modulus inverse calculation of permeable asphalt pavement under dynamic load. Int. J. Transp. Sci. Technol. 2021, 11, 243–254. [Google Scholar] [CrossRef]

- JTG F50-2011; Technical Specification for Construction of Highway Bridge and Culverts. China Communications Press: Beijing, China, 2011; Volume JTG F50-2011.

- Guan, Z.; Zhuang, C.; Lin, M. Accelerated loading dynamic response of full-scale asphalt concrete pavement. J. Traffic Transp. Eng. 2012, 12, 24–31. [Google Scholar]

- Dong, Z.; Xu, Q.; Lu, P. Dynamic Response of Semi-rigid Base Asphalt Pavement Based on Accelerated Pavement Test. China J. Highw. Transp. 2011, 24, 1. [Google Scholar]

- Wang, H.; Zhao, J.; Hu, X.; Zhang, X. Flexible Pavement Response Analysis under Dynamic Loading at Different Vehicle Speeds and Pavement Surface Roughness Conditions. J. Transp. Eng. B Pavements 2020, 146, 04020040. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Xin, C.; Zuo, H.; An, P.; Zuo, S.; Liu, P. Dynamic Strain Response of Hot-Recycled Asphalt Pavement under Dual-Axle Accelerated Loading Conditions. Coatings 2022, 12, 843. [Google Scholar] [CrossRef]

- Hu, X.-D.; Walubita, L.F. Modeling mechanistic responses in asphalt pavements under three-dimensional tire-pavement contact pressure. J. Cent. South Univ. Technol. 2011, 18, 250–258. [Google Scholar] [CrossRef]

| Bandwidth (MHz) | Detection Depth (m) | Sampling Point in Horizontal Direction | Time Window (ns) | Ranging Method | Signal-To-Noise Ratio | Sampling Interval |

|---|---|---|---|---|---|---|

| 400 MHz (channel 1) 800 MHz (channel 2) | 4.5 m for channel 1 1.5 m for channel 2 | 400 | 26 | DMI | >100 dB | 5 cm |

| RLR of pavement (%) | Performance classification | Traffic grades | ||||

| Light (Ne < 300) | Moderate (300 ≤ Ne < 1200) | Slightly heavy (1200 ≤ Ne < 2500) | Heavy (Ne ≥ 2500) | |||

| Excellent | Capital repair | 23.5 | 31.0 | 25.3 | 29.7 | |

| Partial repair | 59.2 | 55.7 | 65.6 | 65.5 | ||

| Average | Capital repair | 33.7 | 42.5 | 38.3 | 43.4 | |

| Partial repair | 69.4 | 67.2 | 78.6 | 79.3 | ||

| Poor | Capital repair | 43.9 | 54.0 | 51.3 | 91.6 | |

| Partial repair | 79.6 | 78.7 | 91.6 | 93.1 | ||

| Structure Layer | Direction | Loading Speed (km/h) | Temperature (°C) | |||

|---|---|---|---|---|---|---|

| 20 | 30 | 40 | 50 | |||

| Bottom of the middle layer at asphalt surface | Vertical | 10 | 177.8 | 376.3 | 796.6 | 1686.2 |

| 15 | 157.7 | 333.8 | 706.5 | 1495.6 | ||

| 22 | 133.3 | 282.1 | 597.3 | 1264.3 | ||

| Transverse | 10 | 17.3 | 49.5 | 141.6 | 404.5 | |

| 15 | 15.3 | 43.7 | 124.9 | 356.9 | ||

| 22 | 12.8 | 36.7 | 104.9 | 299.7 | ||

| Longitudinal | 10 | 42.1 | 101.5 | 244.7 | 589.9 | |

| 15 | 34.7 | 83.5 | 201.4 | 485.4 | ||

| 22 | 26.4 | 63.6 | 153.2 | 369.5 | ||

| Bottom of the lower layer at asphalt surface | Vertical | 10 | 116.1 | 248.3 | 530.9 | 1135.3 |

| 15 | 100.9 | 215.9 | 461.6 | 986.9 | ||

| 22 | 83.0 | 177.5 | 379.5 | 811.3 | ||

| Transverse | 10 | 8.0 | 20.6 | 52.6 | 134.7 | |

| 15 | 6.8 | 17.5 | 44.8 | 114.7 | ||

| 22 | 5.5 | 13.9 | 35.8 | 91.7 | ||

| Longitudinal | 10 | 17.8 | 40.4 | 91.8 | 208.3 | |

| 15 | 16.1 | 36.6 | 83 | 188.5 | ||

| 22 | 14 | 31.8 | 72.2 | 163.9 | ||

| T (°C) | v (km/h) | Inversion Results and Error | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 10 | E | 7220 | 7240 | 7260 | 7280 1 | 7300 | 7320 | 7340 | 7360 |

| S | 6.3 | 5.5 | 5.1 | 4.6 | 5.2 | 5.9 | 6.7 | 7.9 | ||

| 15 | E | 7640 | 7660 | 7680 | 7700 | 7720 | 7740 | 7760 | 7780 | |

| S | 7.9 | 6.7 | 5.7 | 5.1 | 4.8 | 5.2 | 5.7 | 6.6 | ||

| 22 | E | 8080 | 8100 | 8120 | 8140 | 8160 | 8180 | 8200 | 8220 | |

| S | 7.5 | 6.1 | 5.3 | 4.9 | 5.3 | 5.8 | 6.7 | 8.1 | ||

| 30 | 10 | E | 2630 | 2640 | 2650 | 2660 | 2670 | 2680 | 2690 | 2700 |

| S | 5.7 | 5.2 | 4.8 | 5.1 | 5.8 | 6.7 | 8.1 | 9.5 | ||

| 15 | E | 2820 | 2830 | 2840 | 2850 | 2860 | 2870 | 2880 | 2890 | |

| S | 8.9 | 7.6 | 6.5 | 5.7 | 5.1 | 4.8 | 5.2 | 5.9 | ||

| 22 | E | 3310 | 3320 | 3330 | 3340 | 3350 | 3360 | 3370 | 3380 | |

| S | 5.8 | 5.0 | 4.6 | 4.9 | 5.5 | 6.4 | 7.6 | 8.9 | ||

| 40 | 10 | E | 940 | 945 | 950 | 955 | 960 | 965 | 970 | 975 |

| S | 6.3 | 5.5 | 5.0 | 4.7 | 4.9 | 5.3 | 5.9 | 6.7 | ||

| 15 | E | 1735 | 1740 | 1745 | 1750 | 1755 | 1760 | 1765 | 1770 | |

| S | 5.7 | 5.2 | 4.8 | 5.1 | 5.5 | 6.1 | 6.8 | 7.7 | ||

| 22 | E | 2200 | 2205 | 2210 | 2215 | 2220 | 2225 | 2230 | 2235 | |

| S | 7.2 | 6.1 | 5.2 | 4.9 | 5.1 | 5.5 | 6.1 | 6.9 | ||

| 50 | 10 | E | 216 | 217 | 218 | 219 | 220 | 221 | 222 | 223 |

| S | 5.2 | 5.0 | 4.8 | 4.9 | 5.1 | 5.4 | 5.7 | 6.1 | ||

| 15 | E | 247 | 248 | 249 | 250 | 251 | 252 | 253 | 254 | |

| S | 5.1 | 5.1 | 5.0 | 4.9 | 4.8 | 4.9 | 5.0 | 5.1 | ||

| 22 | E | 264 | 265 | 266 | 267 | 268 | 269 | 270 | 271 | |

| S | 5.2 | 4.9 | 4.7 | 4.8 | 4.9 | 5.1 | 5.3 | 5.6 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Yang, Q.; Gu, X. Assessment of Pavement Structural Conditions and Remaining Life Combining Accelerated Pavement Testing and Ground-Penetrating Radar. Remote Sens. 2023, 15, 4620. https://doi.org/10.3390/rs15184620

Liu Z, Yang Q, Gu X. Assessment of Pavement Structural Conditions and Remaining Life Combining Accelerated Pavement Testing and Ground-Penetrating Radar. Remote Sensing. 2023; 15(18):4620. https://doi.org/10.3390/rs15184620

Chicago/Turabian StyleLiu, Zhen, Qifeng Yang, and Xingyu Gu. 2023. "Assessment of Pavement Structural Conditions and Remaining Life Combining Accelerated Pavement Testing and Ground-Penetrating Radar" Remote Sensing 15, no. 18: 4620. https://doi.org/10.3390/rs15184620