Mesoporous Silica as an Alternative Vehicle to Overcome Solubility Limitations

Abstract

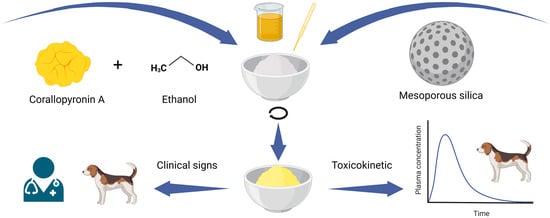

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of the Mesoporous Silica Formulation

2.2.2. Non-Sink Dissolution

2.2.3. Toxicology Study Setup

2.2.4. Toxicokinetic Analysis

2.2.5. Solubility Determination in Biorelevant Medium

3. Results and Discussion

3.1. Non-Sink Dissolution of CorA-Silica

3.2. Toxicokinetics

3.3. Clinical Observations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Parasuraman, S. Toxicological Screening. J. Pharmacol. Pharmacother. 2011, 2, 74–79. [Google Scholar] [CrossRef] [PubMed]

- Neervannan, S. Preclinical Formulations for Discovery and Toxicology: Physicochemical Challenges. Expert Opin. Drug Metab. Toxicol. 2006, 2, 715–731. [Google Scholar] [CrossRef] [PubMed]

- European Medicines Agency. Guideline on Repeated Dose Toxicity. 2010. Available online: https://www.ema.europa.eu/en/documents/scientific-guideline/guideline-repeated-dose-toxicity-revision-1_en.pdf (accessed on 28 January 2024).

- Gad, S.C.; Spainhour, C.B.; Shoemake, C.; Pallman, D.R.S.; Stricker-Krongrad, A.; Downing, P.A.; Seals, R.E.; Eagle, L.A.; Polhamus, K.; Daly, J. Tolerable Levels of Nonclinical Vehicles and Formulations Used in Studies by Multiple Routes in Multiple Species With Notes on Methods to Improve Utility. Int. J. Toxicol. 2016, 35, 95–178. [Google Scholar] [CrossRef] [PubMed]

- Stokes, A.H.; Kemp, D.C.; Faiola, B.; Jordan, H.L.; Merrill, C.L.; Hailey, J.R.; Brown, R.E.; Bailey, D.W. Effects of Solutol (Kolliphor) and Cremophor in Polyethylene Glycol 400 Vehicle Formulations in Sprague-Dawley Rats and Beagle Dogs. Int. J. Toxicol. 2013, 32, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Gierke, H.; Pfrommer, T.; Schäfer, K.; Weitschies, W.; Nolte, T. Pharmacobezoar Formation from HPMC-AS-Containing Spray-Dried Formulations in Nonclinical Safety Studies in Rats. Toxicol. Pathol. 2022, 50, 920–929. [Google Scholar] [CrossRef] [PubMed]

- Krome, A.K.; Becker, T.; Kehraus, S.; Schiefer, A.; Gütschow, M.; Chaverra-Muñoz, L.; Hüttel, S.; Jansen, R.; Stadler, M.; Ehrens, A.; et al. Corallopyronin A: Antimicrobial Discovery to Preclinical Development. Nat. Prod. Rep. 2022, 39, 1705–1720. [Google Scholar] [CrossRef] [PubMed]

- McCarthy, C.A.; Ahern, R.J.; Dontireddy, R.; Ryan, K.B.; Crean, A.M. Mesoporous Silica Formulation Strategies for Drug Dissolution Enhancement: A Review. Expert Opin. Drug Deliv. 2016, 13, 93–108. [Google Scholar] [CrossRef] [PubMed]

- GRACE. Technical Data Sheet SYLOID®-XDP Silica-Solution for Liquisolid Formulations. 2020. Available online: https://grace.com/products/syloid-silica/ (accessed on 24 February 2024).

- Vraníková, B.; Niederquell, A.; Ditzinger, F.; Šklubalová, Z.; Kuentz, M. Mechanistic Aspects of Drug Loading in Liquisolid Systems with Hydrophilic Lipid-Based Mixtures. Int. J. Pharm. 2020, 578, 119099. [Google Scholar] [CrossRef] [PubMed]

- Zecevic, D.E.; Wagner, K.G. Rational Development of Solid Dispersions via Hot-Melt Extrusion Using Screening, Material Characterization, and Numeric Simulation Tools. J. Pharm. Sci. 2013, 102, 2297–2310. [Google Scholar] [CrossRef] [PubMed]

- Krome, A.K.; Becker, T.; Kehraus, S.; Schiefer, A.; Steinebach, C.; Aden, T.; Frohberger, S.J.; Mármol, Á.L.; Kapote, D.; Jansen, R.; et al. Solubility and Stability Enhanced Oral Formulations for the Anti-Infective Corallopyronin A. Pharmaceutics 2020, 21, 1105. [Google Scholar] [CrossRef] [PubMed]

- Becker, T.; Krome, A.K.; Vahdati, S.; Schiefer, A.; Pfarr, K.; Ehrens, A.; Aden, T.; Grosse, M.; Jansen, R.; Alt, S.; et al. In Vitro–In Vivo Relationship in Mini-Scale—Enabling Formulations of Corallopyronin A. Pharmaceutics 2022, 14, 1657. [Google Scholar] [CrossRef] [PubMed]

- Hirlak, O.; Dieluweit, S.; Merkel, R.; Wagner, K.G. Polymer-Mediated Drug Supersaturation—A Spotlight on the Interplay between Phase-Separated Amorphous Drug Colloids and Dissolved Molecules. J. Colloid Interface Sci. 2021, 603, 370–379. [Google Scholar] [CrossRef] [PubMed]

| AUC0-inf | AUC0-inf per mg/kg Dose | Cmax | Tmax | |

|---|---|---|---|---|

| (µg/mL) | (h) | |||

| 150 mg/kg | 814.2 | 5.428 | 209.36 | 1 |

| (736.1–869.4) | (4.91–5.80) | (202.72–214.40) | (1–1.25) | |

| 450 mg/kg | 2805.3 | 6.234 | 287.79 | 3 |

| (2735.4–3201.5) | (6.08–7.11) | (248.61–337.93) | (2–4) | |

| 750 mg/kg | 3243.3 | 4.324 | 303.28 | 4 |

| (2856.2–3683.6) | (3.81–4.91) | (248.74–355.93) | (3.5–4) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Becker, T.; Heitkötter, J.; Krome, A.K.; Schiefer, A.; Pfarr, K.; Ehrens, A.; Grosse, M.; Sandargo, B.; Stammberger, I.; Stadler, M.; et al. Mesoporous Silica as an Alternative Vehicle to Overcome Solubility Limitations. Pharmaceutics 2024, 16, 386. https://doi.org/10.3390/pharmaceutics16030386

Becker T, Heitkötter J, Krome AK, Schiefer A, Pfarr K, Ehrens A, Grosse M, Sandargo B, Stammberger I, Stadler M, et al. Mesoporous Silica as an Alternative Vehicle to Overcome Solubility Limitations. Pharmaceutics. 2024; 16(3):386. https://doi.org/10.3390/pharmaceutics16030386

Chicago/Turabian StyleBecker, Tim, Jan Heitkötter, Anna K. Krome, Andrea Schiefer, Kenneth Pfarr, Alexandra Ehrens, Miriam Grosse, Birthe Sandargo, Ingo Stammberger, Marc Stadler, and et al. 2024. "Mesoporous Silica as an Alternative Vehicle to Overcome Solubility Limitations" Pharmaceutics 16, no. 3: 386. https://doi.org/10.3390/pharmaceutics16030386