Removal of Patent Blue (V) Dye Using Indian Bael Shell Biochar: Characterization, Application and Kinetic Studies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Adsorbate

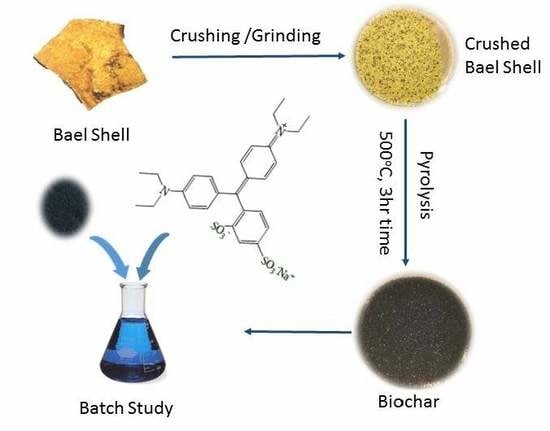

2.2. Preparation of Bael Shell Biochar (BSB)

2.3. Characterization of Bael Shell Biochar (BSB)

2.3.1. Elemental Analysis

2.3.2. Determination of the Point of Zero Charge of Bael Shell Biochar (BSB)

2.4. Batch Adsorption Studies

2.5. Adsorption Isotherms

2.5.1. Langmuir Isotherm

2.5.2. Freundlich Isotherm

2.6. Adsorption Kinetics

2.6.1. Pseudo-First-Order Kinetic Model

2.6.2. Pseudo-Second-Order Kinetic Model

3. Results and Discussion

3.1. Characterization

3.2. Point of Zero Charge

3.3. Effect of pH on Adsorption of Patent Blue (V)

3.4. Kinetic Studies

3.5. Adsorption Isotherm

3.6. Proposed Mechanism for Adsorption of Patent Blue PB (V) Dye on to Bael Shell Biochar (BSB) Surface

3.7. Bael Shell Biochar (BSB) as a Low-Cost Adsorbent for Pollutant Treatment

3.8. Life Cycle Assessment (LCA) of Biochar Systems

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rahman, S.; Parvin, R. Therapeutic potential of Aegle marmelos (L.)—An overview. Asian Pac. J. Trop. Dis. 2014, 4, 71–77. [Google Scholar] [CrossRef]

- Bardalai, M.; Mahanta, D.K. Characterisation of the pyrolysis oil derived from bael shell (Aegle marmelos). Environ. Eng. Res. 2016, 21, 180–187. [Google Scholar] [CrossRef]

- Gottipati, R. Preparation and Characterization of Microporous Activated Carbon from Biomass and Its Application in the Removal of Chromium (vi) from Aqueous Phase; National Institute of Technology Rourkela: Rourkela, India, 2012. [Google Scholar]

- Vikrant, K.; Giri, B.S.; Raza, N.; Roy, K.; Kim, K.-H.; Rai, B.N.; Singh, R.S. Recent advancements in bioremediation of dye: Current status and challenges. Bioresour. Technol. 2018, 253, 355–367. [Google Scholar] [CrossRef] [PubMed]

- Pham, T.D.; Kobayashi, M.; Adachi, Y. Adsorption characteristics of anionic azo dye onto large α-alumina beads. Colloid Polym. Sci. 2015, 293, 1877–1886. [Google Scholar] [CrossRef] [Green Version]

- Bharti, V.; Shahi, A.; Geed, S.R.; Kureel, M.K.; Rai, B.N.; Kumar, S.; Giri, B.S.; Singh, R.S. Biodegradation of reactive orange 16 by dye in the packed bed bioreactor using seeds of Ashoka and Casuarina as packing media. Indian J. Biotechnol. 2017, 16, 216–221. [Google Scholar]

- Padmanaban, V.C.; Geed, S.R.; Achary, A.; Singh, R.S. Kinetic studies on degradation of reactive red 120 dye in immobilized packed bed reactor by Bacillus cohnii rapt1. Bioresour. Technol. 2016, 213, 39–43. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, R.; Kumar, R. Adsorption study of patent blue VF using ginger waste material. J. Iran. Chem. Res. 2008, 1, 85–94. [Google Scholar]

- Idouhar, M.; Tazerouti, A. Spectrophotometric determination of cationic surfactants using patent blue v: Application to the wastewater industry in Algiers. J. Surfactants Deterg. 2008, 11, 263–267. [Google Scholar] [CrossRef]

- Cotillas, S.; Llanos, J.; Cañizares, P.; Clematis, D.; Cerisola, G.; Rodrigo, M.A.; Panizza, M. Removal of Procion Red MX-5B dye from wastewater by conductive-diamond electrochemical oxidation. Electrochim. Acta 2018, 263, 1–7. [Google Scholar] [CrossRef]

- Tarkwa, J.-B.; Oturan, N.; Acayanka, E.; Laminsi, S.; Oturan, M.A. Photo-fenton oxidation of Orange G azo dye: Process optimization and mineralization mechanism. Environ. Chem. Lett. 2018, 1–7. [Google Scholar] [CrossRef]

- Farshchi, M.E.; Aghdasinia, H.; Khataee, A. Modeling of heterogeneous fenton process for dye degradation in a fluidized-bed reactor: Kinetics and mass transfer. J. Clean. Prod. 2018, 182, 644–653. [Google Scholar] [CrossRef]

- Thamaraiselvan, C.; Michael, N.; Oren, Y. Selective separation of dyes and brine recovery from textile wastewater by nanofiltration membranes. Chem. Eng. Technol. 2017, 41, 185–293. [Google Scholar] [CrossRef]

- Katheresan, V.; Kansedo, J.; Lau, S.Y. Efficiency of various recent wastewater dye removal methods: A review. J. Environ. Chem. Eng. 2018, 6, 4676–4697. [Google Scholar] [CrossRef]

- Lam, S.-M.; Low, X.-Z.D.; Wong, K.-A.; Sin, J.-C. Sequencing coagulation–photodegradation treatment of malachite green dye and textile wastewater through ZnO micro/nanoflowers. Chem. Eng. Commun. 2018, 205, 1143–1156. [Google Scholar] [CrossRef]

- Xiao, X.; Li, T.-T.; Lu, X.-R.; Feng, X.-L.; Han, X.; Li, W.-W.; Li, Q.; Yu, H.-Q. A simple method for assaying anaerobic biodegradation of dyes. Bioresour. Technol. 2018, 251, 204–209. [Google Scholar] [CrossRef] [PubMed]

- Dao, T.H.; Tran, T.T.; Nguyen, V.R.; Pham, T.N.M.; Vu, C.M.; Pham, T.D. Removal of antibiotic from aqueous solution using synthesized TiO2 nanoparticles: Characteristics and mechanisms. Environ. Earth Sci. 2018, 77, 359. [Google Scholar]

- Pham, T.D.; Nguyen, H.H.; Nguyen, N.V.; Vu, T.T.; Pham, T.N.M.; Doan, T.H.Y.; Nguyen, M.H.; Ngo, T.M.V. Adsorptive removal of copper by using surfactant modified laterite soil. J. Chem. 2017, 2017, 1986071. [Google Scholar] [CrossRef]

- Pham, T.; Bui, T.; Nguyen, V.; Bui, T.; Tran, T.; Phan, Q.; Pham, T.; Hoang, T. Adsorption of polyelectrolyte onto nanosilica synthesized from rice husk: Characteristics, mechanisms, and application for antibiotic removal. Polymers 2018, 10, 220. [Google Scholar] [CrossRef]

- Pham, T.D.; Do, T.T.; Ha, V.L.; Doan, T.H.Y.; Nguyen, T.A.H.; Mai, T.D.; Kobayashi, M.; Adachi, Y. Adsorptive removal of ammonium ion from aqueous solution using surfactant-modified alumina. Environ. Chem. 2017, 14, 327–337. [Google Scholar] [CrossRef]

- Sophia, A.C.; Lima, E.C. Removal of emerging contaminants from the environment by adsorption. Ecotoxicol. Environ. Saf. 2018, 150, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Bello, O.S.; Ahmad, M.A. Coconut (Cocos nucifera) shell based activated carbon for the removal of malachite green dye from aqueous solutions. Sep. Sci. Technol. 2012, 47, 903–912. [Google Scholar] [CrossRef]

- Singh, D.K.; Srivastava, B. Basic Dyes Removal from Wastewater by Adsorption on Rice Husk Carbon. Indian J. Chem. Technol. 2001, 8, 133–139. [Google Scholar]

- El-Sonbati, A.Z.; El-Deen, I.M.; El-Bindary, M.A. Adsorption of hazardous azorhodanine dye from an aqueous solution using rice straw fly ash. J. Dispers. Sci. Technol. 2016, 37, 715–722. [Google Scholar] [CrossRef]

- Doulati Ardejani, F.; Badii, K.; Limaee, N.Y.; Shafaei, S.Z.; Mirhabibi, A.R. Adsorption of direct red 80 dye from aqueous solution onto almond shells: Effect of PH, initial concentration and shell type. J. Hazard. Mater. 2008, 151, 730–737. [Google Scholar] [PubMed]

- Bangash Fazlullah, K.; Manaf, A. Dyes removal from aqueous solution using wood activated charcoal of bombax cieba tree. J. Chin. Chem. Soc. 2013, 52, 489–494. [Google Scholar] [CrossRef]

- Vikrant, K.; Kim, K.-H.; Ok, Y.S.; Tsang, D.C.W.; Tsang, Y.F.; Giri, B.S.; Singh, R.S. Engineered/designer biochar for the removal of phosphate in water and wastewater. Sci. Total Environ. 2018, 616–617, 1242–1260. [Google Scholar] [CrossRef] [PubMed]

- Zazycki, M.A.; Godinho, M.; Perondi, D.; Foletto, E.L.; Collazzo, G.C.; Dotto, G.L. New biochar from pecan nutshells as an alternative adsorbent for removing reactive red 141 from aqueous solutions. J. Clean. Prod. 2018, 171, 57–65. [Google Scholar] [CrossRef]

- Sewu, D.D.; Boakye, P.; Woo, S.H. Highly efficient adsorption of cationic dye by biochar produced with Korean cabbage waste. Bioresour. Technol. 2017, 224, 206–213. [Google Scholar] [CrossRef] [PubMed]

- Al-Ghouti, M.A.; Khraisheh, M.A.M.; Allen, S.J.; Ahmad, M.N. The removal of dyes from textile wastewater: A study of the physical characteristics and adsorption mechanisms of diatomaceous earth. J. Environ. Manag. 2003, 69, 229–238. [Google Scholar] [CrossRef]

- Bharathi, K.S.; Ramesh, S.T. Removal of dyes using agricultural waste as low-cost adsorbents: A review. Appl. Water Sci. 2013, 3, 773–790. [Google Scholar]

- Ng, C.; Losso, J.N.; Marshall, W.E.; Rao, R.M. Freundlich adsorption isotherms of agricultural by-product-based powdered activated carbons in a geosmin–water system. Bioresour. Technol. 2002, 85, 131–135. [Google Scholar] [CrossRef]

- Senthil Kumar, P.; Palaniyappan, M.; Priyadharshini, M.; Vignesh, A.M.; Thanjiappan, A.; Sebastina Anne Fernando, P.; Tanvir Ahmed, R.; Srinath, R. Adsorption of basic dye onto raw and surface-modified agricultural waste. Environ. Prog. Sustain. Energy 2013, 33, 87–98. [Google Scholar]

- Zhou, Y.; Ge, L.; Fan, N.; Xia, M. Adsorption of congo red from aqueous solution onto shrimp shell powder. Adsorpt. Sci. Technol. 2018, 36, 1310–1330. [Google Scholar]

- Vautard, F.; Grappe, H.; Ozcan, S. Stability of carbon fiber surface functionality at elevated temperatures and its influence on interfacial adhesion. Appl. Surf. Sci. 2013, 268, 61–72. [Google Scholar] [CrossRef]

- Ahmad, R.; Kumar, R. Adsorptive removal of congo red dye from aqueous solution using bael shell carbon. Appl. Surf. Sci. 2010, 257, 1628–1633. [Google Scholar] [CrossRef]

- Prasad, A.L.; Santhi, T. Adsorption of hazardous cationic dyes from aqueous solution onto acacia nilotica leaves as an eco friendly adsorbent. Sustain. Environ. Res. 2012, 22, 113–122. [Google Scholar]

- Anandkumar, J.; Mandal, B. Removal of cr(VI) from aqueous solution using bael fruit (Aegle marmelos correa) shell as an adsorbent. J. Hazard. Mater. 2009, 168, 633–640. [Google Scholar] [CrossRef] [PubMed]

- Gottipati, R.; Mishra, S. Process optimization of adsorption of cr(vi) on activated carbons prepared from plant precursors by a two-level full factorial design. Chem. Eng. J. 2010, 160, 99–107. [Google Scholar] [CrossRef]

- Singh, K.; Lataye, D.H.; Wasewar, K.L. Removal of fluoride from aqueous solution by using bael (Aegle marmelos) shell activated carbon: Kinetic, equilibrium and thermodynamic study. J. Fluor. Chem. 2017, 194, 23–32. [Google Scholar] [CrossRef]

- Hameed, B.H.; Din, A.T.M.; Ahmad, A.L. Adsorption of methylene blue onto bamboo-based activated carbon: Kinetics and equilibrium studies. J. Hazard. Mater. 2007, 141, 819–825. [Google Scholar] [CrossRef] [PubMed]

- Azizi, A.; Moghaddam, M.R.A.; Arami, A. Removal of a reactive dye using ash of pulp and paper sludge. J. Residuals Sci. Technol. 2012, 9, 159–168. [Google Scholar]

- Saleh, S.M.; Maarof, H.I.; Rahim, S.N.S.A.; Nasuha, N. Adsorption of Congo Red onto Bottom Ash. J. Appl. Sci. 2012, 12, 1181–1185. [Google Scholar] [CrossRef]

- Ates, F.; Tezcan Un, U. Production of char from hornbeam sawdust and its performance evaluation in the dye removal. J. Anal. Appl. Pyrolysis 2013, 103, 159–166. [Google Scholar] [CrossRef]

- Duraisamy, R.; Kiruthiga, P.M.; Hirpaye, B.Y.; Berekute, A.K. Adsorption of azure b dye on rice husk activated carbon: Equilibrium, kinetic and thermodynamic studies. Int. J. Water Res. 2015, 5, 18–28. [Google Scholar]

- Breulmann, M.; Schulz, E.; van Afferden, M.; Müller, R.A.; Fühner, C. Hydrochars derived from sewage sludge: Effects of pre-treatment with water on char properties, phytotoxicity and chemical structure. Arch. Agron. Soil Sci. 2018, 64, 860–872. [Google Scholar] [CrossRef]

- Ye, J.; Zhang, R.; Nielsen, S.; Joseph, S.D.; Huang, D.; Thomas, T. A combination of biochar–mineral complexes and compost improves soil bacterial processes, soil quality, and plant properties. Front. Microbiol. 2016, 7, 372. [Google Scholar] [CrossRef] [PubMed]

- Anusha, G. Removal of iron from waste water using bael fruit shell as adsorbent. In Proceedings of the 2nd International Conference on Environmental Science and Technology (IPCBEE), Singapore, 26–28 February 2011; IACSIT Press: Singapore, 2011; Volume 6, pp. 260–285. [Google Scholar]

- Smebye, A.B.; Sparrevik, M.; Schmidt, H.P.; Cornelissen, G. Life-cycle assessment of biochar production systems in tropical rural areas: Comparing flame curtain kilns to other production methods. Biomass Bioenergy 2017, 101, 35–43. [Google Scholar] [CrossRef]

- Jones, D.L.; Rousk, J.; Edwards-Jones, G.; DeLuca, T.H.; Murphy, D.V. Biochar-mediated changes in soil quality and plant growth in a three-year field trial. Soil Biol. Biochem. 2012, 45, 113–124. [Google Scholar] [CrossRef]

| Methods | Description | Result (%) |

|---|---|---|

| Pyrolysis (weight composition) | BSB | 29.1 |

| Bio-oil | 22.5 | |

| Gas | 49.5 | |

| Proximate analysis (Bael Shell) | Moisture (110 °C) | 9.20 |

| Ash (715 °C) | 25.7 | |

| Volatile (930 °C) | 51.9 | |

| Proximate analysis (BSB) | Moisture (110 °C) | 4.50 |

| Ash (715 °C) | 310 | |

| Volatile (930 °C) | 30.0 | |

| Ultimate analysis (Bael Shell) | Carbon | 46.2 |

| Hydrogen | 7.46 | |

| Nitrogen | 0.56 | |

| Ultimate analysis (BSB) | Carbon | 72.2 |

| Hydrogen | 2.93 | |

| Nitrogen | 0.40 |

| Reaction Models | Parameters | Values |

|---|---|---|

| Pseudo-first-order model | k1 (L/min) | 0.0342 |

| qe (mg/g) | 1.7225 | |

| R2 | 0.9585 | |

| Pseudo-second-order model | k2 (g/mg min) | 0.0163 |

| qe (mg/g) | 2.49 | |

| R2 | 0.9723 | |

| Langmuir isotherm model | q (mg/g) | 16.53 |

| b (L/mg) | 0.00834 | |

| R2 | 0.4224 | |

| Freundlich isotherm model | KF (mg/g) | 0.183 |

| 1/n | 0.8264 | |

| R2 | 0.968 |

| Biochar Material | Dye Conc. (mg/L) | Dye Removal | Reference |

|---|---|---|---|

| Paper and pulp sludge | 25–100 | 84.8–90% | [42] |

| Bottom ash | 25–125 | 4.93–24.3 mg/g | [43] |

| Korean cabbage | 50–5000 | 1304 mg/g | [29] |

| Rice straw | 50–5000 | 620.3 mg/g | [29] |

| Wood chip | 50–5000 | 195.6 mg/g | [29] |

| Activated carbon | 50–5000 | 271 mg/g | [29] |

| Hornbeam sawdust | 50–500 | 71% | [44] |

| Rice husk | 50–300 | 25.8–98.2 mg/g | [45] |

| Bael shell | 50–500 | 74% | Present Study |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roy, K.; Verma, K.M.; Vikrant, K.; Goswami, M.; Sonwani, R.K.; Rai, B.N.; Vellingiri, K.; Kim, K.-H.; Giri, B.S.; Singh, R.S. Removal of Patent Blue (V) Dye Using Indian Bael Shell Biochar: Characterization, Application and Kinetic Studies. Sustainability 2018, 10, 2669. https://doi.org/10.3390/su10082669

Roy K, Verma KM, Vikrant K, Goswami M, Sonwani RK, Rai BN, Vellingiri K, Kim K-H, Giri BS, Singh RS. Removal of Patent Blue (V) Dye Using Indian Bael Shell Biochar: Characterization, Application and Kinetic Studies. Sustainability. 2018; 10(8):2669. https://doi.org/10.3390/su10082669

Chicago/Turabian StyleRoy, Kangkan, Kapil Mohan Verma, Kumar Vikrant, Mandavi Goswami, Ravi Kumar Sonwani, Birendra Nath Rai, Kowsalya Vellingiri, Ki-Hyun Kim, Balendu Shekher Giri, and Ram Sharan Singh. 2018. "Removal of Patent Blue (V) Dye Using Indian Bael Shell Biochar: Characterization, Application and Kinetic Studies" Sustainability 10, no. 8: 2669. https://doi.org/10.3390/su10082669