Assessment of Water Flow Glazing as Building-Integrated Solar Thermal Collector

Abstract

:1. Introduction

2. Materials and Methods

2.1. Performance of Thermal Collectors

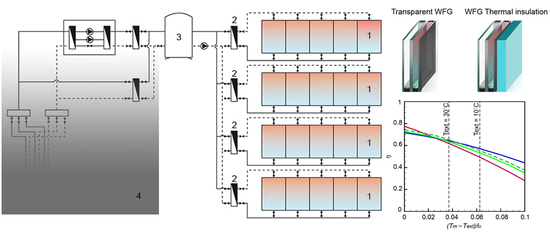

2.2. Water Flow Glazing as a Solar Collector

3. Results

3.1. Water Flow Glazing with Thermal Insulation on the Indoor Layer (Ui = 0)

3.1.1. The Effect of Insulating Air Chambers

3.1.2. The Effect of Low Emissivity Coatings

3.1.3. The Effect of Polyvinyl Butyral (PVB) Layers

3.2. Transparent Water Flow Glazing

3.3. Description of a Case Study

4. Discussion

4.1. Nonlinear Performance in Transient Conditions

4.2. Tested Facility

4.3. Cost Comparison

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- European Union. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018. Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L0844&from=EN (accessed on 25 July 2022).

- Kumar, R.; Rosen, M. A critical review of photovoltaic–thermal solar collectors for air heating. Appl. Energy 2011, 88, 3603–3614. [Google Scholar] [CrossRef]

- Baljit, S.S.S.; Chan, H.Y.; Sopian, K. Review of building integrated applications of photovoltaic and solar thermal systems. J. Clean. Prod. 2016, 137, 677–689. [Google Scholar] [CrossRef]

- Sami Buker, M.; Riffat, S. Building integrated solar thermal collectors—A review. Renew. Sustain. Energy Rev. 2015, 51, 327–346. [Google Scholar] [CrossRef]

- Vassiliades, C.; Agathokleous, R.; Barone, G.; Forzano, C.; Giuzio, G.F.; Palombo, A.; Buonomano, A.; Kalogirou, S. Building integration of active solar energy systems: A review of geometrical and architectural characteristics. Renew. Sustain. Energy Rev. 2022, 164, 112482. [Google Scholar] [CrossRef]

- Moskwa-Bęczkowska, D.; Moskwa, A. Renewable Energy Sources in the Processes of Thermal Modernization of Buildings—Selected Aspects in Poland. Energies 2022, 15, 4613. [Google Scholar] [CrossRef]

- Vassiliades, C.; Kalogirou, S.; Michael, A.; Savvides, A. A roadmap for the integration of active solar systems into buildings. Appl. Sci. 2019, 9, 2462. [Google Scholar] [CrossRef] [Green Version]

- Leonzio, G. Solar systems integrated with absorption heat pumps and thermal energy storages: State of art. Renew. Sustain. Energy Rev. 2017, 70, 492–505. [Google Scholar] [CrossRef]

- Ravi Kumar, K.; Krishna Chaitanya, N.V.V.; Sendhil Kumar, N. Solar thermal energy technologies and its applications for process heating and power generation—A review. J. Clean. Prod. 2021, 282, 125296. [Google Scholar] [CrossRef]

- Rybár, R.; Beer, M.; Mudarri, T.; Zhironkin, S.; Bačová, K.; Dugas, J. Experimental Evaluation of an Innovative Non-Metallic Flat Plate Solar Collector. Energies 2021, 14, 6240. [Google Scholar] [CrossRef]

- Ider, J.; Oliveira, A.; Rubinger, R.; Silva, A.K.; Assini, A.; Tiago-Filho, G.; Baldissera, M. Concentrated Solar Power with Thermoelectric Generator—An Approach Using the Cross-Entropy Optimization Method. Energies 2022, 15, 4774. [Google Scholar] [CrossRef]

- Papadimitratos, A.; Sobhansarbandi, S.; Pozdin, V.; Zakhidov, A.; Hassanipour, F. Evacuated tube solar collectors integrated with phase change materials. Sol. Energy 2016, 129, 10–19. [Google Scholar] [CrossRef] [Green Version]

- Zhu, C.; Dong, X.; Yan, S.; Cui, Y.; Luo, Q. Air-Type Vacuum-Tube Solar Collector Design and Heat Collection Performance Test. Energies 2022, 15, 5679. [Google Scholar] [CrossRef]

- Popsueva, V.; Lopez, A.F.O.; Kosinska, A.; Nikolaev, O.; Balakin, B.V. Field Study on the Thermal Performance of Vacuum Tube Solar Collectors in the Climate Conditions of Western Norway. Energies 2021, 14, 2745. [Google Scholar] [CrossRef]

- Tomas, M.; Borivoj, S. Facade solar collectors. Sol. Energy 2006, 80, 1443–1452. [Google Scholar]

- Rockendorf, G.; Janssen, S.; Felten, H. Transparently insulated hybrid wall. Sol. Energy 1996, 58, 33–38. [Google Scholar] [CrossRef]

- Chow, T.T.; Li, C.; Lin, Z. The function of solar absorbing window as water-heating device. Build. Environ. 2011, 46, 955–960. [Google Scholar] [CrossRef]

- Chow, T.T.; Li, C.; Lin, Z. Thermal characteristics of water-flow double-pane window. Int. J. Therm. Sci. 2010, 50, 140–148. [Google Scholar] [CrossRef]

- Gil-Lopez, T.; Gimenez-Molina, C. Influence of double glazing with a circulating water chamber on the thermal energy savings in buildings. Energy Build. 2013, 56, 56–65. [Google Scholar] [CrossRef]

- Gutai, M.; Kheybari, A.G. Energy consumption of hybrid smart water-filled glass (SWFG) building envelope. Energy Build. 2021, 230, 110508. [Google Scholar] [CrossRef]

- Lyu, Y.L.; Chow, T.T.; Wang, J.L. Numerical prediction of thermal performance of liquid-flow window in different climates with anti-freeze. Energy 2018, 157, 412–423. [Google Scholar] [CrossRef]

- Lyu, Y.L.; Wu, X.; Li, C.; Su, H.; He, L. Numerical analysis on the effectiveness of warm water supply in water flow window for room heating. Sol. Energy 2019, 177, 347–354. [Google Scholar] [CrossRef]

- Moreno Santamaria, B.; Ama Gonzalo, F.; Lauret Aguirregabiria, B.; Hernandez Ramos, J.A. Evaluation of Thermal Comfort and Energy Consumption of Water Flow Glazing as a Radiant Heating and Cooling System: A Case Study of an Office Space. Sustainability 2020, 12, 7596. [Google Scholar] [CrossRef]

- Del Ama Gonzalo, F.; Moreno Santamaria, B.; Ferrándiz Gea, J.A.; Griffin, M.; Hernandez Ramos, J.A. Zero Energy Building Economic and Energetic Assessment with Simulated and Real Data Using Photovoltaics and Water Flow Glazing. Energies 2021, 14, 3272. [Google Scholar] [CrossRef]

- Moreno Santamaria, B.; del Ama Gonzalo, F.; Lauret Aguirregabiria, B.; Hernandez Ramos, J.A. Experimental Validation of Water Flow Glazing: Transient Response in Real Test Rooms. Sustainability 2020, 12, 5734. [Google Scholar] [CrossRef]

- Moreno Santamaria, B.; del Ama Gonzalo, F.; Pinette, D.; Gonzalez-Lezcano, R.-A.; Lauret Aguirregabiria, B.; Hernandez Ramos, J.A. Application and Validation of a Dynamic Energy Simulation Tool: A Case Study with Water Flow Glazing Envelope. Energies 2020, 13, 3203. [Google Scholar] [CrossRef]

- UNE-EN 12975-2:2006; Thermal Solar Systems and Components-Solar Collectors-Part 2: Test Methods. AENOR (Spanish Association for Standardization and Certification): Madrid, Spain, 2007.

- Garg, H.P.; Rani, U. Loss coefficients from solar flat-plate collectors. Appl. Energy 1980, 7, 109–117. [Google Scholar] [CrossRef]

- ISO 9488:2022; Solar Energy—Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2022.

- Evangelisti, L.; De Lieto, R.; Asdrubali, V.F. Latest advances on solar thermal collectors: A comprehensive review. Renew. Sustain. Energy Rev. 2019, 114, 109318. [Google Scholar] [CrossRef]

- Harrison, S.; Cruickshank, C.A. A review of strategies for the control of high temperature stagnation in solar collectors and systems. Energy Procedia 2012, 30, 793–804. [Google Scholar] [CrossRef] [Green Version]

- Resch, K.; Wallner, G.M. Thermotropic layers for flat-plate collectors—A review of various concepts for overheating protection with polymeric materials. Sol. Energy Mater. Sol. Cells 2009, 93, 119–128. [Google Scholar] [CrossRef]

- Sierra, P.; Hernandez, J.A. Solar heat gain coefficient of water flow glazing. Energy Build. 2017, 139, 133–145. [Google Scholar] [CrossRef] [Green Version]

- ISO 15099:2003; Thermal Performance of Windows, Doors and Shading Devices—Detailed Calculations. International Organization for Standardization: Geneva, Switzerland, 2004.

- Karimirad, M.; Rosa-Clot, M.; Armstrong, A.; Whittaker, T. Floating solar: Beyond the state of the art technology. Sol. Energy 2021, 219, 1–2. [Google Scholar] [CrossRef]

- Barone, G.; Buonomano, A.; Forzano, C.; Palombo, A. Building Energy Performance Analysis: An Experimental Validation of an In-House Dynamic Simulation Tool through a Real Test Room. Energies 2019, 12, 4107. [Google Scholar] [CrossRef] [Green Version]

- Del Linz, P.; Hooper, P.A.; Arora, H.; Wang, Y.; Smith, D.; Blackman, B.R.K.; Dear, J.P. Delamination properties of laminated glass windows subject to blast loading. Int. J. Impact Eng. 2017, 105, 39–53. [Google Scholar] [CrossRef] [Green Version]

- Vedrtnam, A.; Pawar, S.J. Laminated glass: Classification, characterization, and future perspectives. J. Mater. Educ. 2020, 42, 51–61. [Google Scholar]

- Vanceva Technical Documents. Available online: https://www.vanceva.com/learn/technical-documents (accessed on 15 July 2022).

- DB CTE HE4. Available online: https://www.codigotecnico.org/pdf/Documentos/HE/DBHE.pdf (accessed on 11 October 2022).

- Beckman, W.A.; Klein, S.A.; Duffie, J.A. Solar Heating Design, by the f-Chart Method; Wiley: New York, NY, USA, 1977. [Google Scholar]

- Deepika, D.; Baig, M.; Reddy, A.; Maneaih, D. Utilization of f-Chart Method for Designing Solar Thermal Heating System. IOSR J. Mech. Civ. Eng. 2016, 16, 23–28. [Google Scholar] [CrossRef]

- IDAE. Instalaciones de Energía Solar Térmica Pliego de Condiciones Técnicas de Instalaciones de Baja Temperatura; Instituto para la Diversificación y Ahorro de la Energía: Madrid, Spain, 2009. [Google Scholar]

- ASHRAE Guidelines 14-2014; Measurement of Energy and Demand Savings. American Society of Heating Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2014.

- ITeC (Instituto de la Tecnología de la Construcción de Cataluña). Available online: https://itec.es/servicios/bedec/ (accessed on 3 February 2021).

- Casini, M. 7-Advanced insulation glazing. In Smart Buildings; Casini, M., Ed.; Woodhead Publishing: Cambridge, MA, USA, 2016; pp. 249–277. [Google Scholar]

- Vanhoutteghem, L.; Skarning, G.C.J.; Hviid, C.A.; Svendsen, S. Impact of façade window design on energy, daylighting and thermal comfort in nearly zero-energy houses. Energy Build. 2015, 102, 149–156. [Google Scholar] [CrossRef] [Green Version]

- Tam, V.W.Y.; Le, K.N.; Wang, J.Y. Cost Implication of Implementing External Facade Systems forCommercial Buildings. Sustainability 2018, 10, 1917. [Google Scholar] [CrossRef]

| Collector Type | Model 1 | η0 | a1 | a2 |

|---|---|---|---|---|

| Flat plate | Disol Satius 22 L Plus | 0.775 | 3.73 | 0.0152 |

| Vacuum-pipe | Thermomax DF100 | 0.781 | 1.44 | 0.0062 |

| Glazing | η0 | Ue (W/m2K) | qe (W/m2) |

|---|---|---|---|

| 4+4/Water/4+4 | 0.462 | 19.28 | 0.040 |

| 4/Air/4+4/Water/4+4 | 0.411 | 5.83 | 0.093 |

| ε1 1 | ε2 1 | η0 | Ue (W/m2K) | qe (W/m2) |

|---|---|---|---|---|

| 0.837 | 0.837 | 0.411 | 5.83 | 0.093 |

| 0.837 | 0.10 | 0.406 | 3.69 | 0.098 |

| 0.837 | 0.01 | 0.405 | 3.33 | 0.099 |

| PVB Layer 1 | Solar Absorption | g | η0 | a1 (W/m2K) |

|---|---|---|---|---|

| Transparent | 0.405 | 3.41 | ||

| 000H | 32.7 | 0.69 | 0.483 | 3.42 |

| 003H | 44.1 | 0.64 | 0.675 | 3.43 |

| 07AH | 61 | 0.57 | 0.778 | 3.42 |

| Glazing | Tilt | η0 | a1 (W/m2K) | Ui (W/m2K) | Ue (W/m2K) | τv | g |

|---|---|---|---|---|---|---|---|

| 4|Air/4+4/Water/4+4 1 | θ = 0° | 0.648 | 9.51 | 4.70 | 4.02 | 0.225 | 0.143 |

| θ = 90° | 0.647 | 7.83 | 4.72 | 2.33 | 0.225 | 0.143 | |

| 4|Air/4+4/Water/4+4|Air/4 1 | θ = 0° | 0.664 | 5.48 | 1.25 | 4.02 | 0.202 | 0.125 |

| θ = 90° | 0.661 | 4.13 | 1.54 | 2.33 | 0.202 | 0.125 |

| Tm,e (m2K/W) | Text (oC) | η0 | a1 (W/m2K) | Ue (W/m2K) | 1Ui (W/m2K) | η(facade) | η(collector) |

|---|---|---|---|---|---|---|---|

| 0.000 | 60 | 0.738 | - | 1.85 | 0.25/0 | 0.727 | 0.738 |

| 0.001 | 59 | 0.738 | 10.59 | 1.84 | 0.25/0 | 0.725 | 0.736 |

| 0.006 | 55 | 0.738 | 3.58 | 1.83 | 0.25/0 | 0.716 | 0.727 |

| 0.013 | 50 | 0.738 | 2.71 | 1.83 | 0.25/0 | 0.704 | 0.715 |

| 0.025 | 40 | 0.738 | 2.40 | 1.97 | 0.25/0 | 0.678 | 0.689 |

| 0.038 | 30 | 0.738 | 2.64 | 2.35 | 0.25/0 | 0.639 | 0.650 |

| 0.050 | 20 | 0.739 | 3.06 | 2.84 | 0.25/0 | 0.586 | 0.597 |

| 0.063 | 10 | 0.740 | 3.26 | 3.08 | 0.25/0 | 0.537 | 0.547 |

| 0.075 | 0 | 0.740 | 3.44 | 3.30 | 0.25/0 | 0.482 | 0.493 |

| 0.088 | −20 | 0.741 | 3.62 | 3.50 | 0.25/0 | 0.424 | 0.435 |

| 0.100 | −30 | 0.742 | 3.80 | 3.69 | 0.25/0 | 0.362 | 0.373 |

| Month | Text (°C) | Tw supply (°C) | Gdi(0) (kWh/m2 day) | DE (kWh) | EI (kWh/m2) | EU (kWh) | f |

|---|---|---|---|---|---|---|---|

| January | 5 | 4 | 1.64 | 4027 | 41.50 | 1437 | 0.357 |

| February | 6 | 5 | 2.44 | 3572 | 46.59 | 1766 | 0.494 |

| March | 9 | 7 | 3.58 | 3811 | 58.10 | 2223 | 0.583 |

| April | 12 | 9 | 4.83 | 3549 | 51.95 | 1927 | 0.543 |

| May | 15 | 10 | 5.19 | 3596 | 40.38 | 1355 | 0.377 |

| June | 20 | 11 | 6.11 | 3410 | 38.09 | 1347 | 0.395 |

| July | 24 | 12 | 7.11 | 3453 | 53.70 | 2153 | 0.624 |

| August | 23 | 11 | 6.19 | 3524 | 68.79 | 2761 | 0.784 |

| September | 20 | 10 | 4.86 | 3480 | 79.41 | 3033 | 0.872 |

| October | 14 | 9 | 3.11 | 3667 | 73.94 | 2809 | 0.766 |

| November | 9 | 7 | 2.00 | 3688 | 55.46 | 2188 | 0.574 |

| December | 6 | 4 | 1.53 | 4027 | 43.78 | 1600 | 0.398 |

| Average | 13.5 | 8.25 | 3651 | 54.31 | 2044 | 0.605 |

| A1 | A2 | A3 | Aw | Av | |

|---|---|---|---|---|---|

| WFG | 0.04 | 0.25 | 0.06 | 0.15 | 0.27 |

| Month | Text (°C) | Tw supply (°C) | Gdi(0) (kWh/m2 day) | DE (kWh) | EI (kWh/m2) | EU (kWh) | f |

|---|---|---|---|---|---|---|---|

| January | 5 | 4 | 1.64 | 4027 | 71.13 | 1160 | 0.288 |

| February | 6 | 5 | 2.44 | 3572 | 88.29 | 1468 | 0.411 |

| March | 9 | 7 | 3.58 | 3811 | 127.75 | 2098 | 0.550 |

| April | 12 | 9 | 4.83 | 3549 | 146.45 | 2343 | 0.660 |

| May | 15 | 10 | 5.19 | 3596 | 146.54 | 2353 | 0.654 |

| June | 20 | 11 | 6.11 | 3410 | 161.33 | 2551 | 0.748 |

| July | 24 | 12 | 7.11 | 3453 | 202.81 | 3068 | 0.889 |

| August | 23 | 11 | 6.19 | 3524 | 197.79 | 3038 | 0.862 |

| September | 20 | 10 | 4.86 | 3480 | 175.00 | 2752 | 0.791 |

| October | 14 | 9 | 3.11 | 3667 | 134.06 | 2188 | 0.597 |

| November | 9 | 7 | 2.00 | 3688 | 91.20 | 1504 | 0.408 |

| December | 6 | 4 | 1.53 | 4027 | 71.04 | 1166 | 0.290 |

| Average | 13.5 | 8.25 | 3651 | 134.45 | 1160 | 0.601 |

| Collector Type | Model | Price (€) | Area (m2) | (€/m2) |

|---|---|---|---|---|

| Flat plate | Disol Satius 22 L Plus 1 | 713 | 1.97 | 362 |

| Vacuum-pipe | Thermomax DF100 1 | 972 | 1.92 | 506 |

| WFG | 4|Aire/4++4/Agua/4++4 | - | Defined by user | 370 |

| Case Study | Glass (€/m2) | Aluminum Frame (€/m2) | Circulating Device (€/m2) | Solar Collectors (€/m2) | Total (€) |

|---|---|---|---|---|---|

| WFG 1 | 370 | 415 | 150 | - | 149,600 |

| Reference Building 1 | 220 | 415 | - | 362 | 112,460 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

del Ama Gonzalo, F.; Moreno Santamaría, B.; Hernández Ramos, J.A. Assessment of Water Flow Glazing as Building-Integrated Solar Thermal Collector. Sustainability 2023, 15, 644. https://doi.org/10.3390/su15010644

del Ama Gonzalo F, Moreno Santamaría B, Hernández Ramos JA. Assessment of Water Flow Glazing as Building-Integrated Solar Thermal Collector. Sustainability. 2023; 15(1):644. https://doi.org/10.3390/su15010644

Chicago/Turabian Styledel Ama Gonzalo, Fernando, Belén Moreno Santamaría, and Juan A. Hernández Ramos. 2023. "Assessment of Water Flow Glazing as Building-Integrated Solar Thermal Collector" Sustainability 15, no. 1: 644. https://doi.org/10.3390/su15010644