Flame Retardancy of Biobased Composites—Research Development

Abstract

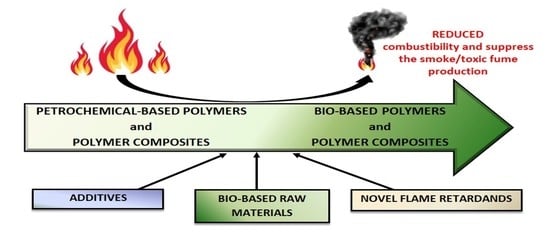

:1. Introduction

2. Strategies of Polymer Flame Retardancy

3. Typical Flame Retardants for Polymer Materials

4. Flame Retardancy of Natural Fibers

5. Other Methods of Reducing the Flammability of Bio-Based Composites

5.1. PLA-Based Composites

5.2. PHA-Based Composites

5.3. Other Bio-Based Polymer Composites

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ramakrishna, S.; Huang, Z.M. Biocomposites. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Christian, S.J. Natural fibre-reinforced noncementitious composites (biocomposites). In Nonconventional and Vernacular Construction Materials; Woodhead Publishing: Cambridge, UK, 2016; pp. 111–126. [Google Scholar]

- Memmott, P.; Martin, D.; Amiralian, N. Nanotechnology and the Dreamtime knowledge of spinifex grass. In Green Composites; Woodhead Publishing: Duxford, UK, 2017; pp. 181–198. [Google Scholar]

- Alfred, R.; Choe, P. Biopolymers. In The Elements of Polymer Science and Engineering, 3rd ed.; Oxford Academic Press: Waltham, MA, USA; Oxford, UK, 2013; pp. 521–535. [Google Scholar]

- Graupner, N.; Herrmann, A.S.; Mussig, J. Natural and man-made cellulose fibre-reinforced poly (lactic acid)(PLA) composites: An overview about mechanical characteristics and application areas. Compos. A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Aidy, A.; Khalina, A.; Jonoobi, M. Concept selection of car bumper beam with developed hybrid bio-composite material. Mater. Des. 2011, 32, 4857–4865. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Ivens, J.; De Coster, A.; Kino, B.; Baetens, E.; Verpoest, I. Influence of processing and chemical treatment of flax fibres on their composites. Compos. Sci. Tech. 2003, 63, 1241–1246. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.S. Cellulose fibers. In Bio- and Nano-Polymer Composites; Springer: Berlin, Germany, 2011. [Google Scholar]

- Dasari, A.; Yu, Z.-Z.; Cai, G.-P.; Mai, Y.-W. Recent developments in the fire retardancy of polymeric materials. Prog. Polym. Sci. 2013, 38, 1357–1387. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Thomas, A.; Arun, M.; Moinuddin, K.; Joseph, P. Mechanistic Aspects of Condensed-and Gaseous-Phase Activities of Some Phosphorus-Containing Fire Retardants. Polymers 2020, 12, 1801. [Google Scholar] [CrossRef]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.M.; Dubois, P. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

- Jurkowski, B.; Jurkowska, B. Flame retardancy of polymeric materials. In Polymer Materials with Reduced Flammability; Scientific Publishing House of the Institute for Sustainable Technologies: Radom, Poland, 2012; pp. 19–174. [Google Scholar]

- Hull, T.R.; Stec, A.A. Polymers and fire. In Fire Retardancy of Polymers. New Strategies and Mechanisms; Hull, T.R., Kandola, B.K., Eds.; Royal Society of Chemistry: Cambridge, UK, 2009. [Google Scholar]

- Hamdani, S.; Longuet, C.; Perrin, D.; Lopez-Cuesta, J.M.; Ganachaud, F. Flame retardancy of silicone-based materials. Polym. Degrad. Stab. 2009, 94, 465–495. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C.D. Polymers on fire. In Polymer Green Flame Retardants; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–43. [Google Scholar]

- Rabek, J.F. Contemporary Knowledge about Polymers; PWN: Warsaw, Poland, 2008; pp. 517–518. [Google Scholar]

- Malucelli, G.; Carosio, F.; Alongi, J.; Fina, A.; Frache, A.; Camino, G. Materials engineering for surface-confined flame retardancy. Mater. Sci. Eng. R Rep. 2014, 84, 1–20. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S.V. Halogenated flame retardants. In Flame Retardants for Plastics and Textiles; Practical Applications; Hanser Publishers: Munich, Germany, 2016. [Google Scholar]

- Amrollahi, M.; Sadeghi, G.M.M. Evaluation of adhesion strength, flammability, and degradation of HBCD-containing polyurethane adhesives. J. Appl. Polym. Sci. 2008, 110, 3538–3543. [Google Scholar] [CrossRef]

- Chaudhary, B.; Barry, R.; Cheung, Y.; Ho, T.; Guest, M.; Stobby, W. Halogenated Fire-Retardant Compositions and Foams and Fabricated Articles Therefrom. U.S. Patent Application No. 09/728,145, 8 August 2002. [Google Scholar]

- Aslzadeh, M.M.; Abdouss, M.; Sadeghi, G.M. Preparation and characterization of new flame retardant polyurethane composite and nanocomposite. J. Appl. Polym. Sci. 2013, 127, 1683–1690. [Google Scholar] [CrossRef]

- Niroumand, J.S.; Peighambardoust, S.J.; Shenavar, A. Polystyrene-based composites and nanocomposites with reduced brominated-flame retardant. Iran. Polym. J. 2016, 25, 607–614. [Google Scholar] [CrossRef]

- Duan, H.; Yu, D.; Zuo, J.; Yang, B.; Zhang, Y.; Niu, Y. Characterization of brominated flame retardants in construction and demolition waste components: HBCD and PBDEs. Sci. Total Environ. 2016, 572, 77–85. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Jiang, H.; Ni, J.; Chen, J.; Zhou, H.; Wang, X.; Xin, F. Study on the effect of PolyFR and its FR system on the flame retardancy and foaming behavior of polystyrene. RSC Adv. 2019, 9, 192–205. [Google Scholar] [CrossRef] [Green Version]

- Kausar, A.; Rafique, I.; Anwar, Z.; Muhammad, B. Recent developments in different types of flame retardants and effect on fire retardancy of epoxy composite. Polym. Plast. Technol. Eng. 2016, 55, 1512–1535. [Google Scholar] [CrossRef]

- Samani, P.; van der Meer, Y. Life cycle assessment (LCA) studies on flame retardants: A systematic review. J. Clean. Prod. 2020, 274, 123259. [Google Scholar] [CrossRef]

- Rahman, F.; Langford, K.H.; Scrimshaw, M.D.; Lester, J.N. Polybrominated diphenyl ether (PBDE) flame retardants. Sci. Total Environ. 2001, 275, 1–17. [Google Scholar] [CrossRef]

- Ülker, O.C.; Ulker, O. Toxicity of formaldehyde, polybrominated diphenyl ethers (PBDEs) and phthalates in engineered wood products (EWPs) from the perspective of the green approach to materials: A review. BioResources 2019, 14, 7465–7493. [Google Scholar]

- Das, G.; Karak, N. Vegetable oil-based flame retardant epoxy/clay nanocomposites. Polym. Degrad. Stab. 2009, 94, 1948–1954. [Google Scholar] [CrossRef]

- Zhou, Q.; Wang, Y.; Xiao, J.; Zhan, Y. Preparation of magnetic core-shell Fe3O4@ polyaniline composite material and its application in adsorption and removal of tetrabromobisphenol A and decabromodiphenyl ether. Ecotoxicol. Environ. Saf. 2019, 183, 109471. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Wang, J.; Song, S.; Wang, Z.; Zhao, S. Antifouling and anticorrosion performance of the composite coating made of tetrabromobisphenol-A epoxy and polyaniline nanowires. Prog. Org. Coat. 2020, 148, 105888. [Google Scholar] [CrossRef]

- Zuiderveen, E.; Slootweg, J.C.; de Boer, J. Novel brominated flame retardants—A review of their occurrence in indoor air, dust, consumer goods and food. Chemosphere 2020, 255, 126816. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Wang, Y.Z. A review on flame retardant technology in China. Part I: Development of flame retardants. Polym. Adv. Technol. 2010, 21, 1–26. [Google Scholar] [CrossRef]

- Hussain, T.; Yousaf, A.M.; Ghori, M.U.; Khan, I.U.; Chohan, T.A.; Rizvi, S.A.; Shahzad, Y. Role of flame-retardants as EDCs in metabolic disorders. In Endocrine Disrupting Chemicals-Induced Metabolic Disorders and Treatment Strategies; Springer: Cham, Switzerland, 2020; pp. 221–238. [Google Scholar]

- Shaw, S.D.; Blum, A.; Weber, R.; Kannan, K.; Rich, D.; Lucas, D.; Koshland, C.P.; Dobraca, D.; Hanson, S.; Birnbaum, L.S. Halogenated flame retardants: Do the fire safety benefits justify the risks? Rev. Environ. Health 2010, 25, 261–305. [Google Scholar] [CrossRef]

- Wu, Z.; He, C.; Han, W.; Song, J.; Li, H.; Zhang, Y.; Jing, X.; Wu, W. Exposure pathways, levels and toxicity of polybrominated diphenyl ethers in humans: A review. Environ. Res. 2020, 187, 109531. [Google Scholar] [CrossRef]

- Wu, L.; Li, Y.; Ru, H.; Xie, H.; Yao, F.; Ni, Z.; Zhong, L. Parental exposure to 2, 2′, 4, 4′ 5-pentain polybrominated diphenyl ethers (BDE-99) causes thyroid disruption and developmental toxicity in zebrafish. Toxicol. Appl. Pharmacol. 2019, 372, 11–18. [Google Scholar] [CrossRef]

- Poston, R.G.; Saha, R.N. Epigenetic effects of polybrominated diphenyl ethers on human health. Int. J. Environ. Res. Public Health 2019, 16, 2703. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, G.; Someya, M.; Takahashi, S.; Tanabe, S.; Sakai, S.I.; Takigami, H. Dioxin-like activity in Japanese indoor dusts evaluated by means of in vitro bioassay and instrumental analysis: Brominated dibenzofurans are an important contributor. Environ. Sci. Technol. 2010, 44, 8330–8336. [Google Scholar] [CrossRef]

- Levchik, S. Phosphorus-based FRs. In Non-Halogenated Flame Retardant Handbook; Morgan, A.B., Wilkie, C.A., Eds.; Scrivener Publishing: Beverly, MA, USA, 2014. [Google Scholar]

- Liu, H.; Shen, Y.; Du, B.; Fang, Z.; Wu, Y. Fabrication of dendrimer-like fullerene (C 60)-decorated oligomeric intumescent flame retardant for reducing the thermal oxidation and flammability of polypropylene nanocomposites. J. Mater. Chem. 2009, 19, 1305–1313. [Google Scholar]

- Guo, Z.; Zhao, L.; Fang, Z. The flame retardant and smoke suppression effect of fullerene by trapping radicals in decabromodiphenyl oxide/Sb2O3 flame-retarded high density polyethylene. Fire Mater. 2017, 41, 916–924. [Google Scholar] [CrossRef]

- Pan, Y.; Guo, Z.; Ran, S.; Fang, Z. Influence of fullerenes on the thermal and flame-retardant properties of polymeric materials. Appl. Polym. Sci. 2020, 137, 47538. [Google Scholar] [CrossRef] [Green Version]

- Beyer, G. Carbon nanotubes as flame retardants for polymers. Fire Mater. 2002, 26, 291–293. [Google Scholar] [CrossRef]

- Huang, G.; Wang, S.; Song, P.; Wu, C.; Chen, S.; Wang, X. Combination effect of carbon nanotubes with graphene on intumescent flame-retardant polypropylene nanocomposites. Compos. Part A Appl. Sci. Manuf. 2014, 59, 18–25. [Google Scholar] [CrossRef]

- Isitman, N.A.; Kaynak, C. Nanoclay and carbon nanotubes as potential synergists of an organophosphorus flame-retardant in poly (methyl methacrylate). Polym. Degrad. Stab. 2010, 95, 1523–1532. [Google Scholar] [CrossRef]

- Cai, H.; Peng, F.; Wang, Y.; Yi, J.; Cai, X.; Liu, H.; Kong, Q. Improving Flame Retardancy of Epoxy Resin Nanocomposites by Carbon Nanotubes Grafted CuAl-Layered Double Hydroxide Hybrid. J. Nanosci. Nanotechnol. 2020, 20, 6406–6412. [Google Scholar] [CrossRef]

- Dittrich, B.; Wartig, K.-A.; Hofmann, D.; Mülhaupt, R.; Schartel, B. Flame retardancy through carbon nanomaterials: Carbon black, multiwall nanotubes, expanded graphite, multi-layer graphene and graphene in polypropylene. Polym. Degrad. Stab. 2013, 98, 1495–1505. [Google Scholar] [CrossRef]

- Fukushima, K.; Murariu, M.; Camino, G.; Dubois, P. Effect of expanded graphite/layered-silicate clay on thermal, mechanical and fire retardant properties of poly (lactic acid). Polym. Degrad. Stab. 2010, 95, 1063–1076. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Zhou, Y.; Hu, L. The study of mechanical behavior and flame retardancy of castor oil phosphate-based rigid polyurethane foam composites containing expanded graphite and triethyl phosphate. Polym. Degrad. Stab. 2013, 98, 2784–2794. [Google Scholar] [CrossRef]

- Cheng, Z.; Liao, D.; Hu, X.; Li, W.; Xie, C.; Zhang, H.; Yang, W. Synergistic fire retardant effect between expandable graphite and ferrocene-based non-phosphorus polymer on polypropylene. Polym. Degrad. Stab. 2020, 178, 109201. [Google Scholar] [CrossRef]

- Franchini, E.; Galy, J.; Gérard, J.-F.; Tabuani, D.; Medici, A. Influence of POSS structure on the fire retardant properties of epoxy hybrid networks. Polym. Degrad. Stab. 2009, 94, 1728–1736. [Google Scholar] [CrossRef]

- Song, L.; Xuan, S.; Wang, X.; Hu, Y. Flame retardancy and thermal degradation behaviors of phosphate in combination with POSS in polylactide composites. Thermochim. Acta 2012, 527, 1–7. [Google Scholar] [CrossRef]

- Fina, A.; Abbenhuis, H.C.L.; Tabuani, D.; Camino, G. Metal functionalized POSS as fire retardants in polypropylene. Polym. Degrad. Stab. 2006, 91, 2275–2281. [Google Scholar] [CrossRef]

- Ye, X.; Li, J.; Zhang, W.; Yang, R.; Li, J. Fabrication of eco-friendly and multifunctional sodium-containing polyhedral oligomeric silsesquioxane and its flame retardancy on epoxy resin. Compos. B Eng. 2020, 191, 107961. [Google Scholar] [CrossRef]

- Szpilska, K.; Czaja, K.; Kudła, S. Thermal stability and flammability of polyolefin/halloysite nanotubes composites. Polymery 2015, 60, 671–750. [Google Scholar] [CrossRef]

- Jing, H.; Higaki, Y.; Ma, W.; Wu, H.; Yah, W.O.; Otsuka, H.; Lvov, Y.M.; Takahara, A. Internally modified halloysite nanotubes as inorganic nanocontainers for a flame retardant. Chem. Lett. 2013, 42, 121–123. [Google Scholar] [CrossRef] [Green Version]

- Goda, E.S.; Yoon, K.R.; El-sayed, S.H.; Hong, S.E. Halloysite nanotubes as smart flame retardant and economic reinforcing materials: A review. Thermochim. Acta 2018, 669, 173–184. [Google Scholar] [CrossRef]

- Su, X.; Li, D.; Tao, J.; Dai, Q. Synergistic effect of allophane with intumescent flame retardants on thermal behavior and fire retardancy of polypropylene. Polym. Bull. 2015, 72, 2089–2104. [Google Scholar] [CrossRef]

- Poncelet, O. Aluminosilicate Polymer as Fire Retardant. U.S. Patent 8,287,779, 16 October 2012. [Google Scholar]

- Wang, X.; Kalali, E.N.; Wan, J.-T.; Wang, D.-Y. Carbon-family materials for flame retardant polymeric materials. Prog. Polym. Sci. 2017, 69, 22–46. [Google Scholar] [CrossRef]

- Kim, N.K.; Dutta, S.; Bhattacharyya, D. Carbon-family materials for flame retardant polymeric materials. Compos. Sci. Technol. 2018, 162, 64–78. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. B Eng. 2019, 176, 107305. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P. Bio-based flame retardants: When nature meets fire protection. Mater. Sci. Eng. R Rep. 2017, 117, 1–25. [Google Scholar] [CrossRef]

- Yiga, V.A.; Lubwama, M. Thermogravimetric analysis of agricultural residue carbonized briquettes for domestic and industrial applications. MRS Adv. 2020, 5, 1039–1048. [Google Scholar] [CrossRef]

- Samyn, F.; Vandewalle, M.; Bellayer, S.; Duquesne, S. Sol–Gel Treatments to Flame Retard PA11/Flax Composites. Fibers 2019, 7, 86. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Li, Z.; Pan, Y.T.; Yáñez, A.P.; Hu, S.; Zhang, X.Q.; Wang, R.; Wang, D.Y. Polydopamine induced natural fiber surface functionalization: A way towards flame retardancy of flax/poly (lactic acid) biocomposites. Compos. B Eng. 2018, 154, 56–63. [Google Scholar] [CrossRef]

- Xu, S.; Li, S.Y.; Zhang, M.; Zeng, H.Y.; Wu, K.; Tian, X.Y.; Chen, C.R.; Pan, Y. Fabrication of green alginate-based and layered double hydroxides flame retardant for enhancing the fire retardancy properties of polypropylene. Carbohydr. Polym. 2020, 234, 115891. [Google Scholar] [CrossRef]

- Boccarusso, L.; Carrino, L.; Durante, M.; Formisano, A.; Langella, A.; Minutolo, F.M.C. Hemp fabric/epoxy composites manufactured by infusion process: Improvement of fire properties promoted by ammonium polyphosphate. Compos. B Eng. 2016, 89, 117–126. [Google Scholar] [CrossRef]

- Yiga, V.A.; Lubwama, M.; Pagel, S.; Benz, J.; Olupot, P.W.; Bonten, C. Flame retardancy and thermal stability of agricultural residue fiber-reinforced polylactic acid: A Review. Polym. Compos. 2020. [Google Scholar] [CrossRef]

- Dashtizadeh, Z.; Abdan, K.; Jawaid, M.; Dashtizadeh, M. Thermal and Flammability Properties of Kenaf/Recycled Carbon Filled with Cardanol Hybrid Composites. Int. J. Polym. Sci. 2019, 2019, 9168342. [Google Scholar] [CrossRef] [Green Version]

- Netnapa, E.; Mariatti, M.; Hamid, Z.A.A.; Todo, M.; Banhan, L. Dielectric breakdown strength and flammability properties of flame retardant filler/PLLA-PLA microsphere/kenaf fiber composites. Procedia Chem. 2016, 19, 290–296. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Chen, S.; Pan, Y.T.; Zhang, S.; Nie, S.; Wei, P.; Zhang, X.; Wang, R.; Wang, D.Y. Nickel metal–organic framework derived hierarchically Mesoporous nickel phosphate toward smoke suppression and mechanical enhancement of intumescent flame retardant wood Fiber/poly (lactic acid) composites. ACS Sustain. Chem. Eng. 2019, 7, 9272–9280. [Google Scholar] [CrossRef]

- Hapuarachchi, T.D.; Peijs, T. Multiwalled carbon nanotubes and sepiolite nanoclays as flame retardants for polylactide and its natural fibre reinforced composites. Compos. A Appl. Sci. Manuf. 2010, 41, 954–963. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Song, L.; Xuan, S.; Xing, W.; Bai, Z.; Lu, H. Flame retardancy and thermal degradation of intumescent flame retardant poly (lactic acid)/starch biocomposites. Ind. Eng. Chem. Res. 2011, 50, 713–720. [Google Scholar] [CrossRef]

- Ran, G.; Liu, X.; Guo, J.; Sun, J.; Li, H.; Gu, X.; Zhang, S. Improving the flame retardancy and water resistance of polylactic acid by introducing polyborosiloxane microencapsulated ammonium polyphosphate. Compos. B Eng. 2019, 173, 106772. [Google Scholar] [CrossRef]

- Shumao, L.; Jie, R.; Hua, Y.; Tao, Y.; Weizhong, Y. Influence of ammonium polyphosphate on the flame retardancy and mechanical properties of ramie fiber-reinforced poly(lactic acid) biocomposites. Polym. Int. 2010, 59, 242–248. [Google Scholar] [CrossRef]

- Kozłowski, R.; Władyka-Przybylak, M. Flammability and fire resistance of composites reinforced by natural fibers. Polym. Adv. Technol. 2008, 19, 446–453. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Moussa, M.; El Hage, R.; Sonnier, R.; Chrusciel, L.; Ziegler-Devin, I.; Brosse, N. Toward the cottonization of hemp fibers by steam explosion. Flame-retardant fibers. Ind. Crops Prod. 2020, 151, 112242. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, L.; Liu, Y.; Zhang, G.; Zhu, P. Characterization and functional assessment of alginate fibers prepared by metal-calcium ion complex coagulation bath. Carbohydr. Polym. 2020, 232, 115693. [Google Scholar] [CrossRef]

- Tian, G.; Ji, Q.; Xu, D.; Tan, L.; Quan, F.; Xia, Y. The effect of zinc ion content on flame retardance and thermal degradation of alginate fibers. Fibers Polym. 2013, 14, 767–771. [Google Scholar] [CrossRef]

- Xu, P.; Shao, P.; Zhang, Q.; Cheng, W.; Li, Z.; Li, Q. A novel inherently flame-retardant composite based on zinc alginate/nano-Cu2O. Polymers 2019, 11, 1575. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carosio, F.; Di Blasio, A.; Alongi, J.; Malucelli, G. Green DNA-based flame retardant coatings assembled through layer by layer. Polymer 2013, 54, 5148–5153. [Google Scholar] [CrossRef]

- Alongi, J.; Carletto, R.A.; Di Blasio, A.; Cuttica, F.; Carosio, F.; Bosco, F.; Malucelli, G. Intrinsic intumescent-like flame retardant properties of DNA-treated cotton fabrics. Carbohydr. Polym. 2013, 96, 296–304. [Google Scholar] [CrossRef] [PubMed]

- Alongi, J.; Carletto, R.A.; Di Blasio, A.; Carosio, F.; Bosco, F.; Malucelli, G. DNA: A novel, green, natural flame retardant and suppressant for cotton. J. Mater. Chem. A 2013, 1, 4779–4785. [Google Scholar] [CrossRef]

- Gallo, E.; Sanchez-Olivares, G.; Schartel, B. Flame retardancy of starch-based biocomposites-aluminum hydroxide-coconut fiber synergy. Polymery 2013, 58, 395–402. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Ren, J. Combustion properties and transference behavior of ultrafine microencapsulated ammonium polyphosphate in ramie fabric-reinforced poly (L-lactic acid) biocomposites. Polym. Int. 2011, 60, 599–606. [Google Scholar] [CrossRef]

- Schartel, B.; Braun, U.; Schwarz, U.; Reinemann, S. Fire retardancy of polypropylene/flax blends. Polymer 2003, 44, 6241–6250. [Google Scholar] [CrossRef]

- Mazela, B.; Batista, A.; Grześkowiak, W. Expandable Graphite as a Fire Retardant for Cellulosic Materials-A Review. Forests 2020, 11, 755. [Google Scholar] [CrossRef]

- He, L.; Zhou, X.; Cai, W.; Xiao, Y.; Chu, F.; Mu, X.; Fu, X.; Hu, Y.; Song, L. Electrochemical exfoliation and functionalization of black phosphorene to enhance mechanical properties and flame retardancy of waterborne polyurethane. Compos. B Eng. 2020, 202, 108446. [Google Scholar] [CrossRef]

- Kodali, D.; Uddin, M.J.; Moura, E.A.; Rangari, V.K. Mechanical and Thermal Properties of Modified Georgian and Brazilian Clay Infused Biobased Epoxy Nanocomposites. Mat. Chem. Phys. 2020, 257, 123821. [Google Scholar] [CrossRef]

- Yu, T.; Jiang, N.; Li, Y. Functionalized multi-walled carbon nanotube for improving the flame retardancy of ramie/poly (lactic acid) composite. Compos. Sci. Technol. 2014, 104, 26–33. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Song, L.; Xing, W.; Lu, H. Preparation, flame retardancy, and thermal degradation of epoxy thermosets modified with phosphorous/nitrogen-containing glycidyl derivative. Polym. Adv. Technol. 2012, 23, 190–197. [Google Scholar] [CrossRef]

- Murariu, M.; Dechief, A.L.; Bonnaud, L.; Gallos, A.; Fontaine, G.; Bourbigot, S.; Dubois, P. The production and properties of polylactide composites filled with expanded graphite. Polym. Degrad. Stab. 2010, 95, 889–900. [Google Scholar] [CrossRef]

- Tshai, K.Y. Advancement in flame retardancy of natural fibre reinforced composites with macro to nanoscale particulates additives. In Interfaces in Particle and Fibre Reinforced Composites; Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2020; pp. 311–342. [Google Scholar]

- Kuan, C.F.; Yen, W.H.; Chen, C.H.; Yuen, S.M.; Kuan, H.C.; Chiang, C.L. Synthesis, characterization, flame retardance and thermal properties of halogen-free expandable graphite/PMMA composites prepared from sol–gel method. Polym. Degrad. Stab. 2008, 93, 1357–1363. [Google Scholar] [CrossRef]

- Han, Z.; Dong, L.; Li, Y.; Zhao, H. A comparative study on the synergistic effect of expandable graphite with APP and IFR in polyethylene. J. Fire Sci. 2007, 25, 79–91. [Google Scholar] [CrossRef]

- Cheng, X.W.; Guan, J.P.; Tang, R.C.; Liu, K.Q. Phytic acid as a bio-based phosphorus flame retardant for poly (lactic acid) nonwoven fabric. J. Clean. Prod. 2016, 124, 114–119. [Google Scholar] [CrossRef]

- Zhang, J.; Fleury, E.; Chen, Y.; Brook, M.A. Flame retardant lignin-based silicone composites. RSC Adv. 2015, 5, 103907–103914. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Hu, Y. Modification of lignin and its application as char agent in intumescent flame-retardant poly (lactic acid). Polym. Eng. Sci. 2012, 52, 2620–2626. [Google Scholar] [CrossRef]

- Ferry, L.; Dorez, G.; Taguet, A.; Otazaghine, B.; Lopez-Cuesta, J.M. Chemical modification of lignin by phosphorus molecules to improve the fire behavior of polybutylene succinate. Polym. Degrad. Stab. 2015, 113, 135–143. [Google Scholar] [CrossRef]

- Prieur, B.; Meub, M.; Wittemann, M.; Klein, R.; Bellayer, S.; Fontaine, G.; Bourbigot, S. Phosphorylation of lignin to flame retard acrylonitrile butadiene styrene (ABS). Polym. Degrad. Stab. 2016, 127, 32–43. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Yang, J.; Hu, Y. The effect of different organic modified montmorillonites (OMMTs) on the thermal properties and flammability of PLA/MCAPP/lignin systems. J. Appl. Polym. Sci. 2013, 127, 4967–4973. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Delvosalle, C.; Dubois, P. Phytic acid–lignin combination: A simple and efficient route for enhancing thermal and flame retardant properties of polylactide. Eur. Polym. J. 2017, 94, 270–285. [Google Scholar] [CrossRef]

- Jin, X.; Cui, S.; Sun, S.; Gu, X.; Li, H.; Liu, X.; Sun, J.; Bourbigot, S.; Zhang, S. The preparation of a bio-polyelectrolytes based core-shell structure and its application in flame retardant polylactic acid composites. Compos. A Appl. Sci. Manuf. 2019, 124, 105485. [Google Scholar] [CrossRef]

- Nassar, M.; Hiraishi, N.; Tamura, Y.; Otsuki, M.; Aoki, K.; Tagami, J. Phytic acid: An alternative root canal chelating agent. J. Endod. 2015, 41, 242–247. [Google Scholar] [CrossRef]

- Bocz, K.; Szolnoki, B.; Marosi, A.; Tábi, T.; Wladyka-Przybylak, M.; Marosi, G. Flax fibre reinforced PLA/TPS biocomposites flame retarded with multifunctional additive system. Polym. Degrad. Stab. 2014, 106, 63–73. [Google Scholar] [CrossRef] [Green Version]

- Battegazzore, D.; Frache, A.; Carosio, F. Layer-by-Layer nanostructured interphase produces mechanically strong and flame retardant bio-composites. Compos. B Eng. 2020, 200, 108310. [Google Scholar] [CrossRef]

- Gallo, E.; Schartel, B.; Acierno, D.; Russo, P.J.E.P.J. Flame retardant biocomposites: Synergism between phosphinate and nanometric metal oxides. Eur. Polym. J. 2011, 47, 1390–1401. [Google Scholar] [CrossRef]

- Jiang, L.; Wolcott, M.P.; Zhang, J. Study of biodegradable polylactide/poly (butylene adipate-co-terephthalate) blends. Biomacromolecules 2006, 7, 199–207. [Google Scholar] [CrossRef]

- Gallo, E.; Schartel, B.; Acierno, D.; Cimino, F.; Russo, P. Tailoring the flame retardant and mechanical performances of natural fiber-reinforced biopolymer by multi-component laminate. Compos. B Eng. 2013, 44, 112–119. [Google Scholar] [CrossRef]

- Martino, L.; Basilissi, L.; Farina, H.; Ortenzi, M.A.; Zini, E.; Di Silvestro, G.; Scandola, M. Bio-based polyamide 11: Synthesis, rheology and solid-state properties of star structures. Eur. Polym. J. 2014, 59, 69–77. [Google Scholar] [CrossRef]

- Nuzzo, A.; Bilotti, E.; Peijs, T.; Acierno, D.; Filippone, G. Nanoparticle-induced co-continuity in immiscible polymer blends—A comparative study on bio-based PLA-PA11 blends filled with organoclay, sepiolite, and carbon nanotubes. Polymer 2014, 55, 4908–4919. [Google Scholar] [CrossRef]

- Benobeidallah, B.; Benhamida, A.; Kaci, M.; Lopez-Cuesta, J.M. Combined effect of palygorskite and melamine polyphosphate on flame retardancy properties of polyamide 11 nanocomposites. Appl. Clay Sci. 2020, 198, 105837. [Google Scholar] [CrossRef]

- Hao, A.; Wong, I.; Wu, H.; Lisco, B.; Ong, B.; Sallean, A.; Butler, S.; Londa, M.; Koo, J.H. Mechanical, thermal, and flame-retardant performance of polyamide 11–halloysite nanotube nanocomposites. J. Mater. Sci. 2015, 50, 157–167. [Google Scholar] [CrossRef]

- Mandlekar, N.; Malucelli, G.; Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Guan, J. Fire retardant action of zinc phosphinate and polyamide 11 blend containing lignin as a carbon source. J. Polym. Degrad. Stab. 2018, 153, 63–74. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A. Halogen-free flame retardants for polymeric foams. Polym. Degrad. Stab. 2002, 78, 167–173. [Google Scholar] [CrossRef]

- Hu, X.M.; Wang, D.M. Enhanced fire behavior of rigid polyurethane foam by intumescent flame retardants. J. Appl. Polym. Sci. 2013, 129, 238–246. [Google Scholar] [CrossRef]

- Green, J. A review of phosphorus-containing flame retardants. J. Fire Sci. 1992, 10, 470–487. [Google Scholar] [CrossRef]

- Bhoyate, S.; Ionescu, M.; Kahol, P.K.; Gupta, R.K. Sustainable flame-retardant polyurethanes using renewable resources. Ind. Crops Prod. 2018, 123, 480–488. [Google Scholar] [CrossRef]

- Abdullah, N.M.; Rus, A.Z.M.; Abdullah, M.F.L. Synergistic influence of graphite on biopolymer composites properties. J. Teknol. 2015, 77, 11–19. [Google Scholar] [CrossRef] [Green Version]

- Guler, T.; Tayfun, U.; Bayramli, E.; Dogan, M. Effect of expandable graphite on flame retardant, thermal and mechanical properties of thermoplastic polyurethane composites filled with huntite & hydromagnesite mineral. Thermochim. Acta 2017, 647, 70–80. [Google Scholar]

- Gama, N.; Costa, L.C.; Amaral, V.; Ferreira, A.; Barros-Timmons, A. Insights into the physical properties of biobased polyurethane/expanded graphite composite foams. Compos. Sci. Technol. 2017, 138, 24–31. [Google Scholar] [CrossRef]

- Kurańska, M.; Cabulis, U.; Auguścik, M.; Prociak, A.; Ryszkowska, J.; Kirpluks, M. Bio-based polyurethane-polyisocyanurate composites with an intumescent flame retardant. Polym. Degrad. Stab. 2016, 127, 11–19. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, G.; Zhou, Y.; Hu, L.; Feng, G.; Zhang, M. Synergistic effect of expandable graphite, diethyl ethylphosphonate and organically-modified layered double hydroxide on flame retardancy and fire behavior of polyisocyanurate-polyurethane foam nanocomposite. Polym. Degrad. Stab. 2014, 101, 92–101. [Google Scholar] [CrossRef]

- Khalili, P.; Tshai, K.Y.; Kong, I. Natural fiber reinforced expandable graphite filled composites: Evaluation of the flame retardancy, thermal and mechanical performances. Compos. Appl. Sci. Manuf. 2017, 100, 194–205. [Google Scholar] [CrossRef]

- Khalili, P.; Tshai, K.Y.; Hui, D.; Kong, I. Synergistic of ammonium polyphosphate and alumina trihydrate as fire retardants for natural fiber reinforced epoxy composite. Compos. B Eng. 2017, 114, 101–110. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Zhang, L.; Molleja, J.G.; Wang, D.Y. Bimetallic metal-organic frameworks and graphene oxide nano-hybrids for enhanced fire retardant epoxy composites: A novel carbonization mechanism. Carbon 2019, 153, 407–416. [Google Scholar] [CrossRef]

- Song, K.; Wang, Y.; Ruan, F.; Yang, W.; Liu, J. Synthesis of a Novel Spirocyclic Inflatable Flame Retardant and Its Application in Epoxy Composites. Polymers 2020, 12, 2534. [Google Scholar] [CrossRef]

- Nie, S.; Jin, D.; Xu, Y.; Han, C.; Dong, X.; Yang, J.N. Effect of a flower-like nickel phyllosilicate-containing iron on the thermal stability and flame retardancy of epoxy resin. J. Mater. Res. Technol. 2020, 9, 10189–10197. [Google Scholar] [CrossRef]

- Zabihi, O.; Ahmadi, M.; Khayyam, H.; Naebe, M. Fish DNA-modified clays: Towards highly flame retardant polymer nanocomposite with improved interfacial and mechanical performance. Sci. Rep. 2016, 6, 38194. [Google Scholar] [CrossRef] [Green Version]

- Weng, Z.; Senthil, T.; Zhuo, D.; Song, L.; Wu, L. Flame retardancy and thermal properties of organoclay and phosphorous compound synergistically modified epoxy resin. J. Appl. Polym. Sci. 2016, 133, 43367. [Google Scholar] [CrossRef]

- Wan, J.; Gan, B.; Li, C.; Molina-Aldareguia, J.; Kalali, E.N.; Wang, X.; Wang, D.Y. A sustainable, eugenol-derived epoxy resin with high biobased content, modulus, hardness and low flammability: Synthesis, curing kinetics and structure–property relationship. Chem. Eng. J. 2016, 284, 1080–1093. [Google Scholar] [CrossRef] [Green Version]

- Wan, J.; Gan, B.; Li, C.; Molina-Aldareguia, J.; Li, Z.; Wang, X.; Wang, D.-Y. A novel biobased epoxy resin with high mechanical stiffness and low flammability: Synthesis, characterization and properties. J. Mater. Chem. A 2015, 3, 21907–21921. [Google Scholar] [CrossRef]

- Faye, I.; Decostanzi, M.; Ecochard, Y.; Caillol, S. Eugenol bio-based epoxy thermosets: From cloves to applied materials. Green Chem. 2017, 19, 5236–5242. [Google Scholar] [CrossRef]

- Li, C.; Fan, H.; Aziz, T.; Bittencourt, C.; Wu, L.; Wang, D.-Y.; Dubois, P. Biobased epoxy resin with low electrical permissivity and flame retardancy: From environmental friendly high-throughput synthesis to properties. ACS Sustain. Chem. Eng. 2018, 6, 8856–8867. [Google Scholar] [CrossRef]

- Wang, S.; Ma, S.; Xu, C.; Liu, Y.; Dai, J.; Wang, Z.; Liu, X.; Chen, J.; Shen, X.; Wei, J.; et al. Vanillin-derived high-performance flame retardant epoxy resins: Facile synthesis and properties. Macromolecules 2017, 50, 1892–1901. [Google Scholar] [CrossRef]

- Xu, X.; Wang, S.; Ma, S.; Yuan, W.; Li, Q.; Feng, J.; Zhu, J. Vanillin-derived phosphorus-containing compounds and ammonium polyphosphate as green fire-resistant systems for epoxy resins with balanced properties. Polym. Adv. Technol. 2019, 30, 264–278. [Google Scholar] [CrossRef]

- Ecochard, Y.; Decostanzi, M.; Negrell, C.; Sonnier, R.; Caillol, S. Cardanol and eugenol based flame retardant epoxy monomers for thermostable networks. Molecules 2019, 24, 1818. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.; Wang, X.; Gangireddy, C.S.R.; Wang, J.; Pan, Y.; Xing, W.; Song, L.; Hu, Y. Cardanol derived benzoxazine in combination with boron-doped graphene toward simultaneously improved toughening and flame retardant epoxy composites. Compos. Part A Appl. Sci. Manuf. 2019, 116, 13–23. [Google Scholar] [CrossRef]

- Thenmozhi, S.; Murugavel, S.C. Investigation on mechanical, thermal, and flame retardant properties of particulate SiO2 reinforced cardanol based composites. Polym. Compos. 2020, 41, 1118–1134. [Google Scholar] [CrossRef]

| Halogen FR | Name | Structure | LOI (%) | Ref. |

|---|---|---|---|---|

| Bromine-containing flame retardants | Hexabromocyclododecane (HBCD) |  | 20.2 —MDI/ BDO/HTPB composite 28.3 —PS680/HCFC/HFC blends | [21,22,23,24,25,26] |

| Tetrabromophthalic anhydride (TBPA) |  | 31.5 —wool/malonic acid | [27] | |

| Polybrominated diphenyl ether (PBDE) |  | 26.7 —tin(II)tungstates/PS | [28,29,30] | |

| Tetrabromobisphenol-A (TBBPA) |  | 45.0 —epoxy resin/5 wt.% MMT nanoclay | [31,32,33,34] | |

| Chlorine-containing flame retardants | 1,4-di(2-hydroxyethoxy)-2,3,5,6-tetrachlorobenzene (TCHQD) |  | 25.0 —unsaturated polyesters | [35,36] |

| 1,4-di(ethoxycarbonyl-methoxy)-2,3,5,6-tetrachlorobenzene (TCHQA) |  | 27.0 —unsaturated polyesters | [35,36] |

| Composite | Remarks | Ref. |

|---|---|---|

| PLA/kenaf fibers/recycled carbon with a cashew nut shell liquid | - cardanol improved the thermal stability of kenaf; - the thermal stability of final composite was additionally improved by hybridization with recycled carbon (the flammability UL 90 HB test determines the flame retardancy property of all specimens) | [73] |

| PLA/kenaf fibers/phosphorus-based non-halogenated flame retardant (NP-100) | Addition of NP-100 flame retardant filler into the PLLA-PLA microsphere/KF composites: - improved the flammability; - decreased the flexural strength and modulus of the composites (NP-100 affects to the presence of void in the microstructure of composite). | [74] |

| PLA/wood fiber/mesoporous nickel phosphate | Ni-PO (when 5 wt.% ammonium polyphosphate was substituted by nickel phosphate) effects: - the reduction of the total smoke release amount of Wood Fiber-PLA composite by 43%; - gradually improved mechanical properties with the increasing loading amount of Ni-PO. | [75] |

| PLA/hemp/sepiolite nanoclay/ multiwalled nanotubes | Combining the flame retarding potential of carbon nanotubes and nanoclay resulted in enhanced flame retardancy of composite (ternary nanocomposite based on sepiolite and MWNTs—58% drop in pHRR, introduction of non-woven hemp fibre—45% reduction in pHRR, and 25% reduction in pHRR upon the introduction of hemp fiber into the PLA nanocomposite system; pHRRPLA = 485 kW/m2, pHRRPLA with hemp = 361 kW/m2, pHRRPLA ternary nanocomposite = 265 kW/m2 and pHRRPLA ternary nanocomposite with hemp = 340 kW/m2, respectively). | [76] |

| PLA/starch/ microencapsulated ammonium polyphosphate | - Microencapsulated ammonium polyphosphate within the PLA/starch biocomposites improves flame retardancy of composite and restrain the reaction between ammonium polyphosphate and starch during processing of PLA (composite PLA/starch/ microencapsulated ammonium polyphosphate: pHRR = 97 W/g; THR = 6.8 kJ/g and max HRR temp. = 365 °C compared to: 398 W/g; 13.9 kJ/g and 375 °C obtained for pure PLA). - Composites containing 30% microencapsulated ammonium polyphosphate reach UL-94 V0 with a LOI value of 41.0. The incorporation of IFR into PLA decreased the pHRR and THR of the composites. | [77] |

| PLA/ammonium polyphosphate (APP) microencapsulated/ polysiloxane/polyborosiloxane | The microencapsulation of ammonium polyphosphate resulted in: - improved compatibility of APP with PLA, resulting in better mechanical properties, enhanced flame retardancy (PLA composite containing 5%APP: pHHR = 512 kW/m2; time to ignition = 35 s and THR = 66 MJ/m2 compared to: 556; 39 and 78 obtained for pure PLA, respectively) and improved water resistance of the composite; - composite with BSi-APP exhibit the best flame retardancy (pHHR = 458 kW/m2; time to ignition = 33 s and THR = 57 MJ/m2 resulting from the formation of Si-O-C, Si-O-B, and B-O-P in the enhanced char residue) among the three tested FRs (APP, Si-APP and BSi-APP) to PLA under the same loading | [78] |

| Ramie fibers/ammonium polyphosphate | The ammonium polyphosphate: - effectively improves flame retardancy (UL94 test and LOI) due to increased char residue at high temperature; - however, disturbs the compatibility between PLA and fibers (worse dynamic mechanical properties and mechanical properties). | [79] |

| Composite | Remarks | Ref. |

|---|---|---|

| Epoxy/pulverized oil palm empty fruit bunch/expandable graphite | Increasing the amount of expandable graphite fillers in the composites: - significantly improved the fire resistivity and thermal properties; - however, reduced mechanical properties. | [129] |

| Epoxy/palm empty fruit bunch fiber/ATH/APP hybrid system | - An addition of APP enhanced the flame-resistant properties of the composite (reduced total flame time and zero drip). - The 10 wt.% ATH and 5 wt.% APP hybrid showed the most promising flame retardancy with a self-extinguishing property as well as the lowest gross heat and greatest char residue. - In order to create an acceptable FR-based systems, ATH required a greater concentration, but at the same time increasing ATH concentration resulted in deterioration of mechanical properties. | [130] |

| Epoxy/bimetallic metal-organic framework (MOF)/graphene oxide (GO) nano-hybrids (MOF@GO) with intumescent fire retardants (IFR) | - EP/0.5MOF@GO-9.5IFR composite exhibited a 41% decrease in peak heat release rate, 30% decrease in total smoke production compared with EP/10IFR and self-extinction behavior in the UL-94 test due to the barrier effect of highly reinforced carbonaceous char. - The intumescent epoxy composites exhibited enhanced mechanical performances (a 11% increase in tensile strength) due to improved interaction between the fillers and matrix. | [131] |

| Epoxy/eiphenylimidazole spirocyclic pentaerythritol bisphosphonate (PIPC) | PIPC was prepared via the substitution reaction between previously synthesized intermediate SPDPC (3,9-dichloro-2,4,8,10-tetraoxa-3,9-diphosphaspiro-(5,5)undecane-3,9-dioxide) and 2-phenylimidazole. An addition of PIPC: - slightly impacted the mechanical properties of epoxy composites with a low loading - in amount of 5 wt.% resulted in LOI of 29.7% and a V-0 rating in the UL 94 Test, decrease in pHRR (by 41.15%) and THR (by 21.64%). | [132] |

| Epoxy/flower-like nickel phyllosilicate (Ni-PS) | Fe/Ni-PS (4.0 wt.%) resulted in: LOI of 28.9 and ability of self-extinguishing with the total burning time of 12.0 s, passing the V-1 rating in UL-94 test, reduction pHRR by 20.1% and THR by 4.7 % compared to those of pure EP. | [133] |

| Epoxy/fish DNA-modified clays | Contribution of DNA molecules results in improvement of thermal stability and fire resistance of epoxy-clay nanocomposites (due to formation of condensed char layers during combustion caused by the release of effective suppressant agents during the decomposition of DNA structures). | [134] |

| Epoxy/DOPO/organoclay | A synergistic flame retardant effect DOPO and organoclay on epoxy composites (2.0 wt.% phosphorus and 4.0 wt.% organoclay) resulted in decrease of pHRR by 40% and smoke production rate by 46% when compared to neat epoxy resin (the single use of 2.0 wt.% phosphorus decreased the pHRR only to 59% of that of neat EP resin). | [135] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sienkiewicz, A.; Czub, P. Flame Retardancy of Biobased Composites—Research Development. Materials 2020, 13, 5253. https://doi.org/10.3390/ma13225253

Sienkiewicz A, Czub P. Flame Retardancy of Biobased Composites—Research Development. Materials. 2020; 13(22):5253. https://doi.org/10.3390/ma13225253

Chicago/Turabian StyleSienkiewicz, Anna, and Piotr Czub. 2020. "Flame Retardancy of Biobased Composites—Research Development" Materials 13, no. 22: 5253. https://doi.org/10.3390/ma13225253