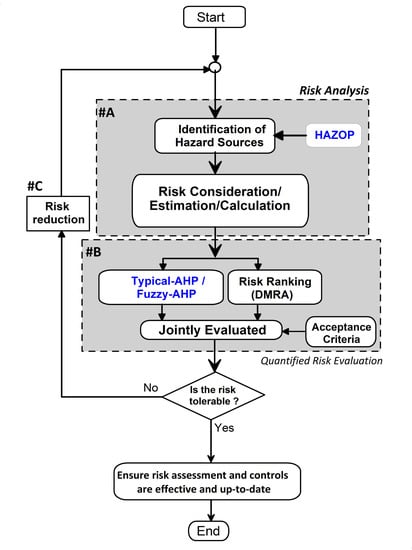

4.2. Application of the HAZOP Process

The systematic HAZOP study was executed in a SCOPI, which is placed in NE-Greece, by the members of the HAZOP team which consisted of two unit-operators, e.g., the plant-operation administrator and the maintenance-department manager. The installation-operation superintendent is a capable chemical engineer with substantial capability in CPIs, whereas the maintenance-department superintendent is a mechanical engineer. The plant-operators have a significant ability for operating the SCOPI’s units, and important experience on preceding incidents. The HAZOP sessions were accomplished through a six-month period, including entirely twelve sessions. The first two sessions included the explanation of the SCOPI process to the team, and also the selection of the HAZOP-nodes. Below, it is collocated the essential steps for implementing the HAZOP process, as follows:

(1) Selection of the nodes and intentions: Taking into consideration the equipment’s operation and their interconnectivity, wholly nine nodes were chosen, such as:

- (i)

“Node–1“, which is the “Water-injection system”

- (ii)

“Node–2“, which is the “Reheating/cooling exchangers”

- (iii)

“Node–3“, that means, the “Desalting process unit”

- (iv)

“Node–4“, i.e., the “Low-Pressure L.P. separator”

- (v)

“Node–5“, which is the “Crude stabilizer column”

- (vi)

“Node–6“, that means the “Gas compressor”

- (vii)

“Node–7“, e.g., the “Compressor gas cooling and liquids recovery”

- (viii)

“Node–8“, i.e., the “Condensate stripper column” that feeds vessel and “Pump P103”

- (ix)

“Node–9“, the “Condensate s t r i p p e r and cooling unit”

(2) Guideword and safe limits of the process: The central idea of HAZOP method is the identification: (a) of deviations (i.e., hazards) from the normal and prospective (by the design) safe-state, and also (ii) the crucial process parameters, like: “Composition”, “Flow”, “Level”, “Phase”, “Pressure” and “Temperature”. Moreover, the proper guidewords concerning the deviation from the safe operation are: “Less”, “More”, “No”, “Other than” and “Reverse”, which are combined with the previous referred process factors (parameters) in order to define the deviation from the conditions of a safe situation.

(3) The identification of the causes and the hazards: This step is realized after the previously referred two steps, whence the HAZOP team identifies the root causes for any hazard that is associated with a particular node.

(4) The determination of consequences: At this step, the members of the HAZOP team define the consequences of any hazard in association with safety, environmental, and economical aspects.

(5) The identification of safeguards: At this step, the HAZOP team documents, in a HAZOP-worksheet, the related safeguards in order to recognize the hazards and prevent the consequences.

(6) Recommendations: At this step, the necessary recommendations about decreasing the risk-level are discussed and analyzed by HAZOP’s team members and are recorded in the worksheet of HAZOP.

It is worthwhile to mention, that the risk-matrix used in RAA, will have the structure presented by

Table 4, involved in the paper of Marhavilas et al. (2019) [

2]. Thus, (i) the probability of the recognized hazards and (ii) the failure-rate of ordinary control-equipment (like level/pressure-transmitters), were specified by the usage of an information-base of preceding incidents in SCOPI-units with equivalent equipment. On the other side, the evaluation of the hazards severity was performed with the accordance of the team’s members and their individual decision. Besides,

Table 5 illustrates the “Guidewords“ and “Elements”, which were used to generate the deviations produced by the HAZOP procedure.

At the beginning of the study, we depicted by drawing colored dashed-line frames, the existence of the previously referred nine nodes, as structural parts of the unit’s ‘process-flow-diagram’ (PFD) presented in

Figure 1.

The first node (Node-1) which is the water-injection system, was analyzed (by HAZOP) in association with the general process parameters (or elements) of “Level”, “Pressure”, “Flow” and “Containment”.

Node-2, i.e., the preheating and cooling exchangers, was analyzed taking into account the elements “Flow”, “Pressure”, “Temperature”, “Composition” and “Containment”.

The HAZOP analysis of the installation’s desalting vessel (i.e., Node-3) was achieved by using the elements “Level”, “Flow”, “Pressure”, “Temperature”, “Composition” and “Containment”.

Besides, the HAZOP analysis of the low-pressure separator vessel (of Node-4) was conducted in association with the process parameters: “Level”, “Flow”, “Pressure”, “Phase” and “Containment”.

Node-5, which is the crude stabilization column-group of equipment, was HAZOP-analyzed taking into consideration the elements of “Composition”, “Containment”, “Flow”, “Level”, “Pressure” and “Temperature”.

What is more, Node-6 (i.e., the ‘gas compressor station’ and its supplementary scrubber vessel) was analyzed taking into account the elements of “Containment”, “Flow”, “Level”, “Phase”, “Pressure”, and “Temperature”.

In addition, the HAZOP analysis of the compressor gas cooling and liquid-recovery system (in Node-7), was performed by the elements “Containment”, “Flow”, “Level”, “Pressure” and “Temperature”.

Moreover, Node-8, i.e., the condensate stripper column that feeds vessel V-107 and pump P103, was HAZOP-analyzed in association with the elements of “Containment”, “Flow”, “Level”, and “Pressure”.

Finally, the HAZOP analysis in Node-9, which is the condensate stripper and cooling system of the facility, was applied by the elements “Containment”, “Flow”, “Level”, “Pressure” and “Temperature”.

Taking into consideration the sizable SCOPI’s plant, the large number of the HAZOP-nodes, and their operability as well, we concentrated, via this article, on a considerable node of the SCOPI’s plant, as far as the risk is concerned. More explicitly, we selected Node-5, for applying (as an instance) the conventional HAZOP-DMRA technique, in order to identify the likely fault causes due to irregular deviations. Hence, for this node, which is shown in

Figure 3, we operate and implement HAZOP analysis using the elements “Level”, “Flow”, “Pressure”, “Temperature”, “Composition” and “Containment” having as final outcomes the ones shown in

Table A1,

Table A2,

Table A3,

Table A4,

Table A5 and

Table A6, correspondingly. We elucidate, that the conventional HAZOP/DMRA technique was also performed for the rest nodes in order to achieve the full application of the HAZOP-DMRA scheme in the specific SCOPI.

In the tables originated from the HAZOP study, all the plausible sources and hazards due to a particular deviation have been defined, and with the intention that HAZOP study forms a useful guide for providing a list of priorities to the maintenance/inspection staff. Many of them are ordinary for multiple deviations and some additional analysis was essential to determine distinctive hazards, which have been categorized into the next three classes: The first one corresponds to ‘

hazards to human life and the environment’ and has been analyzed thoroughly in the work of Marhavilas et al. (2019) [

2]. The second one, presents the ‘

operability hazards’ i.e., the ones associated with the product quality and economic operation of the establishment and will be analyzed comprehensively in a forthcoming work. Finally, the third category includes the ‘

hazards with both economic and health (or environmental) impact’, which means the hazards that influence the economical performance of the establishment and concurrently cause a risk to human life and/or to the environment, and they are depicted in

Table 6.

Several serious deviations (given by

Table 6) are the ‘

H2S releasing’ and also the ‘

hydrocarbons releasing’, taking into consideration the impacts of bad-breathing that might have happened to people, producing substantial problems concerning health. What is more, when

hydrocarbons are taken into consideration, these would be liquid and/or gas. The discrimination can be hard due to the volatility of these components. In addition, “

NGL” can be in liquid form, inside a vessel under pressure, and be evaporated nearly immediately, when it is exposed to atmospheric conditions. An additional important aspect, which has financial effects on the plant’s operations, is the

crude-oil storage, when this specific kind of crude-oil does have proper quality specifications (for instance, due to enhanced

H2S content, and/or because of the existence of water/salt content).

4.3. Application of the Typical-AHP and Fuzzy-AHP Processes

In light of the outcomes of the prior HAZOP/DMRA scheme (shown by

Table 6), we continue to the subsequent stage, e.g., the execution of the Typical-AHP and Fuzzy-AHP processes, on the SCOPI’s plant (as a case study), by the usage of the hazards depicted in

Table 6, so as to entirely implement the HAZOP_TAHP/FAHP approach.

The problem of assessing eight hazard factors with health and environmental impacts in a SCOPI is modeled by a hierarchy in which the goal is safety’s prevention while the first level consists of eight hazard factors (

Figure 4).

It is worthwhile to mention that, the decision-maker fills the pair-wise comparison matrix presented in

Table 7 with numbers that correspond to his preferences about the risks’ relative importance, as described by linguistic variables (

Table 1 and

Table 2). Firstly, the Typical-AHP is applied to calculate each hazard’s weight and construct the ranking. An important element of the Typical-AHP calculation is the consistency-ratio (CR) estimation, which, in a case that is below 10% means that the judgments of the expert are consistent and the ranking is reliable. Note that, in the present case the consistency-ratio is found to be CR ≤ 10%.

The weights for each hazard calculated by Typical-AHP and F_AHP, are illustrated in

Table 8 and also the rankings of hazards extracted by each method, in descending order of importance. It is worth mentioning that both methods use as input the same judgments pair-wise comparison matrix.

According to the Typical-AHP calculations, the factors “NGL release in the sea” (08) and “C-101 damage due to overheating” (06) are more important since their weights are 28.17% and 22.53%, respectively. The second more important group consists of the factor “Higher temperature crude to tanks due to more oil flow” (01) with weight of 16.5%, and the (04) “Volatile hydrocarbons to crude storage tanks from V-102” with 12.22% score. The third more important group includes hazards with small differences on their weights but they are responsible for the 20.57% (cumulatively) of the total risk. The risk factors belonging to this group are “Hydrate formation in V-110” (07), “No crude stabilization due to column flooding” (03), “Stabilized crude containing H2S due to leak in E-102” (02), and “Stabilized crude containing H2S due gas from V-102” (05).

The calculation with Fuzzy-AHP, results to a same ranking of the hazards, as shown in the last column of

Table 8. However, the distance of the weights between the first factor [08] and the second factor [06] is dramatically reduced, meaning that the F_AHP can better describe the uncertainty of the expert’s choices. Additionally, it is observed that except the ranked—as more important—hazards, the scores of all the other hazards are increased, and especially the financial impact hazards ([06], [01], [03]) are responsible (cumulatively) for the 51.62% of the total risk instead of the 45.22% found by T_AHP. In addition, the scores of the hazards with impact on the workers’ health are higher than these computed by Typical-AHP, namely the factor [04] is weighted to 16.14% and [07] to 10.26%. This finding is of great interest for business managers and safety executives who, usually, are concerned more about workers’ safety and health issues, as well as, about business profits, rather than impacts on the environment. Additionally, the above findings could be used for prioritizing investments in health and safety prevention measurements.

These results verify the findings of the recent study of Chan et al. (2019) [

62] wherein the circumstances under which the F_AHP is preferred over Typical-AHP are stated. More specifically, in our case, quantitative difference was observed while the pair-wise comparison matrix is highly consistent, and the importance of hazards is relatively close to one another. Due to the presence of the above conditions, the F_AHP is used, having as a result the efficiency’s rising of the proposed approach, since the proven ability of Fuzzy-AHP to handle uncertainty is necessary for applications such as risk assessment in industry where ambiguous conclusions might affect health and safety of employees.

In the beginning of this article, the execution of the conventional HAZOP study is attained, to identify the potential consequences and causes which correspond to irregular conditions. Thus, several serious hazards/deviations (depicted in

Table 6) are the following: “hydrocarbons releasing”, “H

2S releasing”, and “NGL releasing”, with regards to affecting breathing that may happen to people, causing substantial problems to their health. In association with the results of the HAZOP technique, on the one hand, and also the utilization of the DMRA for risk-ranking, on the other side, the T_AHP and the F_AHP procedure is then applied consecutively, to expand HAZOP study by prioritizing the risks in the SCOPI’s establishment. The choice of the explicit SCOPI for executing the HAZOP study is greatly valuable for the implementation of this approach, due to a variety of hazards included in the process, and because of its innovative design.

The hazards’ recognition (by HAZOP study) denotes that we could systematically assess and judge the SCO process. This technique can be, consequently, considered as an efficient method, for hazards’ identification and prediction, and it may enhance the safety levels, obstruct accidents and increase the reliability of systems, through the decrease of operational and environmental problems [

13]. The specific SCOPI, under consideration in this article, was proved to be trustworthy and safe, at such a level that right establishment inspections and maintenance are imposed. The arranged approach and systematic analysis that HAZOP technique provides, is a brilliant tool for judging the SCOPI’s parts’ operation. In general, the equipment of chemical industries (and of SCOPIs as well) is extremely expensive, because of the unique technical and quality specifications, and due to the fact, that such equipment is regularly custom-engineered to particular applications. Therefore, any act of changing (entirely or partially) the equipment, creates significant economic consequences to the corporation. To be brief, the examined SCOPI’s plant, despite its lengthy lifetime, presents tolerable risk in its functioning, because of the appropriate inspection and maintenance [

2].

The main results derived by applying the T_AHP and F_AHP are the following: (i) The outcomes of the T_AHP and F_AHP process, agree (between them) on the final results as far as the hazards’ ranking is concerned; (ii) The most important source of risk is the deviation Nr [08], which has an environmental impact. This finding is of great value given the fact, that both at the state/national level (with the development of a legislative framework for environmental impacts) and also at the international level (with global transnational agreements on the environmental impact of industrial activity), the international community is becoming more and more aware of environmental issues (e.g., CO2 footprint, climate change, industrial pollutants, etc.); (iii) F_AHP enhances (in comparison with T_AHP) the hazards’ importance factors which have impacts on the financial consequences on the company (e.g., deviations [06], [01], [03], [02]), as well as the impact on employee health (e.g., deviations [04], [07]). This may be of greater interest to business manager and safety executives, who are firstly concerned with the safety/health of workers, and the economical factor of their business, and less with the impact on the environment.

In the present approach, we used F_AHP and T_AHP, so as to rank hazards, while exploiting the expertise of the decision-maker. The hazards’ ranking using F_AHP remains the same with the ranking using T_AHP, but the scores for each hazard are quite different, and the relative distances between them are smaller/larger, respectively. These different scores are very important, in case of spending budget, to safety measures, as they can lead to over/under-investing in measures for a hazard, resulting to lower effectiveness in prevention of accidents. Additionally, as stated in Chan et al. (2019) [

62], given that there are present “

judgments with dominant preference and equal important elements” in our case, the total effectiveness of the approach could be benefited by using the Fuzzy-AHP.