Keu Contamination in Tuscany: The Life Cycle Assessment of Remediation Project as a Decision Support Tool for Local Administration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Goal and Scope Definition

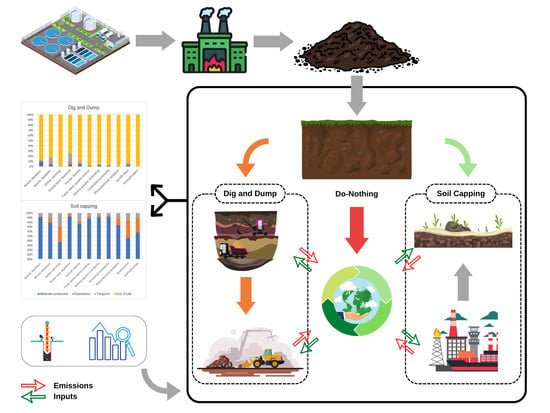

Scenario Analysis and System Boundaries

- Non-woven fabric-TNT 300 g/m2. The membranes would be laid manually over an area of about 11,000 m2 (double layer) and sent to the site from the supply warehouses, by courier; for the supply, it was assumed that they would be purchased from a company located in the Municipality of Santa Maria a Monte (PI).

- Low-density polyethene sheet-LDPE (black silage film with a thickness of 200 microns and a specific weight of 197 g/m2). The membranes would be spread manually over an area of about 5500 m2 and sent to the site from the supply warehouses, by courier; purchase from a company located in the Municipality of Camaiore (LU) was assumed for the supply.

- Cementation of the trench excavation with the soil originated from the excavation performed (clayey silt).

- Approximately 670 m3 (1350 t) of stabilizer are planned to be taken from the PCM Quarry for the formation of a road embankment not more than 30 cm thick. The transport of the stabilizer from the quarry would always be carried out by vehicles owned by an excavation and demolition company based in the municipality of Peccioli (PI), while for the laying, it is planned to use the previously mentioned shovel located on site. The consumption of the vehicle in question is estimated at 8 L/h of diesel fuel, while the stabilized paving operation will take approximately 3 working days.

- Approximately 325 m3 (552.5 t) of closed binder, with a thickness of about 5 cm. The intervention involves the use of a paver machine and a static roller, owned by a company located in the municipality of Ponsacco (PI), 14.4 km away, whose diesel fuel consumption was estimated at 24 L/h (at 2/3 load) and 11 L/h, respectively. Transportation of the work vehicles (total weight of about 10 t) and binder at the intervention site will always be done by vehicles owned by the aforementioned company. The intervention will take approximately 2 working days.

- The pump for the monitoring of groundwater;

- The transport and the process involved in the chemical analysis for the “certification of complete remediation” and for the following site monitoring;

- The process involved in the production of the machinery (excavator and bobcat) used for the operations;

- The periodic transport of the site manager;

- The transport of the employee.

2.2. Life Cycle Inventory (LCI)

2.3. Environmental Sensitivity Analysis

3. Results

- In the first case, the greater contributor is the End-of-Life process (landfill disposal), with small contributions of material production and transport for some categories. This is due to the few materials used for this scenario (quarry materials) and the use of vehicles already on the site for operations and a landfill located near the site.

- In the second case, the impact contributions are more variegated, but the greater contributors are the material production, represented mainly by TNT 300 production process (8–40%) and the binder production process (50–87%).

- The disposal process is not waste-specific, but has used the “Sludge from pulp and paper production disposal”, because the concentration described in SimaPro is similar to its composition;

- In the third scenario, the higher contributor to the potential impacts is the binder production process, which could be potentially replaced with other materials.

3.1. Sensitivity Analysis

3.1.1. Dig and Dump Scenario

3.1.2. Soil Capping Scenario

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Resources Outlook 2019. In Natural Resources for the Future We Want; United Nations: New York, NY, USA, 2020.

- Ellen MacArthur Foundation. The Business Opportunity of a Circular Economy. In An Introduction to Circular Economy; Liu, L., Ramakrishna, A., Eds.; Springer: Singapore, 2021; pp. 397–417. [Google Scholar] [CrossRef]

- Shukla, P.R. Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Araneo, F.; Bartolucci, E. Lo Stato Delle Bonifiche Dei Siti Contaminati in Italia; I Dati Regionali; Edizione 2021; Rapporti 337/21; ISPRA: Varese, Italy, 2021. [Google Scholar]

- European Commission. Joint Research Centre. Institute for Environment and Sustainability. Progress in the Management of Contaminated Sites in Europe; Publications Office: Luxembourg, 2014; Available online: https://data.europa.eu/doi/10.2788/4658 (accessed on 23 September 2022).

- Panagos, P.; Van Liedekerke, M.; Yigini, Y.; Montanarella, L. Contaminated Sites in Europe: Review of the Current Situation Based on Data Collected through a European Network. J. Environ. Public Health 2013, 2013, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Sichler, T.C.; Montag, D.; Barjenbruch, M.; Mauch, T.; Sommerfeld, T.; Ehm, J.-H.; Adam, C. Variation of the element composition of municipal sewage sludges in the context of new regulations on phosphorus recovery in Germany. Environ. Sci. Eur. 2022, 34, 84. [Google Scholar] [CrossRef] [PubMed]

- Nagajyoti, P.C.; Lee, K.D.; Sreekanth, T.V.M. Heavy metals, occurrence and toxicity for plants: A review. Environ. Chem. Lett. 2010, 8, 199–216. [Google Scholar] [CrossRef]

- Rahman, Z.; Singh, V.P. The relative impact of toxic heavy metals (THMs) (arsenic (As), cadmium (Cd), chromium (Cr)(VI), mercury (Hg), and lead (Pb)) on the total environment: An overview. Environ. Monit. Assess. 2019, 191, 419. [Google Scholar] [CrossRef] [PubMed]

- United States Environmental Protection Agency. Priority Pollutant List; United States Environmental Protection Agency: Washington, DC, USA, 2014.

- United States Environmental Protection Agency. Chromium Compounds Hazard Summary; United States Environmental Protection Agency: Washington, DC, USA, 2010.

- United States Environmental Protection Agency. National Primary Drinking Water Regulations; United States Environmental Protection Agency: Washington, DC, USA, 2009.

- Liu, L.; Li, W.; Song, W.; Guo, M. Remediation techniques for heavy metal-contaminated soils: Principles and applicability. Sci. Total Environ. 2018, 633, 206–219. [Google Scholar] [CrossRef] [PubMed]

- Sikdar, S.K.; Grosse, D.; Rogut, I. Membrane technologies for remediating contaminated soils: A critical review. J. Membr. Sci. 1998, 151, 75–85. [Google Scholar] [CrossRef]

- Pasciucco, F.; Pecorini, I.; Di Gregorio, S.; Pilato, F.; Iannelli, R. Recovery Strategies of Contaminated Marine Sediments: A Life Cycle Assessment. Sustainability 2021, 13, 8520. [Google Scholar] [CrossRef]

- Morais, S.A.; Delerue-Matos, C. A perspective on LCA application in site remediation services: Critical review of challenges. J. Hazard. Mater. 2010, 175, 12–22. [Google Scholar] [CrossRef] [Green Version]

- Bardos, P.; Bone, B.; Boyle, R.; Ellis, D.; Evans, F.; Harries, N.D.; Smith, J.W.N. Applying sustainable development principles to contaminated land management using the SuRF-UK framework: Applying Sustainable Development Principles to Contaminated Land Management Using the SuRF-UK Framework. Remediat. J. 2011, 21, 77–100. [Google Scholar] [CrossRef]

- Lemming, G.; Hauschild, M.Z.; Bjerg, P.L. Life cycle assessment of soil and groundwater remediation technologies: Literature review», Int. J. Life Cycle Assess. 2010, 15, 115–127. [Google Scholar] [CrossRef]

- Rocco, M.V.; Cassetti, G.; Gardumi, F.; Colombo, E. Exergy Life Cycle Assessment of soil erosion remediation technologies: An Italian case study. J. Clean. Prod. 2016, 112, 3007–3017. [Google Scholar] [CrossRef]

- Lesage, P.; Ekvall, T.; Deschênes, L.; Samson, R. Environmental assessment of brownfield rehabilitation using two different life cycle inventory models: Part 2: Case study. Int. J. Life Cycle Assess. 2007, 12, 497–513. [Google Scholar] [CrossRef]

- Hou, D.; Al-Tabbaa, A. Sustainability: A new imperative in contaminated land remediation. Environ. Sci. Policy 2014, 39, 25–34. [Google Scholar] [CrossRef]

- Sharma, H.B.; Vanapalli, K.R.; Samal, B.; Cheela, V.S.; Dubey, B.K.; Bhattacharya, J. Circular economy approach in solid waste management system to achieve UN-SDGs: Solutions for post-COVID recovery. Sci. Total Environ. 2021, 800, 149605. [Google Scholar] [CrossRef] [PubMed]

- Vaverková, M.D. Landfill impacts on the Environment—Review. Geosciences 2019, 9, 431. [Google Scholar] [CrossRef] [Green Version]

- Klüppel, H.-J. The Revision of ISO Standards 14040-3—ISO 14040: Environmental management Life cycle assessment Principles and framework—ISO 14044: Environmental management Life cycle assessment Requirements and guidelines. Int. J. Life Cycle Assess. 2005, 10, 165. [Google Scholar] [CrossRef]

- ISO 14044; International Standard. Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14040; Environmental management—Life cycle assessment—Principles and framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Italian Parliament. Italian Legislative Decree 3 April 2006 n. 152; Italian Parliament: Italy, Rome, 2006.

- Meoni, C. Proposta di Interventi di Confinamento Permanente dei Rilevati Realizzati Mediante Utilizzo di Materiali di Riporto Provenienti Dall’impianto di Recupero Lerose, S.r.l. di Pontedera—Relazione Ambientale; S.r.l. di Pontedera: Ponsacco, Italy, 2021. [Google Scholar]

- Corominas, L.; Byrne, D.M.; Guest, J.S.; Hospido, A.; Roux, P.; Shaw, A.; Short, M.D. The application of life cycle assessment (LCA) to wastewater treatment: A best practice guide and critical review. Water Res. 2020, 184, 116058. [Google Scholar] [CrossRef]

- Laurent, A.; Clavreul, J.; Bernstad, A.; Bakas, I.; Niero, M.; Gentil, E.; Christensen, T.H.; Hauschild, M.Z. Review of LCA studies of solid waste management systems—Part II: Methodological guidance for a better practice. Waste Manag. 2014, 34, 589–606. [Google Scholar] [CrossRef]

- International Reference Life Cycle Data System (ILCD) Handbook. General Guide for Life Cycle Assessment: Detailed Guidance, 1st ed.; Publications Office: Luxembourg, 2010. [Google Scholar]

- VanderBorght, J.; Vereecken, H. Review of Dispersivities for Transport Modeling in Soils. Vadose Zone J. 2007, 6, 29–52. [Google Scholar] [CrossRef]

- Lemming, G.; Chambon, J.C.; Binning, P.J.; Bjerg, P.L. Is there an environmental benefit from remediation of a contaminated site? Combined assessments of the risk reduction and life cycle impact of remediation. J. Environ. Manag. 2012, 112, 392–403. [Google Scholar] [CrossRef]

- Søndergaard, G.L.; Binning, P.J.; Bondgaard, M.; Bjerg, P.L. Multi-criteria assessment tool for sustainability appraisal of remediation alternatives for a contaminated site. J. Soils Sediments 2018, 18, 3334–3348. [Google Scholar] [CrossRef] [Green Version]

- Beames, A.; Broekx, S.; Lookman, R.; Touchant, K.; Seuntjens, P. Sustainability appraisal tools for soil and groundwater remediation: How is the choice of remediation alternative influenced by different sets of sustainability indicators and tool structures? Sci. Total Environ. 2014, 470–471, 954–966. [Google Scholar] [CrossRef] [PubMed]

- Salviati, M. Proposta di Interventi di Confinamento Permanente dei Rilevati Realizzati Mediante Utilizzo di Materiali di Riporto Provenienti Dall’impianto di Recupero Lerose, S.r.l. di Pontedera—Analisi di Rischio; S.r.l. di Pontedera: Livorno, Italy, 2021. [Google Scholar]

- Zahmak, A.; Abdallah, M.; Jarah, B.; Arab, M.G. Environmental performance of alkali-activated binders for ground improvement. Transp. Geotech. 2021, 31, 100631. [Google Scholar] [CrossRef]

- ISO Standard 19204; Soil Quality—Procedure for Site-Specific Ecological Risk Assessment of Soil Contamination (Soil Quality TRIAD Approach). International Organization for Standardization: Geneva, Switzerland, 2017.

| Samples | Unit | C1 | C2 | C3 | C4 | C5 | C6 | C7 | WAC 1 | CSC 2 | Natural Soil 3 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mass | kg | 928.7 | 764.7 | 4362.2 | - | 581.5 | 719.9 | 419.6 | Col. A | Col. B | ||

| Cd | mg/kg | 0.5 | 1.1 | 0.6 | 0.2 | 0.6 | 0.9 | 0.5 | 0.7 | 2.0 | 15.0 | 0.2 |

| Cr | mg/kg | 1232.0 | 2371.0 | 1853.0 | 38.0 | 3309.0 | 2775.0 | 1812.0 | 2021.8 | 150.0 | 800.0 | 107.0 |

| Cr(VI) | mg/kg | 9.0 | 15.0 | 9.4 | 0.6 | 8.9 | 5.0 | 6.0 | 9.3 | 2.0 | 15.0 | 2.0 |

| Ni | mg/kg | 55.0 | 53.0 | 58.0 | 22.0 | 48.0 | 66.0 | 34.0 | 55.8 | 120.0 | 500.0 | 102.0 |

| Pb | mg/kg | 26.0 | 63.0 | 26.0 | 17.0 | 30.0 | 31.0 | 24.0 | 30.3 | 100.0 | 1000.0 | 15.0 |

| Cu | mg/kg | 53.0 | 124.0 | 135.0 | 29.0 | 101.0 | 192.0 | 107.0 | 125.3 | 120.0 | 600.0 | 41.0 |

| Zn | mg/kg | 135.0 | 285.0 | 135.0 | 36.0 | 234.0 | 214.0 | 167.0 | 166.2 | 150.0 | 1500.0 | 90.0 |

| As | mg/kg | 5.8 | 7.8 | 7.6 | 3.1 | 6.5 | 6.9 | 6.6 | 7.2 | 20.0 | 75.0 | 8.7 |

| Sb | mg/kg | 7.3 | 18.0 | 9.0 | 1.0 | 13.0 | 15.0 | 12.0 | 10.7 | 10.0 | 30.0 | <1 |

| Be | mg/kg | 0.5 | 0.6 | 0.6 | 0.5 | 0.5 | 0.5 | 0.4 | 0.6 | 2.0 | 10.0 | 1.5 |

| Co | mg/kg | 8.4 | 9.3 | 9.0 | 5.0 | 9.3 | 13.0 | 6.7 | 9.2 | 20.0 | 250.0 | 13.0 |

| Fe | mg/kg | 25.488 | 25.928 | 20.905 | 10.052 | 32.567 | 36.184 | 22.204 | 24.302 | - | - | 31.775 |

| Mn | mg/kg | 442.0 | 350.0 | 473.0 | 321.0 | 387.0 | 423.0 | 301.0 | 436.9 | - | - | 582.0 |

| Mo | mg/kg | - | 3.1 | 1.9 | 0.3 | 3.6 | 1.9 | 2.7 | 2.0 | - | - | 6.5 |

| Hg | mg/kg | 0.6 | 0.7 | 0.1 | 0.1 | 0.2 | 0.3 | 1.5 | 0.3 | 1.0 | 5.0 | <0.1 |

| Se | mg/kg | 0.6 | 2.5 | 1.4 | 0.3 | 2.1 | 42.0 | 0.9 | 5.2 | 3.0 | 15.0 | 0.8 |

| Sn | mg/kg | - | 22.0 | 9.5 | 1.3 | 10.0 | 21.0 | 12.0 | 10.8 | 1.0 | 350.0 | 3.1 |

| Tl | mg/kg | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 1.0 | 10.0 | 0.3 |

| V | mg/kg | 25.0 | 22.0 | 29.0 | 23.0 | 25.0 | 23.0 | 18.0 | 26.4 | 90.0 | 250.0 | 78.0 |

| Processes | Ecoinvent 3.8 Records |

|---|---|

| Transportation of heavy equipment and materials | Transport, freight, lorry >32 metric ton, EURO5 {RER 4}| transport, freight, lorry >32 metric ton, EURO5|APOS 5, U |

| Transport of TNT and LDPE membranes | Transport, freight, light commercial vehicle {CH}| processing|APOS, U |

| Contaminants ground emission | Emission to soil |

| TNT 300 membrane production | Textile, nonwoven polyester {RoW3 6}|textile production, nonwoven polyester, needle-punched|APOS, U |

| LDPE membrane production | Polyethylene, low density, granulate {RER}|production|APOS, U |

| Quarry stabilizer production | Gravel, crushed {CH}|production|APOS, U |

| Binder production | Mastic asphalt {CH}|production|APOS, U |

| Diesel fuel production and consumption | Diesel, burned in building machine {GLO4 7}|market for|APOS, U |

| Landfill disposal | Sludge from pulp and paper production {Europe without Switzerland}|treatment of sludge from pulp and paper production, sanitary landfill|APOS, U |

| Scenario | Abiotic Depletion [kg Sb eq.] | Abiotic Depletion (Fuel) [MJ] | Global Warming [kg CO2 eq.] | Ozone Layer Depletion [kg CFC-11 eq.] * | Human Toxicity [kg 1.4-DB eq.] ** | Fresh Water Aquatic Ecotox. [kg 1.4-DB eq.] ** | Marine Aquatic Ecotox. [kg 1.4-DB eq.] ** | Terrestrial Ecotox. [kg 1.4-DB eq.] ** | Photochemical Oxidation [kg C2H4 eq.] | Acidification [kg SO2 eq.] |

|---|---|---|---|---|---|---|---|---|---|---|

| DN-DD | nd | nd | nd | nd | −69% | −25% | −45% | −99% | nd | nd |

| DN-SC | nd | nd | nd | nd | −98% | −98% | −97% | −100% | nd | nd |

| DD-SC | −88.8% | −70.5% | −99.4% | 10.8% | −92.6% | −97.9% | −94.7% | −94.0% | −98.9% | −94.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castagnoli, A.; Pasciucco, F.; Iannelli, R.; Meoni, C.; Pecorini, I. Keu Contamination in Tuscany: The Life Cycle Assessment of Remediation Project as a Decision Support Tool for Local Administration. Sustainability 2022, 14, 14828. https://doi.org/10.3390/su142214828

Castagnoli A, Pasciucco F, Iannelli R, Meoni C, Pecorini I. Keu Contamination in Tuscany: The Life Cycle Assessment of Remediation Project as a Decision Support Tool for Local Administration. Sustainability. 2022; 14(22):14828. https://doi.org/10.3390/su142214828

Chicago/Turabian StyleCastagnoli, Alessio, Francesco Pasciucco, Renato Iannelli, Carlo Meoni, and Isabella Pecorini. 2022. "Keu Contamination in Tuscany: The Life Cycle Assessment of Remediation Project as a Decision Support Tool for Local Administration" Sustainability 14, no. 22: 14828. https://doi.org/10.3390/su142214828