1. Introduction

The use of nanoporous sacrifice templates is a common technique to obtain negative pore metamaterials (e.g., [

1]). Once the filling material is in place, the template can be removed, hence the “negative porosity” or “sacrifice template” designations. The fabrication of porous materials by a sacrificial template using various biological, chemical or synthetic templates has numerous applications such as thermal insulation [

2], water desalinization [

3], and electronics [

4]. Many applications are related to bone scaffold substitution, which focus on the mechanical properties. Kim et al. use photocrosslinked poly(propylene fumarate) (PPF)- and diethyl fumarate (DEF)-constructed scaffolds to study the mechanical stiffness of substrate materials, pore size, and channel geometry [

5]. Wu et al. studied porous mesopore–bioglass (MBG) scaffolds with a focus on the material’s inherent brittleness, high degradation, and surface instability [

6]. Hydraulic properties have been the main focus in other studies; Reinwald et al. [

7] investigated the interconnectivity and permeability of scCO

-foamed polymer scaffolds fabricated with supercritical fluid technology. The polymer was subjected to a supercritical fluid (exceeding its critical temperature and pressure), thereby creating the sacrifice template with this technique. Supercritical fluid technology has proved effective in the fabrication of materials with tailored structural properties, such as porosity and pore size. In Reinwald et al. [

7] the scaffolds were fabricated with Poly(lactic-co-glycolic acid) (PLGA) with average molecular weights of 37 kDa, 53 kDa, and 109 kDa with the aim of modulating pore connectivity and pore window sizes. SEM images (

Figure 1) show results with the typical characteristics of such material; convex pores connected through relatively small pore windows. The authors concluded that larger PLGA molecular weights result in larger pore sizes and windows, thus increasing permeability. Although the study focused on pore and window sizes only, it is apparent that the different molecular weights may probably affect the mechanical properties as well.

Template materials are often of a biological nature or have biological-like geometry, e.g., macroporous crystals with urchin skeletal sponge-like morphologies produced by templating with a sponge-like polymer membrane [

8], as well as porous biomaterial with structural and mechanical properties similar to cancellous bone prepared using biogenic hydroxyapatite and glass [

9]. The use of geomaterials such as sand for the sacrificial template remains unstudied. Such a ubiquitous material could bring economic and environmental advantages compared to its chemical or biological counterparts. In addition, the use of granular soils as a template could allow for the in situ fabrication of materials in scenarios such as soil improvement in foundations [

10], constructed barriers in nuclear waste repositories [

11], etc.

The advent of deep learning and data science has profoundly impacted some fields, e.g., image recognition [

12]. Their success can be explained by their ability to totally replace human intervention in tasks such as classification. In some cases, the application of deep learning techniques in more traditional scientific disciplines can unlock unseen capabilities (e.g., control theory in geomechanics [

13]). In other cases, deep learning has been limited to fitting problems, e.g., in the prediction of pile bearing capacity [

14], slope staility [

15], or rupture distances and capillary forces in wet granular media [

16]. Fitting problems can be enriched with physics and thermodynamics supervision as well [

17]. In those applications, deep learning usually results in vastly improved accuracy metrics. Nevertheless, where deep learning is especially suited is in more complex applications such as generative models.

In geomechanics and material science, many works address the development of generative models. Those are intended to create materials with a given set of properties while fulfilling classical physical and topological restrictions. Notable examples of those generative models include Markovian theory [

18], cross-correlation [

19], Fourier transform [

20], level-set [

21], spherical-harmonic-based principal component analysis [

22], and the Inwards Packing Method [

23]. Such approaches lack the generalization capability of deep learning and often require prior knowledge of material characteristics or probability distributions of the target materials. Supervised deep learning predictive [

24] and generative [

25] models have emerged in recent years with applications in material science. Supervised learning models are inherently limited by the loss function, upon which they rely to evaluate performance. In contrast, unsupervised learning models have a higher freedom to learn features but lack a metric to evaluate the posterior error. To address those limitations, physics information has been recently used to improve machine learning training in nonlinear partial differential equations [

26]. Similarly, regularization in canonical problems in the form of physical supervision showed good results [

27,

28]. The use of pseudophysics information (permeability in porous media inferred from fractal metrics) has shown positive results in the generation of X-ray

CT images [

29].

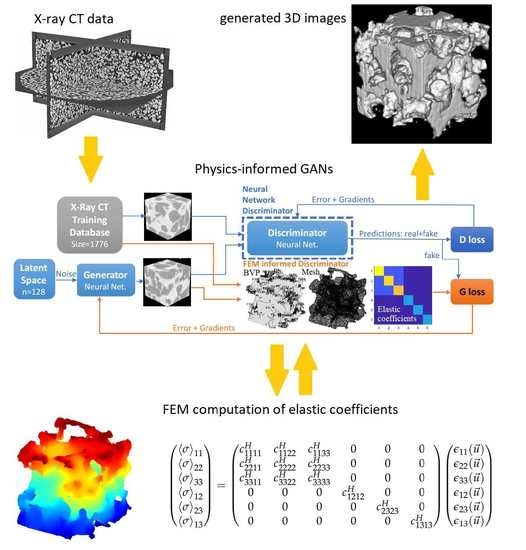

The objective of this work was to develop a physics-supervised deep learning model for the generation of X-ray

CT images of a porous material. Generative adversarial networks [

30] (GANs for short) have been retained as the base deep learning method, and they were enriched with physics supervision consisting of the elastic coefficients from FEM simulations.

The rest of the paper is organized as follows: In

Section 2, the method is developed with enough detail for reproducibility, including a link to the proposed code. In

Section 3, the results are presented. Validation is provided in

Section 4, again including a link to the validation code to allow for full reproducibility. The paper ends with conclusions in

Section 5.

3. Results

To study the properties of the generated images, a central slice orthogonal to the direction

z (parallel to the axis of the cylindrical sample) of the

voxel images was saved at the end of each epoch for 200 epochs. The evolution of the generations showed high variability and the presence of artifacts in the first half (

Figure A1) with better quality images and well-defined pore–solid boundaries in the second half (

Figure A2). As stated before, to avoid a learning imbalance, the FEM-informed discriminator cannot be activated until the generator produces reasonably accurate images. Therefore, a GANs pretraining of 150 epochs was performed before any supervision was added to the model.

The 150-epoch pretrained networks (PT) were saved as a common starting point for successive trainings. A reference simulation (REF) continued from the pretrained state for an additional 50 epochs; the rest of FEM-GAN simulations were compared against the REF simulation (

Figure 8).

Simulations A4 and A5 used the average loss function Equation (

22) in the FEM-informed discriminator, and the images were evaluated sparingly; FEM evaluations were performed every 28 iterations in A4 and every 14 iterations in A5. The probability value obtained by the FEM-informed discriminator

was carried over in the iterations without evaluation. This persistent probability strategy was based on the assumption that the probability would change along iterations in an incremental and smooth manner. In simulations B1 and B4, the same average loss was used from Equation (

22), and images were evaluated once per epoch (B1) and every 28 iterations (B4). However, unlike in A4–A5, the value

was ephemeral, i.e., its value was reset to one in all iterations without evaluation. A probability value of one means that the discriminator believes that the images are real and gives null loss (no updating of networks). All previous simulations were run for 50 epochs, except for A5, which halted at epoch 41 due to a meshing error; this meshing error appeared to be of physical nature because of the images containing too much noise. A restart of the learning process after epoch 41 proved to be impossible because of the noisy images. In simulations C1 and C2, the average loss was used (Equation (

22)), and FEM evaluations were performed in every single iteration: C1 ran for one epoch, and C2 ran for two epochs. In simulations D1 and D2, the norm loss was used (Equation (

23)), and FEM evaluations were performed in every single iteration: C1 ran for one epoch, and C2 ran for two epochs. The simulation overview can be found in

Table 4.

The first step of the FEM-informed discriminator is the histogram-based segmentation, meshing, and obtaining a geometry. Geometry examples are shown for the different types: a real image (

Figure 9a), a generated image after pretraining (

Figure 9b), a generated image in the reference state (

Figure 9c), and an image generated with FEM-GANs, as whown in simulation D1 (

Figure 9d). Elastic properties corresponding to quartz were used for the raw material (stiffness tensor

c in Equation (

4)), i.e., the elastic modulus

GPa and the Poisson ratio

.

The previous BVP was 3D-meshed using tetrahedral elements and quadratic shape functions. Meshes of the different types of images are shown (

Figure 10). For comparison, the four selected images correspond exactly to the ones shown in the previous figure. The mesh node count was in the order of 10,000, and the FEM routine was programmed to return an error and stop the simulation for meshes with a node count outside the interval [2850, 28,800]. This interval was imposed because meshes with very high node counts are usually indicative of noisy images, while very low node counts are indicative of an improper generation of porosity. If the FEM-GANs model was applied early in GANs training (when the generator does not yet produce good images), node count errors were encountered continuously. On the other hand, after a 150 epochs pretraining, the images were almost always within the established interval (with exceptions, see simulation A5 halting in

Table 4).

The previous mesh was solved using the FEM. Because of the small strain elastic nature of the problem, an arbitrary strain magnitude could be applied in the form of a homogeneous strain field to the boundary of the image domain (see Equation (

17)). In the 3D, six independent strain components were required to obtain all the elasticity coefficients.

Figure 11 shows, as an example, the displacement solution in the vertical direction and reference configuration for an applied strain

. The FEM solving was the most computationally expensive step of the entire FEM-GANs code; therefore the six FEM resolutions were parallelized. To increase the performance even further, readers are encouraged to parallelize the FEM routine at a higher level (when called from the GANs code). At the time of this research, this has not been deployed because of a conflict with the mesher

iso2mesh.

The FEM results were homogenized for each one of the stress components and strain inputs to obtain all the coefficients of the elasticity tensor

(36 in general). The magnitudes of the elasticity tensor coefficients were normalized to 8-bit values for graphic display (

Figure 12). The figures show the typical kite shape with 9 independent (12 non-zero) coefficients in agreement with standard energy-based assumptions about symmetry. The diagonal components 11, 22, and 33 showed slight differences in magnitude that indicated a moderate material anisotropy. This anisotropy was consistent with the genesis of the sacrifice template consisting of an oedometric loading in the

z direction.

In the previous figures, one single image of each group is shown. To validate the model, statistical analyses, including larger sample sizes, are needed. In the next section, the validation of the model was performed using both parametric and nonparametric statistics. The validation was performed on a per-component basis in which the nine “kite” coefficients were individually evaluated.

4. Validation

The FEM-informed discriminator in the FEM-GANs approach used Wilcoxon rank sum tests to evaluate the elastic properties of the generated images. The use of nonparametric statistics was required because of the batch size limitation. In the validation, there was no such limitation; larger quantities of images could be generated to compute parametric statistics. In the following, parametric (t-tests) were performed, in addition to nonparametric tests (Wilcoxon rank sum), to evaluate the fit of the generated data to the real data in terms of elastic properties.

Samples of 32 generated images with 1776 ground truth images were used for the nonparametric tests, and 100 generated images and 100 ground truth images were used for the parametric tests (

Table 5). The 100 images from the database were drawn once at random for the parametric tests, and the rest were generated from the trained network at each stage (i.e., pretraining, reference, and the eight FEM-GANs cases). The testing sample was enlarged for the

t-tests, because they require two equally-sized samples to be compared, thereby decreasing the likelihood to reach a rejection of the null hypothesis compared to the rank sum test, which uses the entire database of 1776 images as the ground truth.

Rank sum tests were performed on each individual elasticity coefficient (nine in total after dismissing symmetries) for the pretraining, reference, and the other eight simulations (

Table 6). Bold values indicate a failure to reject the null hypothesis of samples with equal median. From left to right, the table presents the three diagonal components, the three out-of-axis components, and the three diagonal shear components. In the reference, the tests failed to reject the null hypothesis of equal medians in three cases (i.e.,

,

, and

), which meant that those cases could not be discarded from being real at a significance level of

. The number of coefficients with a failed rejection of the null hypothesis (

) is displayed in the last column. Simulations B4, C1, C2, D1, and D2 presented a higher count of hypothesis test results with

compared to the reference, thus meaning that they are better in terms of the number of coefficients that were well reproduced. Interestingly, all hypothesis test rejections (

) happened for the diagonal terms (either axial or shear components), and the model failed to correctly reproduce out-of-axis coefficients (i.e.,

,

, and

).

Upon repeating the same analysis using parametric statistics (

t-tests), simulations B4, C2, and D1 presented a higher count of hypothesis test results with

(

Table 7). In this case, simulation D2 matched five out of the nine coefficients by scoring good

p-values, even in two of the out-of-axis coefficients (

and

). Although B4 and D2 could reproduce out-of-axis coefficients, this came at the cost of lower

p-values in the diagonal coefficients, thereby reducing the overall

count.

Considering previous results, it is apparent that the informed FEM-GANs model could perform better than standard GANs in generating accurate elastic properties in a hypothetical material obtained with the sacrifice templating technique. Configurations B4, C2, and D1 were the only ones performing better than standard GANs in both parametric and nonparametric tests. On the other hand, simulations B4 and D2 were the only ones to score some rejections () in the out-of-axis coefficients, which could be a desirable feature depending on the material application. The author recommends the use of configuration D1 (1 additional epoch, FEM evaluations at every step, 222 FEM evaluations in total, and loss of type norm) in applications in which only diagonal coefficients are essential. In addition, the use of configuration B4 (50 additional epochs, FEM evaluations at every 8 steps, 400 FEM evaluations in total, and loss of type average) is recommended in applications in which out-of-axis coefficients are targeted.

In relying on the central limit theorem, box plots were used to compare the reference-generated images, FEM-GANs-generated (configuration D1) images, and database ground truth images in order to better explain the worst results for the out-of-axis coefficients. As in the two-sample

t-tests, all three cases used a sample size of 100 images (

Figure 13). The red line indicates the median, blue boxes enclose the interquartile range between percentiles 25 and 75, black dashes are the upper and lower adjacents, and red crosses are outliers.

While nonparametric statistics allow for testing the median and parametric statistics allow for testing the mean, box plots allow for visualizing noncentral tendency statistics such as symmetry and data spread. The first observation from the out-of-axis coefficients (, , and ) is that the median was indeed improved by the FEM-informed approach compared to the reference, but not enough to score any in the hypothesis tests. This suggests that the underlying GANs scheme was particularly bad at reproducing those coefficients. In contrast, the data spread of the out-of-axis coefficients (, , and ) in the generated images did not seem to vastly differ from the ground truth, which suggests that physics or thermodynamics central tendency metrics could suffice to improve the model. On the other hand, in the diagonal shear coefficients (, , and ), the ground truth plots show a slight positive skewness, which is seemingly not shown by the generated images. This disagreement could be improved by updating the FEM-GANs model with additional metrics using rank sum tests, although there is not much freedom in this regard due to the limited batch sizes.

An empirical cumulative distribution function (CDF) was presented for the nine elasticity coefficients; in this case, the entire database size of 1776 images was used as the ground truth, and 100 image samples were used for the generations (

Figure 14). An empirical CDF was used instead of a theoretical CDF because, according to Kolmogorov–Smirnov tests, the data were not normally distributed. The CDFs of the out-of-axis coefficients (

,

and

) showed a clear mismatch with the ground truth curve, which was in agreement with hypothesis tests. CDF plots allow for visualizing the shape of the distribution tails, as well as presenting the FEM-GANs very good fit curves for the diagonal coefficients. This is otherwise a surprising ability of the model, given the small batch size used during training (eight images).

Both box plots and empirical CDF indicate that the bad performance in the out-of-axis coefficients was a problem inherited from the GANs approach. Possible techniques to mitigate the problem include the following: dynamically adapting the weight of the GANs loss in the informed loss calculation and formulating new equations for the informed

p-value. The

p-values and box plots presented in this section can be obtained using the database and code provided at

external repository with the DOI:

10.6084/m9.figshare.23280845 (posted on 2 June 2023).