An Experimental Study on Simultaneous Use of Metal Fins and Mirror to Improve the Performance of Photovoltaic Panels

Abstract

:1. Introduction

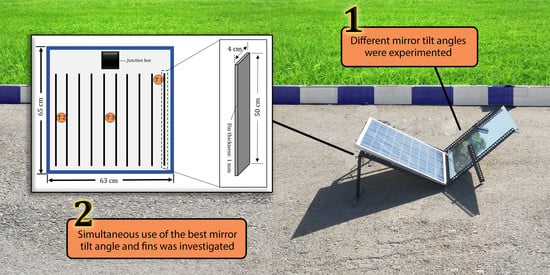

2. Experimental Setup Description

2.1. Equipment and Ambient Condition

2.2. Experimental Procedure

3. Governing Equations

3.1. Energy Efficiency Calculations

3.2. Exergy Efficiency Calculation

3.3. Entropy Generation Calculation

4. Uncertainty Analysis

5. Results and Discussion

5.1. Temperature Variations

5.2. Energy Analysis

5.3. Exergy Analysis and Entropy Generation

6. Conclusions

- Although the use of a mirror increased the obtained radiation by the PV panel, but the temperature of PV cells increased too, so that in the midday, the case of PV 30 attained to about 3 °C more of a temperature in comparison with the conventional one. However, the results show a positive outcome in the system, and 2.2 W more output power was measured for the mentioned case. Moreover, when the fins were also added to this case (PV 30 + fin), the output power was 4.1 W more than the conventional one due to lower PV temperatures at higher irradiations.

- Dual behavior of the increase in emitted irradiation and surface temperature for the cases of mirrors integrated on the electrical efficiency was explored because of the obtaining of more radiation at the same condition. Afterward, it was illustrated that PV 30 has lower electrical efficiency than the conventional case, and when fins were also used (PV 30 + fin), the electrical efficiency of the panel was more than the conventional one due to a higher heat transfer rate in the presence of fins, which leads to lower PV cell temperature.

- Calculation of both electrical and thermal exergies was discussed in detail, and the mistake made by some scholars was described. Then, the generation in entropy as one of the important thermodynamic concepts was calculated, too. Consequently, the case of PV 30 + fin showed 1.6% lower entropy generation compared with the base case.

- Simultaneous application of phase change material and reflectors to enhance the output power of PV panels.

- Assisting of artificial intelligence (AI) techniques to find optimum features of the investigated system, such as; surrounding conditions, PV tilt angle, mirror dimensions, mirror tilt angle, fin numbers, etc.

- Performing of the life cycle assessment (LCA), energy payback time (EPBT), and environmental evaluation to find out the economic justification of the investigated system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghasemikafrudi, E.; Yousefi, S.; Goodarzvand-Chegini, F. Environmental Study of Waste Energy Recovery by Using Exergy and Economic Analysis in a Fluid Catalytic Cracking Unit. Adv. Environ. Technol. 2017, 3, 229–242. [Google Scholar]

- El-Mahallawi, I.; Elshazly, E.; Ramadan, M.; Nasser, R.; Yasser, M.; El-Badry, S.; Elthakaby, M.; Oladinrin, O.T.; Rana, M.Q. Solar PV Panels-Self-Cleaning Coating Material for Egyptian Climatic Conditions. Sustainability 2022, 14, 11001. [Google Scholar] [CrossRef]

- Al-Kouz, W.; Al-Dahidi, S.; Hammad, B.; Al-Abed, M. Modeling and Analysis Framework for Investigating the Impact of Dust and Temperature on PV Systems’ Performance and Optimum Cleaning Frequency. Appl. Sci. 2019, 9, 1397. [Google Scholar] [CrossRef] [Green Version]

- Anwar, K.; Deshmukh, S.; Renikindhi, S. Life-Cycle-Assessment Based Design of a Standalone Photovoltaic System: A Case Study Using a Theoretical and Numerical Approach. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 83. [Google Scholar] [CrossRef]

- Nnamchi, S.; Nnamchi, O.; Nwaigwe, K.; Jagun, Z.; Ezenwankwo, J. Effect of Technological Mismatch on Photovoltaic Array: Analysis of Relative Power Loss. J. Renew. Energy Environ. 2021, 8, 77–89. [Google Scholar]

- Sisodia, A.K. Impact of Bird Dropping Deposition on Solar Photovoltaic Module Performance: A Systematic Study in Western Rajasthan. Environ. Sci. Pollut. Res. 2019, 26, 31119–31132. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Praveenkumar, S.; Alwan, N.T.; Velkin, V.I.; Shcheklein, S.E.; Yaqoob, S.J. Experimental Investigation of the Effect of a Combination of Active and Passive Cooling Mechanism on the Thermal Characteristics and Efficiency of Solar PV Module. Inventions 2021, 6, 63. [Google Scholar] [CrossRef]

- Hasan, A.; Mccormack, S.J.; Huang, M.J.; Norton, B. Energy and Cost Saving of a Photovoltaic-Phase Change Materials (PV-PCM) System through Temperature Regulation and Performance Enhancement of Photovoltaics. Energies 2014, 7, 1318–1331. [Google Scholar] [CrossRef] [Green Version]

- Awda, L.; Khalaf, Y.; Salih, S. Analysis of Temperature Effect on a Crystalline Silicon Photovoltaic Module Performance. Int. J. Eng. 2016, 29, 722–727. [Google Scholar]

- Shiravi, A.H.; Firoozzadeh, M.; Lotfi, M. Experimental Study on the Effects of Air Blowing and Irradiance Intensity on the Performance of Photovoltaic Modules, Using Central Composite Design. Energy 2022, 238, 121633. [Google Scholar] [CrossRef]

- Araneo, R.; Grasselli, U.; Celozzi, S. Assessment of a Practical Model to Estimate the Cell Temperature of a Photovoltaic Module. Int. J. Energy Environ. Eng. 2014, 5, 72. [Google Scholar] [CrossRef] [Green Version]

- Siddiqui, R.; Bajpai, U. Correlation between Thicknesses of Dust Collected on Photovoltaic Module and Difference in Efficiencies in Composite Climate. Int. J. Energy Environ. Eng. 2012, 3, 26. [Google Scholar] [CrossRef] [Green Version]

- Al-Nimr, M.D.A.; Kiwan, S.; Sharadga, H. Simulation of a Novel Hybrid Solar Photovoltaic/Wind System to Maintain the Cell Surface Temperature and to Generate Electricity. Int. J. Energy Res. 2018, 42, 985–998. [Google Scholar] [CrossRef]

- Firoozzadeh, M.; Shiravi, A.H.; Lotfi, M.; Aidarova, S.; Sharipova, A. Optimum Concentration of Carbon Black Aqueous Nanofluid as Coolant of Photovoltaic Modules: A Case Study. Energy 2021, 225, 120219. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Mahdi, M.T.; Kazem, H.A.; Al-Waeli, A.H.; Fayad, M.A.; Al-Amiery, A.A.; Isahak, W.N.R.W.; Kadhum, A.A.H.; Takriff, M.S. Modified Nano-Fe2O3-Paraffin Wax for Efficient Photovoltaic/Thermal System in Severe Weather Conditions. Sustainability 2022, 14, 12015. [Google Scholar] [CrossRef]

- Mohd Shatar, N.; Abdul Rahman, M.A.; Muhtazaruddin, M.N.; Shaikh Salim, S.A.Z.; Singh, B.; Muhammad-Sukki, F.; Bani, N.A.; Mohd Saudi, A.S.; Ardila-Rey, J.A. Performance Evaluation of Unconcentrated Photovoltaic-Thermoelectric Generator Hybrid System under Tropical Climate. Sustainability 2019, 11, 6192. [Google Scholar] [CrossRef] [Green Version]

- Hasan, H.A.; Sherza, J.S.; Mahdi, J.M.; Togun, H.; Abed, A.M.; Ibrahim, R.K.; Yaïci, W. Experimental Evaluation of the Thermoelectrical Performance of Photovoltaic-Thermal Systems with a Water-Cooled Heat Sink. Sustainability 2022, 14, 10231. [Google Scholar] [CrossRef]

- Tabaei, H.; Ameri, M. Improving the Effectiveness of a Photovoltaic Water Pumping System by Using Booster Reflector and Cooling Array Surface by a Film of Water. Iran. J. Sci. Technol. Trans. Mech. Eng. 2015, 39, 51–60. [Google Scholar]

- Firoozzadeh, M.; Shiravi, A.H. Simultaneous Use of Porous Medium and Phase Change Material as Coolant of Photovoltaic Modules; Thermodynamic Analysis. J. Energy Storage 2022, 54, 105276. [Google Scholar] [CrossRef]

- González-Peña, D.; Alonso-Demiguel, I.; Díez-Mediavilla, M.; Alonso-Tristán, C. Experimental Analysis of a Novel PV/T Panel with PCM and Heat Pipes. Sustainability 2020, 12, 1710. [Google Scholar] [CrossRef] [Green Version]

- Grubišić-Čabo, F.; Nižetić, S.; Marinić Kragić, I.; Čoko, D. Further Progress in the Research of Fin-Based Passive Cooling Technique for the Free-Standing Silicon Photovoltaic Panels. Int. J. Energy Res. 2019, 43, 3475–3495. [Google Scholar] [CrossRef]

- Fudholi, A.; Zohri, M.; Jin, G.L.; Ibrahim, A.; Yen, C.H.; Othman, M.Y.; Ruslan, M.H.; Sopian, K. Energy and Exergy Analyses of Photovoltaic Thermal Collector with ∇-Groove. Sol. Energy 2018, 159, 742–750. [Google Scholar] [CrossRef]

- Firoozzadeh, M.; Shiravi, A.H.; Chandel, S.S. Experimental Analysis of Enhancing Cooling of Photovoltaic Modules Using Straight and Zig-Zag Fins. J. Therm. Anal. Calorim. 2022, 147, 8827–8839. [Google Scholar] [CrossRef]

- Sedaghat, A.; Karami, M.; Eslami, M. Improving Performance of a Photovoltaic Panel by Pin Fins: A Theoretical Analysis. Iran. J. Sci. Technol. Trans. Mech. Eng. 2020, 44, 997–1004. [Google Scholar] [CrossRef]

- Tahmasbi, M.; Siavashi, M.; Norouzi, A.M.; Doranehgard, M.H. Thermal and Electrical Efficiencies Enhancement of a Solar Photovoltaic-Thermal/Air System (PVT/Air) Using Metal Foams. J. Taiwan Inst. Chem. Eng. 2021, 124, 276–289. [Google Scholar] [CrossRef]

- Tabasi, S.; Yousefi, H.; Noorollahi, Y.; Aramesh, M. A Detailed Investigation and Performance Optimization of a Photovoltaic Panel Integrated with a Reflecting Mirror. Appl. Therm. Eng. 2019, 160, 114074. [Google Scholar] [CrossRef]

- Malik, P.; Chandel, S.S. Performance Enhancement of Multi-Crystalline Silicon Photovoltaic Modules Using Mirror Reflectors under Western Himalayan Climatic Conditions. Renew. Energy 2020, 154, 966–975. [Google Scholar] [CrossRef]

- Agrawal, M.; Kumar, A.; Chowdhury, A. A Detailed Simulation-Based Study on the Effect of Mirror Integration on PV Module (S) with Analysis of Different Wind Flow Scheme. Sol. Energy 2021, 222, 129–144. [Google Scholar] [CrossRef]

- Palaskar, V.N.; Deshmukh, S.P.; Pandit, A.B. Design and Performance Analysis of Reflectors Attached to Commercial PV Module. Int. J. Renew. Energy Res. (IJRER) 2014, 4, 240–245. [Google Scholar]

- Shiravi, A.H.; Firoozzadeh, M. Performance Assessment of a Finned Photovoltaic Module Exposed to an Air Stream; an Experimental Study. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 535. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H. A Comparison of Dust Impacts on Polycrystalline and Monocrystalline Solar Photovoltaic Performance: An Outdoor Experimental Study. Environ. Sci. Pollut. Res. 2022, 29, 88788–88802. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.; Sopian, K. Effect of Dust and Cleaning Methods on Mono and Polycrystalline Solar Photovoltaic Performance: An Indoor Experimental Study. Sol. Energy 2022, 236, 626–643. [Google Scholar] [CrossRef]

- Kazem, H.A.; Al-Waeli, A.H.; Chaichan, M.T.; Sopian, K. Modeling and Experimental Validation of Dust Impact on Solar Cell Performance. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 1–17. [Google Scholar] [CrossRef]

- Kazem, H.A.; Yousif, J.H.; Al-Balushi, H.; Abuhmaidan, K.; Al-Badi, R. Artificial Neural Network Modelling and Experimental Evaluation of Dust and Thermal Energy Impact on Monocrystalline and Polycrystalline Photovoltaic Modules. Energies 2022, 15, 4138. [Google Scholar]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.; Sopian, K.; Darwish, A.S.K. Evaluation of Dust Elements on Photovoltaic Module Performance: An Experimental Study. Renew. Energy Environ. Sustain. 2021, 6, 30. [Google Scholar] [CrossRef]

- Beygzadeh, S.; Beygzadeh, V.; Beygzadeh, T. Thermodynamic and Economic Comparison of Photovoltaic Electricity Generation with and without Self-Cleaning Photovoltaic Panels. Energy Equip. Syst. 2019, 7, 263–270. [Google Scholar]

- Nabil, T.; Mansour, T.M. Augmenting the Performance of Photovoltaic Panel by Decreasing Its Temperature Using Various Cooling Techniques. Results Eng. 2022, 15, 100564. [Google Scholar] [CrossRef]

- Akbari, H.; Browne, M.C.; Ortega, A.; Huang, M.J.; Hewitt, N.J.; Norton, B.; Mccormack, S.J. Efficient Energy Storage Technologies for Photovoltaic Systems. Sol. Energy 2019, 192, 144–168. [Google Scholar] [CrossRef]

- Nasrin, R.N.; Hossain, M.S. Numerical Analysis of Photovoltaic Power Generation in Different Locations of Bangladesh. J. Comput. Appl. Res. Mech. Eng. (JCARME) 2021, 10, 373–389. [Google Scholar]

- Pagodaripour, A.; Ghasemkhani, A.; Ghazizade-Ahsaee, H.; Namjo, A. The Assessment and Experimental Study of Photovoltaics Panel by Spraying Water (Case Study: Kerman, Iran). Energy Equip. Syst. 2020, 8, 389–399. [Google Scholar]

- Sardarabadi, M.; Passandideh-Fard, M.; Heris, S.Z. Experimental Investigation of the Effects of Silica/Water Nanofluid on PV/T (Photovoltaic Thermal Units). Energy 2014, 66, 264–272. [Google Scholar] [CrossRef]

- Saffarian, M.R.; Moravej, M.; Doranehgard, M.H. Heat Transfer Enhancement in a Flat Plate Solar Collector with Different Flow Path Shapes Using Nanofluid. Renew. Energy 2020, 146, 2316–2329. [Google Scholar] [CrossRef]

- Dincer, I. 1.7 Energy and Exergy Efficiencies. In Comprehensive Energy Systems; Dincer, I., Ed.; Elsevier: Oxford, UK, 2018; pp. 265–339. [Google Scholar]

- Jeter, S.M. Maximum Conversion Efficiency for the Utilization of Direct Solar Radiation. Sol. Energy 1981, 26, 231–236. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.; Sardarabadi, M.; Passandideh-Fard, M. Energy and Exergy Analysis of Nanofluid Based Photovoltaic Thermal System Integrated with Phase Change Material. Energy 2018, 147, 636–647. [Google Scholar] [CrossRef]

- Firoozzadeh, M.; Shiravi, A.H.; Shafiee, M. Thermodynamics Assessment on Cooling Photovoltaic Modules by Phase Change Materials (PCMs) in Critical Operating Temperature. J. Therm. Anal. Calorim. 2021, 144, 1239–1251. [Google Scholar] [CrossRef]

- Chow, T.T.; Pei, G.; Fong, K.F.; Lin, Z.; Chan, A.L.S.; Ji, J. Energy and Exergy Analysis of Photovoltaic–Thermal Collector with and without Glass Cover. Appl. Energy 2009, 86, 310–316. [Google Scholar] [CrossRef]

- Fudholi, A.; Zohri, M.; Rukman, N.S.B.; Nazri, N.S.; Mustapha, M.; Yen, C.H.; Mohammad, M.; Sopian, K. Exergy and Sustainability Index of Photovoltaic Thermal (PVT) Air Collector: A Theoretical and Experimental Study. Renew. Sustain. Energy Rev. 2019, 100, 44–51. [Google Scholar] [CrossRef]

- Lotfi, M.; Shiravi, A.H.; Firoozzadeh, M. Experimental Study on Simultaneous Use of Phase Change Material and Reflector to Enhance the Performance of Photovoltaic Modules. J. Energy Storage 2022, 54, 105342. [Google Scholar] [CrossRef]

- Chamkha, A.J.; Rufuss, D.; Kabeel, A.; Sathyamurthy, R.; Abdelgaid, M.; Manokar, A.M.; Madhu, B. Augmenting the Potable Water Produced from Single Slope Solar Still Using CNT-Doped Paraffin Wax as Energy Storage: An Experimental Approach. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 625. [Google Scholar] [CrossRef]

- Aberoumand, S.; Ghamari, S.; Shabani, B. Energy and Exergy Analysis of a Photovoltaic Thermal (PV/T) System Using Nanofluids: An Experimental Study. Sol. Energy 2018, 165, 167–177. [Google Scholar] [CrossRef]

- Akyuz, E.; Coskun, C.; Oktay, Z.; Dincer, I. A Novel Approach for Estimation of Photovoltaic Exergy Efficiency. Energy 2012, 44, 1059–1066. [Google Scholar] [CrossRef]

- Bayrak, F.; Oztop, H.F.; Selimefendigil, F. Effects of Different Fin Parameters on Temperature and Efficiency for Cooling of Photovoltaic Panels under Natural Convection. Sol. Energy 2019, 188, 484–494. [Google Scholar] [CrossRef]

- Eisapour, M.; Eisapour, A.H.; Hosseini, M.J.; Talebizadehsardari, P. Exergy and Energy Analysis of Wavy Tubes Photovoltaic-Thermal Systems Using Microencapsulated PCM Nano-Slurry Coolant Fluid. Appl. Energy 2020, 266, 114849. [Google Scholar] [CrossRef]

| Equipment | Parameter |

|---|---|

| PV panel | Manufacturer: Yingli Solar Co., Baoding, China |

| Nominal power output : 60 W | |

| Nominal module efficiency : 14.4% | |

| Voltage at : 18.47 V | |

| Open-circuit voltage : 22.86 V | |

| Current at : 3.25 A | |

| Short-circuit current : 3.44 A | |

| Temperature sensor | Model: DS-18B20, China |

| Operating range: −55 to +125 °C | |

| Accuracy: 0.1 °C | |

| Solarimeter | Model: TES-132, China |

| Operating range: 200–2000 W/m2 | |

| Accuracy: 1 W/m2 |

| No. | Name | Fin | Mirror |

|---|---|---|---|

| 1 | Conventional PV | × | × |

| 2 | PV + Fin | ✓ | × |

| 3 | PV 20 | × | 20° |

| 4 | PV 30 | × | 30° |

| 5 | PV 40 | × | 40° |

| 6 | PV 30 + Fin | ✓ | 30° |

| Case | Mean Temperature (°C) |

|---|---|

| Conventional PV module | 69.5 |

| PV 20 | 71.6 |

| PV 30 | 73.2 |

| PV 40 | 70.1 |

| PV + Fin | 59.3 |

| PV 30 + Fin | 62.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Firoozzadeh, M.; Lotfi, M.; Shiravi, A.H. An Experimental Study on Simultaneous Use of Metal Fins and Mirror to Improve the Performance of Photovoltaic Panels. Sustainability 2022, 14, 16986. https://doi.org/10.3390/su142416986

Firoozzadeh M, Lotfi M, Shiravi AH. An Experimental Study on Simultaneous Use of Metal Fins and Mirror to Improve the Performance of Photovoltaic Panels. Sustainability. 2022; 14(24):16986. https://doi.org/10.3390/su142416986

Chicago/Turabian StyleFiroozzadeh, Mohammad, Marzieh Lotfi, and Amir Hossein Shiravi. 2022. "An Experimental Study on Simultaneous Use of Metal Fins and Mirror to Improve the Performance of Photovoltaic Panels" Sustainability 14, no. 24: 16986. https://doi.org/10.3390/su142416986