The Role of Electrical Polarity in Electrospinning and on the Mechanical and Structural Properties of As-Spun Fibers

Abstract

:1. Introduction

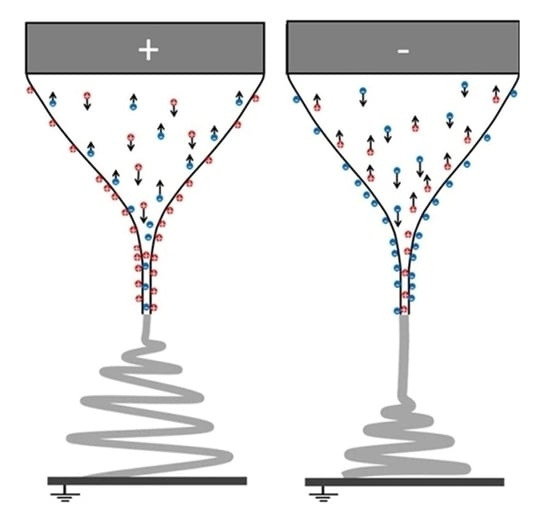

Electrical Field Polarity and Strength

2. Materials and Methods

2.1. Electrospinning Process

2.2. Electrical Current

2.3. Fiber Morphology and Contact Angle

2.4. Crystallinity, Density and Molecular Mass of PMMA Fiber Membranes

2.5. Mechanical Testing of PMMA Fibers Mat

2.6. Statistical Analyses

3. Results and Discussion

3.1. Electrospinning

3.2. Fibers Morphology and Microstructure

3.3. Fiber Crystallinity and Density

3.4. Mechanical Properties of Fibers

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Stachewicz, U.; Li, S.; Bilotti, E.; Barber, A.H. Dependence of surface free energy on molecular orientation in polymer films. Appl. Phys. Lett. 2012, 100, 1–5. [Google Scholar] [CrossRef]

- Wang, M.; Hsieh, A.J.; Rutledge, G.C. Electrospinning of poly(MMA-co-MAA) copolymers and their layered silicate nanocomposites for improved thermal properties. Polymer (Guildford) 2005, 46, 3407–3418. [Google Scholar] [CrossRef]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.M.; Reynolds, C.T.; Govaert, L.E.; Peijs, T. The effect of temperature and strain rate on the mechanical properties of highly oriented polypropylene tapes and all-polypropylene composites. Compos. Sci. Technol. 2007, 67, 2061–2070. [Google Scholar] [CrossRef]

- Persano, L.; Camposeo, A.; Tekmen, C.; Pisignano, D. Industrial upscaling of electrospinning and applications of polymer nanofibers: A review. Macromol. Mater. Eng. 2013, 298, 504–520. [Google Scholar] [CrossRef]

- Forward, K.M.; Rutledge, G.C. Free surface electrospinning from a wire electrode. Chem. Eng. J. 2012, 183, 492–503. [Google Scholar] [CrossRef] [Green Version]

- Jiang, S.; Chen, Y.; Duan, G.; Mei, C.; Greiner, A.; Agarwal, S. Electrospun nanofiber reinforced composites: A review. Polym. Chem. 2018, 9, 2685–2720. [Google Scholar] [CrossRef]

- Pawłowska, S.; Nakielski, P.; Pierini, F.; Piechocka, I.K.; Zembrzycki, K.; Kowalewski, T.A. Lateral migration of electrospun hydrogel nanofilaments in an oscillatory flow. PLoS ONE 2017, 12, 1–21. [Google Scholar] [CrossRef]

- Cherpinski, A.; Szewczyk, P.K.; Gruszczyński, A.; Stachewicz, U.; Lagaron, J.M. Oxygen-scavenging multilayered biopapers containing palladium nanoparticles obtained by the electrospinning coating technique. Nanomaterials 2019, 9, 262. [Google Scholar] [CrossRef] [Green Version]

- Arinstein, A.; Zussman, E. Electrospun polymer nanofibers: Mechanical and thermodynamic perspectives. J. Polym. Sci. Part. B Polym. Phys. 2011, 49, 691–707. [Google Scholar] [CrossRef]

- Arinstein, A.; Burman, M.; Gendelman, O.; Zussman, E. Effect of supramolecular structure on polymer nanofibre elasticity. Nat. Nanotechnol. 2007, 2, 59–62. [Google Scholar] [CrossRef]

- Mirjalili, M.; Zohoori, S. Review for application of electrospinning and electrospun nanofibers technology in textile industry. J. Nanostructure Chem. 2016, 6, 207–213. [Google Scholar] [CrossRef] [Green Version]

- Thakkar, S.; Misra, M. Electrospun polymeric nanofibers: New horizons in drug delivery. Eur. J. Pharm. Sci. 2017, 107, 148–167. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Liu, R.; Huang, Y.; Zhou, J. Effects of reversed arrangement of electrodes on electrospun nanofibers. J. Appl. Polym. Sci. 2017, 134, 1–8. [Google Scholar] [CrossRef]

- Wu, C.; Chiou, H.; Lin, S.; Lin, J. Effects of electrostatic polarity and the types of electrical charging on electrospinning behavior. J. Appl. Phys. 2012, 126, E89–E97. [Google Scholar] [CrossRef]

- Prabu, G.T.V.; Dhurai, B.; Saxena, A. Influence of high voltage polarity in multi-pin upward electrospinning system on the Fiber morphology of poly (vinyl alcohol). J. Polym. Res. 2020, 27. [Google Scholar] [CrossRef]

- Stachewicz, U.; Stone, C.A.; Willis, C.R.; Barber, A.H. Charge assisted tailoring of chemical functionality at electrospun nanofiber surfaces. J. Mater. Chem. 2012, 22, 22935–22941. [Google Scholar] [CrossRef]

- Metwally, S.; Karbowniczek, J.E.; Szewczyk, P.K.; Marzec, M.M.; Gruszczyński, A.; Bernasik, A.; Stachewicz, U. Single-Step Approach to Tailor Surface Chemistry and Potential on Electrospun PCL Fibers for Tissue Engineering Application. Adv. Mater. Interfaces 2019, 6, 1–12. [Google Scholar] [CrossRef]

- Szewczyk, P.K.; Metwally, S.; Karbowniczek, J.E.; Marzec, M.M.; Stodolak-Zych, E.; Gruszczyński, A.; Bernasik, A.; Stachewicz, U. Surface-Potential-Controlled Cell Proliferation and Collagen Mineralization on Electrospun Polyvinylidene Fluoride (PVDF) Fiber Scaffolds for Bone Regeneration. Acs Biomater. Sci. Eng. 2019, 5, 582–593. [Google Scholar] [CrossRef]

- Busolo, T.; Ura, D.P.; Kim, S.; Marzec, M.; Bernasik, A.; Stachewicz, U.; Kar-Narayan, S. Surface potential tailoring of PMMA fibres by electrospinning for enhanced triboelectric performance. Nano Energy 2018, 57, 500–506. [Google Scholar] [CrossRef]

- Szewczyk, P.K.; Gradys, A.; Kim, S.K.; Persano, L.; Marzec, M.; Kryshtal, A.; Busolo, T.; Toncelli, A.; Pisignano, D.; Bernasik, A.; et al. Enhanced Piezoelectricity of Electrospun Polyvinylidene Fluoride Fibers for Energy Harvesting. Acs Appl. Mater. Interfaces 2020, 12, 13575–13583. [Google Scholar] [CrossRef]

- Riba, J.R.; Morosini, A.; Capelli, F. Comparative study of ac and positive and negative dc visual corona for sphere-plane gaps in atmospheric air. Energies 2018, 11, 2671. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Li, S.; Wu, Z.; Zhu, K.; Han, Y.; Wang, N. Interaction between electrospray using ionic liquid and simultaneous corona discharge under positive and negative polarity. Phys. Plasmas 2019, 26, 1–9. [Google Scholar] [CrossRef]

- Sahay, R.; Teo, C.J.; Chew, Y.T. New correlation formulae for the straight section of the electrospun jet from a polymer drop. J. Fluid Mech. 2013, 735, 150–175. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L.; Fong, H.; Koombhongse, S. Bending instability of electrically charged liquid jets of polymer solutions in electrospinning. J. Appl. Phys. 2000, 87, 4531–4547. [Google Scholar] [CrossRef] [Green Version]

- Garg, K.; Bowlin, G.L. Electrospinning jets and nanofibrous structures. Biomicrofluidics 2011, 5, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Theron, S.A.; Zussman, E.; Yarin, A.L. Experimental investigation of the governing parameters in the electrospinning of polymer solutions. Polymer (Guildford) 2004, 45, 2017–2030. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L.; Zussman, E.; Xu, H. Electrospinning of Nanofibers from Polymer Solutions and Melts. Adv. Appl. Mech. 2007, 41, 43–195. [Google Scholar] [CrossRef]

- Saville, D.A. ELECTROHYDRODYNAMICS: The Taylor-Melcher Leaky Dielectric Model. Annu. Rev. Fluid Mech. 1997, 29, 27–64. [Google Scholar] [CrossRef]

- Hohman, M.M.; Shin, M.; Rutledge, G.; Brenner, M.P. Electrospinning and electrically forced jets. I. Stability theory. Phys. Fluids 2001, 13, 2201–2220. [Google Scholar] [CrossRef] [Green Version]

- Yousefzadeh, M.; Ramakrishna, S. Modeling Performance of Electrospun Nanofibers and Nanofibrous Assemblies; Elsevier Ltd.: Oxford, UK, 2016; ISBN 9780081009116. [Google Scholar]

- Reznik, S.N.; Yarin, A.L.; Theron, A.; Zussman, E. Transient and steady shapes of droplets attached to a surface in a strong electric field. J. Fluid Mech. 2004, 516, 349–377. [Google Scholar] [CrossRef] [Green Version]

- Stanger, J.; Tucker, N.; Kirwan, K.; Staiger, M.P. Effect of Charge Density on the Taylor Cone in Electrospinning. Solid State Phenom. 2009, 23, 1956–1961. [Google Scholar] [CrossRef]

- Brooks, H.; Tucker, N. Electrospinning predictions using artificial neural networks. Polymer (Guildford) 2015, 58, 22–29. [Google Scholar] [CrossRef] [Green Version]

- Widartiningsih, P.M.; Iskandar, F.; Munir, M.M.; Viridi, S. Predicting jet radius in electrospinning by superpositioning exponential functions. J. Phys. Conf. Ser. 2016, 739, 1–10. [Google Scholar] [CrossRef]

- Liu, Z.; Ju, K.; Wang, Z.; Li, W.; Ke, H.; He, J. Electrospun Jets Number and Nanofiber Morphology Effected by Voltage Value: Numerical Simulation and Experimental Verification. Nanoscale Res. Lett. 2019, 14, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Reznik, S.N.; Zussman, E. Capillary-dominated electrified jets of a viscous leaky dielectric liquid. Phys. Rev. E-Stat. NonlinearSoft Matter Phys. 2010, 81, 1–7. [Google Scholar] [CrossRef]

- Ding, C.; Fang, H.; Duan, G.; Zou, Y.; Chen, S.; Hou, H. Investigating the draw ratio and velocity of an electrically charged liquid jet during electrospinning. Rsc Adv. 2019, 9, 13608–13613. [Google Scholar] [CrossRef] [Green Version]

- Higuera, J.F. Charge separation in the conical meniscus of an electrospray of a very polar liquid: Its effect on the minimum flow rate. Phys. Fluids 2009, 21, 1–12. [Google Scholar] [CrossRef]

- Zheng, Y.; Meng, N.; Xin, B. Effects of jet path on electrospun polystyrene fibers. Polymer (Basel) 2018, 10, 842. [Google Scholar] [CrossRef] [Green Version]

- Subbotin, A.V.; Semenov, A.N. Electrohydrodynamics of stationary cone-jet streaming. Proc. R. Soc. A 2015, 471, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Carroll, C.P.; Joo, Y.L. Electrospinning of viscoelastic Boger fluids: Modeling and experiments. Phys. Fluids 2006, 18, 1–14. [Google Scholar] [CrossRef]

- Shin, Y.M.; Hohman, M.M.; Brenner, M.P.; Rutledge, G.C. Experimental characterization of electrospinning: The electrically forced jet and instabilities. Polymer (Guildford) 2001, 42, 09955–09967. [Google Scholar] [CrossRef]

- Stachewicz, U.; Dijksman, J.F.; Soudani, C.; Tunnicliffe, L.B.; Busfield, J.J.C.; Barber, A.H. Surface free energy analysis of electrospun fibers based on Rayleigh-Plateau/Weber instabilities. Eur. Polym. J. 2017, 91, 368–375. [Google Scholar] [CrossRef] [Green Version]

- O’Reilly, J.M.; Bair, H.E.; Karasz, F.E.; O’Reilly, J.M.; Bair, H.E.; Karasz, F.E. Thermodynamic Properties of Stereoregular Poly(methyl methacrylate). Macromolecules 1982, 15, 1083–1088. [Google Scholar] [CrossRef]

- Luo, C.J.; Stride, E.; Edirisinghe, M. Mapping the influence of solubility and dielectric constant on electrospinning polycaprolactone solutions. Macromolecules 2012, 45, 4669–4680. [Google Scholar] [CrossRef]

- Scheffler, R.; Bell, N.S.; Sigmund, W. Electrospun Teflon AF fibers for superhydrophobic membranes. J. Mater. Res. 2010, 25, 1595–1600. [Google Scholar] [CrossRef]

- Luo, C.J.; Nangrejo, M.; Edirisinghe, M. A novel method of selecting solvents for polymer electrospinning. Polymer (Guildford) 2010, 51, 1654–1662. [Google Scholar] [CrossRef]

- Shmukler, L.E.; Van Thuc, N.; Safonova, L.P. Conductivity and thermal stability of proton-conducting electrolytes at confined geometry of polymeric gel. Ionics (Kiel) 2013, 19, 701–707. [Google Scholar] [CrossRef]

- Fridrikh, S.V.; Yu, J.H.; Brenner, M.P.; Rutledge, G.C. Controlling the Fiber Diameter during Electrospinning. Phys. Rev. Lett. 2003, 90, 144502. [Google Scholar] [CrossRef] [Green Version]

- Yalcinkaya, B.; Yener, F.; Jirsak, O.; Cengiz-Callioglu, F. On the Nature of Electric Current in the Electrospinning Process. J. Nanomater. 2013, 2013, 1–10. [Google Scholar] [CrossRef]

- Supaphol, P.; Mit-uppatham, C.; Nithitanakul, M. Ultrafine electrospun polyamide-6 fibers: Effects of solvent system and emitting electrode polarity on morphology and average fiber diameter. Macromol. Mater. Eng. 2005, 290, 933–942. [Google Scholar] [CrossRef]

- Urbanek, O.; Sajkiewicz, P.; Pierini, F. The effect of polarity in the electrospinning process on PCL/chitosan nanofibres’ structure, properties and efficiency of surface modification. Polymer (Guildford) 2017, 124, 168–175. [Google Scholar] [CrossRef]

- Bhattacharjee, P.K.; Schneider, T.M.; Brenner, M.P.; McKinley, G.H.; Rutledge, G.C. On the measured current in electrospinning. J. Appl. Phys. 2010, 107, 4306. [Google Scholar] [CrossRef] [Green Version]

- Andersson, R.L.; Salajkova, M.; Mallon, P.E.; Berglund, L.A.; Hedenqvist, M.S.; Olsson, R.T. Micromechanical Tensile Testing of Cellulose-Reinforced Electrospun Fibers Using a Template Transfer Method (TTM). J. Polym. Environ 2012, 20, 967–975. [Google Scholar] [CrossRef]

- Andersson, R.L.; Ström, V.; Gedde, U.W.; Mallon, P.E.; Hedenqvist, M.S.; Olsson, R.T. Micromechanics of ultra-toughened electrospun PMMA/PEO fibres as revealed by in-situ tensile testing in an electron microscope. Sci. Rep. 2014, 3, 1–8. [Google Scholar] [CrossRef]

- Liu, L.Q.; Tasis, D.; Prato, M.; Wagner, H.D. Tensile mechanics of electrospun multiwalled nanotube/poly(methyl methacrylate) nanofibers. Adv. Mater. 2007, 19, 1228–1233. [Google Scholar] [CrossRef]

- Sui, X.; Wiesel, E.; Wagner, H.D. Mechanical properties of electrospun PMMA micro-yarns: Effects of NaCl mediation and yarn twist. Polymer (UK) 2012, 53, 5037–5044. [Google Scholar] [CrossRef]

- Bae, H.-S.; Haider, A.; Selim, K.M.K.; Kang, D.-Y.; Kim, E.-J.; Kang, I.-K. Fabrication of highly porous PMMA electrospun fibers and their application in the removal of phenol and iodine. J. Polym. Res. 2013, 20, 158. [Google Scholar] [CrossRef]

- Li, L.; Jiang, Z.; Li, M.; Li, R.; Fang, T. Hierarchically structured PMMA fibers fabricated by electrospinning. Rsc Adv. 2014, 4, 52973–52985. [Google Scholar] [CrossRef]

- Son, S.-R.; Linh, N.-T.B.; Yang, H.-M.; Lee, B.-T. In vitro and in vivo evaluation of electrospun PCL/PMMA fibrous scaffolds for bone regeneration. Sci. Technol. Adv. Mater. 2013, 14, 015009. [Google Scholar] [CrossRef]

- Zander, N.E.; Strawhecker, K.E.; Orlicki, J.A.; Rawlett, A.M.; Beebe, T.P. Coaxial electrospun poly(methyl methacrylate)-polyacrylonitrile nanofibers: Atomic force microscopy and compositional characterization. J. Phys. Chem. B 2011, 115, 12441–12447. [Google Scholar] [CrossRef] [Green Version]

- Greyling, G.; Pasch, H. Tacticity separation of poly(methyl methacrylate) by multidetector thermal field-flow fractionation. Anal. Chem. 2015, 87, 3011–3018. [Google Scholar] [CrossRef] [PubMed]

- Lemieux, E.; Prud’homme, R.E. Crystallization and morphology of isotactic poly(methyl methacrylates). Polym. Bull. 1989, 21, 621–626. [Google Scholar] [CrossRef]

- Crist, B.; Schultz, J.M. Polymer spherulites: A critical review. Prog. Polym. Sci. 2016, 56, 1–63. [Google Scholar] [CrossRef]

- Pavlov, V.I. Investigation of the effect of spherulite size on the strength and deformation characteristics of isotactic polypropylene films. Sov. Mater. Sci. 1971, 4, 438–440. [Google Scholar] [CrossRef]

- Carrizales, C.; Pelfrey, S.; Rincon, R.; Eubanks, T.M.; Kuang, A.; McClure, M.J.; Bowlin, G.L.; Macossay, J. Thermal and mechanical properties of electrospun PMMA, PVC, Nylon 6 and Nylon 6,6. Polym. Adv. Technol. 2007, 19, 124–130. [Google Scholar] [CrossRef]

- Kusanagi, H.; Chatani, Y.; Tadokoro, H. The crystal structure of isotactic poly(methyl methacrylate): Packing-mode of double stranded helices. Polymer (Guildford) 1994, 35, 2028–2039. [Google Scholar] [CrossRef]

- Richard-Lacroix, M.; Pellerin, C. Molecular orientation in electrospun fibers: From mats to single fibers. Macromolecules 2013, 46, 9473–9493. [Google Scholar] [CrossRef]

- Yano, T.; Higaki, Y.; Tao, D.; Murakami, D.; Kobayashi, M.; Ohta, N.; Koike, J.I.; Horigome, M.; Masunaga, H.; Ogawa, H.; et al. Orientation of poly(vinyl alcohol) nanofiber and crystallites in non-woven electrospun nanofiber mats under uniaxial stretching. Polymer (Guildford) 2012, 53, 4702–4708. [Google Scholar] [CrossRef]

- Li, B.; Pan, S.; Yuan, H.; Zhang, Y. Optical and mechanical anisotropies of aligned electrospun nanofibers reinforced transparent PMMA nanocomposites. Compos. Part. A Appl. Sci. Manuf. 2016, 90, 380–389. [Google Scholar] [CrossRef]

- Stachewicz, U.; Hang, F.; Barber, A.H. Adhesion anisotropy between contacting electrospun fibers. Langmuir 2014, 30, 6819–6825. [Google Scholar] [CrossRef]

- Stachewicz, U.; Peker, I.; Tu, W.; Barber, A.H. Stress delocalization in crack tolerant electrospun nanofiber networks. Acs Appl. Mater. Interfaces 2011, 3, 1991–1996. [Google Scholar] [CrossRef] [PubMed]

- Sui, X.; Wiesel, E.; Wagner, H.D. Enhanced Mechanical Properties of Electrospun Nano-Fibers Through NaCl Mediation. J. Nanosci. Nanotechnol. 2011, 11, 7931–7936. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.J.L.; Andriyana, A.; Ang, B.C.; Huneau, B.; Verron, E. Electrospun PMMA polymer blend nanofibrous membrane: Electrospinability, surface morphology and mechanical response. Mater. Res. Express 2018, 5, 1–19. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Greenfeld, I.; Zussman, E. Polymer entanglement loss in extensional flow: Evidence from electrospun short nanofibers. J. Polym. Sci. Part. B Polym. Phys. 2013, 51, 1377–1391. [Google Scholar] [CrossRef]

- Mohammad Khanlou, H.; Chin Ang, B.; Talebian, S.; Muhammad Afifi, A.; Andriyana, A. Electrospinning of polymethyl methacrylate nanofibers: Optimization of processing parameters using the Taguchi design of experiments. Text. Res. J. 2015, 85, 356–368. [Google Scholar] [CrossRef]

| PMMA Fibers | Density [g·cm−3] | σmax [kPa] | εmax [%] | εf [%] | EY [kPa] | W [kJ∙m−3] |

|---|---|---|---|---|---|---|

| A+ | 1.24 ± 0.01 c | 446.4 ± 47.5 a | 3.2 ± 0.4 a | 17.7 ± 2.4 b | 141.6 ± 20.1 a | 1084.1 ± 188.3 b |

| A− | 1.25 ± 0.01 b | 186.8 ± 27.2 c | 1.8 ± 0.2 b | 9.5 ± 4.6 b | 106.7 ± 13.6 b | 433.1 ± 130.4 d |

| R+ | 1.25 ± 0.01 a | 129.4 ± 31.7 d | 3.0 ± 0.3 a | 38.1 ± 2.6 a | – | 811.0 ± 162.2 c |

| R− | 1.24 ± 0.01 c | 228.5 ± 24.3 b | 3.2 ± 0.7 a | 37.8 ± 5.5 a | – | 1402.0 ± 283.3 a |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ura, D.P.; Rosell-Llompart, J.; Zaszczyńska, A.; Vasilyev, G.; Gradys, A.; Szewczyk, P.K.; Knapczyk-Korczak, J.; Avrahami, R.; Šišková, A.O.; Arinstein, A.; et al. The Role of Electrical Polarity in Electrospinning and on the Mechanical and Structural Properties of As-Spun Fibers. Materials 2020, 13, 4169. https://doi.org/10.3390/ma13184169

Ura DP, Rosell-Llompart J, Zaszczyńska A, Vasilyev G, Gradys A, Szewczyk PK, Knapczyk-Korczak J, Avrahami R, Šišková AO, Arinstein A, et al. The Role of Electrical Polarity in Electrospinning and on the Mechanical and Structural Properties of As-Spun Fibers. Materials. 2020; 13(18):4169. https://doi.org/10.3390/ma13184169

Chicago/Turabian StyleUra, Daniel P., Joan Rosell-Llompart, Angelika Zaszczyńska, Gleb Vasilyev, Arkadiusz Gradys, Piotr K. Szewczyk, Joanna Knapczyk-Korczak, Ron Avrahami, Alena O. Šišková, Arkadii Arinstein, and et al. 2020. "The Role of Electrical Polarity in Electrospinning and on the Mechanical and Structural Properties of As-Spun Fibers" Materials 13, no. 18: 4169. https://doi.org/10.3390/ma13184169