Industry 4.0 and Beyond: A Review of the Literature on the Challenges and Barriers Facing the Agri-Food Supply Chain

Abstract

:1. Introduction

1.1. Industry 4.0 Key Technologies

1.1.1. Cyber-Physical Systems (CP), and Their Application in the Agri-Food Industry

1.1.2. Internet of Things (IoT), and Its Application in the Agri-Food Industry

1.1.3. Internet of Services (IoS), and Its Application in the Agri-Food Industry

1.1.4. Smart Factory and Its Application in the Agri-Food Industry

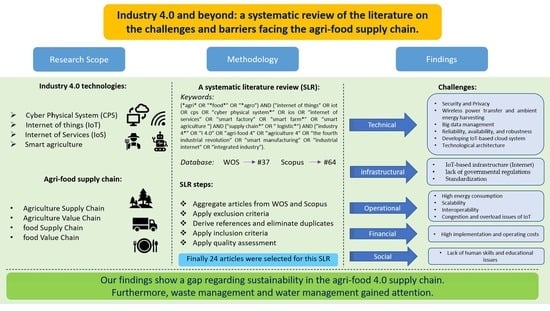

2. Materials and Methods

2.1. Research Questions

- RQ1: What classifications of agri-food products have been discussed with the emergence of industry 4.0?RQ1 aims to identify the agri-food products that have used the industry 4.0 context. By answering this question, scholars have a better understanding of potential research in the agri-food industry, and it demonstrates which products have adapted industry 4.0 technologies compared to others.

- RQ2: Among industry 4.0 technologies, which one has gained more attention in the agri-food supply chain considering product classification? (Which technology in which agri-food products).We defined four key technologies above: IoT, CPS, IOS, and smart factory for agri-food supply chain. It is essential to realize if there are only mentioned technologies in the agri-food supply chain or other technologies contribute to the supply chain.

- RQ3: What percentage of the literature addressed sustainability in the agri-food 4.0 supply chain? (Based on three aspects of sustainability).The all-new types of supply chains try to address sustainability in a specific way, and the new technologies facilitate this process with their unique features. This research question aims to find out how many of the selected articles addressed sustainability.

- RQ4: How does Industry 4.0 contribute to a sustainable agri-food supply chain?This research question aims to explore how industry 4.0 addresses sustainability in the supply chain. It focuses on the sub-classification of sustainability in the agri-food supply chain.

- RQ5: What challenges are ahead of applying industry 4.0 (I 4.0 adoption) in the agri-food supply chain?This research question aims to find the challenges of applying industry 4.0 in the agri-food supply chain. Practitioners need to know the challenges in advance to contemplate solutions.

- RQ 6: What are the main discussed themes in the agri-food 4.0 supply chain?Based on the answer to the previous question, this research question focuses on classifying challenges. We display a better perspective of challenges in an organized category with the answer.

2.2. Search Strategy

2.2.1. Search Keywords

- Derive major keywords from the research questions;

- Identify alternative spellings and synonyms for principal keywords;

- Check the keywords in the relevant articles or publications;

- Use the Boolean OR to incorporate alternative spellings and synonyms;

- Use the Boolean ASTERISK to replace multiple characters to find the terms that have different appearances with the same meaning;

- Use the Boolean AND to connect the significant keywords;

- Find relevant references for defining the main scope of the research.

2.2.2. Literature Databases

2.3. Study Selection

- Only the studies that addressed the I 4.0 technologies based on the scope of this research will be included;

- Only the studies that addressed the agri-food supply chain will remain in this SLR;

- For the research that has both journal version and conference version, only the journal version will be included;

- For duplicated publications of the same study, only the newest and the complete one will be included.

- Duplicates are eliminated by Mendeley and a final revision by the authors;

- In the “Document type”, we applied a filter by excluding article reviews, conference reviews, editorials, and short surveys in this research;

- Check the keywords in the relevant articles or publications; The authors omitted other languages such as Germany, Chinese, and Russian.

2.4. Study Quality Assessment

2.5. Data Extraction

3. Results and Discussion

3.1. Overview of Selected Articles

3.2. Types of Agri-Food Products (RQ1)

3.3. Types of Technologies (RQ2)

3.4. Sustainability Area (RQ3)

3.5. The Contribution of I 4.0 in a Sustainable Agri-Food Supply Chain (RQ4)

3.6. Challenges and Themes in the Agri-Food 4.0 Supply Chain (RQ5 and RQ6)

3.6.1. Technical Theme

- Security and Privacy

- Wireless power transfer and ambient energy harvesting

- Big data management:

- Reliability, availability, and robustness:

- Developing IoT-based cloud system:

- Technological architecture:

3.6.2. Infrastructural Theme

- IoT-based infrastructure:

- Lack of governmental regulations:

- Standardization:

3.6.3. Operational Theme

- High energy consumption:

- Scalability:

- Interoperability:

- Congestion and overload issues of IoT:

3.6.4. Financial Theme

- High implementation and operating costs:

3.6.5. Social Theme

- Lack of human skills and educational issues:

4. Discussion and Conclusions

- (RQ1) There are five categories in terms of agri-food products in the agri-food 4.0 supply chain. Three specific products and two general ones. The particular products contain fresh fruits and vegetables, cold chain, and packaging. On the other hand, in some studies, almost 40% of this SLR generally addresses food and agricultural products due to their concentration on frameworks or reviews. Since there have not been similar articles that classify products, our findings contribute to the agri-food supply chain by demonstrating the importance of the I 4.0 application for perishable products such as fresh fruits, vegetables, and cold chains.

- (RQ2) This research question aimed to find the most applicable technology in this field: IoT with its wide application. IoT has gotten considerable attention compared to other technologies. In this section, we found some other technologies in addition to the four leading mentioned ones; IoT, CPS, IoS, and smart agriculture. Other technologies are big data, robotics and automation, cloud computing, AI, 3D printing, blockchain, augmented reality (AR), cybersecurity, simulation, and VR. These technologies also play a role in the agri-food 4.0 supply chain. The results of this question are shown in Figure 5, another contribution of this study. We displayed which technology has been used on which type of products. For example, IoT and its application in fresh fruits and vegetables, agriculture, and food products have the highest number of articles, respectively.

- (RQ3) The answer to this research question identified a vast gap in sustainability in the agri-food 4.0 supply chain. When new technologies come up, sustainability should be considered. Nevertheless, some new technologies, such as a single AI, not only do not reduce carbon emissions but also can emit carbon as much as five cars through its lifetime [62]. The selected articles that addressed sustainability were 37.5% of selected studies. In this era, the importance of sustainability is inevitable in various contexts from climate change to the social terms. This gap is an opportunity for future research.

- (RQ4) The answer to this research question determined that waste management has gotten more attention due to the perishability of products in the agri-food supply chain. Then water resource management is another area that industry 4.0 contributes to the sustainable agri-food supply chain. Climate change has caused new challenges in the agri-food supply chain, such as water shortages and droughts. Scholars in this area should address how new technologies in I 4.0 would affect sustainability from different aspects. There is a necessity for the hard work of scholars and researchers to analyze I 4.0 impacts on sustainable development goals.

- (RQ5) In answer to this question, we found 15 challenges, including security and privacy, wireless power transfer and ambient energy harvesting, big data management, reliability, availability, and robustness, developing IoT-based cloud system, technological architecture, IoT-based infrastructure (Internet), lack of governmental regulations, standardization, high energy consumption, scalability, interoperability, congestion and overload issues of IoT, high implementing and operating costs, and lack of human skills and educational issues. The challenges are shown in Table A1 in which a column represents the number of articles discussing each challenge. With these numbers, we found the most notable barriers ahead of I 4.0 in the agri-food supply chains. Here we name the four most discussed challenges: technological architecture, security and privacy, big data management, and IoT-based infrastructure, respectively. Designing a professional framework or model in which technologies perform properly is the biggest challenge in the selected articles. Before doing any action, it is essential to have a map or an architecture that demonstrates how I 4.0 technologies should function. The second most discussed issue is security and privacy, which is a barrier for enterprises, farmers, and all layers of the agri-food supply chain to trust the new technologies. Security and privacy have always been a striking challenge for new technologies. Lastly, big data management and IoT-based infrastructure have the third important position in the list of challenges. It is vital to address this issue because data is the main component of this supply chain that facilitates procedures and speeds up functions. Therefore, managing an immense of data is recognized as an issue. Furthermore, all efforts towards I 4.0 are useless without proper infrastructure like the internet.

- (RQ6) Finally, after reading the challenges, we classified them into five main classifications: technical, operational, social, infrastructural, and financial.

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| ID | QA1 | QA2 | QA3 | QA4 | QA5 | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | C16 | C17 | SCORE | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 1 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 79.36 | [56] |

| 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 97 | [51] |

| 3 | 1 | 0 | 0 | 0 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 54.36 | [27] |

| 4 | 1 | 1 | 1 | 0 | 0.67 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 79.36 | [47] |

| 5 | 1 | 0 | 0 | 1 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 66.36 | [52] |

| 6 | 1 | 0 | 1 | 0 | 0.67 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 66.36 | [23] |

| 7 | 1 | 1 | 1 | 0 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 74.36 | [46] |

| 8 | 1 | 1 | 1 | 1 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 86.36 | [63] |

| 9 | 1 | 1 | 0 | 1 | 0.33 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 63.64 | [48] |

| 10 | 1 | 1 | 1 | 0 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 75.36 | [49] |

| 11 | 1 | 1 | 1 | 1 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 84 | [39] |

| 12 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 87 | [50] |

| 13 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 81.36 | [41] |

| 14 | 1 | 1 | 1 | 1 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 84 | [42] |

| 15 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 69.36 | [40] |

| 16 | 1 | 1 | 1 | 0 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 71.36 | [43] |

| 17 | 1 | 1 | 1 | 0 | 0.67 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 56.36 | [53] |

| 18 | 1 | 0 | 0 | 1 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 53.36 | [54] |

| 19 | 1 | 1 | 1 | 0 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 72 | [20] |

| 20 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 61.36 | [44] |

| 21 | 1 | 1 | 1 | 1 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 84 | [45] |

| 22 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 92 | [58] |

| 23 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 68.36 | [58] |

| 24 | 1 | 1 | 1 | 1 | 0.67 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 78.36 | [55] |

References

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Brettel, M.; Friederichsen, N.; Keller, M.; Rosenberg, M. How Virtualization, Decentralization and Network Building Change the Manufacturing Landscape: An Industry 4.0 Perspective. World Acad. Sci. Eng. Technol. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2014, 8, 37–44. [Google Scholar]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Nosalska, K.; Piątek, Z.M.; Mazurek, G.; Rządca, R. Industry 4.0: Coherent definition framework with technological and organizational interdependencies. J. Manuf. Technol. Manag. 2020, 31, 837–862. [Google Scholar] [CrossRef]

- Akanmu, A.; Anumba, C.J. Cyber-physical systems integration of building information models and the physical construction. Eng. Constr. Archit. Manag. 2015, 22, 516–535. [Google Scholar] [CrossRef]

- Baheti, R.; Gill, H. Cyber-Physical Systems. Impact Control Technol. 2011, 12, 161–166. [Google Scholar]

- An, W.; Wu, D.; Ci, S.; Luo, H.; Adamchuk, V.; Xu, Z. Agriculture Cyber-Physical Systems. In Cyber-Physical Systems: Foundations, Principles and Applications; Academic Press: Cambridge, MA, USA, 2017; pp. 399–417. [Google Scholar] [CrossRef]

- Chowhan, R.S.; Dayya, P. Sustainable Smart Farming for Masses Using Modern Ways of Internet of Things (IoT) Into Agriculture. In Research Anthology on Strategies for Achieving Agricultural Sustainability; IGI Global: Hershey, PA, USA, 2019; pp. 189–219. [Google Scholar]

- Kumar, S.A.; Ilango, P. The Impact of Wireless Sensor Network in the Field of Precision Agriculture: A Review. Wirel. Pers. Commun. 2018, 98, 685–698. [Google Scholar] [CrossRef]

- Rad, C.-R.; Hancu, O.; Takacs, I.-A.; Olteanu, G. Smart Monitoring of Potato Crop: A Cyber-Physical System Architecture Model in the Field of Precision Agriculture. Agric. Agric. Sci. Procedia 2015, 6, 73–79. [Google Scholar] [CrossRef] [Green Version]

- Vuran, M.C.; Salam, A.; Wong, R.; Irmak, S. Internet of underground things in precision agriculture: Architecture and technology aspects. Ad Hoc Netw. 2018, 81, 160–173. [Google Scholar] [CrossRef] [Green Version]

- Hardie, M.; Hoyle, D. Underground Wireless Data Transmission Using 433-MHz LoRa for Agriculture. Sensors 2019, 19, 4232. [Google Scholar] [CrossRef] [Green Version]

- Pandey, G.; Weber, R.J.; Kumar, R. Agricultural Cyber-Physical System: In-Situ Soil Moisture and Salinity Estimation by Dielectric Mixing. IEEE Access 2018, 6, 43179–43191. [Google Scholar] [CrossRef]

- Chen, R.Y. Intelligent Predictive Food Traceability Cyber Physical System in Agriculture Food Supply Chain. J. Phys. Conf. Ser. 2018, 1026, 012017. [Google Scholar] [CrossRef] [Green Version]

- Verdouw, C.N.; Wolfert, J.; Beulens, A.J.M.; Rialland, A. Virtualization of food supply chains with the internet of things. J. Food Eng. 2016, 176, 128–136. [Google Scholar] [CrossRef] [Green Version]

- Verboven, P.; Defraeye, T.; Datta, A.K.; Nicolai, B. Digital twins of food process operations: The next step for food process models? Curr. Opin. Food Sci. 2020, 35, 79–87. [Google Scholar] [CrossRef]

- Sundmaeker, H.; Verdouw, C.; Wolfert, S.; Freire, L.P. Internet of food and farm 2020. In Digitising the Industry Internet of Things Connecting the Physical, Digital and Virtual Worlds; River Publishers: Aalborg, Denmark, 2016. [Google Scholar]

- Accorsi, R.; Tufano, A.; Gallo, A.; Galizia, F.G.; Cocchi, G.; Ronzoni, M.; Abbate, A.; Manzini, R. An application of collaborative robots in a food production facility. Procedia Manuf. 2019, 38, 341–348. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0. Final Report of the Industrie 4.0 Working Group. 2013. Available online: https://www.bibsonomy.org/bibtex/25c352acf1857c1c1839c1a11fe9b7e6c/flint63 (accessed on 8 April 2013).

- Khan, S.; Altayar, M. Industrial internet of things: Investigation of the applications, issues, and challenges. Int. J. Adv. Appl. Sci. 2021, 8, 104–113. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Da Xu, L.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef] [Green Version]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Joshi, S. Modeling the internet of things adoption barriers in food retail supply chains. J. Retail. Consum. Serv. 2019, 48, 154–168. [Google Scholar] [CrossRef]

- Barros, A.; Oberle, D. (Eds.) Handbook of Service Description; Springer: New York, NY, USA, 2012. [Google Scholar]

- Wang, P.; Valerdi, R.; Zhou, S.; Li, L. Introduction: Advances in IoT research and applications. Inf. Syst. Front. 2015, 17, 239–241. [Google Scholar] [CrossRef] [Green Version]

- Codeluppi, G.; Cilfone, A.; Davoli, L.; Ferrari, G. LoRaFarM: A LoRaWAN-Based Smart Farming Modular IoT Architecture. Sensors 2020, 20, 2028. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adhitya, Y.; Prakosa, S.W.; Köppen, M.; Leu, J.-S. Feature extraction for cocoa bean digital image classification prediction for smart farming application. Agronomy 2020, 10, 1642. [Google Scholar] [CrossRef]

- Marsden, T.; Banks, J.; Bristow, G. Food Supply Chain Approaches: Exploring their Role in Rural Development. Sociol. Rural. 2000, 40, 424–438. [Google Scholar] [CrossRef]

- Salin, V. Information technology in agri-food supply chains. Int. Food Agribus. Manag. Rev. 1998, 1, 329–334. [Google Scholar] [CrossRef]

- Apaiah, R.K.; Hendrix, E.M.T. Design of a supply chain network for pea-based novel protein foods. J. Food Eng. 2005, 70, 383–391. [Google Scholar] [CrossRef] [Green Version]

- Van der Vorst, J.G.A.J.; Da Silva, C.A.; Trienekens, J.H. Agro-Industrial Supply Chain Management: Concepts and Applications; Agricultural management, marketing and finance occasional paper; FAO: Rome, Italy, 2007; p. 71. Available online: https://www.fao.org/publications/card/en/c/e35e5c44-8bc7-5abc-90a3-77cd1d6cd8bf/ (accessed on 1 January 2023).

- Luo, J.; Ji, C.; Qiu, C.; Jia, F. Agri-Food Supply Chain Management: Bibliometric and Content Analyses. Sustainability 2018, 10, 1573. [Google Scholar] [CrossRef] [Green Version]

- D’Adamo, I.; Gastaldi, M.; Morone, P.; Rosa, P.; Sassanelli, C.; Settembre-Blundo, D.; Shen, Y. Bioeconomy of Sustainability: Drivers, Opportunities and Policy Implications. Sustainability 2022, 14, 200. [Google Scholar] [CrossRef]

- Kitchenham, B.; Charters, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering; Version 2.3; EBSE Technical Report; Keele University: Keele, UK; University of Durham: Durham, UK, 2007. [Google Scholar]

- Wen, J.; Li, S.; Lin, Z.; Hu, Y.; Huang, C. Systematic literature review of machine learning based software development effort estimation models. Inf. Softw. Technol. 2012, 54, 41–59. [Google Scholar] [CrossRef]

- Dybå, T.; Dingsøyr, T. Empirical studies of agile software development: A systematic review. Inf. Softw. Technol. 2008, 50, 833–859. [Google Scholar] [CrossRef]

- Serrano, R.; Pinilla, V. Changes in the structure of world trade in the agri-food industry: The impact of the home market effect and regional liberalization from a long-term perspective, 1963–2010. Agribusiness 2014, 30, 165–183. [Google Scholar] [CrossRef]

- Taddei, E.; Sassanelli, C.; Rosa, P.; Terzi, S. Circular supply chains in the era of industry 4.0: A systematic literature review. Comput. Ind. Eng. 2022, 170, 108268. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, X.; Shu, L.; Hancke, G.P.; Abu-Mahfouz, A.M. From Industry 4.0 to Agriculture 4.0: Current Status, Enabling Technologies, and Research Challenges. IEEE Trans. Ind. Inform. 2021, 17, 4322–4334. [Google Scholar] [CrossRef]

- Yadav, S.; Garg, D.; Luthra, S. Analysing challenges for internet of things adoption in agriculture supply chain management. Int. J. Ind. Syst. Eng. 2020, 36, 73–97. [Google Scholar] [CrossRef]

- Fernandez, C.M.; Alves, J.; Gaspar, P.D.; Lima, T.M. Fostering awareness on environmentally sustainable technological solutions for the post-harvest food supply chain. Processes 2021, 9, 1611. [Google Scholar] [CrossRef]

- Grecuccio, J.; Giusto, E.; Fiori, F.; Rebaudengo, M. Combining Blockchain and IoT: Food-Chain Traceability and Beyond. Energies 2020, 13, 3820. [Google Scholar] [CrossRef]

- Mantravadi, S.; Moller, C.; Christensen, F.M.M. Perspectives on Real-Time Information Sharing through Smart Factories: Visibility via Enterprise Integration. In Proceedings of the 3rd International Conference on Smart Systems and Technologies (SST 2018), Osijek, Croatia, 10–12 October 2018; pp. 133–137. [Google Scholar] [CrossRef]

- Capello, F.; Toja, M.; Trapani, N. A Real-Time Monitoring Service Based on Industrial Internet of Things to Manage Agrifood Logistics. 2016. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84985961212&partnerID=40&md5=69c0be5721ad524f102f986f1dab7b85 (accessed on 1 January 2023).

- Kuaban, G.S.; Czekalski, P.; Molua, E.L.; Grochla, K. An Architectural Framework Proposal for IoT Driven Agriculture. In Proceedings of the 26th International Conference on Computer Networks, CN 2019, Gliwice, Poland, 25–27 June 2019; Springer: Berlin/Heidelberg, Germany; Institute of Theoretical and Applied Informatics: Gliwice, Poland; Polish Academy of Sciences: Gdańsk, Poland, 2019; Volume 1039, pp. 18–33. [Google Scholar] [CrossRef]

- Jagtap, S.; Bader, F.; Garcia-Garcia, G.; Trollman, H.; Fadiji, T.; Salonitis, K. Food Logistics 4.0: Opportunities and Challenges. Logistics 2021, 5, 2. [Google Scholar] [CrossRef]

- Khan, P.W.; Byun, Y.-C.; Park, N. IoT-blockchain enabled optimized provenance system for food industry 4.0 using advanced deep learning. Sensors 2020, 20, 2990. [Google Scholar] [CrossRef]

- Yadav, S.; Luthra, S.; Garg, D. Modelling Internet of things (IoT)-driven global sustainability in multi-tier agri-food supply chain under natural epidemic outbreaks. Environ. Sci. Pollut. Res. 2021, 28, 16633–16654. [Google Scholar] [CrossRef]

- Smetana, S.; Aganovic, K.; Heinz, V. Food Supply Chains as Cyber-Physical Systems: A Path for More Sustainable Personalized Nutrition. FOOD Eng. Rev. 2021, 13, 92–103. [Google Scholar] [CrossRef]

- Mondragon, A.E.; Mondragon, C.E.; Coronado, E.S. Managing the food supply chain in the age of digitalisation: A conceptual approach in the fisheries sector. Prod. Plan. Control 2021, 32, 242–255. [Google Scholar] [CrossRef]

- Almadani, B.; Mostafa, S.M. IIoT Based Multimodal Communication Model for Agriculture and Agro-Industries. IEEE Access 2021, 9, 10070–10088. [Google Scholar] [CrossRef]

- Jagtap, S.; Garcia-Garcia, G.; Rahimifard, S. Optimisation of the resource efficiency of food manufacturing via theInternet of Things. Comput. Ind. 2021, 127, 103397. [Google Scholar] [CrossRef]

- Kanagachidambaresan, G.R. IoT Projects in Smart City Infrastructure. In Internet of Things; Springer: Berlin/Heidelberg, Germany; Department of CSE, Vel Tech Rangarajan Dr Sagunthala R&D Institute of Science and Technology: Avadi, India; Chennai, India; Tamil Nadu, India, 2021; pp. 199–215. [Google Scholar] [CrossRef]

- Sharma, R.; Parhi, S.; Shishodia, A. Industry 4.0 Applications in Agriculture: Cyber-Physical Agricultural Systems (CPASs). In Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021; pp. 807–813. [Google Scholar] [CrossRef]

- Corallo, A.; Latino, M.E.; Menegoli, M. Agriculture 4.0: How Use Traceability Data to Tell Food Product to the Consumers. In Proceedings of the ICITM 2020—2020 9th International Conference on Industrial Technology and Management, Oxford, UK, 11–13 February 2020; pp. 197–201. [Google Scholar] [CrossRef]

- Ekren, B.Y.; Mangla, S.K.; Turhanlar, E.E.; Kazancoglu, Y.; Li, G. Lateral inventory share-based models for IoT-enabled E-commerce sustainable food supply networks. Comput. Oper. Res. 2021, 130, 105237. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, D.; Zhou, H. Intelligent circulation system modeling using bilateral matching theory under Internet of Things technology. J. Supercomput. 2021, 77, 13514–13531. [Google Scholar] [CrossRef]

- Boccia, F.; Covino, D.; Di Pietro, B. Industry 4.0: Food supply chain, sustainability and servitization. Riv. Di Stud. Sulla Sostenibilita 2019, 2019, 77–92. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Fiorini, P.D.C.; Ndubisi, N.O.; Queiroz, M.M.; Piato, E.L. Digitally-enabled sustainable supply chains in the 21st century: A review and a research agenda. Sci. Total Environ. 2020, 725, 138177. [Google Scholar] [CrossRef] [PubMed]

- Aamer, A.M.; Al-Awlaqi, M.A.; Affia, I.; Arumsari, S.; Mandahawi, N. The internet of things in the food supply chain: Adoption challenges. Benchmarking 2021, 28, 2521–2541. [Google Scholar] [CrossRef]

- Herczeg, G.; Akkerman, R.; Hauschild, M.Z. Supply chain collaboration in industrial symbiosis networks. J. Clean. Prod. 2018, 171, 1058–1067. [Google Scholar] [CrossRef] [Green Version]

- Hao, K. Training a Single AI Model Can Emit as Much Carbon as Five Cars in Their Lifetimes. 2019. Available online: https://www.technologyreview.com/2019/06/06/239031/training-a-single-ai-model-can-emit-as-much-carbon-as-five-cars-in-their-lifetimes/ (accessed on 1 January 2023).

- Vanderroost, M.; Ragaert, P.; Verwaeren, J.; De Meulenaer, B.; De Baets, B.; Devlieghere, F. The digitization of a food package’s life cycle: Existing and emerging computer systems in the pre-logistics phase. Comput. Ind. 2017, 87, 15–30. [Google Scholar] [CrossRef]

| No. | Criteria or Question | Weight |

|---|---|---|

| QA1 | Are the aims of the research clearly defined? | 7 |

| QA2 | Is industry 4.0 adequately described? | 10 |

| QA3 | Is the agri-food supply chain sufficiently defined? | 10 |

| QA4 | Does the research address sustainability? | 10 |

| QA5 | How well does the evaluation address its original aims and purpose? | 8 |

| C1 | Less than 15 words | 1 |

| C2 | Keyword in title | 1 |

| C3 | Present a logical structure in the Abstract | 2 |

| C4 | The introduction has a high-quality context | 2 |

| C5 | The introduction mentions the Hypothesis | 5 |

| C6 | The problem is defined in the Introduction | 5 |

| C7 | State of the Art is in a logical order | 5 |

| C8 | Has an appropriate Content of theoretical framework | 4 |

| C9 | The methodology is explained in detail | 5 |

| C10 | Data in the Results is available | 3 |

| C11 | Results are consistent with the objectives | 3 |

| C12 | Present complementary graphs for the text information | 2 |

| C13 | Findings are discussed in relation to objectives | 5 |

| C14 | Results are compared with the state of the art | 3 |

| C15 | The conclusions correspond to the stated objective(s) | 4 |

| C16 | Present future research | 3 |

| C17 | References match | 2 |

| Quality Level | Of Studies | Percent |

|---|---|---|

| Very high (0.85 ≤ score ≤ 1) | 3 | 0.125 |

| high (0.7 ≤ score < 0.85) | 13 | 0.54 |

| Medium (0.5 ≤ score < 0.7) | 8 | 0.33 |

| Low (0 ≤ score < 0.5) | 0 | 0 |

| Total | 24 | 100 |

| Themes | Challenges | References | Number of Observations |

|---|---|---|---|

| technical | Security and privacy | [20,23,39,40,41,42,43,44,45,46] | 10 |

| Wireless power transfer and ambient energy harvesting | [39] | 1 | |

| Big data management | [20,47,48,49,50] | 5 | |

| Reliability, availability, and robustness | [20,46] | 2 | |

| Developing IoT-based cloud system | [40,43] | 3 | |

| Technological architecture | [20,27,42,45,49,50,51,52,53,54,55,56,57] | 13 | |

| infrastructural | IoT-based infrastructure (Internet) | [39,40,44,45,48] | 5 |

| lack of governmental regulations | [23,48] | 2 | |

| Standardization | [20,23,44] | 3 | |

| operational | High energy consumption | [39,45,47] | 3 |

| Scalability | [23,39,40,44] | 4 | |

| Interoperability | [20,39] | 2 | |

| Congestion and overload issues of IoT | [40] | 1 | |

| financial | High implementation and operating costs | [23,41,58] | 3 |

| social | Lack of human skills and educational issues | [39,45,48,58] | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Derakhti, A.; Santibanez Gonzalez, E.D.R.; Mardani, A. Industry 4.0 and Beyond: A Review of the Literature on the Challenges and Barriers Facing the Agri-Food Supply Chain. Sustainability 2023, 15, 5078. https://doi.org/10.3390/su15065078

Derakhti A, Santibanez Gonzalez EDR, Mardani A. Industry 4.0 and Beyond: A Review of the Literature on the Challenges and Barriers Facing the Agri-Food Supply Chain. Sustainability. 2023; 15(6):5078. https://doi.org/10.3390/su15065078

Chicago/Turabian StyleDerakhti, Arman, Ernesto D. R. Santibanez Gonzalez, and Abbas Mardani. 2023. "Industry 4.0 and Beyond: A Review of the Literature on the Challenges and Barriers Facing the Agri-Food Supply Chain" Sustainability 15, no. 6: 5078. https://doi.org/10.3390/su15065078