Basalt Fiber-Based Flame Retardant Epoxy Composites: Preparation, Thermal Properties, and Flame Retardancy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modified Basalt Fibers

- (1)

- 10 g basalt fibers were immersed in 200 mL acetone solution ultrasonic cleaning at 50 °C for 3 h, then the fibers were soaked in acetone for 21 h and dried for 48 h at 60 °C after the filtration.

- (2)

- 10 g basalt fibers were immersed in 150 mL glacial acetic acid ultrasonic and cleaned at 50 °C for 3 h using sonication bath. Then, the fibers were soaked in glacial acetic acid for 21 h. The pretreated basalt fiber was rinsed with deionized water to achieve a neutral pH, dried for 24 h at 60 °C after the filtration.

- (3)

- 10 g basalt fibers were added to the mixture of NaOH and deionized water with a mass ratio of 1:20. The mixtures was sonicated at 90 °C for 1 h. The fibers were then diluted and washed with deionized water until the pH = 7. The treated fiber was dried in an oven for 3 h at 60 °C.

- (4)

- 10 g basalt fibers were put into the muffle furnace, which were sealed and heated to 350 °C for 2 h. After that, the pretreated basalt fiber was added to the mixture of deionized water, anhydrous ethanol of analytical purity.

2.3. Preparation of Flame Retardant Modified Fiber Epoxy Resin (EP/AP750/BF-AT)

2.4. Characterization of Morphology, Structure, and Properties

3. Results and Discussion

3.1. Effect of Fiber Pretreatment on Surface Organics

3.1.1. SEM Analysis of Basalt Fiber

3.1.2. FTIR and TG Analysis of Basalt Fiber

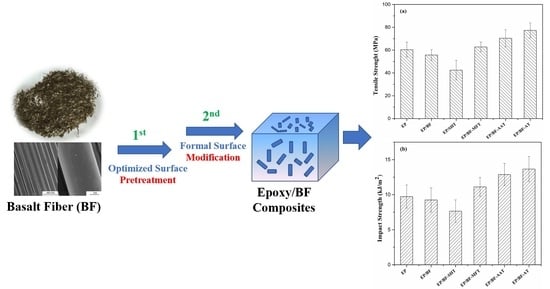

3.2. Effect of Modified Basalt Fiber on the Mechanical Properties of Epoxy Composites

3.2.1. Tensile and Impact Properties

3.2.2. Dynamic Mechanical Analysis (DMA)

3.3. Thermal Degradation Behavior of Flame-Retardant Epoxy Resin

3.4. Effect of Modified Fiber on Combustion Performance of Epoxy Resin

3.4.1. Flammability

3.4.2. Fire behaviors

3.5. Mechanical Properties of EP/AP750 and EP/AP750/BF-AT

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Chevali, V.S.; Xu, Z.G.; Hui, D.; Wang, H. A review of extending performance of epoxy resins using carbon nanomaterials. Compos. Part B Eng. 2018, 136, 197–214. [Google Scholar] [CrossRef]

- Kalali, E.N.; Wang, X.; Wang, D.Y. Synthesis of a Fe3O4 Nanosphere@Mg-Al Layered-Double-Hydroxide Hybrid and Application in the Fabrication of Multifunctional Epoxy Nanocomposites. Ind. Eng. Chem. Res. 2016, 55, 6634–6642. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Dufosse, F.; Wang, D.Y. Ultrafine nickel nanocatalyst-engineering organic layered double hydroxide towards super-efficiently fire-safe epoxy resin via interfacial catalysis. J. Mater. Chem. A 2018, 6, 8488–8498. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Qi, X.L.; Wang, D.Y. Recent Progress on Metal-Organic Framework and Its Derivatives as Novel Fire Retardants to Polymeric Materials. Nano-Micro Lett. 2020, 12, 173. [Google Scholar] [CrossRef]

- Pan, Y.T.; Wan, J.; Zhao, X.; Li, C.; Wang, D.Y. Interfacial growth of MOF-derived layered double hydroxide nanosheets on graphene slab towards fabrication of multifunctional epoxy nanocomposites. Chem. Eng. J. 2017, 330, 1222–1231. [Google Scholar] [CrossRef]

- Dhaliwal, G.S.; Bajwa, D.S.; Bajwa, S. Fabrication and Testing of Soy-Based Polyurethane Foam with Flame Retardant Properties. J. Polym. Environ. 2020. [Google Scholar] [CrossRef]

- Fabia, J.; Gawłowski, A.; Rom, M.; Ślusarczyk, C.; Brzozowska-Stanuch, A.; Sieradzka, M. PET Fibers Modified with Cloisite Nanoclay. Polymers 2020, 12, 774. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Babu, H.V.; Llorca, J.; Wang, D.Y. Impact of halogen-free flame retardant with varied phosphorus chemical surrounding on the properties of diglycidyl ether of bisphenol—A type epoxy resin: Synthesis, fire behaviour, flame-retardant mechanism and mechanical properties. RSC Adv. 2016, 6, 59226–59236. [Google Scholar] [CrossRef] [Green Version]

- Wen, Y.; Cheng, Z.; Li, W.X.; Li, Z.; Liao, D.J.; Hu, X.P.; Pan, N.; Wang, D.Y.; Hull, T.R. A novel oligomer containing DOPO and ferrocene groups: Synthesis, characterization, and its application in fire retardant epoxy resin. Polym. Degrad. Stabil. 2018, 156, 111–124. [Google Scholar] [CrossRef]

- Wang, D.L.; Liu, Y.; Wang, D.Y.; Zhao, C.X.; Mou, Y.R.; Wang, Y.Z. A novel intumescent flame-retardant system containing metal chelates for polyvinyl alcohol. Polym. Degrad. Stabil. 2007, 92, 1555–1564. [Google Scholar] [CrossRef]

- Wang, X.B.; Bi, B.; Liu, J.W.; Yang, S.S.; Zhou, L.; Lu, L.G.; Wang, Y.; Xu, F.; Huang, R. Halogen-free intumescent flame-retardant ethylene-vinyl acetate copolymer system based on organic montmorillonite and graphene nanosheets. J. Appl. Polym. Sci. 2018, 135, 46361. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, D.Y.; Wang, J.S.; Song, Y.P.; Wang, Y.Z. A novel intumescent flame-retardant LDPE system and its thermo-oxidative degradation and flame-retardant mechanisms. Polym. Adv. Technol. 2008, 19, 1566–1575. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; Iorio, I.D. Mechanical characterisation of basalt fibre reinforced plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.L.; Song, S.H. Degradation of basalt fibre and glass fibre/epoxy resin composites in seawater. Corros. Sci. 2011, 53, 426–431. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z.; Wu, G.; Zhu, H.; Zen, F. Enhancement of basalt FRP by hybridization for long-span cable-stayed bridge. Compos. Part B Eng. 2013, 44, 184–192. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Jamali, N.; Rezvani, A.; Khosravi, H.; Tohidlou, E. On the mechanical behavior of basalt fiber/epoxy composites filled with silanized graphene oxide nanoplatelets. Polym. Compos. 2018, 39, E2472–E2482. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, X.; Wu, Z.S.; Keller, T.; Vassilopoulos, A.P. Effect of stress ratios on tension–tension fatigue behavior and micro-damage evolution of basalt fiber-reinforced epoxy polymer composites. J. Mater. Sci. 2018, 53, 9545–9556. [Google Scholar] [CrossRef]

- Kim, D.; Mittal, G.; Kim, M.K.; Kim, S.H.; Rhee, K.Y. Surface modification of MMT and its effect on fatigue and fracture behavior of basalt/epoxy based composites in a seawater environment. Appl. Surf. Sci. 2019, 47, 55–58. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Wei, J.; Zhou, X.T.; Akihiro, H.; Li, S.W.; Chen, Y.Y.; Jiang, S.Y.; Liang, Z.S.; Wu, Z.R.; Qiu, F.X. Evaluation of modified basalt fiber as biological carrier media for wastewater treatment with the extended DLVO theory model. Environ. Sci. Pollut. R. 2019, 26, 29789–29798. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Chen, M.; Huang, M.J.; Wang, M.Y.; Huang, J. Systematic evaluation of PDA/PAM/MAH-modified basalt fiber as biofilm carrier for wastewater treatment. Environ. Technol. 2020, 1–27. [Google Scholar] [CrossRef] [PubMed]

- Manikandan, V.; Jappes, J.T.W.; Kumar, S.M.S.; Amuthakkannan, P. Investigation of the effect of surface modifications on the mechanical properties of basalt fiber reinforced polymer composites. Compos. Part B-Eng. 2012, 43, 812–818. [Google Scholar] [CrossRef]

- Yao, D.W.; Yin, G.Z.; Bi, Q.Q.; Yin, X.; Wang, N.; Wang, D.Y. Basalt Fiber Modified Ethylene Vinyl Acetate/Magnesium Hydroxide Composites with Balanced Flame Retardancy and Improved Mechanical Properties. Polymers 2020, 12, 2107. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.H.; Ju, Y.Z.; Shen, H.; Xu, L.B. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Khosravi, H.; Eslamifarsani, R. Enhanced mechanical properties of unidirectional basalt fiber/epoxy composites using silane-modified Na+-montmorillonite nanoclay. Polym. Test. 2016, 55, 135–142. [Google Scholar] [CrossRef]

- Zhu, M.M.; Ma, J.X. Basalt fiber modified with lanthanum-ethylenediaminetetraacetic acid as potential reinforcement of cyanate matrix composites. Appl. Surf. Sci. 2019, 4644, 636–643. [Google Scholar] [CrossRef]

- Afroz, M.; Patnaikuni, I.; Venkatesan, S. Chemical durability and performance of modified basalt fiber in concrete medium. Constr. Build. Mater. 2017, 154, 191–203. [Google Scholar] [CrossRef]

- Li, W.; Huang, W.; Kang, Y.; Gong, Y.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Che, S. Fabrication and investigations of G-POSS/cyanate ester resin composites reinforced by silane-treated silica fibers. Compos. Sci. Technol. 2019, 173, 7–14. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Pan, Y.T.; Adriana, P.Y.; Hu, S.; Zhang, X.Q.; Wang, R.; Wang, D.Y. Polydopamine induced natural fiber surface functionalization: A way towards flame retardancy of flax/poly (lactic acid) biocomposites. Compos. Part B Eng. 2018, 154, 56–63. [Google Scholar] [CrossRef]

- Iorio, M.; Santarelli, M.L.; González-Gaitano, G.; González-Benito, J. Surface modification and characterization of basalt fibers as potential reinforcement of concretes. Appl. Surf. Sci. 2018, 427, 1248–1256. [Google Scholar] [CrossRef]

- Bi, Q.Q.; Yao, D.W.; Yin, G.Z.; You, J.Q.; Liu, X.Q.; Wang, N.; Wang, D.Y. Surface engineering of magnesium hydroxide via bioinspired iron-loaded polydopamine as green and efficient strategy to epoxy composites with improved flame retardancy and reduced smoke release. React. Funct. Polym. 2020, 155, 104690. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M.; Michalowski, S. Basalt powder as an eco-friendly filler for epoxy composites: Thermal and thermo-mechanical properties assessment. Compos. Part B Eng. 2019, 164, 272–279. [Google Scholar] [CrossRef]

- Wu, W.; Wang, J. Effect of KH550 on the Preparation and Compatibility of Carbon Fibers Reinforced Silicone Rubber Composites. Silicon 2018, 10, 1903–1910. [Google Scholar] [CrossRef]

- Xu, M.J.; Xia, S.Y.; Liu, C.; Li, B. Preparation of Poly (phosphoric acid piperazine) and Its Application as an Effective Flame Retardant for Epoxy Resin. Chin. J. Polym. Sci. 2018, 36, 655–664. [Google Scholar] [CrossRef]

- Yang, W.; Jia, Z.J.; Chen, Y.N.; Zhang, Y.R.; Si, J.Y.; Lu, H.D.; Yang, B.H. Carbon nanotube reinforced polylactide/basalt fiber composites containing aluminium hypophosphite: Thermal degradation, flame retardancy and mechanical properties. RSC Adv. 2015, 5, 105869–105879. [Google Scholar] [CrossRef]

| Sample | EP/phr | AP750/phr | BF/phr | BF-AT/phr | BF-AAT/phr | BF-SHT/phr | BF-MFT/phr |

|---|---|---|---|---|---|---|---|

| EP/BF | 100 | / | 6.78 | / | / | / | / |

| EP/BF-AT | 100 | / | / | 6.78 | / | / | / |

| EP/BF-AAT | 100 | / | / | / | 6.78 | / | / |

| EP/BF-SHT | 100 | / | / | / | / | 6.78 | / |

| EP/BF-MFT | 100 | / | / | / | / | / | 6.78 |

| EP/AP750 | 100 | 13.57 | / | / | / | / | / |

| EP/AP750/BF-AT | 100 | 13.57 | / | 6.78 | / | / | / |

| Sample | T5% (°C) | T50% (°C) | Tmax (°C) | Rmax (%/°C) | Residue Yield at 600 °C (%) |

|---|---|---|---|---|---|

| EP | 360 | 409 | 408 | 22 | 17.3 |

| EP/AP750 | 338 | 376 | 368 | 19 | 25.3 |

| EP/AP750/BF-AT | 335 | 378 | 362 | 18 | 33.5 |

| Sample | LOI (%) | Burn Time t1/t2 a (s) | Dripping |

|---|---|---|---|

| Pure EP | 23.2 ± 0.2 | >30/- b | Yes |

| EP/AP750 | 26.3 ± 0.2 | 1/2 | No |

| EP/AP750/BF-AT | 25.1 ± 0.2 | 1/3 | No |

| Sample | TTI (s) | pHRR (kW/m2) | EHC (MJ/kg) | THR (MJ/m2) | pSPR (m2/s) | Char Yield (wt.%) | FPI (m2·s/ kW) | MARHE (kW/m2) | FIGRA (kW/(m2·s)) |

|---|---|---|---|---|---|---|---|---|---|

| EP | 46 ± 4 | 950 ± 21 | 22 ± 0 | 83 ± 3 | 0.285 ± 0.001 | 8.2 ± 0.6 | 4.8 ± 0.3 | 406 ± 13 | 10.3 |

| EP/AP750 | 40 ± 6 | 273 ± 12 | 20 ± 2 | 48 ± 5 | 0.099 ± 0.004 | 32.8 ± 0.3 | 14.7 ± 0.8 | 149 ± 21 | 1.7 |

| EP/AP750/BF-AT | 41 ± 1 | 458 ± 15 | 19 ± 1 | 51 ± 4 | 0.159 ± 0.002 | 29.5 ± 0.2 | 9.3 ± 0.4 | 240 ± 19 | 4.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Zhou, M.; Yin, G.-Z.; Kalali, E.; Wang, N.; Wang, D.-Y. Basalt Fiber-Based Flame Retardant Epoxy Composites: Preparation, Thermal Properties, and Flame Retardancy. Materials 2021, 14, 902. https://doi.org/10.3390/ma14040902

Guo Y, Zhou M, Yin G-Z, Kalali E, Wang N, Wang D-Y. Basalt Fiber-Based Flame Retardant Epoxy Composites: Preparation, Thermal Properties, and Flame Retardancy. Materials. 2021; 14(4):902. https://doi.org/10.3390/ma14040902

Chicago/Turabian StyleGuo, Yu, Meihui Zhou, Guang-Zhong Yin, Ehsan Kalali, Na Wang, and De-Yi Wang. 2021. "Basalt Fiber-Based Flame Retardant Epoxy Composites: Preparation, Thermal Properties, and Flame Retardancy" Materials 14, no. 4: 902. https://doi.org/10.3390/ma14040902