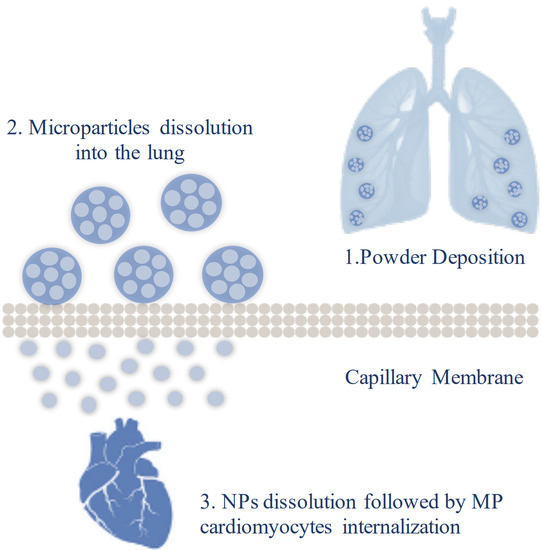

Inhalable Microparticles Embedding Calcium Phosphate Nanoparticles for Heart Targeting: The Formulation Experimental Design

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. DoE for the Manufacturing of Microparticles Embedding Nanoparticles

2.2.2. Microparticle Morphology by Scanning Electron Microscopy (FESEM-FIB)

2.2.3. Microparticle Size Distribution by Laser Diffraction

2.2.4. In Vitro Aerodynamic Assessment of Microparticles by Fast-Screening Impactor (FSI)

2.2.5. Density Measurement

2.2.6. Thermogravimetric Analysis (TGA)

2.2.7. Dimensional Analysis and Surface Charge of Released Nanoparticles by Dynamics Light Scattering

3. Results and Discussion

3.1. DoE Analysis of Microparticle Manufacturing

3.1.1. Yield of the Spray Drying Process

3.1.2. Moisture Content

3.1.3. Particle Size Distribution of Microparticulate Dry Powders

3.1.4. Aerodynamic Performance of Spray Dried Powders

3.1.5. Z-Average of Nanoparticles Released in Water

3.2. Particle Morphology of DoE Powders

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rusconi, F.; Ceriotti, P.; Miragoli, M.; Carullo, P.; Salvarani, N.; Rocchetti, M.; Pasquale, E.D.; Rossi, S.; Tessari, M.; Caprari, S.; et al. Peptidomimetic Targeting of Cavβ2 Overcomes Dysregulation of the L-Type Calcium Channel Density and Recovers Cardiac Function. Circulation 2016, 134, 534–546. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miragoli, M.; Ceriotti, P.; Iafisco, M.; Vacchiano, M.; Salvarani, N.; Alogna, A.; Carullo, P.; Ramirez-Rodríguez, G.B.; Patrício, T.; Esposti, L.D.; et al. Inhalation of Peptide-Loaded Nanoparticles Improves Heart Failure. Sci. Transl. Med. 2018, 10, eaan6205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Malamatari, M.; Charisi, A.; Malamataris, S.; Kachrimanis, K.; Nikolakakis, I. Spray Drying for the Preparation of Nanoparticle-Based Drug Formulations as Dry Powders for Inhalation. Process 2020, 8, 788. [Google Scholar] [CrossRef]

- Politis, S.N.; Colombo, P.; Colombo, G.; Rekkas, D.M. Design of Experiments (DoE) in Pharmaceutical Development. Drug Dev. Ind. Pharm. 2017, 43, 889–901. [Google Scholar] [CrossRef]

- Buttini, F.; Rozou, S.; Rossi, A.; Zoumpliou, V.; Rekkas, D.M. The Application of Quality by Design Framework in the Pharmaceutical Development of Dry Powder Inhalers. Eur. J. Pharm. Sci. 2018, 113, 64–76. [Google Scholar] [CrossRef]

- Esposti, L.D.; Dotti, A.; Adamiano, A.; Fabbi, C.; Quarta, E.; Colombo, P.; Catalucci, D.; Luca, C.D.; Iafisco, M. Calcium Phosphate Nanoparticle Precipitation by a Continuous Flow Process: A Design of an Experiment Approach. Crystals 2020, 10, 953. [Google Scholar] [CrossRef]

- Iafisco, M.; Bosco, R.; Leeuwenburgh, S.C.G.; van den Beucken, J.J.J.P.; Jansen, J.A.; Prat, M.; Roveri, N. Electrostatic Spray Deposition of Biomimetic Nanocrystalline Apatite Coatings onto Titanium. Adv. Eng. Mater. 2012, 14, B13–B20. [Google Scholar] [CrossRef]

- Dormenval, C.; Lokras, A.; Cano-Garcia, G.; Wadhwa, A.; Thanki, K.; Rose, F.; Thakur, A.; Franzyk, H.; Foged, C. Identification of Factors of Importance for Spray Drying of Small Interfering RNA-Loaded Lipidoid-Polymer Hybrid Nanoparticles for Inhalation. Pharmaceut. Res. 2019, 36, 142. [Google Scholar] [CrossRef]

- Kanojia, G.; Willems, G.-J.; Frijlink, H.W.; Kersten, G.F.A.; Soema, P.C.; Amorij, J.-P. A Design of Experiment Approach to Predict Product and Process Parameters for a Spray Dried Influenza Vaccine. Int. J. Pharmaceut. 2016, 511, 1098–1111. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- LeClair, D.A.; Cranston, E.D.; Xing, Z.; Thompson, M.R. Optimization of Spray Drying Conditions for Yield, Particle Size and Biological Activity of Thermally Stable Viral Vectors. Pharmaceut. Res. 2016, 33, 2763–2776. [Google Scholar] [CrossRef] [Green Version]

- Maa, Y.-F.; Nguyen, P.-A.; Andya, J.D.; Dasovich, N.; Sweeney, T.D.; Shire, S.J.; Hsu, C.C. Effect of Spray Drying and Subsequent Processing Conditions on Residual Moisture Content and Physical/Biochemical Stability of Protein Inhalation Powders. Pharmaceut. Res. 1998, 15, 768–775. [Google Scholar] [CrossRef]

- Belotti, S.; Rossi, A.; Colombo, P.; Bettini, R.; Rekkas, D.; Politis, S.; Colombo, G.; Balducci, A.G.; Buttini, F. Spray Dried Amikacin Powder for Inhalation in Cystic Fibrosis Patients: A Quality by Design Approach for Product Construction. Int. J. Pharmaceut. 2014, 471, 507–515. [Google Scholar] [CrossRef]

- Vehring, R. Pharmaceutical Particle Engineering via Spray Drying. Pharmaceut. Res. 2008, 25, 999–1022. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Boer, A.H.; Thalberg, K. Inhaled Medicines; Chapter 5—Dry powder inhalers (DPIs); Academic Press: New York, NY, USA, 2021; pp. 99–146. [Google Scholar] [CrossRef]

- Lechanteur, A.; Evrard, B. Influence of Composition and Spray-Drying Process Parameters on Carrier-Free DPI Properties and Behaviors in the Lung: A Review. Pharmaceutics 2020, 12, 55. [Google Scholar] [CrossRef] [Green Version]

- De Boer, A.H.; Hagedoorn, P.; Hoppentocht, M.; Buttini, F.; Grasmeijer, F.; Frijlink, H.W. Dry Powder Inhalation: Past, Present and Future. Expert. Opin. Drug Del. 2016, 14, 499–512. [Google Scholar] [CrossRef] [Green Version]

- Thorley, A.J.; Ruenraroengsak, P.; Potter, T.E.; Tetley, T.D. Critical Determinants of Uptake and Translocation of Nanoparticles by the Human Pulmonary Alveolar Epithelium. ACS Nano 2014, 8, 11778–11789. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Islam, M.A.; Barua, S.; Barua, D. A Multiscale Modeling Study of Particle Size Effects on the Tissue Penetration Efficacy of Drug-Delivery Nanoparticles. BMC Syst. Biol. 2017, 11, 113. [Google Scholar] [CrossRef] [Green Version]

- Keil, T.W.M.; Feldmann, D.P.; Costabile, G.; Zhong, Q.; da Rocha, S.; Merkel, O.M. Characterization of Spray Dried Powders with Nucleic Acid-Containing PEI Nanoparticles. Eur. J. Pharm. Biopharm. 2019, 143, 61–69. [Google Scholar] [CrossRef] [PubMed]

- Peng, T.; Zhang, X.; Huang, Y.; Zhao, Z.; Liao, Q.; Xu, J.; Huang, Z.; Zhang, J.; Wu, C.; Pan, X.; et al. Nanoporous Mannitol Carrier Prepared by Non-Organic Solvent Spray Drying Technique to Enhance the Aerosolization Performance for Dry Powder Inhalation. Sci. Rep. 2017, 7, 46517. [Google Scholar] [CrossRef] [Green Version]

- Torge, A.; Grützmacher, P.; Mücklich, F.; Schneider, M. The Influence of Mannitol on Morphology and Disintegration of Spray-Dried Nano-Embedded Microparticles. Eur. J. Pharm. Sci. 2017, 104, 171–179. [Google Scholar] [CrossRef]

- Chougule, M.; Padhi, B.; Jinturkar, K.; Misra, A. Development of Dry Powder Inhalers. Recent Patents Drug Deliv. Formul. 2007, 1, 11–21. [Google Scholar] [CrossRef] [PubMed]

- Littringer, E.M.; Mescher, A.; Schroettner, H.; Achelis, L.; Walzel, P.; Urbanetz, N.A. Spray Dried Mannitol Carrier Particles with Tailored Surface Properties—The Influence of Carrier Surface Roughness and Shape. Eur. J. Pharm. Biopharm. 2012, 82, 194–204. [Google Scholar] [CrossRef] [PubMed]

- Boel, E.; Koekoekx, R.; Dedroog, S.; Babkin, I.; Vetrano, M.R.; Clasen, C.; den Mooter, G.V. Unraveling Particle Formation: From Single Droplet Drying to Spray Drying and Electrospraying. Pharmaceutics 2020, 12, 625. [Google Scholar] [CrossRef]

- Singh, A.; Mooter, G.V. den Spray Drying Formulation of Amorphous Solid Dispersions. Adv. Drug Deliv. Rev. 2016, 100, 27–50. [Google Scholar] [CrossRef] [PubMed]

- Vehring, R.; Snyder, H.; Lechuga-Ballesteros, D. Drying Technologies for Biotechnology and Pharmaceutical Applications; Chapter 7—Spray drying; Wiley Online Library: Hoboken, NJ, USA, 2020; pp. 179–216. [Google Scholar] [CrossRef] [Green Version]

- Muddana, H.S.; Morgan, T.T.; Adair, J.H.; Butler, P.J. Photophysics of Cy3-Encapsulated Calcium Phosphate Nanoparticles. Nano Lett. 2009, 9, 1559–1566. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Höistad, M.; Chen, K.C.; Nicholson, C.; Fuxe, K.; Kehr, J. Quantitative Dual-probe Microdialysis: Evaluation of [3H]Mannitol Diffusion in Agar and Rat Striatum. J. Neurochem. 2002, 81, 80–93. [Google Scholar] [CrossRef] [Green Version]

- Gomez, M.; McCollum, J.; Wang, H.; Ordoubadi, M.; Jar, C.; Carrigy, N.B.; Barona, D.; Tetreau, I.; Archer, M.; Gerhardt, A.; et al. Development of a Formulation Platform for a Spray-Dried, Inhalable Tuberculosis Vaccine Candidate. Int. J. Pharmaceut. 2020, 593, 120121. [Google Scholar] [CrossRef] [PubMed]

- Tsapis, N.; Dufresne, E.R.; Sinha, S.S.; Riera, C.S.; Hutchinson, J.W.; Mahadevan, L.; Weitz, D.A. Onset of Buckling in Drying Droplets of Colloidal Suspensions. Phys. Rev. Lett. 2005, 94, 018302. [Google Scholar] [CrossRef]

- Wang, H.; Nobes, D.S.; Vehring, R. Particle Surface Roughness Improves Colloidal Stability of Pressurized Pharmaceutical Suspensions. Pharmaceut. Res. 2019, 36, 43. [Google Scholar] [CrossRef]

- Chew, N.Y.K.; Tang, P.; Chan, H.-K.; Raper, J.A. How Much Particle Surface Corrugation Is Sufficient to Improve Aerosol Performance of Powders? Pharmaceut. Res. 2005, 22, 148–152. [Google Scholar] [CrossRef]

| Std | Run | Factor A CaPs Concentration (mg/mL) | Factor B Mannitol Concentration (mg/mL) | Factor C Feed Rate (mL/min) |

|---|---|---|---|---|

| 4 | 1 | 7.00 | 2.00 | 3.50 |

| 2 | 2 | 7.00 | 0.50 | 3.50 |

| 3 | 3 | 0.50 | 2.00 | 3.50 |

| 9 | 4 | 3.75 | 1.25 | 5.25 |

| 1 | 5 | 0.50 | 0.50 | 3.50 |

| 6 | 6 | 7.00 | 0.50 | 7.00 |

| 5 | 7 | 0.50 | 0.50 | 7.00 |

| 10 | 8 | 3.75 | 1.25 | 5.25 |

| 7 | 9 | 0.50 | 2.00 | 7.00 |

| 11 | 10 | 3.75 | 1.25 | 5.25 |

| 8 | 11 | 7.00 | 2.00 | 7.00 |

| Factors | Responses | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Run | A CaPs (mg/mL) | B Mannitol (mg/mL) | C Feed Rate (ml/min) | Yield (%) | Moisture Content (%) | Z-Average Diameter (nm) | Dv50 (μm) | ED (mg) | FPD (mg) |

| 1 | +1 | +1 | −1 | 84.4 | 1.2 ± 0.1 | 313.4 ± 7.0 | 3.0 ± 0.1 | 38.1 ± 0.2 | 11.8 ± 0.2 |

| 2 | +1 | −1 | −1 | 62.5 | 1.3 ± 0.1 | 1787.0 ± 15.0 | 2.1 ± 0.1 | 33.0 ± 0.4 | 17.0 ± 0.3 |

| 3 | −1 | +1 | −1 | 58.4 | 1.5 ± 0.1 | 85.4 ± 6.0 | 1.6 ± 0.1 | 32.1 ± 0.3 | 23.8 ± 0.4 |

| 4 | 0 | 0 | 0 | 85.0 | 3.2 ± 0.2 | 400.0 ± 7.0 | 2.6 ± 0.2 | 34.0 ± 0.2 | 20.0 ± 0.3 |

| 5 | −1 | −1 | −1 | 53.2 | 4.0 ± 0.2 | 839.5 ± 6.0 | 3.1 ± 0.1 | 34.6 ± 0.3 | 24.3 ± 0.2 |

| 6 | +1 | −1 | +1 | 75.2 | 3.6 ± 0.1 | 1992.0 ± 21.0 | 3.3 ± 0.2 | 37.6 ± 0.2 | 12.9 ± 0.2 |

| 7 | −1 | −1 | +1 | 34.4 | 3.2 ± 0.1 | 957.4 ± 4.0 | 2.3 ± 0.2 | 31.5 ± 0.2 | 16.2 ± 0.3 |

| 8 | 0 | 0 | 0 | 72.2 | 2.8 ± 0.1 | 892.0 ± 8.0 | 3.0 ± 0.1 | 32.2 ± 0.1 | 23.4 ± 0.3 |

| 9 | −1 | +1 | +1 | 61.8 | 1.4 ± 0.1 | 428.0 ± 7.0 | 2.8 ± 0.2 | 35.6 ± 0.1 | 15.4 ± 0.3 |

| 10 | 0 | 0 | 0 | 85.0 | 2.5 ± 0.2 | 423.0 ± 6.0 | 2.9 ± 0.1 | 32.7 ± 0.2 | 24.3 ± 0.2 |

| 11 | +1 | +1 | +1 | 81.8 | 1.5 ± 0.2 | 418.4 ± 10.0 | 3.5 ± 0.1 | 37.1 ± 0.4 | 15.4 ± 0.4 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 1621.05 | 2 | 810.53 | 15.02 | 0.0029 | significant |

| A-CaPs conc. | 1154.40 | 1 | 1154.40 | 21.39 | 0.0024 | |

| B-Mannitol conc. | 466.65 | 1 | 466.65 | 8.65 | 0.0217 | |

| Curvature | 613.66 | 1 | 613.66 | 11.37 | 0.0119 | |

| Residual | 377.85 | 7 | 53.98 | |||

| Lack of Fit | 268.63 | 5 | 53.73 | 0.98 | 0.5738 | not significant |

| Pure Error | 109.23 | 2 | 54.61 | |||

| Cor Total | 2612.57 | 10 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 5.28 | 1 | 5.28 | 9.20 | 0.0162 | significant |

| B-Mannitol conc. | 5.28 | 1 | 5.28 | 9.20 | 0.0162 | |

| Curvature | 0.84 | 1 | 0.84 | 1.46 | 0.2608 | |

| Residual | 4.59 | 8 | 0.57 | |||

| Lack of Fit | 4.35 | 6 | 0.72 | 5.88 | 0.1526 | not significant |

| Pure Error | 0.25 | 2 | 0.12 | |||

| Cor Total | 10.72 | 10 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 0.95 | 5 | 0.18 | 0.35 | 0.8590 | not significant |

| A-CaPs conc | 0.03 | 1 | 0.03 | 0.06 | 0.8214 | |

| B-Mannitol conc | 0.00 | 1 | 0.00 | 0.02 | 0.8920 | |

| C-Feed rate | 0.00 | 1 | 0.00 | 0.00 | 0.9639 | |

| AC | 0.45 | 1 | 0.45 | 0.84 | 0.4116 | |

| BC | 0.45 | 1 | 0.45 | 0.84 | 0.4116 | |

| Curvature | 0.00 | 1 | 0.00 | 0.01 | 0.9051 | |

| Residual | 2.15 | 4 | 0.54 | |||

| Lack of Fit | 0.21 | 2 | 0.11 | 0.11 | 0.9013 | not significant |

| Pure Error | 1.94 | 2 | 0.97 | |||

| Cor Total | 3.11 | 10 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 131.97 | 3 | 43.99 | 9.64 | 0.0104 | significant |

| A-CaPs conc | 63.84 | 1 | 63.84 | 13.99 | 0.0096 | |

| C-Feed rate | 36.12 | 1 | 36.13 | 7.92 | 0.0306 | |

| AC | 32.00 | 1 | 32.00 | 7.01 | 0.0381 | |

| Curvature | 65.20 | 1 | 65.20 | 14.29 | 0.0092 | |

| Residual | 27.38 | 6 | 4.56 | |||

| Lack of Fit | 17.09 | 4 | 4.27 | 0.83 | 0.6103 | not significant |

| Pure Error | 10.29 | 2 | 5.14 | |||

| Cor Total | 224.55 | 10 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 3.339 × 106 | 3 | 1.113 × 106 | 27.10 | 0.0007 | significant |

| A-CaPs conc. | 6.053 × 105 | 1 | 6.053 × 105 | 14.74 | 0.0086 | |

| B-Mannitol conc. | 2.344 × 106 | 1 | 2.344 × 106 | 57.10 | 0.0003 | |

| AB | 3.888 × 105 | 1 | 3.888 × 105 | 9.47 | 0.0217 | |

| Curvature | 1.722 × 105 | 1 | 1.722 × 105 | 4.19 | 0.0865 | |

| Residual | 2.644 × 105 | 6 | 41060.16 | |||

| Lack of Fit | 92176.29 | 4 | 23044.07 | 0.30 | 0.8600 | not significant |

| Pure Error | 1.542 × 105 | 2 | 77092.33 | |||

| Cor Total | 3.757 × 106 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quarta, E.; Sonvico, F.; Bettini, R.; De Luca, C.; Dotti, A.; Catalucci, D.; Iafisco, M.; Degli Esposti, L.; Colombo, G.; Trevisi, G.; et al. Inhalable Microparticles Embedding Calcium Phosphate Nanoparticles for Heart Targeting: The Formulation Experimental Design. Pharmaceutics 2021, 13, 1825. https://doi.org/10.3390/pharmaceutics13111825

Quarta E, Sonvico F, Bettini R, De Luca C, Dotti A, Catalucci D, Iafisco M, Degli Esposti L, Colombo G, Trevisi G, et al. Inhalable Microparticles Embedding Calcium Phosphate Nanoparticles for Heart Targeting: The Formulation Experimental Design. Pharmaceutics. 2021; 13(11):1825. https://doi.org/10.3390/pharmaceutics13111825

Chicago/Turabian StyleQuarta, Eride, Fabio Sonvico, Ruggero Bettini, Claudio De Luca, Alessandro Dotti, Daniele Catalucci, Michele Iafisco, Lorenzo Degli Esposti, Gaia Colombo, Giovanna Trevisi, and et al. 2021. "Inhalable Microparticles Embedding Calcium Phosphate Nanoparticles for Heart Targeting: The Formulation Experimental Design" Pharmaceutics 13, no. 11: 1825. https://doi.org/10.3390/pharmaceutics13111825