Investigation of Spark Plasma Sintering on Microstructure-Properties of Zirconia Reinforced Fluormica Glass for Dental Restorations

Abstract

:1. Introduction

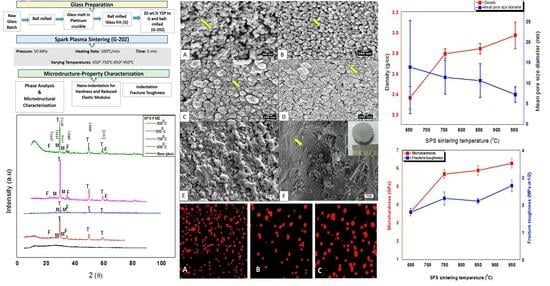

2. Materials and Methods

2.1. Glass Preparation

2.2. Sintering Method

2.3. Phase Analysis and Microstructural Characterization

2.4. Density and Porosity Characterization

2.5. Mechanical Characterization

2.5.1. Micro-Hardness

2.5.2. Nano-Indentation

2.5.3. Indentation Fracture Toughness

2.6. Comet Assay for Genotoxicity

2.7. Statistical Analysis

3. Results

4. Discussion

4.1. Phase Assemblage

4.2. Microstructural Characterization

4.3. Density and Porosity

4.4. Mechanical Characterization

4.5. Genotoxicity

5. Conclusions and Future Outlook

- Increase in SPS temperatures from 650 °C to 950 °C at a pressure of 50 MPa with a heating rate of 100 °C/min of 20 wt.% YSZ in fluormica glass retained tetragonal and monoclinic peaks of YSZ with amorphous glass.

- SPS-FMZ at 950 °C resulted in a microstructure of spherical agglomerates with particle coalescence.

- SPS with an increase in temperature improved the density and reduced the porosity of FMZ.

- The fracture toughness and hardness of SPS-FMZ were comparable to the properties required for a dental restorative material.

- There was an absence of genotoxicity of SPS-FMZ in human gingival fibroblast cells, indicating their cytocompatible nature in the oral cavity.

- YSZ played a role in enhancing the fracture toughness and densification of SPS FM glass.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Restorative Dentistry Market Size & Share Industry Report, 2018–2025. 2016. Available online: https//www.grandviewresearch.com/industry-analysis/restorative-dentistry-market (accessed on 12 February 2020).

- Kelly, J.R. Ceramics in Restorative and Prosthetic Dentistry. Annu. Rev. Mater. Sci. 1997, 27, 443–468. [Google Scholar] [CrossRef]

- McLaren, E.A.; Cao, P.T. Ceramics in Dentistry-Part I.; Classes of Materials. Inside Dentistry 2009, 7, 94–103. [Google Scholar]

- Pollington, S. Novel Glass-Ceramics for Dental Restorations. J. Contemp. Dent. Pract. 2011, 12, 60–67. [Google Scholar] [CrossRef]

- El-Meliegy, E.; Noort, R.V. Glasses and Glass-Ceramics for Medical Applications, 1st ed.; Springer: New York, NY, USA, 2012. [Google Scholar]

- Amaral, M.; Valandro, L.F.; Bottino, M.A.; Souza, R.O.A. Low-temperature degradation of a Y-TZP ceramic after surface treatments. J. Biomed. Mater. Res. Part B: Appl. Biomater. 2013, 101, 1387–1392. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-T.; Han, J.-S.; Yang, J.-H.; Lee, J.-B.; Kim, S.-H. The effect of low temperature aging on the mechanical property & phase stability of Y-TZP ceramics. J. Adv. Prosthodont. 2009, 1, 113–117. [Google Scholar] [CrossRef] [PubMed]

- Pereira, G.; Venturini, A.; Silvestri, T.; Dapieve, K.; Montagner, A.; Soares, F.; Valandro, L. Low-temperature degradation of Y-TZP ceramics: A systematic review and meta-analysis. J. Mech. Behav. Biomed. Mater. 2015, 55, 151–163. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lawn, B.R.; Malament, K.A.; Van Thompson, P.; Rekow, E.D. Damage accumulation and fatigue life of particle-abraded ceramics. Int. J. Prosthodont. 2007, 19, 442–448. [Google Scholar]

- Rinke, S.; Rödiger, M.; Ziebolz, D.; Schmidt, A.-K. Fabrication of Zirconia-Reinforced Lithium Silicate Ceramic Restorations Using a Complete Digital Workflow. Case Rep. Dent. 2015, 2015, 162178. [Google Scholar] [CrossRef]

- Molla, A.R.; Basu, B. Microstructure, mechanical, and in vitro properties of mica glass-ceramics with varying fluorine content. J. Mater. Sci. Mater. Med. 2009, 20, 869–882. [Google Scholar] [CrossRef]

- Qin, F.; Zheng, S.; Luo, Z.; Li, Y.; Guo, L.; Zhao, Y.; Fu, Q. Evaluation of machinability and flexural strength of a novel dental machinable glass-ceramic. J. Dent. 2009, 37, 776–780. [Google Scholar] [CrossRef] [PubMed]

- Taruta, S.; Sakata, M.; Yamaguchi, T.; Kitajima, K. Crystallization process and some properties of novel transparent machinable calcium-mica glass-ceramics. Ceram. Int. 2008, 34, 75–79. [Google Scholar] [CrossRef]

- Li, H.; You, D.-Q.; Zhou, C.-R.; Ran, J.-G. Study on machinable glass-ceramic containing fluorophlogopite for dental CAD/CAM system. J. Mater. Sci. Mater. Med. 2006, 17, 1133–1137. [Google Scholar] [CrossRef]

- Henry, J.; Hill, R. The influence of lithia content on the properties of fluorphlogopite glass-ceramics. II. Microstructure hardness and machinability. J. Non-Cryst. Solids 2003, 319, 13–30. [Google Scholar] [CrossRef]

- Taruta, S.; Watanabe, K.; Kitajima, K.; Takusagawa, N. Effect of titania addition on crystallization process and some properties of calcium mica–apatite glass-ceramics. J. Non-Cryst. Solids 2003, 321, 96–102. [Google Scholar] [CrossRef]

- Uno, T.; Kasuga, T.; Nakajima, K. High-Strength Mica-Containing Glass-Ceramics. J. Am. Ceram. Soc. 1991, 74, 3139–3141. [Google Scholar] [CrossRef]

- Gali, S.; Ravikumar, K.; Murthy, B.; Basu, B. Zirconia toughened mica glass ceramics for dental restorations. Dent. Mater. 2018, 34, e36–e45. [Google Scholar] [CrossRef]

- Gali, S.; RaviKumar, K. Zirconia toughened mica glass ceramics for dental restorations: Wear, thermal, optical and cytocompatibility properties. Dent. Mater. 2019, 35, 1706–1717. [Google Scholar] [CrossRef]

- Montazerian, M.; Alizadeh, P.; Yekta, B.E. Processing and properties of a mica–apatite glass–ceramic reinforced with Y-PSZ particles. J. Eur. Ceram. Soc. 2008, 28, 2693–2699. [Google Scholar] [CrossRef]

- Verné, E.; Defilippi, R.; Carl, G.; Brovarone, C.V.; Appendino, P. Viscous flow sintering of bioactive glass-ceramic composites toughened by zirconia particles. J. Eur. Ceram. Soc. 2003, 23, 675–683. [Google Scholar] [CrossRef]

- Yang, H.; Wu, S.; Hu, J.; Wang, Z.; Wang, R.; He, H. Influence of nano-ZrO2 additive on the bending strength and fracture toughness of fluoro-silicic mica glass–ceramics. Mater. Des. 2011, 32, 1590–1593. [Google Scholar] [CrossRef]

- Persson, C.; Unosson, E.; Ajaxon, I.; Engstrand, J.; Engqvist, H.; Xia, W. Nano grain sized zirconia–silica glass ceramics for dental applications. J. Eur. Ceram. Soc. 2012, 32, 4105–4110. [Google Scholar] [CrossRef]

- Uno, T.; Kasuga, T.; Nakayama, S.; Ikushima, A.J. Microstructure of Mica-Based Nanocomposite Glass-Ceramics. J. Am. Ceram. Soc. 1993, 76, 539–541. [Google Scholar] [CrossRef]

- Montazerian, M.; Alizadeh, P.; Yekta, B.E. Pressureless sintering and mechanical properties of mica glass–ceramic/Y-PSZ composite. J. Eur. Ceram. Soc. 2008, 28, 2687–2692. [Google Scholar] [CrossRef]

- Taruta, S.; Yamaguchi, I.; Yamakami, T.; Yamaguchi, T. Sintering behaviour and mechanical properties of machinable zirconia/mica composites. J. Asian Ceram. Soc. 2019, 7, 342–349. [Google Scholar] [CrossRef]

- Cavaliere, P. Spark Plasma Sintering, Advances in Processing and Applications, 1st ed.; Springer Link Nature: Cham, Switzerland, 2019. [Google Scholar]

- Gururaja, S.; Taya, M.; Kang, Y.S. Design of ferromagnetic shape memory alloy composite made of Fe and TiNi particles. J. Appl. Phys. 2007, 102, 064910. [Google Scholar] [CrossRef]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Shen, Z.; Johnsson, M.; Zhao, Z.; Nygren, M. Spark Plasma Sintering of Alumina. J. Am. Ceram. Soc. 2002, 85, 1921–1927. [Google Scholar] [CrossRef]

- Santanach, J.G.; Weibel, A.; Estournès, C.; Yang, Q.; Laurent, C.; Peigney, A. Spark plasma sintering of alumina, study of parameters, formal sintering analysis and hypotheses on the mechanism(s) involved in densification and grain growth. Acta Mater. 2011, 59, 1400–1408. [Google Scholar] [CrossRef]

- Stanciu, L.A.; Kodash, V.Y.; Groza, J.R. Effects of heating rate on densification and grain growth during field-assisted sintering of α-Al2O3 and MoSi2 powders. Met. Mater. Trans. A 2001, 32, 2633–2638. [Google Scholar] [CrossRef]

- Grasso, S.; Yoshida, H.; Porwal, H.; Sakka, Y.; Reece, M. Highly transparent α-alumina obtained by low cost high pressure SPS. Ceram. Int. 2012, 39, 3243–3248. [Google Scholar] [CrossRef]

- Wang, S.F.; Zhang, J.; Luo, D.W.; Gu, F.; Tang, D.Y.; Dong, Z.L.; Tan, G.E.B.; Que, W.X.; Zhang, T.S.; Li, S.; et al. Transparent ceramics, processing, materials and applications. Prog. Solid State Chem. 2013, 41, 20–54. [Google Scholar] [CrossRef]

- Chakravarty, D.; Ramesh, H.; Rao, T.N. High strength porous alumina by spark plasma sintering. J. Eur. Ceram. Soc. 2009, 29, 1361–1369. [Google Scholar] [CrossRef]

- Xue, B.; Calvez, L.; Nazabal, V.; Zhang, X.H.; Delaizir, G.; Monnier, J.; Martinelli, G.; Quiquempois, Y. Mechanical milling and SPS used to obtainGeS2-betaGeS2infrared glass-ceramic. J. Non-Cryst. Solids 2013, 377, 240–244. [Google Scholar] [CrossRef]

- Fu, L.; Engqvist, H.; Xia, W. Highly translucent and strong ZrO2-SiO2 nanocrystalline glass ceramic prepared by sol-gel method and spark plasma sintering with fine 3D microstructure for dental restoration. J. Eur. Ceram. Soc. 2017, 37, 4067–4081. [Google Scholar] [CrossRef]

- Riello, P.; Bucella, S.; Zamengo, L.; Anselmi-Tamburini, U.; Francini, R.; Pietrantoni, S.; Munir, Z. Erbium-doped LAS glass ceramics prepared by spark plasma sintering (SPS). J. Eur. Ceram. Soc. 2006, 26, 3301–3306. [Google Scholar] [CrossRef]

- Fu, L.; Wu, C.; Grandfield, K.; Unosson, E.; Chang, J.; Engqvist, H.; Xia, W. Transparent single crystalline ZrO2-SiO2 glass nanoceramic sintered by SPS. J. Eur. Ceram. Soc. 2016, 36, 3487–3494. [Google Scholar] [CrossRef]

- Lerdprom, W.; Grasso, S.; Jayaseelan, D.D.; Reece, M.J.; Lee, W.E. Densification behaviour and physico-mechanical properties of porcelains prepared using spark plasma sintering. Adv. Appl. Ceram. 2017, 116, 307–315. [Google Scholar] [CrossRef]

- Al Mansour, F.; Karpukhina, N.; Grasso, S.; Wilson, R.M.; Reece, M.J.; Cattell, M.J. The effect of spark plasma sintering on lithium disilicate glass-ceramics. Dent. Mater. 2015, 31, e226–e235. [Google Scholar] [CrossRef]

- Tsukada, G.; Sueyoshi, H.; Kamibayashi, H.; Tokuda, M.; Torii, M. Bending strength of zirconia/porcelain functionally graded materials prepared using spark plasma sintering. J. Dent. 2014, 42, 1569–1576. [Google Scholar] [CrossRef]

- Ghayebloo, M.; Alizadeh, P. Effect of zirconia nanoparticles on ZrO2-Bearing Lithium-Silicate glass-ceramic composite obtained by spark plasma sintering. J. Mech. Behav. Biomed. Mater. 2020, 110, 103880. [Google Scholar] [CrossRef]

- Singarapu, B.; Galusek, D.; Durán, A.; Pascual, M.J. Glass-Ceramics Processed by Spark Plasma Sintering (SPS) for Optical Applications. Appl. Sci. 2020, 10, 2791. [Google Scholar] [CrossRef]

- López-Esteban, S.; Gómez, J.F.B.; Díaz, L.A.; Esteban-Tejeda, L.; Prado, C.; López-Píriz, R.; Torrecillas, R.; Moya, J.S. Mechanical performance of a biocompatible biocide soda–lime glass-ceramic. J. Mech. Behav. Biomed. Mater. 2014, 34, 302–312. [Google Scholar] [CrossRef]

- Ghayebloo, M.; Alizadeh, P.; Melo, R. Fabrication of ZrO2-Bearing lithium-silicate glass-ceramics by pressureless sintering and spark plasma sintering. J. Mech. Behav. Biomed. Mater. 2020, 105, 103709. [Google Scholar] [CrossRef] [PubMed]

- Grasso, S.; Chinnam, R.K.; Porwal, H.; Boccaccini, A.R.; Reece, M.J. Low temperature spark plasma sintering of 45S5 Bioglass®. J. Non-Cryst. Solids 2013, 362, 25–29. [Google Scholar] [CrossRef]

- Soleimani, F.; Babaei, H.A.; Soleimani, M. Improving the machinability of fluorophlogopite glass-ceramic by spark plasma sintering. Ceram. Int. 2022, 48, 22545–22547. [Google Scholar] [CrossRef]

- Jayasree, R.; Raghava, K.; Sadhasivam, M.; Srinivas, P.; Vijay, R.; Pradeep, K.; Rao, T.; Chakravarty, D. Bi-layered metal-ceramic component for dental implants by spark plasma sintering. Mater. Lett. 2023, 344, 134403. [Google Scholar] [CrossRef]

- Msweli, N.P.; Akinwamide, S.O.; Olubambi, P.A.; Obadele, B.A. Microstructure and biocorrosion studies of spark plasma sintered yttria stabilized zirconia reinforced Ti6Al7Nb alloy in Hanks’ solution. Mater. Chem. Phys. 2023, 293, 126940. [Google Scholar] [CrossRef]

- Kubota, M. Properties of nano-structured pure Al produced by mechanical grinding and spark plasma sintering. J. Alloys Compd. 2007, 434–435, 294–297. [Google Scholar] [CrossRef]

- Ponton, C.B.; Rawlings, R.D. Vickers indentation fracture toughness test Part 1 Review of literature and formulation of standardised indentation toughness equations. Mater. Sci. Technol. 1989, 5, 865–872. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Anstis, G.; Chantikul, P.; Lawn, B.; Marshall, D. A Critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Bertolla, L.; Dlouhy, I.; Tatarko, P.; Viani, A.; Mahajan, A.; Chlup, A.; Reece, M.J.; Boccaccini, A.R. Pressureless spark plasma—Sintered Bioglass 45S5 with enhanced mechanical properties and stress—Induced new phase formation. J. Eur. Ceram. Soc. 2017, 37, 2727–2736. [Google Scholar] [CrossRef]

- Desogus, L.; Cuccu, A.; Montinaro, S.; Orru, R.; Cao, G.; Bellucci, D.; Sola, A.; Cannillo, V. Classical Bioglass® and innovative CaO-rich bioglass powders processed by Spark Plasma Sintering, A comparative study. J. Eur. Ceram. Soc. 2015, 35, 4277–4285. [Google Scholar] [CrossRef]

- Sharafat, A.; Abbas, S.H.; Mirva, E.; Natalia, A.W. A novel approach for processing CaAlSiON glass-ceramics by spark plasma sintering, Mechanical and electrical properties. J. Eur. Ceram. Soc. 2022, 42, 96–104. [Google Scholar]

- Dutta, S.; Devi, K.B.; Gupta, S.; Kundu, B.; Bhalla, V.K.; Roy, M. Mechanical and in vitro degradation behavior of magnesium-bioactive glass composites prepared by SPS for biomedical applications. J. Biomed. Mater. Res. B Appl. Biomater. 2019, 107, 352–365. [Google Scholar] [CrossRef] [PubMed]

- Holand, W.; Beall, G. Glass–Ceramic Technology; The American Ceramic Society: Westerville, OH, USA, 2002. [Google Scholar]

- Fuss, T.; Ray, C.; Lesher, C.; Day, D. In situ crystallization of lithium disilicate glass: Effect of pressure on crystal growth rate. J. Non-Cryst. Solids 2006, 352, 2073–2081. [Google Scholar] [CrossRef]

- Ulhmann, D.R.; Hays, J.F.; Turnbull, D. Effect of high pressure on crystallization kinetics with special reference to fused silica. Phys. Chem. Glasses 1966, 7, 159–166. [Google Scholar]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-Assisted Sintering Technology/Spark Plasma Sintering: Mechanisms, Materials, and Technology Developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Sakaguchi, R.L.; Powers, J.M. Physical Properties. In Craig’s Textbook for Dental Materials, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Mange, E.J.; Mange, A.P. Basic Human Genetics, 2nd ed.; Sinauer Associates Inc.: Sunderland, MA, USA, 1999; pp. 119–141. [Google Scholar]

- Fairbairn, D.W.; Olive, P.L.; O’Neill, K.L. The Comet assay, a comprehensive review. Mutat. Res. 1995, 339, 37–59. [Google Scholar] [CrossRef]

- Collins, A.R.; Dobson, V.L.; Dusinska, M.; Kennedy, G.; Stetina, R. The Comet assay, what can it really tell us? Mutat. Res. 1997, 375, 183–193. [Google Scholar] [CrossRef]

- Ribeiro, D.A.; Scolastici, C.; de Lima, P.L.A.; Marques, M.E.A.; Salvadori, D.M.F. Genotoxicity of antimicrobial endodontic compounds by single cell gel (comet) assay in Chinese hamster ovary (CHO) cells. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endodontol. 2005, 99, 637–640. [Google Scholar] [CrossRef]

- Ostling, O.; Johanson, K. Microelectrophoretic study of radiation-induced DNA damages in individual mammalian cells. Biochem. Biophys. Res. Commun. 1984, 123, 291–298. [Google Scholar] [CrossRef]

- Singh, N.P.; McCoy, M.T.; Tice, R.R.; Schneider, E.L. A simple technique for quantitation of low levels of DNA damage in individual cells. Exp. Cell Res. 1988, 175, 184–191. [Google Scholar] [CrossRef] [PubMed]

- dos Santos, N.C.N.; Soares, B.M.; Pessoa, C.D.; de Freitas, L.M.A.; Cruz, J.P.P.; Ramos, M.E.S.P.; Pithon, M.M.; Cerqueira, E.M.d.M. Evaluation of the Genotoxicity of Endodontic Materials for Deciduous Teeth Using the Comet Assay. Pesqui. Bras. Odontopediatria Clín. Integr. 2021, 21, e0060. [Google Scholar] [CrossRef]

- Noushad, M.; Kannan, T.P.; Husein, A.; Abdullah, H.; Ismail, A.R. Genotoxicity evaluation of locally produced dental porcelain—An in vitro study using the Ames and Comet assays. Toxicol. Vitr. 2009, 23, 1145–1150. [Google Scholar] [CrossRef]

- Anusavice, K.J.; Shen, C.; Rawls, H.R. Chapter 7 Biocompatibility. In Phillips Science of Dental Materials, 12th ed.; Saunders: Philadelphia, PA, USA, 2003; pp. 608–618. [Google Scholar]

- Fan, J.; Lin, T.; Hu, F.; Yu, Y.; Ibrahim, M.; Zheng, R.; Huang, S.; Ma, J. Effect of sintering temperature on microstructure and mechanical properties of Zirconia toughened alumina machinable dental ceramics. Ceram. Int. 2016, 43, 3647–3653. [Google Scholar] [CrossRef]

- Soňa, H.; Willi, P. Theoretical study of the influence of carbon contamination on the transparency of spinel ceramics prepared by spark plasma sintering (SPS). J. Eur. Ceram. Soc. 2021, 41, 4337–4342. [Google Scholar]

- Koji, M.; Kim, B.-N.; Hidehiro, Y.; Keijiro, H.; Yoshio, S. Spectroscopic study of the discoloration of transparent MgAl2O4 spinel fabricated by spark-plasma-sintering (SPS) processing. Acta Mater. 2015, 84, 9–19. [Google Scholar]

- Morita, K.; Kim, B.-N.; Yoshida, H.; Hiraga, K.; Sakka, Y. Distribution of carbon contamination in oxide ceramics occurring during spark-plasma-sintering (SPS) processing: II—Effect of SPS and loading temperatures. J. Eur. Ceram. Soc. 2018, 38, 2596–2604. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Z.; Kim, B.-N.; Morita, K.; Yoshida, H.; Hiraga, K.; Sakka, Y. Highly Infrared Transparent Nanometric Tetragonal Zirconia Prepared by High-Pressure Spark Plasma Sintering. J. Am. Ceram. Soc. 2011, 94, 2739–2741. [Google Scholar] [CrossRef]

- Spear, F.; Holloway, J. Which All-Ceramic System Is Optimal for Anterior Esthetics? J. Am. Dental Assoc. 2008, 139, S19–S24. [Google Scholar] [CrossRef]

| Starting Materials | Source | Lot No. | Oxide Constituent | wt.% |

|---|---|---|---|---|

| Silica gel | Loba, Jehangir Villa, India (400–700 mesh) | 5699H | SiO2 | 44.5 |

| Aluminum oxide Active | Loba (Neutral) | 00950 | Al2O3 | 16.7 |

| Magnesium carbonate | Sigma Aldrich, St. Louis, MO, USA (99.5% AR) | 227668 | MgO | 14.5 |

| Potassium carbonate anhydrous | Loba (99.5% AR/ACS) | 05336 | K2O | 9.5 |

| Ammonium fluoride | Loba (98% Ar/ACS) | 01200 | F | 6.3 |

| Boric acid crystal (granular) | Loba (99.5% Extra pure) | 00218 | B2O | 8.5 |

| SPS-FMZ | Apparent Density (g/cc) | Percentage Porosity (%) | Mean Pore Size Diameter (nm) ± SD | Pore Diameter Range (nm) |

|---|---|---|---|---|

| 650 °C | 2.36 ± 0.11 | 42 | 14 ± 11.4 | 3–51 |

| 750 °C | 2.79 ± 0.05 | 35 | 11.5 ± 4.1 | 4–18 |

| 850 °C | 2.84 ± 0.05 | 18 | 10.7 ± 4.1 | 4–18 |

| 950 °C | 2.97 ± 0.13 | 12 | 7.3 ± 1.9 | 4–10 |

| SPS-FM without YSZ at 950 °C | 1.63 ± 0.0 | - | ||

| SPS-FMZ | Micro-Hardness (GPa) | Nano-Hardness (GPa) | Reduced Elastic Modulus (GPa) | Fracture Toughness (MPa m1/2) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean ± S.D. | Median | IQR | Min | Max | Median | IQR | Min | Max | Mean ± S.D. | |

| 650 °C | 3.61 ± 0.21 a | 4.93 a | 5.42 | 3.06 | 12.39 | 93.79 a | 20.76 | 74.76 | 173.00 | 1.73 ± 0.13 a |

| 750 °C | 5.69 ± 0.24 b | 10.02 b | 1.37 | 7.70 | 18.94 | 98.86 a | 47.02 | 38.34 | 192.62 | 2.24 ± 0.24 a |

| 850 °C | 5.89 ± 0.26 c | 11.03 b | 7.24 | 6.47 | 63.39 | 121.56 b | 6.59 | 107.80 | 158.57 | 2.14 ± 0.10 a |

| 950 °C | 6.28 ± 0.26 b,c | 11.22 b | 2.72 | 8.40 | 20.27 | 112.94 b | 14.03 | 103.45 | 170.60 | 2.70 ± 0.21 b |

| SPS-FM without YSZ at 950 °C | 5.34 ± 0.06 | 7.29 | 0.96 | 6.13 | 9.51 | 80.48 | 4.33 | 74.96 | 86.79 | 1.22 ± 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gali, S.; Gururaja, S.; Prabhu, T.N.; Srinivasan, S. Investigation of Spark Plasma Sintering on Microstructure-Properties of Zirconia Reinforced Fluormica Glass for Dental Restorations. Materials 2023, 16, 6125. https://doi.org/10.3390/ma16186125

Gali S, Gururaja S, Prabhu TN, Srinivasan S. Investigation of Spark Plasma Sintering on Microstructure-Properties of Zirconia Reinforced Fluormica Glass for Dental Restorations. Materials. 2023; 16(18):6125. https://doi.org/10.3390/ma16186125

Chicago/Turabian StyleGali, Sivaranjani, Suhasini Gururaja, T. Niranjana Prabhu, and Srikari Srinivasan. 2023. "Investigation of Spark Plasma Sintering on Microstructure-Properties of Zirconia Reinforced Fluormica Glass for Dental Restorations" Materials 16, no. 18: 6125. https://doi.org/10.3390/ma16186125