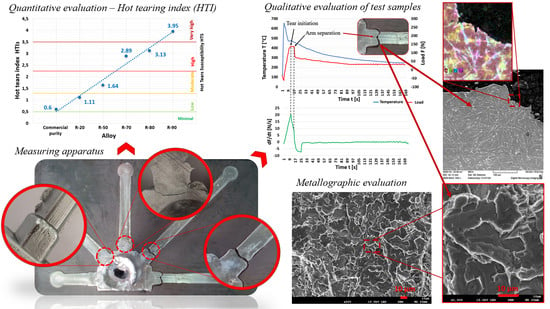

3.1. Quantitative Evaluation—Hot Tearing Index (HTI)

It can be seen from the results shown in the graph for HTI

1 (2) (

Figure 3) that the reference alloy consisting only of the commercial grade AlSi9Cu3 alloy reached an HTI

1 value of 0.43, which means a minimum susceptibility to hot tearing. After increasing the content of returnable material in the batch to 20% and 50%, the susceptibility to hot tearing increased from the minimum value to a low HTS level. The R-20 alloy reached HTI1 = 0.70, and the R-50 alloy had HTI

1 = 0.99. In the case of alloys consisting of a major proportion of returnable material, the resulting HTS values shifted to a slight rate of hot tearing susceptibility. The maximum value of the HTI

1 index of 2.09 was recorded for the R-90 alloy, which represents an approximately 5-fold increase compared to the commercial grade alloy (the reference alloy).

By using the second Equation (3) for HTI

2, the numerical value of which depends not only on the nature of the hot tear but also on its position and the arm length, we obtained orders-of-magnitude higher values of the HTI

2 index compared to HTI

1. The resulting values of HTI

2 are shown graphically in

Figure 4. The HTS index of the reference alloy in this case was on the border between low and moderate hot tearing susceptibility with a HTI

2 value of 1.2. Compared to HTI

1, where a high level of hot tearing susceptibility was not reached by any alloy, then, using Equation (2) for HTI

2, the R-70 and R-80 alloys reached this level. The R-90 alloy reached a very high hot tearing susceptibility HTI

2 value of 3.81.

The graph in

Figure 5 shows the HTI

3 values obtained from Equation (4). Using the HTI

3 relationship, the largest difference between the reference alloy and the R-90 alloy (containing 90% returnable material) was measured. The reference alloy with an HTI

3 of 0.60 showed low susceptibility to hot tear formation. The R-20 alloy also reached a low susceptibility level. On the other hand, in the R-90 alloy, the HTI

3 was 3.95, and thus the alloy reached very high hot tearing susceptibility.

3.2. Qualitative Evaluation of Test Samples

It can be seen from the graphs below (

Figure 6 and

Figure 7) that no stress occurs in the material at the beginning of solidification. As solidification continues and the temperature decreases, a crystalline structure begins to form, and deformation occurs. The casting begins to shrink, which is reflected in the increase of the tensile force recorded by the load cell.

The first and fourth measurements of the commercial grade alloy are characterized by a smooth force curve without hot tear detection.

Figure 6a shows the graph with the courses of temperature, force and its derivatives of the fourth measurement. Hot tear occurrence was detected on the force curve during the second and third measurements. In both cases, there was no complete rupture of the arm, and a subsequent increase in force was recorded.

When using a 20% proportion of returnable material (R-20 alloy) in the batch, no hot tear was formed on the through-arm only in the third measurement. In the other three measurements, the formation of hot tears was detected, and after their propagation, a repeated increase in force (first measurement) and stabilization of the force was recorded, when the curve maintained a constant value (second and fourth measurements).

At the equilibrium batch ratio (R-50 alloy), the formation of a severe hot tear was recorded in the first and fourth measurements, which led to complete tearing off of the arm. Conversely, no hot tear formation was detected in the third measurement. The graph (

Figure 6b) shows the course of the second measurement. It is characterized by the formation of a hot tear. It can be seen from the course of the curve that the arm did not rupture completely, and 80 s after the formation of the hot tear, its propagation was terminated by repeatedly increasing the rate of load.

Table 5,

Table 6 and

Table 7 present detailed values of each measurement for the commercial grade alloy, R-20 and R-50 alloys obtained in the qualitative evaluation.

In the case of alloys with a predominant content of returnable material in the batch, not a single measurement was recorded without the occurrence of hot tearing. In the case of an alloy with a 70% content of returnable material, in two cases, the arm was completely torn off due to the formation a hot tear (third and fourth measurements). The graph in

Figure 7a clearly shows that the tearing off of the arm during the third measurement did not occur immediately, but only after 6 s of hot tear propagation. With 80% returnable material in the batch, complete tearing off of the arm occurred in three cases. In the first measurement, the alloy was still able to stop the hot tear propagation with the subsequent re-increase of force.

The alloy with the highest content of returnable material (R-90) showed the worst results. The arm was torn off in all measurements (

Figure 7b). The detailed values of each measurement for alloys with higher contents of returnable material (R-70, R-80, R-90) obtained in qualitative evaluation are given in

Table 8,

Table 9 and

Table 10.

Table 11 shows the solidification interval of experimental alloys, which significantly affects the overall susceptibility of the alloy to hot tearing. Increase of returnable material in the batch led to a change in wt.% of some elements, especially Fe, Si and Cu (

Table 1 and

Table 2). Elements Si and Cu can affect the width of the solidification interval and thus also the susceptibility of the alloy to hot tearing [

17,

18,

19]. From the temperatures, it can be stated that due to the increase of the returnable material in the batch and thus the change in weight. % of some elements, there was no significant change in the width of the solidification interval.

3.3. Fracture Surfaces and Tear Profile

The first alloy evaluated is R-50, which in the quantitative evaluation showed a moderate HTS (for HTI3) and in the qualitative evaluation there were two arm separations (

Table 7). The hot tear profile of the R-50 alloy clearly shows that the weakest regions for hot tear propagation were the iron phases in acicular morphology (

Figure 8a). The sharp ends of the iron phase acicular formations acted as a critical point for the formation of micro-tears. Due to the fragility of the phases, conditions were created for further hot tear propagation of a transcrystalline, but also with an inter-crystalline nature—mixed hot tear propagation (fracture). When looking at the arm fracture surface, brittle fracture predominates—failure by cleavage of iron-based intermetallic phases (

Figure 8b).

In the case of the alloy with a 70% content of returnable material (high HTS according to HTI

3,

Figure 5), the transcrystalline hot tear propagation mechanism is the main component of the hot tear profile shown in

Figure 9a. Regions of closed micro-tears with a transcrystalline mechanism can be observed in the image of the hot tear profile. The fracture surface is, similarly to the alloy, characterized by brittle fracture—failure by cleaving thicker plates of iron phases (

Figure 9b), which could have the greatest effect on the two detached arms in the qualitative evaluation, and on the immediate arm separation in the fourth measurement (

Table 8).

The R-90 alloy with the largest content of returnable material reached the worst results in the qualitative test, when arms were torn off all cases (in three cases there was immediate tear-off,

Table 10). The hot tear profile shows transcrystalline propagation of hot tears in brittle acicular formations of iron phases and a large occurrence of closed micro-tears in the region of the fracture profile (

Figure 10a), which led to a very high susceptibility to hot tearing (

Figure 5). The brittle fracture on the R-90 alloy fracture surface is also characterized by a significant inter-phase failure at the boundary between the iron phase plate and the matrix (

Figure 10b).

Figure 11 shows EDX analysis of the iron phase Al

5FeSi in acicular morphology, which served as a stress concentrator and a suitable site for transcrystalline hot tear propagation.