The Influence of Formulation Components and Environmental Humidity on Spray-Dried Phage Powders for Treatment of Respiratory Infections Caused by Acinetobacter baumannii

Abstract

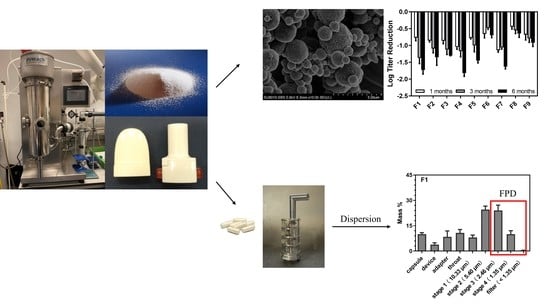

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Design of Experiment–Factorial Design

2.3. Phage Powder Preparation

2.4. Particle Morphology

2.5. Particle Size Distribution

2.6. Particle Crystallinity

2.7. Dynamic Vapor Sorption (DVS)

2.8. Thermal Analysis

2.9. In Vitro Aerosol Performance

2.10. Quantification of Trehalose by HPLC

2.11. Phage Stability in Powder

2.12. Statistical Analysis

3. Results

3.1. Production Loss AB406 Phage

3.2. Phage and Particle Morphology

3.3. Particle Size

3.4. Powder Crystallinity

3.5. Residual Moisture Content and Glass Transition Temperature

3.6. Moisture Sorption

3.7. In Vitro Aerosol Performance and the Effect of High Humidity

3.8. Phage Storage Stability

3.9. Response Surface Methodology Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gootz, T.D. The global problem of antibiotic resistance. Crit. Rev. Immunol. 2010, 30, 79–93. [Google Scholar] [CrossRef]

- World Health Organization. Global Priority List of Antibiotic-Resistant Bacteria to Guide Research, Discovery, and Development of New Antibiotics. 2017. Available online: https://www.who.int/medicines/publications/global-priority-list-antibiotic-resistant-bacteria/en/ (accessed on 18 February 2020).

- Czaplewski, L.; Bax, R.; Clokie, M.; Dawson, M.; Fairhead, H.; Fischetti, V.A.; Foster, S.; Gilmore, B.F.; Hancock, R.E.W.; Harper, D.; et al. Alternatives to antibiotics—A pipeline portfolio review. Lancet Infect. Dis. 2016, 16, 239–251. [Google Scholar] [CrossRef] [Green Version]

- Durdu, B.; Kritsotakis, E.I.; Lee, A.C.; Torun, P.; Hakyemez, I.N.; Gultepe, B.; Aslan, T. Temporal trends and patterns in antimicrobial-resistant Gram-negative bacteria implicated in intensive care unit-acquired infections: A cohort-based surveillance study in Istanbul, Turkey. J. Glob. Antimicrob. Resist. 2018, 14, 190–196. [Google Scholar] [CrossRef]

- Falagas, M.E.; Rafailidis, P.I. Attributable mortality of Acinetobacter baumannii: No longer a controversial issue. Crit. Care 2007, 11, 134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elizabeth, K.; Jan, B.; Ryszard, M.; Andrzej, G.; Beata, W.-D.; Mzia, K.; Zemphira, A.; Marina, G.; Revaz, A. Clinical phage therapy. In Phage Therapy: Current Research and Applications; Caister Academic Press: Norfolk, UK, 2014; Volumes 257–288. [Google Scholar]

- Schooley, R.T.; Biswas, B.; Gill, J.J.; Morales, A.C.H.; Lancaster, J.; Lessor, L.; Barr, J.J.; Reed, S.L.; Rohwer, F.; Benler, S.; et al. Development and use of personalized bacteriophage-based therapeutic cocktails to treat a patient with a disseminated resistant acinetobacter baumannii infection. Antimicrob. Agents Chemother. 2017, 61. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lavergne, S.; Hamilton, T.; Biswas, B.; Kumaraswamy, M.; Schooley, R.T.; Wooten, D. Phage therapy for a multidrug-resistant acinetobacter baumannii craniectomy site infection. Open Forum Infect. Dis. 2018, 5, ofy064. [Google Scholar] [CrossRef] [Green Version]

- Strathdee, S.A.; Patterson, T.L.; Barker, T. The Perfect Predator: A Scientist’s Race to Save Her Husband from a Deadly Superbug, 1st ed.; Hachette Books: New York, NY, USA; Boston, MA, USA, 2019. [Google Scholar]

- Hua, Y.; Luo, T.; Yang, Y.; Dong, D.; Wang, R.; Wang, Y.; Xu, M.; Guo, X.-K.; Hu, F.; He, P. Phage therapy as a promising new treatment for lung infection caused by carbapenem-resistant Acinetobacter baumannii in mice. Front. Microbiol. 2018, 8, 2659. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Mi, Z.; Niu, W.; An, X.; Yuan, X.; Liu, H.; Li, P.; Liu, Y.; Feng, Y.; Huang, Y.; et al. Intranasal treatment with bacteriophage rescues mice from Acinetobacter baumannii-mediated pneumonia. Future Microbiol. 2016, 11, 631–641. [Google Scholar] [CrossRef]

- Jeon, J.; Park, J.-H.; Yong, D. Efficacy of bacteriophage treatment against carbapenem-resistant Acinetobacter baumannii in Galleria mellonella larvae and a mouse model of acute pneumonia. BMC Microbiol. 2019, 19, 70. [Google Scholar] [CrossRef]

- Cha, K.; Oh, H.K.; Jang, J.Y.; Jo, Y.; Kim, W.K.; Ha, G.U.; Ko, K.S.; Myung, H. Characterization of two novel bacteriophages infecting multidrug-resistant (MDR) Acinetobacter baumannii and evaluation of their therapeutic efficacy in vivo. Front. Microbiol. 2018, 9, 696. [Google Scholar] [CrossRef] [Green Version]

- Wienhold, S.-M.; Brack, M.C.; Nouailles, G.; Suttorp, N.W.; Seitz, C.; Ross, A.; Ziehr, H.; Gurtner, C.; Kershaw, O.; Dietert, K.; et al. Witzenrath, intratracheal phage therapy against acinetobacter baumannii lung infection in mice. In D107. Host Pathogen Interactions; 2018; A7571. [Google Scholar]

- Zhou, Q.; Tang, P.; Leung, S.S.Y.; Chan, J.G.Y.; Chan, H.-K. Emerging inhalation aerosol devices and strategies: Where are we headed? Adv. Drug Deliv. Rev. 2014, 75, 3–17. [Google Scholar] [CrossRef]

- Leung, S.; Parumasivan, T.; Gao, F.G.; Carrigy, N.B.; Vehring, R.; Finlay, W.H.; Morales, S.; Britton, W.J.; Kutter, E.; Chan, H.-K. Production of inhalation phage powders using spray freeze drying and spray drying techniques for treatment of respiratory infections. Pharm. Res. 2016, 33, 1486–1496. [Google Scholar] [CrossRef]

- Leung, S.; Parumasivan, T.; Gao, F.G.; Carter, E.; Carrigy, N.B.; Vehring, R.; Finlay, W.H.; Morales, S.; Britton, W.J.; Kutter, E.; et al. Effects of storage conditions on the stability of spray dried, inhalable bacteriophage powders. Int. J. Pharm. 2017, 521, 141–149. [Google Scholar] [CrossRef] [Green Version]

- Leung, S.; Parumasivan, T.; Nguyen, A.; Gengenbach, T.; Carter, E.; Carrigy, N.B.; Wang, H.; Vehring, R.; Finlay, W.H.; Morales, S.; et al. Effect of storage temperature on the stability of spray dried bacteriophage powders. Eur. J. Pharm. Biopharm. 2018, 127, 213–222. [Google Scholar] [CrossRef]

- Matinkhoo, S.; Lynch, K.H.; Dennis, J.; Finlay, W.H.; Vehring, R. Spray-dried respirable powders containing bacteriophages for the treatment of pulmonary infections. J. Pharm. Sci. 2011, 100, 5197–5205. [Google Scholar] [CrossRef]

- Vandenheuvel, D.; Singh, A.; Vandersteegen, K.; Klumpp, J.; Lavigne, R.; Mooter, G.V.D. Feasibility of spray drying bacteriophages into respirable powders to combat pulmonary bacterial infections. Eur. J. Pharm. Biopharm. 2013, 84, 578–582. [Google Scholar] [CrossRef] [PubMed]

- Chang, R.Y.K.; Wong, J.; Mathai, A.; Morales, S.; Kutter, E.; Britton, W.; Li, J.; Chan, H.-K. Production of highly stable spray dried phage formulations for treatment of Pseudomonas aeruginosa lung infection. Eur. J. Pharm. Biopharm. 2017, 121, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Chang, R.Y.K.; Chen, K.; Wang, J.; Wallin, M.; Britton, W.; Morales, S.; Kutter, E.; Li, J.; Chan, H.-K. Proof-of-principle study in a murine lung infection model of antipseudomonal activity of phage PEV20 in a dry-powder formulation. Antimicrob. Agents Chemother. 2018, 62, e01714-17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vandenheuvel, D.; Meeus, J.; Lavigne, R.; Mooter, G.V.D. Instability of bacteriophages in spray-dried trehalose powders is caused by crystallization of the matrix. Int. J. Pharm. 2014, 472, 202–205. [Google Scholar] [CrossRef]

- STAT 503, PennState Stat. Lesson 9: 3-Level and Mixed-Level Factorials and Fractional Factorials. Available online: https://online.stat.psu.edu/stat503/lesson/9 (accessed on 12 January 2021).

- Chan, P.K.; Mok, H.; Lee, T.; Chu, I.M.; Lam, W.-Y.; Sung, J.J.Y. Seasonal influenza activity in Hong Kong and its association with meteorological variations. J. Med. Virol. 2009, 81, 1797–1806. [Google Scholar] [CrossRef]

- Brooks, R.T.; Kyker-Snowman, T.D. Forest floor temperature and relative humidity following timber harvesting in southern New England, USA. For. Ecol. Manag. 2008, 254, 65–73. [Google Scholar] [CrossRef]

- Current Results. Average Humidity by US State. Available online: https://www.currentresults.com/Weather/US/annual-average-humidity-by-state.php (accessed on 12 January 2021).

- Procedures and Protocols. The Actinobacteriophage Database. Available online: https://phagesdb.org/workflow/ (accessed on 14 September 2020).

- Adriaenssens, E.M.; Lehman, S.M.; Vandersteegen, K.; Vandenheuvel, D.; Philippe, D.L.; Cornelissen, A.; Clokie, M.R.; García, A.J.; De Proft, M.; Maes, M.; et al. CIM® monolithic anion-exchange chromatography as a useful alternative to CsCl gradient purification of bacteriophage particles. Virology 2012, 434, 265–270. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zimmer, F.; Souza, A.; Silveira, A.; Santos, M.; Matsushita, M.; Souza, N.; Rodrigues, A. Application of factorial design for optimization of the synthesis of lactulose obtained from whey permeate. J. Braz. Chem. Soc. 2017. [Google Scholar] [CrossRef]

- Malcolmson, R.J.; Embleton, J.K. Dry powder formulations for pulmonary delivery. Pharm. Sci. Technol. Today 1998, 1, 394–398. [Google Scholar] [CrossRef]

- Kutter, E.; Sulakvelidze, A. Bacteriophages: Biology and Applications. CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Dini, C.; De Urraza, P. Effect of buffer systems and disaccharides concentration on Podoviridae coliphage stability during freeze drying and storage. Cryobiology 2013, 66, 339–342. [Google Scholar] [CrossRef]

- Merabishvili, M.; Vervaet, C.; Pirnay, J.-P.; De Vos, D.; Verbeken, G.; Mast, J.; Chanishvili, N.; Vaneechoutte, M. Stability of staphylococcus aureus phage ISP after freeze-drying (lyophilization). PLoS ONE 2013, 8, e68797. [Google Scholar] [CrossRef] [Green Version]

- Carrigy, N.; Liang, L.; Wang, H.; Kariuki, S.; Nagel, T.E.; Connerton, I.; Vehring, R. Spray-dried anti-Campylobacter bacteriophage CP30A powder suitable for global distribution without cold chain infrastructure. Int. J. Pharm. 2019, 569, 118601. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, S.S.; Suryanarayanan, R.; Rinella, J.V.; Bogner, R.H. Mechanisms by which crystalline mannitol improves the reconstitution time of high concentration lyophilized protein formulations. Eur. J. Pharm. Biopharm. 2018, 131, 70–81. [Google Scholar] [CrossRef]

- Mandato, S.; Rondet, E.; Delaplace, G.; Barkouti, A.; Galet, L.; Accart, P.; Ruiz, T.; Cuq, B. Liquids’ atomization with two different nozzles: Modeling of the effects of some processing and formulation conditions by dimensional analysis. Powder Technol. 2012, 224, 323–330. [Google Scholar] [CrossRef] [Green Version]

- Sou, T.; Kaminskas, L.; Nguyen, T.-H.; Carlberg, R.; McIntosh, M.P.; Morton, D.A. The effect of amino acid excipients on morphology and solid-state properties of multi-component spray-dried formulations for pulmonary delivery of biomacromolecules. Eur. J. Pharm. Biopharm. 2013, 83, 234–243. [Google Scholar] [CrossRef]

- Li, L.; Sun, S.; Parumasivan, T.; Denman, J.A.; Gengenbach, T.; Tang, P.; Mao, S.; Chan, H.-K. l-Leucine as an excipient against moisture on in vitro aerosolization performances of highly hygroscopic spray-dried powders. Eur. J. Pharm. Biopharm. 2016, 102, 132–141. [Google Scholar] [CrossRef] [PubMed]

- Kaialy, W.; Hussain, T.; Alhalaweh, A.; Nokhodchi, A. Towards a more desirable dry powder inhaler formulation: Large spray-dried mannitol microspheres outperform small microspheres. Pharm. Res. 2014, 31, 60–76. [Google Scholar] [CrossRef] [Green Version]

- Roe, K.D.; Labuza, T.P. Glass transition and crystallization of amorphous trehalose-sucrose mixtures. Int. J. Food Prop. 2005, 8, 559–574. [Google Scholar] [CrossRef]

- Stojanovska, S.; Gruevska, N.; Tomovska, J.; Tasevska, J. Maillard reaction and lactose structural changes during milk processing. Mail. React. Lact. Struct. Chang. Milk Process. 2017, 2, 139–145. [Google Scholar]

- Zhang, Y.; Zhang, H.; Ghosh, D. The stabilizing excipients in dry state therapeutic phage formulations. AAPS Pharmscitech 2020, 21, 1–14. [Google Scholar] [CrossRef]

- Trouwborst, T.; De Jong, J.C.; Winkler, K.C. Mechanism of inactivation in aerosols of bacteriophage T1. J. Gen. Virol. 1972, 15, 235–242. [Google Scholar] [CrossRef] [PubMed]

- Feng, A.; Boraey, M.; Gwin, M.; Finlay, P.; Kuehl, P.; Vehring, R. Mechanistic models facilitate efficient development of leucine containing microparticles for pulmonary drug delivery. Int. J. Pharm. 2011, 409, 156–163. [Google Scholar] [CrossRef]

- Chang, R.Y.K.; Kwok, P.C.L.; Khanal, D.; Morales, S.; Kutter, E.; Li, J.; Chan, H. Inhalable bacteriophage powders: Glass transition temperature and bioactivity stabilization. Bioeng. Transl. Med. 2020, 5, e10159. [Google Scholar] [CrossRef]

- Drake, A.C.; Lee, Y.; Burgess, E.M.; Karlsson, J.O.M.; Eroglu, A.; Higgins, A.Z. Effect of water content on the glass transition temperature of mixtures of sugars, polymers, and penetrating cryoprotectants in physiological buffer. PLoS ONE 2018, 13, e0190713. [Google Scholar] [CrossRef] [Green Version]

- Puapermpoonsiri, U.; Ford, S.; van der Walle, C. Stabilization of bacteriophage during freeze drying. Int. J. Pharm. 2010, 389, 168–175. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, X.; Zhang, H.; Watts, A.B.; Ghosh, D. Manufacturing and ambient stability of shelf freeze dried bacteriophage powder formulations. Int. J. Pharm. 2018, 542, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Greco, S.; Authelin, J.-R.; Leveder, C.; Segalini, A. A practical method to predict physical stability of amorphous solid dispersions. Pharm. Res. 2012, 29, 2792–2805. [Google Scholar] [CrossRef] [PubMed]

- Cleland, J.L.; Lam, X.; Kendrick, B.; Yang, J.; Yang, T.; Overcashier, D.; Brooks, D.; Hsu, C.; Carpenter, J.F. A specific molar ratio of stabilizer to protein is required for storage stability of a lyophilized monoclonal antibody. J. Pharm. Sci. 2001, 90, 310–321. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef] [PubMed]

| Formulation | Trehalose % | Mannitol % | Leucine % | Total Solid Content (mg/mL) | VMD ± SD (μm) | Span ± SD |

|---|---|---|---|---|---|---|

| F1 (T80M0-20) | 80 | 0 | 20 | 20 | 4.59 ± 0.06 | 1.07 ± 0.02 |

| F2 (T60M20-20) | 60 | 20 | 20 | 20 | 3.99 ± 0.02 | 0.68 ± 0.04 |

| F3 (T40M40-20) | 40 | 40 | 20 | 20 | 3.69 ± 0.01 | 1.61 ± 0.01 |

| F4 (T80M0-40) | 80 | 0 | 20 | 40 | 4.55 ± 0.05 | 1.04 ± 0.01 |

| F5(T60M20-40) | 60 | 20 | 20 | 40 | 4.64 ± 0.01 | 1.01 ± 0.01 |

| F6 (T40M40-40) | 40 | 40 | 20 | 40 | 4.36 ± 0.01 | 1.02 ± 0.01 |

| F7 (T80M0-60) | 80 | 0 | 20 | 60 | 4.81 ± 0.03 | 1.04 ± 0.01 |

| F8 (T60M20-60) | 60 | 20 | 20 | 60 | 4.55 ± 0.01 | 1.01 ± 0.01 |

| F9 (T40M40-60) | 40 | 40 | 20 | 60 | 4.41 ± 0.01 | 1.04 ± 0.01 |

| Formulation | Residual Moisture Content (%) | Tg (°C) |

|---|---|---|

| F1 (T80M0-20) | 2.93 | 110.76 |

| F2 (T60M20-20) | 1.91 | 44.82 |

| F3 (T40M40-20) | 2.55 | 15.97 |

| F4 (T80M0-40) | 2.57 | 112.22 |

| F5(T60M20-40) | 2.34 | 45.32 |

| F6 (T40M40-40) | 1.77 | 17.04 |

| F7 (T80M0-60) | 3.12 | 112.95 |

| F8 (T60M20-60) | 3.49 | 45.54 |

| F9 (T40M40-60) | 2.77 | 16.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, W.; He, R.; Tang, X.; Tian, B.; Liu, Y.; Tong, Y.; To, K.K.W.; Leung, S.S.Y. The Influence of Formulation Components and Environmental Humidity on Spray-Dried Phage Powders for Treatment of Respiratory Infections Caused by Acinetobacter baumannii. Pharmaceutics 2021, 13, 1162. https://doi.org/10.3390/pharmaceutics13081162

Yan W, He R, Tang X, Tian B, Liu Y, Tong Y, To KKW, Leung SSY. The Influence of Formulation Components and Environmental Humidity on Spray-Dried Phage Powders for Treatment of Respiratory Infections Caused by Acinetobacter baumannii. Pharmaceutics. 2021; 13(8):1162. https://doi.org/10.3390/pharmaceutics13081162

Chicago/Turabian StyleYan, Wei, Ruide He, Xiaojiao Tang, Bin Tian, Yannan Liu, Yigang Tong, Kenneth K. W. To, and Sharon S. Y. Leung. 2021. "The Influence of Formulation Components and Environmental Humidity on Spray-Dried Phage Powders for Treatment of Respiratory Infections Caused by Acinetobacter baumannii" Pharmaceutics 13, no. 8: 1162. https://doi.org/10.3390/pharmaceutics13081162