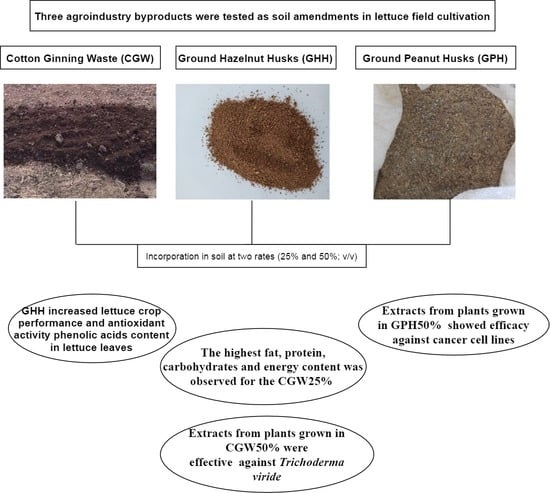

The Sustainable Use of Cotton, Hazelnut and Ground Peanut Waste in Vegetable Crop Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material and Growing Conditions

2.2. Nutritional Value and Hydrophilic Compounds

2.2.1. Macronutrients and Energetic Value

2.2.2. Free Sugars

2.2.3. Organic Acids

2.3. Lipophilic Compounds

2.3.1. Fatty Acids

2.3.2. Tocopherols

2.4. Phenolic Compounds Characterization

2.4.1. Extracts Preparation

2.4.2. Phenolic Compounds

2.5. Selected Bioactivities

2.5.1. Antioxidant Activity

2.5.2. Cytotoxicity Assays

2.5.3. Antimicrobial Properties

2.6. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Petropoulos, S.; Fernandes, Â.; Stojković, D.; Pereira, C.; Taofiq, O.; Di Gioia, F.; Tzortzakis, N.; Soković, M.; Barros, L.; Ferreira, I. Cotton and cardoon byproducts as potential growing media components for Cichorium spinosum L. commercial cultivation. J. Clean. Prod. 2019, 240, 118254. [Google Scholar] [CrossRef] [Green Version]

- Morales, A.B.; Ros, M.; Ayuso, L.M.; Bustamante, M.D.L.A.; Moral, R.; Pascual, J.A. Agroindustrial composts to reduce the use of peat and fungicides in the cultivation of muskmelon seedlings. J. Sci. Food Agric. 2017, 97, 875–881. [Google Scholar] [CrossRef] [PubMed]

- FAOSTAT Production and Trade Statistics. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 28 September 2020).

- Zied, D.C.; Prado, E.P.; Dias, E.S.; Pardo, J.E.; Pardo-gimenez, A. Use of peanut waste for oyster mushroom substrate supplementation—oyster mushroom and peanut waste. Braz. J. Microbiol. 2019, 50, 1021–1029. [Google Scholar] [CrossRef] [PubMed]

- Nalluri, N.; Karri, V.R. Use of groundnut shell compost as a natural fertilizer for the cultivation of vegetable plants. Int. J. Adv. Res. Sci. Eng. 2018, 7, 97–104. [Google Scholar]

- Mennan, H.; Ngouajio, M. Effect of Brassica Cover Crops and Hazelnut Husk Mulch on Weed Control in Hazelnut Orchards. Horttechnology 2012, 22, 99–105. [Google Scholar] [CrossRef] [Green Version]

- Özenç, D.B. Growth and Transpiration of Tomato Seedlings Grown in Hazelnut Husk Compost Under Water- Deficit Stress Growth and Transpiration of Tomato Seedlings Grown in Hazelnut Husk Compost Under Water-Deficit Stress. Compost Sci. Util. 2008, 16, 125–131. [Google Scholar] [CrossRef]

- Kazemi, H.; Shokrgozar, M.; Kamkar, B.; Soltani, A. Analysis of cotton production by energy indicators in two different climatic regions. J. Clean. Prod. 2018, 190, 729–736. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Andreou, K. Development of alternative energy sources for GHG emissions reduction in the textile industry by energy recovery from cotton ginning waste. J. Clean. Prod. 2010, 18, 784–790. [Google Scholar] [CrossRef]

- De Corato, U.; De Bari, I.; Viola, E.; Pugliese, M. Assessing the main opportunities of integrated biorefining from agro-bioenergy co/by-products and agroindustrial residues into high-value added products associated to some emerging markets: A review. Renew. Sustain. Energy Rev. 2018, 88, 326–346. [Google Scholar] [CrossRef]

- Guney, M.S. Utilization of hazelnut husk as biomass. Sustain. Energy Technol. Assess. 2013, 4, 72–77. [Google Scholar] [CrossRef]

- Branca, C.; Di Blasi, C. A unified mechanism of the combustion reactions of lignocellulosic fuels. Thermochim. Acta 2013, 565, 58–64. [Google Scholar] [CrossRef]

- Demirbas, A. Fuel Properties of Pyrolysis Oils from Biomass. Energy Sources Part A Recover. Util. Environ. Eff. 2009, 31, 412–419. [Google Scholar] [CrossRef]

- Dede, O.H.; Dede, G.; Ozdemir, S.; Abad, M. Physicochemical characterization of hazelnut husk residues with different decomposition degrees for soilless growing media preparation. J. Plant Nutr. 2011, 34, 1973–1984. [Google Scholar] [CrossRef]

- Papafotiou, M.; Vagena, A. Cotton gin trash compost in the substrate reduces the daminozide spray dose needed to produce compact potted chrysanthemum. Sci. Hortic. 2012, 143, 102–108. [Google Scholar] [CrossRef]

- Papamichalaki, M.; Papadaki, A.; Tzortzakis, N. Substitution of peat with municipal solid waste compost in watermelon seedling production combined with fertigation. Chil. J. Agric. Res. 2014, 74, 452–459. [Google Scholar] [CrossRef] [Green Version]

- Rincón, L.F.; García, A.L.; Madrid, R.; Valverde, M.; Del Amor, F.M. Use of almond shell and almond hull as substrates for sweet pepper cultivation. Effects on fruit yield and mineral content. Span. J. Agric. Res. 2013, 11, 164. [Google Scholar]

- Torkashvand, A.M.; Mahboub, M.A.A. The reuse of peanut organic wastes as a growth medium for ornamental plants. Int. J. Recycl. Org. Waste Agric. 2015, 4, 85–94. [Google Scholar] [CrossRef] [Green Version]

- Khah, E.M.; Petropoulos, S.A.; Karapanos, I.C.; Passam, H.C. Evaluation of growth media incorporating cotton ginning by-products for vegetable production. Compost Sci. Util. 2012, 20, 24–28. [Google Scholar] [CrossRef]

- Özenç, D.B. Effects of Composted Hazelnut Husk On Growth of Tomato Plants Effects of Composted Hazelnut Husk. Compost Sci. Util. 2006, 14, 271–275. [Google Scholar] [CrossRef]

- Özenç, D.B.; Özenç, N. The Effect of Hazelnut Husk Compost and Some Organic and Inorganic Media on Root Growth of Kiwifruit (Actinidia deliciosa). J. Agron. 2007, 6, 113–118. [Google Scholar]

- Tejada, M.; Gonzalez, J.L. Crushed cotton gin compost on soil biological properties and rice yield. Eur. J. Agron. 2006, 25, 22–29. [Google Scholar] [CrossRef]

- Dixon, G.; Aldous, D. Horticulture: Plants for People and Places, Volume 2; Dixon, G., Aldous, D., Eds.; Springer: Dordrecht, The Netherlands, 2014; ISBN 9789401785808. [Google Scholar]

- Ozdemir, S.; Dede, O.H.; Dede, G. Comparison of the composting performance of four different sewage sludge amendments. Compost Sci. Util. 2014, 22, 207–215. [Google Scholar] [CrossRef]

- Krstić, V.; Urošević, T.; Pešovski, B. A review on adsorbents for treatment of water and wastewaters containing copper ions. Chem. Eng. Sci. 2018, 192, 273–287. [Google Scholar] [CrossRef]

- AOAC Official methods of analysis of AOAC International. In Official Methods of Analysis of AOAC International; Horwitz, W.; Latimer, G. (Eds.) MD: AOAC International: Gaithersburg, MD, USA, 2016. [Google Scholar]

- Da Silva, L.P.; Pereira, E.; Pires, T.C.; Alves, M.J.; Pereira, O.R.; Barros, L.; Ferreira, I.C. Rubus ulmifolius Schott fruits: A detailed study of its nutritional, chemical and bioactive properties. Food Res. Int. 2019, 119, 34–43. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pereira, C.; Barros, L.; Carvalho, A.M.; Ferreira, I.C. Use of UFLC-PDA for the analysis of organic acids in thirty-five species of food and medicinal plants. Food Anal. Methods 2013, 6, 1337–1344. [Google Scholar] [CrossRef]

- Spréa, R.M.; Fernandes, Â.; Calhelha, R.C.; Pereira, C.; Pires, T.C.S.P.; Alves, M.J.; Canan, C.; Barros, L.; Amaral, J.S.; Ferreira, I.C. Chemical and bioactive characterization of the aromatic plant Levisticum officinale W.D.J. Koch: A comprehensive study. Food Funct. 2020, 11, 1292–1303. [Google Scholar] [CrossRef] [PubMed]

- Bessada, S.M.F.; Barreira, J.C.M.; Barros, L.; Ferreira, I.C.; Oliveira, M.B.P.P. Phenolic profile and antioxidant activity of Coleostephus myconis (L.) Rchb.f.: An underexploited and highly disseminated species. Ind. Crop. Prod. 2016, 89, 45–51. [Google Scholar] [CrossRef] [Green Version]

- Abreu, R.M.; Ferreira, I.C.; Calhelha, R.C.; Lima, R.T.; Vasconcelos, M.H.; Adega, F.; Chaves, R.; Queiroz, M.-J.R.P. Anti-hepatocellular carcinoma activity using human HepG2 cells and hepatotoxicity of 6-substituted methyl 3-aminothieno[3,2-b]pyridine-2-carboxylate derivatives: In vitro evaluation, cell cycle analysis and QSAR studies. Eur. J. Med. Chem. 2011, 46, 5800–5806. [Google Scholar] [CrossRef] [Green Version]

- Soković, M.; Glamočlija, J.; Marin, P.D.; Brkić, D.; van Griensven, L.J.L.D. Antibacterial effects of the essential oils of commonly consumed medicinal herbs using an in vitro model. Molecules 2010, 15, 7532–7546. [Google Scholar] [CrossRef] [Green Version]

- Riley, E.; Kraus, H.T.; Bilderback, T.E.; Jackson, B.E. Composted cotton stalks and cotton gin trash substrate amendments and irrigation/ground cover management I. Effect on physical and chemical properties of pine bark and pine tree substrates. J. Environ. Hortic. 2016, 32, 133–140. [Google Scholar] [CrossRef]

- Ozdemir, S.; Dede, O.H.; Yaqub, M. Assessment of Long-Term Nutrient Effective Waste-Derived Growth Media for Ornamental Nurseries. Waste Biomass Valorization 2017, 8, 2663–2671. [Google Scholar] [CrossRef]

- Aşkın, T.; Aygün, S. Does hazelnut husk compost (HHC) effect on soil water holding capacity (WHC)? An environmental approach. Eurasian J. Soil Sci. 2018, 7, 87–92. [Google Scholar] [CrossRef]

- Gülser, C.; Kızılkaya, R.; Askın, T.; Ekberli, I. Changes in Soil Quality by Compost and Hazelnut Husk Applications in a Hazelnut Orchard. Compost Sci. Util. 2015, 23, 135–141. [Google Scholar] [CrossRef]

- Gülser, C.; Candemir, F. Soil Science and Plant Nutrition Effects of agricultural wastes on the hydraulic properties of a loamy sand cropland in Turkey Effects of agricultural wastes on the hydraulic properties of a loamy sand cropland in Turkey. Soil Sci. Plant Nutr. 2015, 61, 384–391. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.J.; Moon, Y.; Tou, J.C.; Mou, B.; Waterland, N.L. Nutritional value, bioactive compounds and health benefits of lettuce (Lactuca sativa L.). J. Food Compos. Anal. 2016, 49, 19–34. [Google Scholar] [CrossRef]

- Fallovo, C.; Rouphael, Y.; Rea, E.; Battistelli, A.; Colla, G. Nutrient solution concentration and growing season affect yield and quality of Lactuca sativa L. var. acephala in floating raft culture. J. Sci. Food Agric. 2009, 89, 1682–1689. [Google Scholar]

- Mou, B. Nutritional quality of lettuce. Curr. Nutr. Food Sci. 2012, 8, 177–187. [Google Scholar] [CrossRef]

- Awad, Y.M.; Lee, S.-E.; Ahmed, M.B.M.; Vu, N.T.; Farooq, M.; Kim, I.S.; Kim, H.S.; Vithanage, M.; Usman, A.R.A.; Al-Wabel, M.; et al. Biochar, a potential hydroponic growth substrate, enhances the nutritional status and growth of leafy vegetables. J. Clean. Prod. 2017, 156, 581–588. [Google Scholar] [CrossRef]

- Atila, F.; Tuzel, Y.; Fernández, J.A.; Cano, A.F.; Sen, F. The effect of some agro– industrial wastes on yield, nutritional characteristics and antioxidant activities of Hericium erinaceus isolates. Sci. Hortic. 2018, 238, 246–254. [Google Scholar] [CrossRef]

- Barcelos, C.; Machado, R.M.A.; Alves-Pereira, I.; Ferreira, R.; Bryla, D.R. Effects of substrate type on plant growth and nitrogen and nitrate concentration in spinach. Int. J. Plant Biol. 2017, 7, 44–47. [Google Scholar] [CrossRef] [Green Version]

- Hernández, T.; Chocano, C.; Moreno, J.L.; García, C. Use of compost as an alternative to conventional inorganic fertilizers in intensive lettuce (Lactuca sativa L.) crops-Effects on soil and plant. Soil Tillage Res. 2016, 160, 14–22. [Google Scholar] [CrossRef]

- Barickman, T.C.; Horgan, T.E.; Wheeler, J.R.; Sams, C.E. Elevated levels of potassium in greenhouse-grown red Romaine lettuce impacts mineral nutrient and soluble sugar concentrations. HortScience 2016, 51, 504–509. [Google Scholar] [CrossRef] [Green Version]

- Fallovo, C.; Rouphael, Y.; Cardarelli, M.; Rea, E.; Battistelli, A.; Colla, G. Yield and quality of leafy lettuce in response to nutrient solution composition and growing season. J. Food Agric. Environ. 2009, 7, 456–462. [Google Scholar]

- El-Nakhel, C.; Petropoulos, S.A.; Pannico, A.; Kyriacou, M.C.; Giordano, M.; Colla, G.; Dario, A.; Vitaglione, P.; Pascale, S. De The bioactive profile of lettuce produced in a closed soilless system as configured by combinatorial effects of genotype and macrocation supply composition. Food Chem. 2020, 309, 125713. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wang, L.; Li, T.; Yang, Q.; Guo, W. Sugar accumulation and growth of lettuce exposed to different lighting modes of red and blue LED light. Sci. Rep. 2019, 9, 6926. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Va, V.; Miliauskien, J.; Novi, A.; Lau, K. The distinct impact of multi-color LED light on nitrate, amino acid, soluble sugar and organic acid contents in red and green leaf lettuce cultivated in controlled environment. Food Chem. 2020, 310, 125799. [Google Scholar]

- Samuolienė, G.; Viršilė, A.; Haimi, P.; Miliauskienė, J. Photoresponse to different lighting strategies during red leaf lettuce growth. J. Photochem. Photobiol. B Biol. 2020, 202, 111726. [Google Scholar] [CrossRef]

- Becker, C.; Kläring, H.P. CO2 enrichment can produce high red leaf lettuce yield while increasing most flavonoid glycoside and some caffeic acid derivative concentrations. Food Chem. 2016, 199, 736–745. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Wei, S.; Liu, B.; Guo, D.; Zheng, B.; Feng, L.; Liu, Y.; Tomás-Barberán, F.A.; Luo, L.; Huang, D. A novel integrated non-targeted metabolomic analysis reveals significant metabolite variations between different lettuce (Lactuca sativa. L) varieties. Hortic. Res. 2018, 5, 33. [Google Scholar] [CrossRef] [Green Version]

- Petropoulos, S.A.; Fernandes, Â.; Dias, M.I.; Pereira, C.; Calhelha, R.; Gioia, F.D.; Tzortzakis, N.; Ivanov, M.; Sokovic, M.; Barros, L.; et al. Wild and cultivated Centaurea raphanina subsp. mixta: A valuable source of bioactive compounds. Antioxidants 2020, 9, 314. [Google Scholar] [CrossRef]

- Petropoulos, S.; Karkanis, A.; Fernandes, Â.; Barros, L.; Ferreira, I.C.; Ntatsi, G.; Petrotos, K.; Lykas, C.; Khah, E. Chemical composition and yield of six genotypes of common purslane (Portulaca oleracea L.): An alternative source of omega-3 fatty acids. Plant Foods Hum. Nutr. 2015, 70, 420–426. [Google Scholar] [CrossRef]

- Pereira, C.; Dias, M.I.; Petropoulos, S.A.; Plexida, S.; Chrysargyris, A.; Tzortzakis, N.; Calhelha, R.C.; Ivanov, M.; Stojković, D.; Soković, M.; et al. The Effects of Biostimulants, Biofertilizers and Water-Stress on Nutritional Value and Chemical Composition of Two Spinach Genotypes (Spinacia oleracea L.). Molecules 2019, 24, 4494. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, D.E.; Shang, X.; Assefa, A.D.; Keum, Y.S.; Saini, R.K. Metabolite profiling of green, green/red, and red lettuce cultivars: Variation in health beneficial compounds and antioxidant potential. Food Res. Int. 2018, 105, 361–370. [Google Scholar] [CrossRef]

- Ko, E.Y.; Choi, J.H.; Keum, Y. Characterization of nutritionally important phytoconstituents in minimally processed ready-to-eat baby-leaf vegetables using HPLC–DAD and GC–MS. J. Food Meas. Charact. 2016, 10, 341–349. [Google Scholar]

- Samuolienė, G.; Brazaitytė, A.; Sirtautas, R.; Viršilė, A.; Sakalauskait, J.; Sakalauskienė, S.; Duchovskis, P. LED illumination affects bioactive compounds in romaine baby leaf lettuce. J. Sci. Food Agric. 2013, 93, 3286–3291. [Google Scholar] [CrossRef] [PubMed]

- Samuolienė, G.; Sirtautas, R.; Brazaitytė, A.; Duchovskis, P. LED lighting and seasonality effects antioxidant properties of baby leaf lettuce. Food Chem. 2012, 134, 1494–1499. [Google Scholar] [CrossRef] [PubMed]

- Petropoulos, S.A.; Fernandes, Â.; Dias, M.I.; Pereira, C.; Calhelha, R.C.; Chrysargyris, A.; Tzortzakis, N.; Ivanov, M.; Sokovic, M.D.; Barros, L.; et al. Chemical composition and plant growth of Centaurea raphanina subsp. mixta plants cultivated under saline conditions. Molecules 2020, 25, 2204. [Google Scholar]

- Petropoulos, S.A.; Fernandes, Â.; Dias, M.I.; Pereira, C.; Calhelha, R.C.; Ivanov, M.; Sokovic, M.D.; Ferreira, I.C.; Barros, L. The Effect of Nitrogen Fertigation and Harvesting Time on Plant Growth and Chemical Composition of Centaurea raphanina subsp. mixta (DC.) Runemark. Molecules 2020, 25, 3175. [Google Scholar] [CrossRef] [PubMed]

- Petropoulos, S.A.; Fernandes, Â.; Dias, M.I.; Vasilakoglou, I.B.; Petrotos, K.; Barros, L.; Ferreira, I.C. Nutritional value, chemical composition and cytotoxic properties of common purslane (Portulaca oleracea L.) in relation to harvesting stage and plant part. Antioxidants 2019, 8, 293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Petropoulos, S.A.; Fernandes, Â.; Tzortzakis, N.; Sokovic, M.; Ciric, A.; Barros, L.; Ferreira, I.C. Bioactive compounds content and antimicrobial activities of wild edible Asteraceae species of the Mediterranean flora under commercial cultivation conditions. Food Res. Int. 2019, 119, 859–868. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Petropoulos, S.A.; Fernandes, Â.; Katsoulas, N.; Barros, L.; Ferreira, I.C. The effect of covering material on the yield, quality and chemical composition of greenhouse-grown tomato fruit. J. Sci. Food Agric. 2019, 99, 3057–3068. [Google Scholar] [CrossRef] [PubMed]

- Helyes, L.; Lugasi, A.; Daood, H.G.; Pék, Z. The simultaneous effect of water supply and genotype on yield quantity, antioxidants content and composition of processing tomatoes. Not. Bot. Horti Agrobot. Cluj Napoca 2014, 42, 143–149. [Google Scholar] [CrossRef] [Green Version]

- Pék, Z.; Szuvandzsiev, P.; Daood, H.; Neményi, A.; Helyes, L. Effect of irrigation on yield parameters and antioxidant profiles of processing cherry tomato. Cent. Eur. J. Biol. 2014, 9, 383–395. [Google Scholar] [CrossRef] [Green Version]

- Oh, M.; Carey, E.E.; Rajashekar, C.B. Antioxidant phytochemicals in lettuce grown in high tunnels and open field. Hortic. Environ. Biotechnol. 2011, 52, 133–139. [Google Scholar] [CrossRef]

- Oh, M.; Carey, E.E. Regulated Water Deficits Improve Phytochemical Concentration in Lettuce. J. Am. Soc. Hortic. Sci. 2010, 135, 223–229. [Google Scholar] [CrossRef] [Green Version]

- Clifford, M.N.; Zheng, W.; Kuhnert, N. Profiling the chlorogenic acids of aster by HPLC-MSn. Phytochem. Anal. 2006, 17, 384–393. [Google Scholar] [CrossRef]

- Clifford, M.N.; Kirkpatrick, J.; Kuhnert, N.; Roozendaal, H.; Salgado, P.R. LC–MS n analysis of the cis isomers of chlorogenic acids. Food Chem. 2008, 106, 379–385. [Google Scholar] [CrossRef]

- Ribas-Agustí, A.; Gratacós-Cubarsí, M.; Sárraga, C.; García-Regueiro, J.-A.; Castellari, M. Analysis of Eleven Phenolic Compounds Including Novel p-Coumaroyl Derivatives in Lettuce (Lactuca sativa L.) by Ultra-high-performance Liquid Chromatography with Photodiode Array and Mass Spectrometry Detection. Phytochem. Anal. 2011, 22, 555–563. [Google Scholar] [CrossRef]

- Alarcón-Flores, M.I.; Romero-González, R.; Vidal, J.L.M.; Frenich, A.G. Multiclass determination of phytochemicals in vegetables and fruits by ultra high performance liquid chromatography coupled to tandem mass spectrometry. Food Chem. 2013, 141, 1120–1129. [Google Scholar] [CrossRef]

- Viacava, G.E.; Roura, S.I.; Berrueta, L.A.; Iriondo, C.; Gallo, B.; Alonso-Salces, R.M. Characterization of phenolic compounds in green and red oak-leaf lettuce cultivars by UHPLC-DAD-ESI-QToF/MS using MSEscan mode. J. Mass Spectrom. 2017, 52, 873–902. [Google Scholar] [CrossRef]

- Materska, M.; Olszówka, K.; Chilczuk, B.; Stochmal, A.; Pecio, Ł.; Pacholczyk-Sienicka, B.; Piacente, S.; Pizza, C.; Masullo, M. Polyphenolic profiles in lettuce (Lactuca sativa L.) after CaCl2 treatment and cold storage. Eur. Food Res. Technol. 2019, 245, 733–744. [Google Scholar] [CrossRef] [Green Version]

- Saleh, H.A.R.; El-Nashar, Y.I.; Serag-El-Din, M.F.; Dewir, Y.H. Plant growth, yield and bioactive compounds of two culinary herbs as affected by substrate type. Sci. Hortic. 2019, 243, 464–471. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Stavrinides, M.; Moustakas, K.; Tzortzakis, N. Utilization of paper waste as growing media for potted ornamental plants. Clean Technol. Environ. Policy 2018, 21, 1937–1948. [Google Scholar] [CrossRef]

- Chrysargyris, A.; Antoniou, O.; Athinodorou, F.; Vassiliou, R.; Papadaki, A.; Tzortzakis, N. Deployment of olive-stone waste as a substitute growing medium component for Brassica seedling production in nurseries. Environ. Sci. Pollut. Res. 2019, 26, 35461–35472. [Google Scholar] [CrossRef] [PubMed]

- Morales, P.; Carvalho, A.M.; Sánchez-Mata, M.C.; Cámara, M.; Molina, M.; Ferreira, I.C. Tocopherol composition and antioxidant activity of Spanish wild vegetables. Genet. Resour. Crop Evol. 2012, 59, 851–863. [Google Scholar] [CrossRef]

- Khanam, U.K.S.; Oba, S.; Yanase, E.; Murakami, Y. Phenolic acids, flavonoids and total antioxidant capacity of selected leafy vegetables. J. Funct. Foods 2012, 4, 979–987. [Google Scholar] [CrossRef]

- Mampholo, B.M.; Maboko, M.M.; Soundy, P.; Sivakumar, D. Phytochemicals and overall quality of leafy lettuce (Lactuca sativa L.) varieties grown in closed hydroponic system. J. Food Qual. 2016, 39, 805–815. [Google Scholar] [CrossRef]

- Cano, A.; Arnao, M.B. Hydrophilic and lipophilic antioxidant activity in different leaves of three lettuce varieties. Int. J. Food Prop. 2005, 8, 521–528. [Google Scholar] [CrossRef]

- Karkanis, A.C.; Fernandes, A.; Vaz, J.; Petropoulos, S.; Georgiou, E.; Ciric, A.; Sokovic, M.; Oludemi, T.; Barros, L.; Ferreira, I. Chemical composition and bioactive properties of Sanguisorba minor Scop. under Mediterranean growing conditions. Food Funct. 2019, 10, 1340–1351. [Google Scholar] [CrossRef] [Green Version]

- Zhao, C.; Xie, Y.; Huang, D. Luteolin-7-O-Glucoside Present in Lettuce Extracts Inhibits Hepatitis B Surface Antigen Production and Viral Replication by Human Hepatoma Cells In Vitro. Front. Microbiol. 2017, 8, 2425. [Google Scholar]

- Koronowicz, A.A.; Kope, A.; Master, A.; Smole, S. Transcriptome Profiling of Caco-2 Cancer Cell Line following Treatment with Extracts from Iodine-Biofortified Lettuce (Lactuca sativa L.). PLoS ONE 2016, 11, e0147336. [Google Scholar] [CrossRef] [PubMed]

- Durazzo, A.; Azzini, E.; Lazzé, M.C.; Raguzzini, A.; Pizzala, R.; Maiani, G.; Palomba, L.; Maiani, G. Antioxidants in italian head lettuce (Lactuca sativa var. capitata L.) grown in organic and conventional systems under greenhouse conditions. J. Food Biochem. 2014, 38, 56–61. [Google Scholar] [CrossRef]

- Noumedem, J.A.K.; Mihasan, M.; Lacmata, S.T.; Stefan, M.; Kuiate, J.R.; Kuete, V. Antibacterial activities of the methanol extracts of ten Cameroonian vegetables against Gram-negative multidrug-resistant bacteria. BMC Complement. Altern. Med. 2013, 13, 26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| By-Product | Bulk Density (g/cm) | WHC (%) | OM (%) | pH | EC (dS/cm) | N (%) | K (cmol/kg) |

|---|---|---|---|---|---|---|---|

| Soil | 1.07 | 45.5 | 3.4 | 7.6 | 1.73 | 0.13 | 0.91 |

| CGW * | 0.30 | 139.3 | 82.9 | 6.8 | 5.42 | 0.19 | 0.87 |

| GHH | 0.54 | 78.9 | 110.7 | 5.8 | 1.93 | 0.85 | 2.18 |

| GPH | 0.17 | 262.2 | 59.1 | 5.9 | 1.36 | 1.1 | 3.05 |

| Control | GHH25% * | GHH50% | CGW25% | CGW50% | GPH25% | GPH50% | |

|---|---|---|---|---|---|---|---|

| Nutritional Value | |||||||

| Moisture | 95.9 ± 0.7 b | 95.8± 0.6 b | 96.2± 0.3 a | 95.0 ± 0.5 c | 95.9 ± 0.1 b | 95.2 ± 0.1 c | 95.8 ± 0.6 b |

| Fat | 0.142 ± 0.002 e | 0.15 ± 0.01 c | 0.148 ± 0.003 c | 0.157 ± 0.003 b | 0.133 ± 0.009 e | 0.162 ± 0.003 a | 0.161 ± 0.003 a |

| Proteins | 0.753 ± 0.005 f | 0.889 ± 0.001 d | 0.812 ± 0.004 e | 1.15 ± 0.01 a | 0.977 ± 0.003 c | 1.02 ± 0.01 b | 0.882 ± 0.001 e |

| Ash | 0.56 ± 0.01 d | 0.60 ± 0.01 c | 0.60 ± 0.03 c | 0.86 ± 0.02 a | 0.73 ± 0.01 b | 0.84 ± 0.01 a | 0.74 ± 0.01 b |

| Carbohydrates | 2.61 ± 0.01 c | 2.58 ± 0.02 c | 2.19 ± 0.02 f | 2.81 ± 0.01 a | 2.30 ± 0.01 e | 2.74 ± 0.01 b | 2.46 ± 0.01 d |

| Energy | 14.73 ± 0.03 d | 15.23 ± 0.01 c | 13.35 ± 0.08 f | 17.28 ± 0.05 a | 14.31 ± 0.03 e | 16.51 ± 0.04 b | 14.83 ± 0.01 d |

| Free Sugars | |||||||

| Fructose | 0.47 ± 0.03 c | 0.43 ± 0.03 d | 0.43 ± 0.01 d | 0.59 ± 0.01 a | 0.43 ± 0.04 d | 0.46 ± 0.02 c | 0.49 ± 0.01 b |

| Glucose | 0.267 ± 0.009 a | 0.244 ± 0.005 b | 0.22 ± 0.03 c | 0.22 ± 0.02 c | 0.18 ± 0.01 d | 0.26 ± 0.03 a | 0.223 ± 0.001 c |

| Sucrose | 0.123 ± 0.003 a | 0.088 ± 0.005 d | 0.104 ± 0.001 b | 0.125 ± 0.002 a | 0.094 ± 0.002 c | 0.087 ± 0.001 d | 0.105 ± 0.001 b |

| Trehalose | 0.017 ± 0.002 b | 0.017 ± 0.002 b | 0.013 ± 0.001 e | 0.023 ± 0.001 a | 0.015 ± 0.003 d | 0.017 ± 0.001 b | 0.016 ± 0.001 c |

| Sum | 0.88 ± 0.02 b | 0.77 ± 0.05 d | 0.77 ± 0.02 d | 0.96 ± 0.03 a | 0.72 ± 0.05 e | 0.83 ± 0.01 c | 0.83 ± 0.01 c |

| Organic Acids | |||||||

| Oxalic acid | 286 ± 1 f | 315 ± 3 e | 278 ± 1 g | 413 ± 8 a | 339 ± 4 c | 358 ± 1 b | 330 ± 2 d |

| Malic acid | 319 ± 7 e | 389 ± 1 b | 318 ± 6 e | 401 ± 7 a | 369 ± 5 c | 405 ± 2 a | 335 ± 6 d |

| Fumaric acid | tr | tr | tr | tr | tr | tr | tr |

| Sum | 605 ± 9 e | 704 ± 4 c | 596 ± 7 f | 814 ± 15 a | 708 ± 1 c | 763 ± 2 b | 666 ± 8 d |

| Fatty Acids | Control | GHH25% * | GHH50% | CGW25% | CGW50% | GPH25% | GPH50% |

|---|---|---|---|---|---|---|---|

| C12:0 | 0.106 ± 0.004 a | 0.089 ± 0.005 b | 0.086 ± 0.006 b | 0.066 ± 0.001 c | 0.059 ± 0.002 d | 0.069 ± 0.002 c | 0.045 ± 0.001 e |

| C13:0 | 0.125 ± 0.001 a | 0.034 ± 0.001 d | 0.065 ± 0.004 b | 0.025 ± 0.001 e | 0.022 ± 0.002 f | 0.051 ± 0.004 c | 0.026 ± 0.002 e |

| C14:0 | 1.86 ± 0.02 a | 1.5 ± 0.1 c | 1.5 ± 0.1 c | 1.46 ± 0.02 d | 1.7 ± 0.1 b | 1.03 ± 0.01 f | 1.06 ± 0.01 e |

| C14:1 | 0.069 ± 0.001 c | 0.047 ± 0.002 d | 0.035 ± 0.002 e | 0.012 ± 0.001 f | 0.084 ± 0.002 b | 0.38 ± 0.01 a | 0.049 ± 0.001 d |

| C15:0 | 0.252 ± 0.007 a | 0.25 ± 0.01 a | 0.22 ± 0.01 c | 0.230 ± 0.003 b | 0.215 ± 0.004 d | 0.153 ± 0.008 e | 0.23 ± 0.01 b |

| C16:0 | 19.2 ± 0.2 a | 16.93 ± 0.03 d | 15.7 ± 0.8 f | 17.41 ± 0.05 c | 17.0 ± 0.5 d | 17.7 ± 0.2 b | 16.7 ± 0.4 e |

| C16:1 | 2.0 ± 0.1 d | 1.9 ± 0.1 e | 1.98 ± 0.05 d | 1.95 ± 0.02 d | 2.2 ± 0.1 b | 2.3 ± 0.1 a | 2.12 ± 0.06 c |

| C17:0 | 0.222 ± 0.001 a | 0.20 ± 0.02 b | 0.19 ± 0.01 c | 0.202 ± 0.002 b | 0.203 ± 0.004 b | 0.18 ± 0.01 d | 0.20 ± 0.01 b |

| C18:0 | 1.67 ± 0.07 b | 1.56 ± 0.04 d | 1.57 ± 0.06 c | 1.73 ± 0.04 a | 1.67 ± 0.01 b | 1.67 ± 0.03 b | 1.52 ± 0.01 e |

| C18:1n9 c | 1.77 ± 0.01 c | 1.75 ± 0.07 c | 1.47 ± 0.04 e | 2.4 ± 0.2 a | 1.82 ± 0.07 b | 1.61 ± 0.06 d | 1.65 ± 0.02 d |

| C18:2n6 c | 25.7 ± 0.3 a | 24.6 ± 0.4 c | 23.6 ± 0.3 d | 24.4 ± 0.1 c | 22.4 ± 0.3 e | 24.3 ± 0.2 c | 25.01 ± 0.03 b |

| C18:3n3 | 42.1 ± 0.1 e | 47.1 ± 0.3 c | 50.2 ± 0.7 a | 46.0 ± 0.2 d | 49.3 ± 0.2 b | 45.6 ± 0.4 d | 47.1 ± 0.3 c |

| C20:0 | 0.48 ± 0.01 c | 0.47 ± 0.01 c | 0.43 ± 0.02 d | 0.52 ± 0.02 b | 0.53 ± 0.01 b | 0.62 ± 0.02 a | 0.46 ± 0.01 c |

| C20:2 | 0.65 ± 0.02 a | 0.313 ± 0.001 c | 0.31 ± 0.01 c | 0.259 ± 0.008 e | 0.256 ± 0.004 e | 0.362 ± 0.004 b | 0.265 ± 0.001 d |

| C22:0 | 1.27 ± 0.02 c | 1.17 ± 0.02 d | 1.06 ± 0.01 e | 1.30 ± 0.02 b | 1.31 ± 0.04 b | 1.48 ± 0.01 a | 1.31 ± 0.05 b |

| C23:0 | 0.191 ± 0.001 d | 0.215 ± 0.001 b | 0.20 ± 0.01 c | 0.17 ± 0.01 f | 0.178 ± 0.002 e | 0.366 ± 0.009 a | 0.214 ± 0.001 b |

| C24:0 | 2.29 ± 0.07 a | 1.83 ± 0.01 e | 1.34 ± 0.03 f | 1.91 ± 0.01 d | 1.0 ± 0.3 g | 2.14 ± 0.01 b | 2.08 ± 0.16 c |

| SFA | 27.7 ± 0.2 a | 24.24 ± 0.07 d | 22.4 ± 0.9 f | 25.03 ± 0.07 v | 23.9 ± 0.3 e | 25.5 ± 0.2 b | 23.8 ± 0.3 e |

| MUFA | 3.8 ± 0.1 c | 3.68 ± 0.03 d | 3.49 ± 0.09 e | 4.3 ± 0.2 a | 4.1 ± 0.2 b | 4.28 ± 0.06 a | 3.82 ± 0.04 c |

| PUFA | 68.5 ± 0.4 e | 72.08 ± 0.04 c | 74 ± 1 a | 70.7 ± 0.3 d | 72.0 ± 0.5 c | 70.3 ± 0.2 d | 72.3 ± 0.3 b |

| Tocopherols | |||||||

| α-Tocopherol | 0.054 ± 0.002 f | 0.101 ± 0.002 c | 0.141 ± 0.001 a | 0.115 ± 0.001 b | 0.091 ± 0.002 d | 0.089 ± 0.001 e | 0.089 ± 0.001 e |

| γ-Tocopherol | 0.293 ± 0.002 g | 0.405 ± 0.001 e | 0.420 ± 0.001 d | 0.509 ± 0.002 b | 0.459 ± 0.007 c | 0.517 ± 0.006 a | 0.348 ± 0.008 f |

| δ-Tocopherol | 0.011 ± 0.001 e | 0.016 ± 0.001 b | 0.016 ± 0.001 b | 0.014 ± 0.001 c | 0.013 ± 0.001 d | 0.018 ± 0.001 a | 0.014 ± 0.001 c |

| Sum | 0.360 ± 0.001 g | 0.520 ± 0.001 e | 0.580 ± 0.001 d | 0.640 ± 0.001 a | 0.570 ± 0.007 c | 0.630 ± 0.007 b | 0.460 ± 0.007 f |

| Peak | Rt (min) | λmax (nm) | [M-H]− (m/z) | MS2 (m/z) | Tentative Identification |

|---|---|---|---|---|---|

| 1 | 5.21 | 323 | 341 | 179 (100) | Caffeic acid hexoside isomer I |

| 2 | 5.73 | 323 | 341 | 179 (100) | Caffeic acid hexoside isomer II |

| 3 | 6.44 | 323 | 341 | 179 (100) | Caffeic acid hexoside isomer III |

| 4 | 7.1 | 324 | 353 | 191 (100), 179 (11), 173 (3) | 5-O-Caffeoylquinic acid |

| 5 | 9.6 | 326 | 295 | 179 (100), 133 (33) | Caffeoylmalic acid isomer I |

| 6 | 9.89 | 326 | 295 | 179 (100), 133 (42) | Caffeoylmalic acid isomer II |

| 7 | 11.42 | 315 | 337 | 191 (100), 173 (3), 163 (17) | p-Coumaroylquinic acid |

| 8 | 12.8 | 326 | 473 | 311 (100), 293 (92), 179 (5), 149 (3) | di-O-Caffeoyltartaric acid isomer I |

| 9 | 13.25 | 329 | 473 | 311 (100), 293 (98), 179 (6), 149(4) | di-O-Caffeoyltartaric acid isomer II |

| 10 | 13.72 | 328 | 473 | 311 (100), 293 (90), 179 (5), 149 (3) | di-O-Caffeoyltartaric acid isomer III |

| 11 | 18.08 | 352 | 477 | 301 (100) | Quercetin-3-O-glucuronide |

| 12 | 18.57 | 348 | 461 | 285 (100) | Kaempferol-3-O-glucuronide |

| 13 | 20.12 | 354 | 549 | 505 (52), 463 (33), 301 (100) | Quercetin-O-malonylhexoside |

| Peak | Compound | Control | GHH25% * | GHH50% | CGW25% | CGW50% | GPH25% | GPH50% |

|---|---|---|---|---|---|---|---|---|

| 1 | Caffeic acid hexoside isomer I | tr | 0.36 ± 0.02 b | 0.35 ± 0.02 c | 0.38 ± 0.02 a | tr | 0.36 ± 0.02 b | tr |

| 2 | Caffeic acid hexoside isomer II | tr | 0.39 ± 0.02 b | 0.35 ± 0.02 c | 0.68 ± 0.04 a | 0.13 ± 0.01 d | 0.38 ± 0.01 b | tr |

| 3 | Caffeic acid hexoside isomer III | tr | 0.75 ± 0.03 a | 0.56 ± 0.01 b | 0.10 ± 0.01 e | 0.14 ± 0.01 d | 0.25 ± 0.01 c | tr |

| 4 | 5-O-Caffeoylquinic acid | 10.2 ± 0.1 e | 16.4 ± 0.7 b | 18.7 ± 0.1 a | 15.7 ± 0.4 c | 5.60 ± 0.06 g | 10.9 ± 0.1 d | 9.80 ± 0.06 f |

| 5 | Caffeoylmalic acid isomer I | 5.63 ± 0.04 e | 9.75 ± 0.02 a | 9.39 ± 0.02 b | 8.20 ± 0.05 c | 3.38 ± 0.05 g | 3.54 ± 0.02 f | 6.81 ± 0.02 d |

| 6 | Caffeoylmalic acid isomer II | 7.8 ± 0.2 c | 10.8 ± 0.1 a | 10.1 ± 0.2 b | 7.67 ± 0.07 dd | 5.7 ± 0.1 f | 6.72 ± 0.08 e | 7.60 ± 0.03 |

| 7 | p-Coumaroylquinic acid | 1.49 ± 0.05 d | 1.96 ± 0.05 b | 2.02 ± 0.04 b | 1.42 ± 0.02 e | 2.96 ± 0.08 a | 2.9 ± 0.1 a | 1.86 ± 0.05 c |

| 8 | di-O-Caffeoyltartaric acid isomer I | 12.8 ± 0.5 e | 17.97 ± 0.06 a | 18 ± 1 a | 15.4 ± 0.6 d | 17 ± 1 c | 17.8 ± 0.4 b | 10.1 ± 0.2 f |

| 9 | di-O-Caffeoyltartaric acid isomer II | 11.8 ± 0.2 f | 16.7 ± 0.1 a | 15.9 ± 0.1 b | 13.3 ± 0.4 e | 15.6 ± 0.2 c | 15.0 ± 0.3 d | 9.71 ± 0.08 g |

| 10 | di-O-Caffeoyltartaric acid isomer III | 8.5 ± 0.1 e | 13.9 ± 0.2 a | 12.3 ± 0.4 b | 10.3 ± 0.1 d | 12 ± 1 c | 12.4 ± 0.7 b | 7.57 ± 0.08 f |

| 11 | Quercetin-3-O-glucuronide | 7.28 ± 0.01 f | 8.05 ± 0.07 d | 8.35 ± 0.01 c | 9.28 ± 0.03 a | 8.09 ± 0.02 d | 8.92 ± 0.01 b | 7.71 ± 0.01 e |

| 12 | Kaempferol-3-O-glucuronide | 7.48 ± 0.02 f | 8.3 ± 0.2 e | 8.47 ± 0.05 d | 10.09 ± 0.06 a | 8.82 ± 0.03 c | 9.56 ± 0.02 b | 8.29 ± 0.05 e |

| 13 | Quercetin-O-malonylhexoside | 7.70 ± 0.01 f | 8.52 ± 0.01 d | 9.31 ± 0.07 c | 10.12 ± 0.04 a | 8.41 ± 0.03 e | 9.47 ± 0.02 b | 8.5 ± 0.1 d |

| Total Phenolic Acids | 58 ± 1 e | 89 ± 1 a | 88 ± 1 a | 73.2 ± 0.2 b | 62.4 ± 0.1 d | 70 ± 1 c | 53.4 ± 0.3 f | |

| Total Flavonoids | 22.46 ± 0.02 f | 24.89 ± 0.08 d | 26.1 ± 0.1 c | 29.49 ± 0.08 a | 25.3 ± 0.1 d | 28.0 ± 0.1 b | 24.5 ± 0.1 e | |

| Total Phenolic Compounds | 81 ± 1 e | 114 ± 1 a | 114 ± 1 a | 102.7 ± 0.1 b | 87.7 ± 0.7 d | 98 ± 1 c | 77.9 ± 0.5 f |

| Control | GHH25% * | GHH50% | CGW25% | CGW50% | GPH25% | GPH50% | Positive Control | |

|---|---|---|---|---|---|---|---|---|

| Antioxidant activity | Trolox | |||||||

| TBARS | 169 ± 8 a | 50 ± 2 e | 27 ± 1 f | 96 ± 5 c | 76 ± 1 d | 74 ± 5 d | 114 ± 6 b | 23 ± 0.1 |

| OxHLIA Δt = 60 min | 383 ± 16 e | 553 ± 32 b | 186 ± 11 f | 550 ± 28 b | 500 ± 15 c | 590 ± 73 a | 451 ± 17 d | 19.6 ± 0.7 |

| Cytotoxicity to non-tumor cell lines | Ellipticine | |||||||

| PLP2 | >400 | >400 | >400 | >400 | >400 | >400 | >400 | 2.3 ± 0.1 |

| Cytotoxicity to tumor cell lines | ||||||||

| HeLa | >400 | >400 | >400 | >400 | >400 | >400 | 258 ± 14 | 0.91 ± 0.1 |

| HepG2 | >400 | >400 | >400 | >400 | >400 | >400 | 269 ± 20 | 1.10 ± 0.09 |

| MCF-7 | >400 | >400 | 329 ± 17 a | >400 | >400 | >400 | 307 ± 6 b | 1.21 ± 0.02 |

| NCI-H460 | >400 | >400 | >400 | >400 | >400 | >400 | >400 | 1.03 ± 0.09 |

| Control | GHH25% ¥ | GHH50% | CGW 5% | CGW50% | GPH25% | GPH50% | Positive Controls | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Antibacterial Activity | Streptomycin | Ampicillin | ||||||||

| S. aureus (ATCC 11632) | MIC * MBC | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 0.89 1.75 | 0.89 1.75 | 0.89 1.75 | 1.75 3.50 | 0.006 0.012 | 0.012 0.025 |

| B. cereus (food isolate) | MIC MBC | 0.89 1.75 | 0.89 1.75 | 0.44 0.89 | 0.44 0.89 | 0.89 1.75 | 0.89 1.75 | 0.89 1.75 | 0.10 0.20 | 0.25 0.40 |

| L. monocytogenes (NCTC 7973) | MIC MBC | 1.75 3.50 | 3.50 7.00 | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 0.20 0.30 | 0.40 0.50 |

| S. typhimurium (ATCC 13311) | MIC MBC | 1.75 3.50 | 3.50 7.00 | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 0.20 0.30 | 0.75 1.20 |

| E. cloacae (ATCC 35030) | MIC MBC | 1.75 3.50 | 3.50 7.00 | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 1.75 3.50 | 0.003 0.006 | 0.006 0.012 |

| E. coli (ATCC 25922) | MIC MBC | 0.89 1.75 | 3.50 7.00 | 0.89 1.75 | 0.89 1.75 | 0.89 1.75 | 0.89 1.75 | 0.89 1.75 | 0.20 0.30 | 0.40 0.50 |

| Antifungal Activity | Ketoconazole | |||||||||

| A. fumigatus (ATCC 9197) | MIC MFC | 0.88 1.75 | 0.88 1.75 | 0.44 0.88 | 0.44 0.88 | 0.44 0.88 | 0.88 1.75 | 0.22 0.44 | 0.20 0.50 | |

| A. versicolor (ATCC 11730) | MIC MFC | 0.88 1.75 | 0.88 1.75 | 0.44 0.88 | 0.44 0.88 | 0.44 0.88 | 0.88 1.75 | 0.44 0.88 | 0.20 0.47 | |

| A. niger (ATCC 6275) | MIC MFC | 0.88 1.75 | 0.88 1.75 | 0.44 0.88 | 0.44 0.88 | 0.44 0.88 | 0.44 0.88 | 0.44 0.88 | 0.20 0.50 | |

| P. funiculosum (ATCC 36839) | MIC MFC | 0.44 0.88 | 0.44 0.88 | 0.44 0.88 | 0.44 0.88 | 0.22 0.44 | 0.44 0.88 | 0.44 0.88 | 0.20 0.50 | |

| P. v. var. cyclopium (food isolate) | MIC MFC | 1.75 3.20 | 0.44 0.88 | 0.88 1.75 | 0.44 0.88 | 0.44 0.88 | 0.44 0.88 | 0.44 0.88 | 0.20 0.30 | |

| T. viride (IAM 5061) | MIC MFC | 0.44 0.88 | 0.22 0.44 | 0.44 0.88 | 0.22 0.44 | 0.11 0.22 | 0.22 0.44 | 0.22 0.44 | 0.20 0.30 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petropoulos, S.A.; Fernandes, Â.; Plexida, S.; Pereira, C.; Dias, M.I.; Calhelha, R.; Chrysargyris, A.; Tzortzakis, N.; Petrović, J.; Soković, M.D.; et al. The Sustainable Use of Cotton, Hazelnut and Ground Peanut Waste in Vegetable Crop Production. Sustainability 2020, 12, 8511. https://doi.org/10.3390/su12208511

Petropoulos SA, Fernandes Â, Plexida S, Pereira C, Dias MI, Calhelha R, Chrysargyris A, Tzortzakis N, Petrović J, Soković MD, et al. The Sustainable Use of Cotton, Hazelnut and Ground Peanut Waste in Vegetable Crop Production. Sustainability. 2020; 12(20):8511. https://doi.org/10.3390/su12208511

Chicago/Turabian StylePetropoulos, Spyridon A., Ângela Fernandes, Sofia Plexida, Carla Pereira, Maria Inês Dias, Ricardo Calhelha, Antonios Chrysargyris, Nikolaos Tzortzakis, Jovana Petrović, Marina D. Soković, and et al. 2020. "The Sustainable Use of Cotton, Hazelnut and Ground Peanut Waste in Vegetable Crop Production" Sustainability 12, no. 20: 8511. https://doi.org/10.3390/su12208511