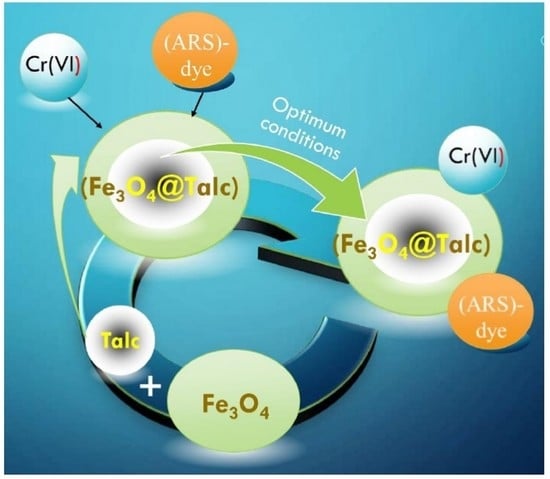

Preparation and Characterization of Magnetite Talc (Fe3O4@Talc) Nanocomposite as an Effective Adsorbent for Cr(VI) and Alizarin Red S Dye

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Fe3O4@Talc Nanocomposite

2.3. Characterization of Fe3O4@Talc Nanocomposite

2.4. Adsorption Studies

2.5. Regeneration and Reuse Studies of Adsorbent

3. Results and Discussion

3.1. Characterization of Fe3O4@Talc Nanocomposite

3.1.1. SEM

3.1.2. FTIR Analysis

3.1.3. XRD Analysis

3.1.4. Thermogravimetric Analysis (TGA)

3.2. Adsorption Processes

3.2.1. Effect of Initial Concentrations

3.2.2. Adsorption Kinetics

3.2.3. Effect of Adsorbent Dosage

3.2.4. Effect of Initial pH

3.2.5. Effects of Temperature

3.2.6. Thermodynamics

3.3. Regenaration and Reuse

3.4. Comparison of (Fe3O4@Talc) Nanocomposite Adsorption Efficiency with Other Adsorbents

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, J.-Y.; Jiang, X.-Y.; Jiao, F.-P.; Yu, J.-G. The oxygen-rich pentaerythritol modified multi-walled carbon nanotube as an efficient adsorbent for aqueous removal of alizarin yellow R and alizarin red S. Appl. Surf. Sci. 2018, 436, 198–206. [Google Scholar] [CrossRef]

- Yuan, N.; Gong, X.-R.; Han, B.-H. Hydrophobic Fluorous Metal−Organic Framework Nanoadsorbent for Removal of Hazardous Wastes from Water. ACS Appl. Nano Mater. 2021, 4, 1576–1585. [Google Scholar] [CrossRef]

- Nayl, A.A.; Abd-Elhamid, A.I.; Awwad, N.S.; Abdelgawad, M.A.; Wu, J.; Mo, X.; Gomha, S.M.; Aly, A.A.; Bräse, S. Review of the Recent Advances in Electrospun Nanofibers Applications in Water Purification. Polymers 2022, 14, 1594. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Guo, S.; Li, A.; Liu, D.; Sun, H.; Zhao, F. Low-cost bauxite residue-MoS2 possessing adsorption and photocatalysis ability for removing organic pollutants in wastewater. Sep. Purif. Technol. 2022, 283, 120144. [Google Scholar] [CrossRef]

- Adlnasab, L.; Shabanian, M.; Ezoddin, M.; Maghsodi, A. Amine rich functionalized mesoporous silica for the effective removal of alizarin yellow and phenol red dyes from waste waters based on response surface methodology. Mater. Sci. Eng. B 2017, 226, 188–198. [Google Scholar] [CrossRef]

- Iqbal, M.J.; Ashiq, M.N. Adsorption of dyes from aqueous solutions on activated charcoal. J. Hazard. Mater. 2007, 139, 57–66. [Google Scholar] [CrossRef]

- Jabbar, K.Q.; Azeez, A.; Barzinjy, A.A.; Hamad, S.M. Iron oxide nanoparticles: Preparation methods, functions, adsorption and coagulation/flocculation in wastewater treatment. Environ. Nanotechnol. Monit. Manag. 2022, 17, 100661. [Google Scholar] [CrossRef]

- Abbas, H.; Jamil, T.S.; Hammad, F. Synthesis, characterization and photocatalytic activity of nano sized undoped and Ga doped SrTi0.7Fe0.3O3 for 2,4,6-trichlorophenol photodegradation. J. Environ. Chem. Eng. 2016, 4, 2384–2393. [Google Scholar] [CrossRef]

- Sheikhmohammadi, A.; Hashemzadeh, B.; Alinejad, A.; Mohseni, S.M.; Sardar, M.; Sharafkhani, R.; Sarkhosh, M.; Asgari, E.; Bay, A. Application of graphene oxide modified with the phenopyridine and 2-mercaptobenzothiazole for the adsorption of Cr (VI) from wastewater: Optimization, kinetic, thermodynamic and equilibrium studies. J. Mol. Liq. 2019, 285, 586–597. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, H.; Wang, X.; Wu, J.; Xue, Y. Effects of chronic exposure of 2,4-dichlorophenol on the antioxidant system in liver of freshwater fish Carassius auratus. Chemosphere 2004, 55, 167–174. [Google Scholar] [CrossRef]

- Minamisawa, H.; Kojima, Y.; Aizawa, M. Adsorption of Inositol Phosphate on Hydroxyapatite Powder with High Specific Surface Area. Materials 2022, 15, 2176. [Google Scholar] [CrossRef] [PubMed]

- Vilela, P.B.; Dalalibera, A.; Duminelli, E.C.; Becegato, V.A.; Paulino, A.T. Adsorption and removal of chromium (VI) contained in aqueous solutions using a chitosan-based hydrogel. Environ. Sci. Pollut. Res. 2019, 26, 28481–28489. [Google Scholar] [CrossRef] [PubMed]

- Pang, L.-J.; Hu, J.-T.; Zhang, M.-J.; Yang, C.-G.; Wu, G.-Z. An efficient and reusable quaternary ammonium fabric adsorbent prepared by radiation grafting for removal of Cr(VI) from wastewater. Environ. Sci. Pollut. Res. 2018, 25, 11045–11053. [Google Scholar] [CrossRef] [PubMed]

- United States Environmental Protection Agency (USEPA). Basic Information about Chromium in Drinking Water. 2012. Available online: http://water.epa.gov/drink/contaminants/basicinformation/chromium.cfm (accessed on 24 May 2018).

- Som, I.; Roy, M.; Saha, R. Advances in Nanomaterial-based Water Treatment Approaches for Photocatalytic Degradation of Water Pollutants. ChemCatChem 2020, 12, 3409–3433. [Google Scholar] [CrossRef]

- Khamis, M.I.; Ibrahim, T.H.; Jumean, F.H.; Sara, Z.A.; Atallah, B.A. Cyclic Sequential Removal of Alizarin Red S Dye and Cr(VI) Ions UsingWool as a Low-Cost Adsorbent. Processes 2020, 8, 556. [Google Scholar] [CrossRef]

- Fan, X.; Deng, L.; Li, K.; Lu, H.; Wang, R.; Li, W. Adsorption of malachite green in aqueous solution using sugarcane bagasse-barium carbonate composite. Colloid Interface Sci. Commun. 2021, 44, 100485. [Google Scholar] [CrossRef]

- Khalifa, M.A.S.; Malek, N.A.N.N.; Farimani, A.Y.; Sani, N.S.; Kamaru, A.A. Cetylpyridinium bromide (CPB)-treated sugarcane bagasse for the removal of chromate in aqueous solution. Mater. Today Proc. 2021, 47, 1252–1257. [Google Scholar] [CrossRef]

- Yadav, V.B.; Gadi, R.; Kalra, S. Clay based nanocomposites for removal of heavy metals from water: A review. J. Environ. Manag. 2019, 232, 803–817. [Google Scholar] [CrossRef]

- Wadhawan, S.; Jain, A.; Nayyar, J.; Mehta, S.K. Role of nanomaterials as adsorbents in heavy metal ion removal from waste water: A review. J. Water Process Eng. 2020, 33, 101038. [Google Scholar] [CrossRef]

- Bayat, M.; Nasernejad, B.; Falamaki, C. Preparation and characterization of nano-galvanic bimetallic Fe/Sn nanoparticles deposited on talc and its enhanced performance in Cr(VI) removal. Sci. Rep. 2021, 11, 7715. [Google Scholar] [CrossRef]

- Ali, I.; Basheer, A.A.; Mbianda, X.Y.; Burakov, A.; Galunin, E.; Burakova, I.; Mkrtchyan, E.; Tkachev, A.; Grachev, V. Graphene based adsorbents for remediation of noxious pollutants from wastewater. Environ. Int. 2019, 127, 160–180. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.J.; Hameed, B.H.; Hummadi, E.H. Review on recent progress in chitosan/chitin-carbonaceous material composites for the adsorption of water pollutants. Carbohydr. Polym. 2020, 247, 116690. [Google Scholar] [CrossRef] [PubMed]

- Dim, P.E.; Mustapha, L.S.; Termtanun, M.; Okafor, J.O. Adsorption of chromium (VI) and iron (III) ions onto acid-modified kaolinite: Isotherm, kinetics and thermodynamics studies. Arab. J. Chem. 2021, 14, 103064. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Feng, X.; Yu, J.; Jiang, X. Self-assembly of sponge-like kaolin/chitosan/reduced graphene oxide composite hydrogels for adsorption of Cr(VI) and AYR. Environ. Sci. Pollut. Res. 2019, 26, 28898–28908. [Google Scholar] [CrossRef] [PubMed]

- Shukla, S.; Khan, R.; Daverey, A. Synthesis and characterization of magnetic nanoparticles, and their applications in wastewater treatment: A review. Environ. Technol. Innov. 2021, 24, 101924. [Google Scholar] [CrossRef]

- Alshammari, M.S.; Ahmed, I.M.; Alsharari, J.S.; Alsohaimi, I.H.; Al-Muaikel, N.S.; Alraddadi, T.S.; Hasanin, T.H.A. Adsorption of Cr(VI) using α-Fe2O3 coated hydroxy magnesium silicate (HMS): Isotherm, thermodynamic and kinetic study. Int. J. Environ. Anal. Chem. 2021. [Google Scholar] [CrossRef]

- Zayed, A.M.; Fathy, M.; Sillanpää, M.; Abdel Wahed, M.S.M. Talc-graphite schist as a natural organo-mineral complex for methylene blue remediation: Kinetic and isotherm study. SN Appl. Sci. 2020, 2, 740. [Google Scholar] [CrossRef] [Green Version]

- Rahman, A.; Kishimoto, N.; Urabe, T. Adsorption characteristics of clay adsorbents–sepiolite, kaolin and synthetic talc–for removal of Reactive Yellow 138:1. Water Environ. J. 2015, 29, 375–382. [Google Scholar] [CrossRef]

- Alizadeh, A.; Fakhari, M.; Safaei, Z.; Khodeai, M.M.; Repo, E.; Asadi, A. Ionic liquid-decorated Fe3O4@SiO2 nanocomposite coated on talc sheets: An efficient adsorbent for methylene blue in aqueous solution. Inorg. Chem. Commun. 2020, 121, 108204. [Google Scholar] [CrossRef]

- Darajeh, N.; Masoumi, H.R.F.; Kalantar, K.; Ahmad, M.B.; Shameli, K.; Basri, M.; Khandanlou, R. Optimization of process parameters for rapid adsorption of Pb(II), Ni(II), and Cu(II) by magnetic/talc nanocomposite using wavelet neural network. Res. Chem. Intermed. 2016, 42, 1977–1987. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, W.; Li, L.; Guo, W.; Xing, J.; Wang, H.; Hu, X.; Lyu, W.; Chen, R.; Song, J.; et al. Novel talc encapsulated lanthanum alginate hydrogel for efficient phosphate adsorption and fixation. Chemosphere 2020, 256, 127124. [Google Scholar] [CrossRef] [PubMed]

- Kalantari, K.; Afifi, M. Novel chitosan/polyvinyl alcohol/talc composite for adsorption of heavy metals and dyes from aqueous solution. Separ. Sci. Technol. 2018, 53, 2527–2535. [Google Scholar] [CrossRef]

- Huong, N.T.; Son, N.N.; Phuong, V.H.; Dung, C.T.; Huong, P.T.M.; Son, L.T. Synthesis Fe3O4/Talc nanocomposite by coprecipition-ultrasonication method and advances in hexavalent chromium removal from aqueous solution. Adsorpt. Sci. Technol. 2020, 38, 483–501. [Google Scholar] [CrossRef]

- An, Y.; Zheng, H.; Zheng, X.; Sun, Q.; Zhou, Y. Use of a floating adsorbent to remove dyes from water: A novel efficient surface separation method. J. Hazard. Mater. 2019, 375, 138–148. [Google Scholar] [CrossRef]

- Yamaura, M.; Camilo, R.L.; Sampaio, L.C.; Macêdo, M.A.; Nakamura, M.; Toma, H.F. Preparation and characterization of (3-aminopropyl)triethoxysilane-coated magnetite nanoparticles. J. Magn. Magn. Mater. 2004, 279, 210–217. [Google Scholar] [CrossRef]

- Gholivand, M.B.; Yamini, Y.; Dayeni, M.; Seidi, S.; Tahmasebi, E. Adsorptive removal of alizarin red-S and alizarin yellow GG from aqueous solutions using polypyrrole-coated magnetic nanoparticles. J. Environ. Chem. Eng. 2015, 3, 529–540. [Google Scholar] [CrossRef]

- Kalantari, K.; Ahmad, M.B.; Shameli, K.; Khandanlou, R. Size-controlled synthesis of Fe3O4 magnetite nanoparticles on the exterior of talc layers. Res. Chem. Intermed. 2015, 41, 2139–2151. [Google Scholar] [CrossRef]

- Gul, A.; Muhammad, S.; Nawaz, S.; Munir, S.; Rehman, K.U.; Ahmad, S.; Humphrey, O.S. Ficus religiosa bark an efficient adsorbent for Alizarin Red S dye: Equilibrium and kinetic analysis. J. Iran. Chem. Soc. 2021, 19, 1737–1746. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Zheng, J.; Lin, H.; Chen, G.; Wang, C.; Chhuon, K.; Wei, Z.; Jin, C.; Zhang, X. Thermal Preparation and Application of a Novel Silicon Fertilizer Using Talc and Calcium Carbonate as Starting Materials. Molecules 2021, 26, 4493. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, W.; An, Z.; Kong, S.; Chen, D. Adsorption of anionic dye onto magnetic Fe3O4/CeO2 nanocomposite: Equilibrium, kinetics, and thermodynamics. Adsorpt. Sci. Technol. 2019, 37, 185–204. [Google Scholar] [CrossRef] [Green Version]

- Xie, H.; Zhang, S.; Zhong, L.; Wang, Q.; Hu, J.; Tang, A. Effect of the occurrence state of magnesium in talc on the adsorption of Pb(II). J. Alloy. Compd. 2021, 887, 161288. [Google Scholar] [CrossRef]

- Bhomick, P.C.; Supong, A.; Baruah, M.; Pongener, C.; Sinha, D. Pine Cone biomass as an efficient precursor for the synthesis of activated biocarbon for adsorption of anionic dye from aqueous solution: Isotherm, kinetic, thermodynamic and regeneration studies. Sustain. Chem. Pharm. 2018, 10, 41–49. [Google Scholar] [CrossRef]

- Ahmed, I.M.; Nayl, A.A. A Novel Adsorbent functionalized with tri-octylamine (TOA) to Effective Removal of Cr(VI) from Sulfate Medium. J. Taiwan Inst. Chem. Eng. 2021, 121C, 299–308. [Google Scholar] [CrossRef]

- Kalantari, K.; Ahmad, M.B.; Masoumi, H.R.F.; Shameli, K.; Basri, M.; Khandanlou, R. Rapid Adsorption of Heavy Metals by Fe3O4/Talc Nanocomposite and Optimization Study Using Response Surface Methodology. Int. J. Mol. Sci. 2014, 15, 12913–12927. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhong, X.; Lu, Z.; Liang, W.; Baowei, H. The magnetic covalent organic framework as a platform for high-performance extraction of Cr(VI) and bisphenol a from aqueous solution. J. Hazard. Mater. 2020, 393, 122353. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, S.; Tyagi, I.; Gupta, V.K.; Ghasemi, N.; Shahivand, M.; Ghasemi, M. Kinetics, equilibrium studies and thermodynamics of methylene blue adsorption on Ephedra strobilacea saw dust and modified using phosphoric acid and zinc chloride. J. Mol. Liq. 2016, 218, 208–218. [Google Scholar] [CrossRef]

- Jiang, X.; Fan, W.; Li, C.; Wang, Y.; Bai, J.; Yang, H.; Liu, X. Removal of Cr(VI) from wastewater by a two-step method of oxalic acid reduction-modified fly ash adsorption. RSC Adv. 2019, 9, 33949–33956. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Chen, G.; Xu, L.; Hu, F.; Duan, X.Y. Removal of Cr(VI) from wastewater by a novel adsorbent of magnetic goethite: Adsorption performance and adsorbent characterisation. ChemistrySelect 2019, 4, 13817–13827. [Google Scholar] [CrossRef]

- Derdour, K.; Bouchelta, C.; Naser-Eddine, A.K.; Medjram, M.S.; Magri, P. Removal of Cr(VI) from aqueous solutions by using activated carbon supported iron catalysts as efficient adsorbents. World J. Eng. 2018, 15, 3–13. [Google Scholar] [CrossRef]

- Arraza, I.; López-Gónzalez, M.; Corrales, T.; Marcelo, G. Hybrid Materials: Magnetite–Polyethylenimine–Montmorillonite, as Magnetic Adsorbents for Cr (VI) Water Treatment. J. Colloid Interface Sci. 2012, 385, 24–33. [Google Scholar] [CrossRef]

- Zhao, X.-R.; Xu, X.; Teng, J.; Zhou, N.; Zhou, Z.; Jiang, X.-Y.; Jiao, F.-P.; Yu, J.-G. Three-dimensional porous graphene oxide-maize amylopectin composites with controllable pore-sizes and good adsorption-desorption properties: Facile fabrication and reutilization, and the adsorption mechanism. Ecotoxicol. Environ. Saf. 2019, 176, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Burakov, A.; Neskoromnay, E.; Babkin, A. Removal of the Alizarin Red S Anionic Dye Using Graphene Nanocomposites: A study on Kinetics under Dynamic Conditions. Mater. Today Proc. 2019, 11, 392–397. [Google Scholar] [CrossRef]

- Nasoudari, E.; Ameri, M.; Shams, M.; Ghavami, V.; Bonyadi, Z. The biosorption of Alizarin Red S by Spirulina platensis; process modelling, optimisation, kinetic and isotherm studies. Int. J. Environ. Anal. Chem. 2021. [Google Scholar] [CrossRef]

- Badran, I.; Khala, R. Adsorptive removal of alizarin dye from wastewater using maghemite nanoadsorbents. Sep. Sci. Technol. 2020, 55, 2433–2448. [Google Scholar] [CrossRef]

| Adsorbate | Langmuir Isotherm Model | Freundlich Isotherm Model | |||||

|---|---|---|---|---|---|---|---|

| Qmax (mg/g) | b (L/mg) | RL | R2 | 1/n | Kf (mg/g) | R2 | |

| Cr(VI) (ARS)-dye | 13.50 11.76 | 0.0124 0.080 | 0.89 0.2 | 0.838 0.997 | 0.784 0.142 | 0.247 13.860 | 0.997 0.985 |

| Adsorbate | T, °C | qe exp (mg/g) | First-Order Kinetic Parameter | Second-Order Kinetic Parameter | Intra-Particle Diffusion | Elovich | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| K1 (min−1) | qe cal (mg/g) | R2 | K2 (g·mg−1·min−1) | qe·cal (mg/g) | R2 | Ki | C | R2 | a | b | R2 | |||

| Cr(VI) | 20 | 0.940 | −0.085 | 0.977 | 0.969 | 0.05 | 1.314 | 0.902 | 0.194 | −0.1136 | 0.96 | 0.209 | 3.992 | 0.942 |

| 30 | 0.884 | −0.085 | 0.948 | 0.947 | 0.046 | 1.28 | 0.837 | 0.185 | −0.1237 | 0.990 | 0.188 | 4.181 | 0.946 | |

| 40 | 0.820 | −0.081 | 0.867 | 0.952 | 0.051 | 1.163 | 0.805 | 0.171 | −0.1212 | 0.990 | 0.171 | 4.608 | 0.944 | |

| 50 | 0.770 | −0.071 | 0.800 | 0.933 | 0.058 | 1.013 | 0.720 | 0.159 | −0.130 | 0.976 | 01.52 | 5.276 | 0.945 | |

| (ARS)-dye | 20 | 7.55 | −0.047 | 9.42 | 0.932 | 1.99 × 10−4 | 31.25 | 0.818 | 1.334 | −2.334 | 0.992 | 0.591 | 0.399 | 0.944 |

| 30 | 7.73 | −0.044 | 8.79 | 0.941 | 8.94 × 10−4 | 16.67 | 0.924 | 1.225 | −1.74 | 0.992 | 0.674 | 0.423 | 0.947 | |

| 40 | 7.90 | −0.041 | 8.17 | 0.953 | 2.39 × 10−3 | 11.78 | 0.946 | 1.11 | −1.182 | 0.990 | 0.784 | 0.444 | 0.956 | |

| 50 | 8.0 | −0.0345 | 7.13 | 0.963 | 4.42 × 10−3 | 9.80 | 0.931 | 1.101 | −0.571 | 0.978 | 0.931 | 0.480 | 0.945 | |

| T (K) | ΔG° (kJ·mol−1) | ΔH° (kJ·mol−1) | ΔS° (J·mol−1·K−1) | |||

|---|---|---|---|---|---|---|

| Cr(VI) | (ARS)-Dye | Cr(VI) | (ARS)-Dye | Cr(VI) | (ARS)-Dye | |

| 293 | −4.21 | −1.18 | −9.24 | 6.96 | −46.0 | 19.8 |

| 303 | −4.64 | −0.97 | ||||

| 313 | −5.13 | −0.74 | ||||

| 323 | −5.58 | −0.60 | ||||

| Adsorbent | Cr(VI) | (ARS)-Dye | Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Qmax, mg/g | pH | °C | Time (min) | Qmax, mg/g | pH | °C | Time (min) | ||

| acetic acid modified clay (AMC) | 10.42 | 6 | 90 | [24] | |||||

| hydrochloric acid modified clay (HMC) | 18.15 | 7 | 50 | ||||||

| Fe3O4/Talc nanocomposite | 7.17 | 5 | 20 | 60 | [34] | ||||

| 7.47 | 30 | ||||||||

| oxalic acid reduction-modified fly ash (MFA) | 12.34 | 120 | [48] | ||||||

| Magnetic Goethite | 4.32 | 4 | 30 | 240 | [49] | ||||

| activated carbon supported iron catalysts (Fe5-AWS) | 10.11 | 2 | 60 | [50] | |||||

| Fe3O4–PEI800–MMT | 8.8 | 6 | 25 | 120 | [51] | ||||

| Fe3O4–PEI25000–MMT | 7.7 | 6 | 25 | 120 | [51] | ||||

| GO-MA30:1 composite | 13.6 | 10 | [52] | ||||||

| Fe3O4/Talc nanocomposite | 13.5 | 2 | 20 | 30 | This Work | ||||

| mesoporous carbon | 2923 | 6 | 80 | [53] | |||||

| polyquinone/graphene | 3290 | 120 | |||||||

| Spirulina platensis | 17.15 | 6.47 | 46.29 | [54] | |||||

| Maghemite Fe2O3 | 23.2 | 11 | 60 | [55] | |||||

| 11.9 | 8 | 60 | |||||||

| Fe3O4/Talc nanocomposite | 11.7 | 3 | 20 | 60 | This Work | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nayl, A.A.; Abd-Elhamid, A.I.; Ahmed, I.M.; Bräse, S. Preparation and Characterization of Magnetite Talc (Fe3O4@Talc) Nanocomposite as an Effective Adsorbent for Cr(VI) and Alizarin Red S Dye. Materials 2022, 15, 3401. https://doi.org/10.3390/ma15093401

Nayl AA, Abd-Elhamid AI, Ahmed IM, Bräse S. Preparation and Characterization of Magnetite Talc (Fe3O4@Talc) Nanocomposite as an Effective Adsorbent for Cr(VI) and Alizarin Red S Dye. Materials. 2022; 15(9):3401. https://doi.org/10.3390/ma15093401

Chicago/Turabian StyleNayl, AbdElAziz A., Ahmed I. Abd-Elhamid, Ismail M. Ahmed, and Stefan Bräse. 2022. "Preparation and Characterization of Magnetite Talc (Fe3O4@Talc) Nanocomposite as an Effective Adsorbent for Cr(VI) and Alizarin Red S Dye" Materials 15, no. 9: 3401. https://doi.org/10.3390/ma15093401