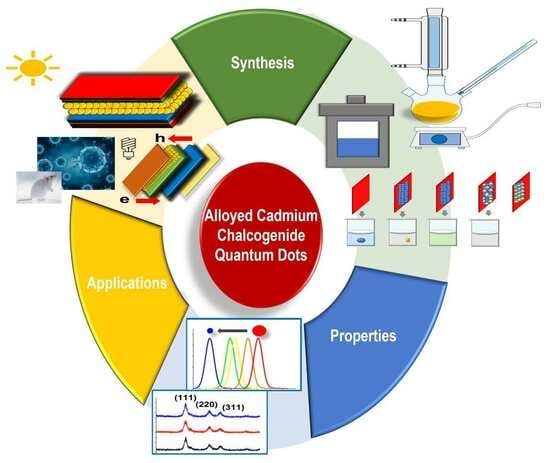

Cadmium-Based Quantum Dots Alloyed Structures: Synthesis, Properties, and Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hot-Injection

2.2. Colloidal Method in Aqueous Media (Co-Precipitation)

2.3. Successive Ionic Layer Adsorption and Reaction (SILAR)

2.4. Hydrothermal

2.5. Microwave-Assisted (MW-Assisted)

3. Properties

3.1. Optical Properties

3.2. Structural Properties

4. Applications

4.1. Solar Cells

4.2. Light-Emitting Diodes (LEDs)

4.3. Biological Application

5. Conclusions and Future Outlook

- Applying more research to strictly determine the best synthesis conditions to maintain high PL quantum yield and stability even without passivation;

- To put a lot of effort into understanding what type of electrical transition may occur in these quantum dots, investigate the different scenarios for these transitions that govern the quantum dot properties;

- To carry out synthesis techniques for high production.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gui, R.; Jin, H.; Wang, Z.; Tan, L. Recent advances in optical properties and applications of colloidal quantum dots under two-photon excitation. Coord. Chem. Rev. 2017, 338, 141–185. [Google Scholar] [CrossRef]

- Yi, M.; Shen, Z. A review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 2015, 3, 11700–11715. [Google Scholar] [CrossRef]

- Kumar, R.; Joanni, E.; Singh, R.K.; Singh, D.P.; Moshkalev, S.A. Recent advances in the synthesis and modification of carbon-based 2D materials for application in energy conversion and storage. Prog. Energy Combust. Sci. 2018, 67, 115–157. [Google Scholar] [CrossRef]

- Kumar, P. Semiconductor (CdSe and CdTe)quantum dot: Synthesis, properties and applications. Mater. Today Proc. 2022, 51, 900–904. [Google Scholar] [CrossRef]

- Singh, R.K.; Kumar, R.; Singh, D.P.; Savu, R.; Moshkalev, S.A. Progress in microwave-assisted synthesis of quantum dots (graphene/carbon/semiconducting) for bioapplications: A review. Mater. Today Chem. 2019, 12, 282–314. [Google Scholar] [CrossRef]

- Li, X.; Wu, Y.; Steel, D.; Gammon, D.; Stievater, T.; Katzer, D.; Park, D.; Piermarocchi, C.; Sham, L. An all-optical quantum gate in a semiconductor quantum dot. Science 2003, 301, 809–811. [Google Scholar] [CrossRef]

- Sethi, R.; Kumar, L.; Sharma, P.K.; Mishra, P.; Pandey, A.C. Synthesis and characterization of Cd1−xZnxS ternary nanocrystals. In Proceedings of the 2007 International Workshop on Physics of Semiconductor Devices, Mumbai, India, 16–20 December 2007; pp. 472–474. [Google Scholar]

- Nozik, A.J.; Beard, M.C.; Luther, J.M.; Law, M.; Ellingson, R.J.; Johnson, J.C. Semiconductor Quantum Dots and Quantum Dot Arrays and Applications of Multiple Exciton Generation to Third-Generation Photovoltaic Solar Cells. Chem. Rev. 2010, 110, 6873–6890. [Google Scholar] [CrossRef]

- Kulkarni, S.K.; Winkler, U.; Deshmukh, N.; Borse, P.H.; Fink, R.; Umbach, E. Investigations on chemically capped CdS, ZnS and ZnCdS nanoparticles. Appl. Surf. Sci. 2001, 169–170, 438–446. [Google Scholar] [CrossRef]

- Tyagi, J.; Gupta, H.; Purohit, L.P. Ternary alloyed CdS1−xSex quantum dots on TiO2/ZnS electrodes for quantum dots-sensitized solar cells. J. Alloys Compd. 2021, 880, 160480. [Google Scholar] [CrossRef]

- Chung, N.T.K.; Nguyen, P.T.; Tung, H.T.; Phuc, D.H. Quantum Dot Sensitized Solar Cell: Photoanodes, Counter Electrodes, and Electrolytes. Molecules 2021, 26, 2638. [Google Scholar] [CrossRef]

- Song, X.; Ma, Z.; Li, L.; Tian, T.; Yan, Y.; Su, J.; Deng, J.; Xia, C. Aqueous synthesis of alloyed CdSexTe1-x colloidal quantum dots and their In-situ assembly within mesoporous TiO2 for solar cells. Sol. Energy 2020, 196, 513–520. [Google Scholar] [CrossRef]

- Sánchez-Solís, A.; Esparza, D.; Orona-Navar, A.; Torres-Castro, A.; Rivas, J.M.; Ornelas-Soto, N.; López-Luke, T. Light-emitting diodes based on quaternary CdZnSeS quantum dots. J. Lumin. 2021, 235, 118025. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Y.; Hao, J.; Tang, H.; Ding, S.; Wang, Z.; Fang, F.; Wu, D.; Zhang, W.; Liu, H.; et al. Alloyed Green-Emitting CdZnSeS/ZnS Quantum Dots with Dense Protective Layers for Stable Lighting and Display Applications. ACS Appl. Mater. Interfaces 2021, 13, 32217–32225. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Hwang, D.W.; Jung, H.S.; Kim, K.W.; Pham, X.-H.; Lee, S.-H.; Byun, J.W.; Kim, W.; Kim, H.-M.; Hahm, E.; et al. High-quantum yield alloy-typed core/shell CdSeZnS/ZnS quantum dots for bio-applications. J. Nanobiotechnology 2022, 20, 22. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Liu, H.; Liu, J.; Haley, K.N.; Treadway, J.A.; Larson, J.P.; Ge, N.; Peale, F.; Bruchez, M.P. Immunofluorescent labeling of cancer marker Her2 and other cellular targets with semiconductor quantum dots. Nat. Biotechnol. 2003, 21, 41–46. [Google Scholar] [CrossRef]

- Alivisatos, A.P. Semiconductor clusters, nanocrystals, and quantum dots. Science 1996, 271, 933–937. [Google Scholar] [CrossRef]

- Alivisatos, P. The use of nanocrystals in biological detection. Nat. Biotechnol. 2004, 22, 47–52. [Google Scholar] [CrossRef]

- Adegoke, O.; Nyokong, T.; Forbes, P.B.C. Optical properties of water-soluble l-cysteine-capped alloyed CdSeS quantum dot passivated with ZnSeTe and ZnSeTe/ZnS shells. Opt. Mater. 2015, 46, 548–554. [Google Scholar] [CrossRef]

- Reiss, P.; Protiere, M.; Li, L. Core/shell semiconductor nanocrystals. Small 2009, 5, 154–168. [Google Scholar] [CrossRef]

- Medintz, I.L.; Uyeda, H.T.; Goldman, E.R.; Mattoussi, H. Quantum dot bioconjugates for imaging, labelling and sensing. Nat. Mater. 2005, 4, 435–446. [Google Scholar] [CrossRef]

- Boles, M.A.; Engel, M.; Talapin, D.V. Self-Assembly of Colloidal Nanocrystals: From Intricate Structures to Functional Materials. Chem. Rev. 2016, 116, 11220–11289. [Google Scholar] [CrossRef] [PubMed]

- Hühn, J.; Carrillo-Carrion, C.; Soliman, M.G.; Pfeiffer, C.; Valdeperez, D.; Masood, A.; Chakraborty, I.; Zhu, L.; Gallego, M.; Yue, Z.; et al. Selected Standard Protocols for the Synthesis, Phase Transfer, and Characterization of Inorganic Colloidal Nanoparticles. Chem. Mater. 2017, 29, 399–461. [Google Scholar] [CrossRef]

- Cheng, J.; Li, D.; Cheng, T.; Ren, B.; Wang, G.; Li, J. Aqueous synthesis of high-fluorescence CdZnTe alloyed quantum dots. J. Alloys Compd. 2014, 589, 539–544. [Google Scholar] [CrossRef]

- Adegoke, O.; Nyokong, T.; Forbes, P.B.C. Structural and optical properties of alloyed quaternary CdSeTeS core and CdSeTeS/ZnS core–shell quantum dots. J. Alloys Compd. 2015, 645, 443–449. [Google Scholar] [CrossRef]

- Adegoke, O.; Seo, M.-W.; Kato, T.; Kawahito, S.; Park, E.Y. Gradient band gap engineered alloyed quaternary/ternary CdZnSeS/ZnSeS quantum dots: An ultrasensitive fluorescence reporter in a conjugated molecular beacon system for the biosensing of influenza virus RNA. J. Mater. Chem. B 2016, 4, 1489–1498. [Google Scholar] [CrossRef]

- Yang, F.; Xu, Z.; Wang, J.; Zan, F.; Dong, C.; Ren, J. Microwave-assisted aqueous synthesis of new quaternary-alloyed CdSeTeS quantum dots; and their bioapplications in targeted imaging of cancer cells. Luminescence 2013, 28, 392–400. [Google Scholar] [CrossRef]

- Hien, N.T.T.; Hung, L.X.; Nga, P.T.; Dat, N.N. Optical Properties of Ternary Alloyed CdSe1−xTex Quantum Dots. J. Electron. Mater. 2021, 50, 1275–1281. [Google Scholar] [CrossRef]

- Ostadebrahim, M.; Dehghani, H. Improving the photovoltaic performance of CdSe0.2S0.8 alloyed quantum dot sensitized solar cells using CdMnSe outer quantum dot. Sol. Energy 2020, 199, 901–910. [Google Scholar] [CrossRef]

- Zhan, H.-J.; Zhou, P.-J.; He, Z.-Y.; Tian, Y. Microwave-Assisted Aqueous Synthesis of Small-Sized, Highly Luminescent CdSeS/ZnS Core/Shell Quantum Dots for Live Cell Imaging. Eur. J. Inorg. Chem. 2012, 2012, 2487–2493. [Google Scholar] [CrossRef]

- Lee, K.-H.; Lee, J.-H.; Kang, H.-D.; Han, C.-Y.; Bae, S.M.; Lee, Y.; Hwang, J.Y.; Yang, H. Highly fluorescence-stable blue CdZnS/ZnS quantum dots against degradable environmental conditions. J. Alloys Compd. 2014, 610, 511–516. [Google Scholar] [CrossRef]

- Murray, C.; Norris, D.; Bawendi, M. Synthesis and Characterization of Nearly Monodisperse CdE (E 5 S, Se, Te) Semiconductor Nanocrystall. J. Am. Chem. Soc. 1992, 115, 8706–8715. [Google Scholar] [CrossRef]

- Elibol, E. Synthesis of near unity photoluminescence CdSeTe alloyed Quantum Dots. J. Alloys Compd. 2020, 817, 152726. [Google Scholar] [CrossRef]

- Verma, S.K.; Verma, R.; Li, N.; Xiong, D.; Tian, S.; Xiang, W.; Zhang, Z.; Xie, Y.; Zhao, X. Fabrication and band engineering of Cu-doped CdSe0.6Te0.4-alloyed quantum dots for solar cells. Sol. Energy Mater. Sol. Cells 2016, 157, 161–170. [Google Scholar] [CrossRef]

- Chatterjee, A.; Jagtap, A.; Pendyala, N.; Rao, K. HgCdTe Quantum Dot Over Interdigitated Electrode for Mid-Wave Infrared Photon Detection and Its Noise Characterization. Int. J. Nanosci. 2019, 19, 1950020. [Google Scholar] [CrossRef]

- Osman, H.; Li, W.; Zhang, X.; Chun, F.; Deng, W.; Moatasim, M.; Zheng, X.; Deng, W.; Zhang, H.; Yang, W. One-step hot injection synthesis of gradient alloy CdxZn1−xSySe1−y quantum dots with large-span self-regulating ability. J. Lumin. 2019, 206, 565–570. [Google Scholar] [CrossRef]

- Samadi-Maybodi, A.; Tirbandpay, R. Synthesis, optical properties and tuning size of CdSe quantum dots by variation capping agent. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2021, 250, 119369. [Google Scholar] [CrossRef]

- Wageh, S.; Al-Ghamdi, A.; Jilani, A.; Iqbal, J. Facile Synthesis of Ternary Alloy of CdSe1−xSx Quantum Dots with Tunable Absorption and Emission of Visible Light. Nanomaterials 2018, 8, 979. [Google Scholar]

- Wageh, S.; Al-Ghamdi, A.A.; Al-Zahrani, A.A.; Driss, H. High quantum yield Cu doped CdSe quantum dots. Mater. Res. Express 2019, 6, 0850d0854. [Google Scholar] [CrossRef]

- Ouyang, J.; Vincent, M.; Kingston, D.; Descours, P.; Boivineau, T.; Zaman, M.B.; Wu, X.; Yu, K. Noninjection, One-Pot Synthesis of Photoluminescent Colloidal Homogeneously Alloyed CdSeS Quantum Dots. J. Phys. Chem. C 2009, 113, 5193–5200. [Google Scholar] [CrossRef]

- Mahmoud, W.E.; Yaghmour, S.J. Synthesis, characterization and luminescence properties of thiol-capped CdSe quantum dots at different processing conditions. Opt. Mater. 2013, 35, 652–656. [Google Scholar] [CrossRef]

- Muñoz, R.; Santos, E.M.; Galan-Vidal, C.A.; Miranda, J.M.; Lopez-Santamarina, A.; Rodriguez, J.A. Ternary Quantum Dots in Chemical Analysis. Synthesis and Detection Mechanisms. Molecules 2021, 26, 2764. [Google Scholar] [CrossRef] [PubMed]

- Moslemi, Z.; Soheyli, E.; Majles Ara, M.H.; Sahraei, R. Facile preparation of yellow and red emitting ZnCdSeS quantum dots and their third-order nonlinear optical properties. J. Phys. Chem. Solids 2018, 120, 64–70. [Google Scholar] [CrossRef]

- Gaponik, N.; Talapin, D.V.; Rogach, A.L.; Hoppe, K.; Shevchenko, E.V.; Kornowski, A.; Eychmu1ller, A.; Weller, H. Thiol-Capping of CdTe Nanocrystals: An Alternative to Organometallic Synthetic Routes. J. Phys. Chem. B 2002, 106, 7177–7185. [Google Scholar] [CrossRef]

- Nicolau, Y.; Menard, J. Solution growth of ZnS, CdS and Zn1−xCdxS thin films by the successive ionic-layer adsorption and reaction process; growth mechanism. J. Cryst. Growth 1988, 92, 128–142. [Google Scholar] [CrossRef]

- Solis, O.E.; Rivas, J.M.; Lopez-Luke, T.; Zarazua, I.; Torre, J.d.l.; Esparza, D. Synthesis of Alloyed CdxZn1-xS Quantum Dots for Photovoltaic Applications. IEEE J. Photovolt. 2020, 10, 1319–1328. [Google Scholar] [CrossRef]

- Jia, Z.; Tang, Y.; Luo, L.; Li, B. Shape-controlled synthesis of single-crystalline CdCO3 and corresponding porous CdO nanostructures. Cryst. Growth Des. 2008, 8, 2116–2120. [Google Scholar] [CrossRef]

- Tadjarodi, A.; Imani, M.; Kerdari, H.; Bijanzad, K.; Khaledi, D.; Rad, M. Preparation of CdO rhombus-like nanostructure and its photocatalytic degradation of azo dyes from aqueous solution. Nanomater. Nanotechnol. 2014, 4, 4–16. [Google Scholar] [CrossRef]

- Zang, J.; Zhao, G.; Han, G. Preparation of CdS nanoparticles by hydrothermal method in microemulsion. Front. Chem. China 2007, 2, 98–101. [Google Scholar] [CrossRef]

- Kim, W.; Baek, M.; Yong, K. Fabrication of ZnO/CdS, ZnO/CdO core/shell nanorod arrays and investigation of their ethanol gas sensing properties. Sens. Actuators B Chem. 2016, 223, 599–605. [Google Scholar] [CrossRef]

- Li, H.; Wang, C.; Peng, Z.; Fu, X. A review on the synthesis methods of CdSeS-based nanostructures. J. Nanomater. 2015, 2015, 519385. [Google Scholar] [CrossRef]

- Gerbec, J.A.; Magana, D.; Washington, A.; Strouse, G.F. Microwave-Enhanced Reaction Rates for Nanoparticle Synthesis. J. Am. Chem. Soc. 2005, 127, 15791–15800. [Google Scholar] [CrossRef] [PubMed]

- Ameta, C.; Vyas, Y.; Chundawat, P. Microwave-assisted synthesis of quantum dots. In Quantum Dots; Elsevier: Amsterdam, The Netherlands, 2023; pp. 115–145. [Google Scholar]

- Agranovich, D.; Ishai, P.B.; Katz, G.; Bezman, D.; Feldman, Y. Microwave dielectric spectroscopy study of water dynamics in normal and contaminated raw bovine milk. Colloids Surf. B Biointerfaces 2017, 154, 391–396. [Google Scholar] [CrossRef] [PubMed]

- El-Hamidy, S.M. The Luminescence and optical behavior of Cd1−xWxSe QDs synthesized using microwave assisted hydrothermal approach for bioimaging applications. Optik 2021, 238, 166733. [Google Scholar] [CrossRef]

- Luo, J.; Wei, H.; Li, F.; Huang, Q.; Li, D.; Luo, Y.; Meng, Q. Microwave assisted aqueous synthesis of core–shell CdSexTe1−x–CdS quantum dots for high performance sensitized solar cells. Chem. Commun. 2014, 50, 3464–3466. [Google Scholar] [CrossRef] [PubMed]

- Kyobe, J.W.; Khan, M.D.; Kinunda, G.; Mubofu, E.B.; Revaprasadu, N. Synthesis of CdTe quantum dots capped with castor oil using a hot injection solution method. Mater. Sci. Semicond. Process. 2020, 106, 104780. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Y.; Li, J.; Pu, C.; Zhou, J.; Lv, L.; Peng, X. Formation of Size-Tunable and Nearly Monodisperse InP Nanocrystals: Chemical Reactions and Controlled Synthesis. Chem. Mater. 2019, 31, 5331–5341. [Google Scholar] [CrossRef]

- Cao, S.; Li, C.; Wang, L.; Shang, M.; Wei, G.; Zheng, J.; Yang, W. Long-lived and Well-resolved Mn2+ Ion Emissions in CuInS-ZnS Quantum Dots. Sci. Rep. 2014, 4, 7510. [Google Scholar] [CrossRef]

- Won, Y.-H.; Cho, O.; Kim, T.; Chung, D.-Y.; Kim, T.; Chung, H.; Jang, H.; Lee, J.; Kim, D.; Jang, E. Highly efficient and stable InP/ZnSe/ZnS quantum dot light-emitting diodes. Nature 2019, 575, 634–638. [Google Scholar] [CrossRef]

- Deng, B.; Zhu, Y.; Li, J.; Chen, X.; He, K.; Yang, J.; Qin, K.; Bi, Z.; Xiao, X.; Chen, S.; et al. Low temperature synthesis of highly bright green emission CuInS2/ZnS quantum dots and its application in light-emitting diodes. J. Alloys Compd. 2021, 851, 155439. [Google Scholar] [CrossRef]

- Mukherjee, A.; Satpati, B.; Bhattacharyya, S.R.; Ghosh, R.; Mitra, P. Synthesis of nanocrystalline CdS thin film by SILAR and their characterization. Phys. E Low-Dimens. Syst. Nanostructures 2015, 65, 51–55. [Google Scholar] [CrossRef]

- Lee, W.-J.; Wang, X.-J. Structural, Optical, and Electrical Properties of Copper Oxide Films Grown by the SILAR Method with Post-Annealing. Coatings 2021, 11, 864. [Google Scholar] [CrossRef]

- Kaur, N.; Singh, M.; Moumen, A.; Duina, G.; Comini, E. 1D Titanium Dioxide: Achievements in Chemical Sensing. Materials 2020, 13, 2974. [Google Scholar] [CrossRef] [PubMed]

- Grisaru, H.; Palchik, O.; Gedanken, A.; Palchik, V.; Slifkin, M.A.; Weiss, A.M. Microwave-Assisted Polyol Synthesis of CuInTe2 and CuInSe2 Nanoparticles. Inorg. Chem. 2003, 42, 7148–7155. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Palchik, O.; Chen, S.; Gedanken, A. Microwave Assisted Preparation of CdSe, PbSe, and Cu2−xSe Nanoparticles. J. Phys. Chem. B 2000, 104, 7344–7347. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Zhong, Y.; Li, X.; Pan, M.; Qi, H.; Dong, H.; Zhang, L. Highly efficient and stable CdZnSeS/ZnSeS quantum dots for application in white light-emitting diode. Front. Chem. 2022, 10, 845206. [Google Scholar] [CrossRef]

- Brkić, S. Optical properties of quantum dots. Eur. Int. J. Sci. Technol. 2016, 5, 98–107. [Google Scholar]

- Meltzer, R.; Feofilov, S. Spectral hole burning in the 4f–5d transition of Ce3+ in LuPO4 and YPO4. J. Lumin. 2003, 102, 151–155. [Google Scholar] [CrossRef]

- Hanson, C.J.; Buck, M.R.; Acharya, K.; Torres, J.A.; Kundu, J.; Ma, X.; Bouquin, S.; Hamilton, C.E.; Htoon, H.; Hollingsworth, J.A. Matching Solid-State to Solution-Phase Photoluminescence for Near Unity Down-Conversion Efficiency Using Giant Quantum Dots. ACS Appl. Mater. Interfaces 2015, 7, 13125. [Google Scholar] [CrossRef]

- Susumu, K.; Field, L.D.; Oh, E.; Hunt, M.; Delehanty, J.B.; Palomo, V.; Dawson, P.E.; Huston, A.L.; Medintz, I.L. Purple-, Blue-, and Green-Emitting Multishell Alloyed Quantum Dots: Synthesis, Characterization, and Application for Ratiometric Extracellular pH Sensing. Chem. Mater. 2017, 29, 7330–7344. [Google Scholar] [CrossRef]

- Wageh, S.; Badr, M.H. Cd1−xZnxS nanoparticles stabilized by a bifunctional organic molecule. Phys. E Low-Dimens. Syst. Nanostructures 2008, 40, 2810–2813. [Google Scholar] [CrossRef]

- Wageh, S.; Al-Ghamdi, A.A.; Yakuphanoglu, F. Band edge emission of ZnS nanoparticles prepared by excess of thiourea as a source of sulfur. J. Sol-Gel Sci. Technol. 2013, 66, 443–451. [Google Scholar] [CrossRef]

- Subramanian, S.; Ganapathy, S.; Rajaram, M.; Ayyaswamy, A. Tuning the optical properties of colloidal Quantum Dots using thiol group capping agents and its comparison. Mater. Chem. Phys. 2020, 249, 123127. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, Z.; Yang, B.; Gao, M. The influence of carboxyl groups on the photoluminescence of mercaptocarboxylic acid-stabilized CdTe nanoparticles. J. Phys. Chem. B 2003, 107, 8–13. [Google Scholar] [CrossRef]

- Hien, N.T.; Tan, P.M.; Van, H.T.; Lien, V.T.K.; Do, P.V.; Loan, P.N.; Kien, N.T.; Luyen, N.T.; Ca, N.X. Photoluminescence properties of Cu-doped CdTeSe alloyed quantum dots versus laser excitation power and temperature. J. Lumin. 2020, 218, 116838. [Google Scholar] [CrossRef]

- Li, Q.; Bai, J.; Zhang, T.; Nie, C.; Duan, J.; Tang, Q. CdZnSe@ZnSe colloidal alloy quantum dots for high-efficiency all-inorganic perovskite solar cells. Chem. Commun. 2018, 54, 9575–9578. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Zhang, L.; Tang, Y.; Xiang, W.; Wang, X.; Xiao, M.; Cui, Y.; Zhang, J. Enhanced Multiexciton Emission Property in Gradient Alloy Core/Shell CdZnSeS/ZnS Quantum Dots: Balance between Surface Passivation and Strain-Induced Lattice Defect. J. Phys. Chem. C 2021, 125, 10759–10767. [Google Scholar] [CrossRef]

- Denton, A.R.; Ashcroft, N.W. Vegard’s law. Phys. Rev. A 1991, 43, 3161–3164. [Google Scholar] [CrossRef] [PubMed]

- Kato, T.; Handa, A.; Yagioka, T.; Matsuura, T.; Yamamoto, K.; Higashi, S.; Wu, J.-L.; Tai, K.F.; Hiroi, H.; Yoshiyama, T. Enhanced efficiency of Cd-free Cu (In, Ga)(Se, S) 2 minimodule via (Zn, Mg) O second buffer layer and alkali metal post-treatment. IEEE J. Photovolt. 2017, 7, 1773–1780. [Google Scholar] [CrossRef]

- Sharma, S.K.; Ali, K. Solar Cells: From Materials to Device Technology; Springer Nature: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Giménez, S.; Mora-Seró, I.; Macor, L.; Guijarro, N.; Lana-Villarreal, T.; Gómez, R.; Diguna, L.J.; Shen, Q.; Toyoda, T.; Bisquert, J. Improving the performance of colloidal quantum-dot-sensitized solar cells. Nanotechnology 2009, 20, 295204. [Google Scholar] [CrossRef]

- Elibol, E. Effects of different counter electrodes on performance of CdSeTe alloy QDSSC. Sol. Energy 2020, 197, 519–526. [Google Scholar] [CrossRef]

- Lee, Y.H.; Im, S.H.; Chang, J.A.; Lee, J.-H.; Seok, S.I. CdSe-sensitized inorganic–organic heterojunction solar cells: The effect of molecular dipole interface modification and surface passivation. Org. Electron. 2012, 13, 975–979. [Google Scholar] [CrossRef]

- Pan, Z.; Zhao, K.; Wang, J.; Zhang, H.; Feng, Y.; Zhong, X. Near Infrared Absorption of CdSexTe1–x Alloyed Quantum Dot Sensitized Solar Cells with More than 6% Efficiency and High Stability. ACS Nano 2013, 7, 5215–5222. [Google Scholar] [CrossRef] [PubMed]

- Radich, E.J.; Peeples, N.R.; Santra, P.K.; Kamat, P.V. Charge Transfer Mediation Through CuxS. The Hole Story of CdSe in Polysulfide. J. Phys. Chem. C 2014, 118, 16463–16471. [Google Scholar] [CrossRef]

- Yun, H.J.; Paik, T.; Edley, M.E.; Baxter, J.B.; Murray, C.B. Enhanced Charge Transfer Kinetics of CdSe Quantum Dot-Sensitized Solar Cell by Inorganic Ligand Exchange Treatments. ACS Appl. Mater. Interfaces 2014, 6, 3721–3728. [Google Scholar] [CrossRef]

- Reed, M.; Randall, J.; Aggarwal, R.; Matyi, R.; Moore, T.; Wetsel, A. Observation of discrete electronic states in a zero-dimensional semiconductor nanostructure. Phys. Rev. Lett. 1988, 60, 535–537. [Google Scholar] [CrossRef]

- Yu, W.W.; Peng, X. Formation of high-quality CdS and other II–VI semiconductor nanocrystals in noncoordinating solvents: Tunable reactivity of monomers. Angew. Chem. Int. Ed. 2002, 41, 2368–2371. [Google Scholar] [CrossRef]

- Reiss, P.; Carrière, M.; Lincheneau, C.; Vaure, L.; Tamang, S. Synthesis of Semiconductor Nanocrystals, Focusing on Nontoxic and Earth-Abundant Materials. Chem. Rev. 2016, 116, 10731–10819. [Google Scholar] [CrossRef] [PubMed]

- Hung, C.-C.; Ho, S.-J.; Yeh, C.-W.; Chen, G.-H.; Huang, J.-H.; Chen, H.-S. Highly Luminescent Dual-Color-Emitting Alloyed [ZnxCd1–xSeyS1–y] Quantum Dots: Investigation of Bimodal Growth and Application to Lighting. J. Phys. Chem. C 2017, 121, 28373–28384. [Google Scholar] [CrossRef]

- Dezhurov, S.V.; Trifonov, A.Y.; Lovygin, M.V.; Rybakova, A.V.; Krylsky, D.V. Synthesis of highly photostable NIR-emitting quantum dots CdTeSe/CdS/CdZnS/ZnS. Nanotechnologies Russ. 2016, 11, 337–343. [Google Scholar] [CrossRef]

- Bae, W.K.; Brovelli, S.; Klimov, V.I. Spectroscopic insights into the performance of quantum dot light-emitting diodes. MRS Bull. 2013, 38, 721–730. [Google Scholar] [CrossRef]

- Yang, Z.; Gao, M.; Wu, W.; Yang, X.; Sun, X.W.; Zhang, J.; Wang, H.-C.; Liu, R.-S.; Han, C.-Y.; Yang, H.; et al. Recent advances in quantum dot-based light-emitting devices: Challenges and possible solutions. Mater. Today 2019, 24, 69–93. [Google Scholar] [CrossRef]

- Efros, A.L.; Efros, A.L. Interband absorption of light in a semiconductor sphere. Sov. Phys. Semicond 1982, 16, 772–775. [Google Scholar]

- Zhang, H.; Chen, S.; Sun, X.W. Efficient Red/Green/Blue Tandem Quantum-Dot Light-Emitting Diodes with External Quantum Efficiency Exceeding 21%. ACS Nano 2018, 12, 697–704. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, X.; Chen, S. Over 100 cd A−1 efficient quantum dot light-emitting diodes with inverted tandem structure. Adv. Funct. Mater. 2017, 27, 1700610. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, Y.; Fu, F.; Guo, W.; Huang, W.; Li, L. Facile synthesis of high-quality ZnS, CdS, CdZnS, and CdZnS/ZnS core/shell quantum dots: Characterization and diffusion mechanism. Mater. Sci. Semicond. Process. 2013, 16, 1723–1729. [Google Scholar] [CrossRef]

- Bailey, R.E.; Nie, S. Alloyed semiconductor quantum dots: Tuning the optical properties without changing the particle size. J. Am. Chem. Soc. 2003, 125, 7100–7106. [Google Scholar] [CrossRef]

- Shea-Rohwer, L.E.; Martin, J.E.; Cai, X.; Kelley, D.F. Red-emitting quantum dots for solid-state lighting. ECS J. Solid State Sci. Technol. 2012, 2, R3112–R3118. [Google Scholar] [CrossRef]

- Frasco, M.F.; Chaniotakis, N. Semiconductor Quantum Dots in Chemical Sensors and Biosensors. Sensors 2009, 9, 7266–7286. [Google Scholar] [CrossRef]

- Zylstra, J.; Amey, J.; Miska, N.J.; Pang, L.; Hine, C.R.; Langer, J.; Doyle, R.P.; Maye, M.M. A Modular Phase Transfer and Ligand Exchange Protocol for Quantum Dots. Langmuir 2011, 27, 4371–4379. [Google Scholar] [CrossRef]

- Schiffman, J.D.; Balakrishna, R.G. Quantum dots as fluorescent probes: Synthesis, surface chemistry, energy transfer mechanisms, and applications. Sens. Actuators B Chem. 2018, 258, 1191–1214. [Google Scholar]

- Zhang, Y.; Clapp, A. Overview of stabilizing ligands for biocompatible quantum dot nanocrystals. Sensors 2011, 11, 11036–11055. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.Y.; Fu, Y.; Jang, M.-S.; Li, Y.; Yin, W.P.; Ahn, T.K.; Lee, J.H.; Chae, H.; Lee, D.S. CdSe@ ZnS/ZnS quantum dots loaded in polymeric micelles as a pH-triggerable targeting fluorescence imaging probe for detecting cerebral ischemic area. Colloids Surf. B Biointerfaces 2017, 155, 497–506. [Google Scholar] [CrossRef] [PubMed]

- Cho, J.; Jung, Y.K.; Lee, J.-K.; Jung, H.-S. Highly efficient blue-emitting CdSe-derived core/shell gradient alloy quantum dots with improved photoluminescent quantum yield and enhanced photostability. Langmuir 2017, 33, 3711–3719. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Yang, Y.; Wu, K.; Lian, T. Charge transfer dynamics from photoexcited semiconductor quantum dots. Annu. Rev. Phys. Chem. 2016, 67, 259–281. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.; Weber, F.; Weigert, F.; Wang, Y.; Choudhury, S.; Xiao, J.; Lauermann, I.; Resch-Genger, U.; Bande, A.; Petit, T. Influence of surface chemistry on optical, chemical and electronic properties of blue luminescent carbon dots. Nanoscale 2019, 11, 2056–2064. [Google Scholar] [CrossRef] [PubMed]

- Hines, D.A.; Kamat, P.V. Recent advances in quantum dot surface chemistry. ACS Appl. Mater. Interfaces 2014, 6, 3041–3057. [Google Scholar] [CrossRef]

- Wang, L.; Shi, X.-H.; Zhang, Y.-F.; Liu, A.-A.; Liu, S.-L.; Wang, Z.-G.; Pang, D.-W. CdZnSeS quantum dots condensed with ordered mesoporous carbon for high-sensitive electrochemiluminescence detection of hydrogen peroxide in live cells. Electrochim. Acta 2020, 362, 137107. [Google Scholar] [CrossRef]

| Synthesis Technique | Advantages | Disadvantages | Ref. |

|---|---|---|---|

| Hot-injection | narrow particle size distribution | complicated preparation | [57,58,59,60,61] |

| cost effective | not—applicable for large-area manufacturing | ||

| low repeatability | |||

| Co-precipitation | facile | long time preparation | [51] |

| fast | |||

| ability to manage size and composition depending on reaction conditions | |||

| applicable for large-area manufacturing | |||

| energy saving | |||

| SILAR | facile | long time preparation | [45,62,63] |

| no need for a vacuum or high temperature | |||

| cost effective | |||

| applicable for large-area manufacturing | |||

| Hydrothermal | facile | long time preparation | [51,64] |

| ability to manage size depending on reaction conditions | hard to observe the reaction | ||

| energy saving | needs an expensive autoclave | ||

| Microwave-assisted | facile | hard to observe the reaction | [53,54,65,66] |

| fast | |||

| cost effective | |||

| ability to manage the volumetric and internal heating of reagents | |||

| time saving |

| Quantum Dot | Diffraction Planes | Crystal Structure | Ref. |

|---|---|---|---|

| CdSeS | (111), (220), (311) | zinc blend | [38] |

| CdSeS | (111), (200), (311) | zinc blend | [19] |

| CdSSe | (100), (110) | hexagonal | [10] |

| CdSeTe | (111), (220), (311) | cubic zinc blend | [34] |

| CdSeTe | (111), (220), (311) | zinc blend | [33] |

| CdTeSe | (111), (220), (311) | F43m zinc blend | [76] |

| CdSeTeS | zinc blend | [27] | |

| CdZnSe | zinc blend | [77] | |

| CdZnSeS | (111), (220), (311) | zinc blend | [78] |

| CdZnSeS | (111), (220), (311) | zinc blend | [26] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebrahim, F.; Al-Hartomy, O.; Wageh, S. Cadmium-Based Quantum Dots Alloyed Structures: Synthesis, Properties, and Applications. Materials 2023, 16, 5877. https://doi.org/10.3390/ma16175877

Ebrahim F, Al-Hartomy O, Wageh S. Cadmium-Based Quantum Dots Alloyed Structures: Synthesis, Properties, and Applications. Materials. 2023; 16(17):5877. https://doi.org/10.3390/ma16175877

Chicago/Turabian StyleEbrahim, Fadia, Omar Al-Hartomy, and S. Wageh. 2023. "Cadmium-Based Quantum Dots Alloyed Structures: Synthesis, Properties, and Applications" Materials 16, no. 17: 5877. https://doi.org/10.3390/ma16175877