On the Ejection of Filaments of Polymer Solutions Triggered by a Micrometer-Scale Mixing Mechanism

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preparation of Solutions

2.2. Characterization of Polymer Solutions

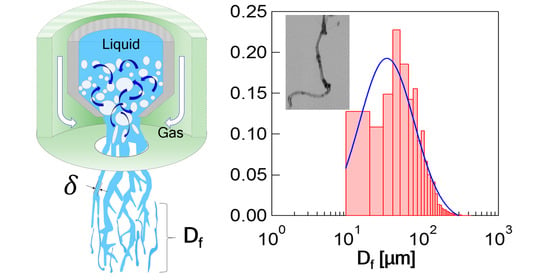

2.3. FB Atomization and Video Processing

3. Results and Discussion

3.1. Rheology of Solutions

3.2. Filament Ejection and Diameter

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petrie, C.J.S. Extensional viscosity: A critical discussion. J. Non-Newton. Fluid Mech. 2006, 137, 15–23. [Google Scholar] [CrossRef] [Green Version]

- Varshney, A.; Steinberg, V. Drag enhancement and drag reduction in viscoelastic flow. Phys. Rev. Fluids 2018, 3, 103302. [Google Scholar] [CrossRef] [Green Version]

- Cooper, J.A.; Lu, H.H.; Ko, F.K.; Freeman, J.W.; Laurencin, C.T. Fiber-based tissue-engineered scaffold for ligament replacement: Design considerations and in vitro evaluation. Biomaterials 2005, 26, 1523–1532. [Google Scholar] [CrossRef]

- Aboutalebi, S.H.; Jalili, R.; Esrafilzadeh, D.; Salari, M.; Gholamvand, Z.; Aminorroaya Yamini, S.; Konstantinov, K.; Shepherd, R.L.; Chen, J.; Moulton, S.E.; et al. High-Performance Multifunctional Graphene Yarns: Toward Wearable All-Carbon Energy Storage Textiles. ACS Nano 2014, 8, 2456–2466. [Google Scholar] [CrossRef]

- Huang, L.; Santiago, D.; Loyselle, P.; Dai, L. Graphene-Based Nanomaterials for Flexible and Wearable Supercapacitors. Small 2018, 14, 1800879. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Xia, Y. Electrospinning of Nanofibers: Reinventing the Wheel? Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Modesto-López, L.B.; Chimentão, R.J.; Álvarez, M.G.; Rosell-Llompart, J.; Medina, F.; Llorca, J. Direct growth of hydrotalcite nanolayers on carbon fibers by electrospinning. Appl. Clay Sci. 2014, 101, 461–467. [Google Scholar] [CrossRef]

- Gañán-Calvo, A.M.; Ferrera, C.; Montanero, J.M. Universal size and shape of viscous capillary jets: Application to gas-focused microjets. J. Fluid Mech. 2011, 670, 427–438. [Google Scholar] [CrossRef]

- Palangetic, L.; Reddy, N.K.; Srinivasan, S.; Cohen, R.E.; McKinley, G.H.; Clasen, C. Dispersity and spinnability: Why highly polydisperse polymer solutions are desirable for electrospinning. Polymer 2014, 55, 4920–4931. [Google Scholar] [CrossRef] [Green Version]

- Reneker, D.H.; Chun, I. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 1996, 7, 216–223. [Google Scholar] [CrossRef] [Green Version]

- Daristotle, J.L.; Behrens, A.M.; Sandler, A.D.; Kofinas, P. A Review of the Fundamental Principles and Applications of Solution Blow Spinning. ACS Appl. Mater. Interfaces 2016, 8, 34951–34963. [Google Scholar] [CrossRef] [Green Version]

- Ponce-Torres, A.; Ortega, E.; Rubio, M.; Rubio, A.; Vega, E.J.; Montanero, J.M. Gaseous flow focusing for spinning micro and nanofibers. Polymer 2019, 178, 121623. [Google Scholar] [CrossRef]

- Gañán-Calvo, A.M.; González-Prieto, R.; Riesco-Chueca, P.; Herrada, M.A.; Flores-Mosquera, M. Focusing capillary jets close to the continuum limit. Nat. Phys. 2007, 3, 737–742. [Google Scholar] [CrossRef]

- Gañán-Calvo, A.M. Enhanced liquid atomization: From flow-focusing to flow-blurring. Appl. Phys. Lett. 2005, 86, 214101. [Google Scholar] [CrossRef]

- Jiang, L.; Agrawal, A.K. Spray features in the near field of a flow-blurring injector investigated by high-speed visualization and time-resolved PIV. Exp. Fluids 2015, 56, 103. [Google Scholar] [CrossRef]

- Rosell-Llompart, J.; Gañán-Calvo, A.M. Turbulence in pneumatic flow focusing and flow blurring regimes. Phys. Rev. E 2008, 77, 036321. [Google Scholar] [CrossRef]

- Simmons, B.M.; Agrawal, A.K. Spray characteristics of a Flow-Blurring atomizer. At. Sprays 2010, 20, 821–835. [Google Scholar] [CrossRef]

- Pongvuthithum, R.; Moran, J.; Sankui, T. A flow blurring nozzle design for combustion in a closed system. Appl. Therm. Eng. 2018, 131, 587–594. [Google Scholar] [CrossRef]

- Serrano, J.; Jiménez-Espadafor, F.J.; Lora, A.; Modesto-López, L.; Gañán-Calvo, A.; López-Serrano, J. Experimental analysis of NOx reduction through water addition and comparison with exhaust gas recycling. Energy 2019, 168, 737–752. [Google Scholar] [CrossRef]

- Matusiewicz, H.; Slachcinski, M.; Almagro, B.; Canals, A. Evaluation of Various Types of Micronebulizers and Spray Chamber Configurations for Microsamples Analysis by Microwave Induced Plasma Optical Emission Spectrometry. Chem. Analityczna 2009, 54, 1219–1244. [Google Scholar]

- Niguse, Y.; Agrawal, A. Low-Emission, Liquid Fuel Combustion System for Conventional and Alternative Fuels Developed by the Scaling Analysis. J. Eng. Gas Turbines Power 2016, 138, 041502. [Google Scholar] [CrossRef]

- Modesto-López, L.B.; Gañán-Calvo, A.M. Visualization and size-measurement of droplets generated by Flow Blurring® in a high-pressure environment. Aerosol Sci. Technol. 2018, 52, 198–208. [Google Scholar] [CrossRef] [Green Version]

- Ramos-Escobar, A.; Uceda-Gallegos, R.; Modesto-López, L.; Gañán-Calvo, A. Dynamics of formation of poly(vinyl alcohol) filaments with an energetically efficient micro-mixing mechanism. Phys. Fluids 2020, 32, 122101. [Google Scholar] [CrossRef]

- Modesto-López, L.B.; Pérez-Arjona, A.; Gañán-Calvo, A.M. Flow Blurring-Enabled Production of Polymer Filaments from Poly(ethylene oxide) Solutions. ACS Omega 2019, 4, 2693–2701. [Google Scholar] [CrossRef] [PubMed]

- Hermosín-Reyes, M.; Gañán-Calvo, A.M.; Modesto-López, L.B. Flow blurring atomization of Poly(ethylene oxide) solutions below the coil overlap concentration. J. Aerosol Sci. 2019, 137, 105429. [Google Scholar] [CrossRef]

- Briscoe, B.; Luckham, P. The effects of hydrogen bonding upon the viscosity of aqueous poly(vinyl alcohol) solutions. Polymer 2000, 41, 3851–3860. [Google Scholar] [CrossRef]

- Devanand, K.; Selser, J.C. Asymptotic Behavior and Long-Range Interactions in Aqueous Solutions of Poly(ethylene oxide). Macromolecules 1991, 24, 5943–5947. [Google Scholar] [CrossRef]

- Clasen, C.; Plog, J.P.; Kulicke, W.-M.; Owens, M.; Macosko, C.; Scriven, L.E.; Verani, M.; McKinley, G.H. How dilute are dilute solutions in extensional flows? J. Rheol. 2006, 50, 849–881. [Google Scholar] [CrossRef] [Green Version]

- Dinic, J.; Biagioli, M.; Sharma, V. Pinch-off dynamics and extensional relaxation times of intrinsically semi-dilute polymer solutions characterized by dripping-onto-substrate rheometry. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1692–1704. [Google Scholar] [CrossRef]

- Bouldin, M.; Kulicke, W.M.; Kehler, H. Prediction of the non-Newtonian viscosity and shear stability of polymer solutions. Colloid Polym. Sci. 1988, 266, 793–805. [Google Scholar] [CrossRef]

- Larson, R.G. The rheology of dilute solutions of flexible polymers: Progress and problems. J. Rheol. 2005, 49, 1–70. [Google Scholar] [CrossRef]

- Colby, R.H. Structure and linear viscoelasticity of flexible polymer solutions: Comparison of polyelectrolyte and neutral polymer solutions. Rheol. Acta 2010, 49, 425–442. [Google Scholar] [CrossRef]

- Heo, Y.; Larson, R.G. Universal Scaling of Linear and Nonlinear Rheological Properties of Semidilute and Concentrated Polymer Solutions. Macromolecules 2008, 41, 8903–8915. [Google Scholar] [CrossRef] [Green Version]

- Mansour, A.; Chigier, N. Turbulence characteristics in cylindrical liquid jets. Phys. Fluids 1994, 6, 3380–3391. [Google Scholar] [CrossRef]

- Tennekes, H.; Lumley, J.L. A First Course in Turbulence; The MIT Press: Cambridge, MA, USA, 1994. [Google Scholar]

| 0.5 | 990.9 | 0.025 | 0.0582 | 1.14 | 0.54 | 2.71 | 37 | 1.92 |

| 0.8 | 993.2 | 0.043 | 0.0567 | 1.82 | 40 | 1.84 | ||

| 1.5 | 999.0 | 0.900 | 0.0570 | 3.41 | 181 | 1.42 | ||

| 1.6 | 994.7 | 1.050 | 0.0575 | 3.64 | 181 | 1.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marín-Brenes, F.; Olmedo-Pradas, J.; Gañán-Calvo, A.M.; Modesto-López, L. On the Ejection of Filaments of Polymer Solutions Triggered by a Micrometer-Scale Mixing Mechanism. Materials 2021, 14, 3399. https://doi.org/10.3390/ma14123399

Marín-Brenes F, Olmedo-Pradas J, Gañán-Calvo AM, Modesto-López L. On the Ejection of Filaments of Polymer Solutions Triggered by a Micrometer-Scale Mixing Mechanism. Materials. 2021; 14(12):3399. https://doi.org/10.3390/ma14123399

Chicago/Turabian StyleMarín-Brenes, Fernando, Jesús Olmedo-Pradas, Alfonso M. Gañán-Calvo, and Luis Modesto-López. 2021. "On the Ejection of Filaments of Polymer Solutions Triggered by a Micrometer-Scale Mixing Mechanism" Materials 14, no. 12: 3399. https://doi.org/10.3390/ma14123399