Flexible 3D Printed Conductive Metamaterial Units for Electromagnetic Applications in Microwaves

Abstract

:1. Introduction

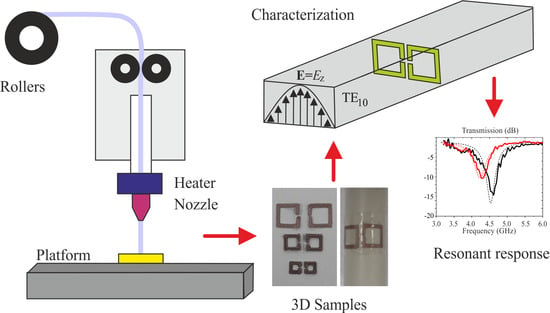

2. Materials and Methods

3. Results and Discussion

4. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. Design and Characterization Details

Appendix B. Meta-Atom Response with Variable Geometry

References

- Soukoulis, C.M.; Wegener, M. Past achievements and future challenges in the development of three-dimensional photonic metamaterials. Nat. Photonics 2011, 5, 523–530. [Google Scholar] [CrossRef] [Green Version]

- Glybovski, S.B.; Tretyakov, S.A.; Belov, P.A.; Kivshar, Y.S.; Simovski, C.R. Metasurfaces: From microwaves to visible. Phys. Rep. 2016, 634, 1. [Google Scholar] [CrossRef]

- Wang, X.; Díaz-Rubio, A.; Li, H.; Tretyakov, S.; Alù, A. Theory and Design of Multifunctional Space-Time Metasurfaces. Phys. Rev. Appl. 2020, 13, 044040. [Google Scholar] [CrossRef]

- Tasolamprou, A.C.; Zhang, L.; Kafesaki, M.; Koschny, T.; Soukoulis, C.M. Experimentally excellent beaming in a two-layer dielectric structure. Opt. Express 2014, 22, 23147. [Google Scholar] [CrossRef]

- Taghvaee, H.; Abadal, S.; Pitilakis, A.; Tsilipakos, O.; Tasolamprou, A.C.; Liaskos, C.; Kafesaki, M.; Kantartzis, N.V.; Cabellos-Aparicio, A.; Alarcón, E. Scalability Analysis of Programmable Metasurfaces for Beam Steering. IEEE Access 2020, 8, 105320–105334. [Google Scholar] [CrossRef]

- Kossifos, K.; Petrou, L.; Varnava, G.; Pitilakis, A.; Tsilipakos, O.; Liu, F.; Karousios, P.; Tasolamprou, A.; Seckel, M.; Manessis, D.; et al. Toward the Realization of a Programmable Metasurface Absorber Enabled by Custom Integrated Circuit Technology. IEEE Access 2020, 8, 92986–92998. [Google Scholar] [CrossRef]

- Tasolamprou, A.C.; Zhang, L.; Koschny, T.; Kafesaki, M.; Soukoulis, C.M. Frequency splitter based on the directional emission from surface modes in dielectric photonic crystal structures. Opt. Express 2015, 23, 13972–13982. [Google Scholar] [CrossRef]

- Hintermayr, V.A.; Lampe, C.; Löw, M.; Roemer, J.; Vanderlinden, W.; Gramlich, M.; Böhm, A.X.; Sattler, C.; Nickel, B.; Lohmüller, T.; et al. Polymer Nanoreactors Shield Perovskite Nanocrystals from Degradation. Nano Lett. 2019, 19, 4928–4933. [Google Scholar] [CrossRef] [Green Version]

- Tasolamprou, A.C.; Koschny, T.; Kafesaki, M.; Soukoulis, C.M. Near-Infrared and Optical Beam Steering and Frequency Splitting in Air-Holes-in-Silicon Inverse Photonic Crystals. ACS Photonics 2017, 4, 2782–2788. [Google Scholar] [CrossRef]

- Xu, S.T.; Fan, F.; Cheng, J.; Chen, H.; Ma, W.; Huang, Y.; Chang, S. Active Terahertz Shielding and Absorption Based on Graphene Foam Modulated by Electric and Optical Field Excitation. Adv. Opt. Mater. 2019, 7, 1900555. [Google Scholar] [CrossRef]

- Assimonis, S.; Fusco, V. Polarization Insensitive, Wide-Angle, Ultra-wideband, Flexible, Resistively Loaded, Electromagnetic Metamaterial Absorber using Conventional Inkjet-Printing Technology. Sci. Rep. 2019, 9, 12334. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, F.; Jayathurathnage, P.; Tretyakov, S. Active metasurfaces as a platform for capacitivewireless power transfer supporting multiple receivers. In Proceedings of the 2019 Thirteenth International Congress on Artificial Materials for Novel Wave Phenomena (Metamaterials), Rome, Italy, 16–21 September 2019; pp. X227–X229. [Google Scholar]

- Perrakis, G.; Tasolamprou, A.C.; Kenanakis, G.; Economou, E.N.; Tzortzakis, S.; Kafesaki, M. Passive radiative cooling and other photonic approaches for the temperature control of photovoltaics: A comparative study for crystalline silicon-based architectures. Opt. Express 2020, 28, 18548–18565. [Google Scholar] [CrossRef] [PubMed]

- Perrakis, G.; Tasolamprou, A.C.; Kenanakis, G.; Economou, E.N.; Tzortzakis, S.; Kafesaki, M. Ultraviolet radiation impact on the efficiency of commercial crystalline silicon-based photovoltaics: A theoretical thermal-electrical study in realistic device architectures. OSA Contin. 2020, 3, 1436–1444. [Google Scholar] [CrossRef]

- Baryshnikova, K.; Smirnova, D.; Luk’yanchuk, B.; Kivshar, Y. Optical Anapoles: Concepts and Applications. Adv. Opt. Mater. 2019, 7, 1801350. [Google Scholar] [CrossRef]

- Kafesaki, M.; Shen, N.; Tzortzakis, S.; Soukoulis, C. Optically switchable and tunable terahertz metamaterials through photoconductivity. J. Opt. 2012, 14, 114008. [Google Scholar] [CrossRef] [Green Version]

- Tasolamprou, A.; Koulouklidis, A.; Daskalaki, C.; Mavidis, C.; Kenanakis, G.; Deligeorgis, G.; Viskadourakis, Z.; Kuzhir, P.; Tzortzakis, S.; Kafesaki, M.; et al. Experimental Demonstration of Ultrafast THz Modulation in a Graphene-Based Thin Film Absorber through Negative Photoinduced Conductivity. ACS Photonics 2019, 6, 720–727. [Google Scholar] [CrossRef] [Green Version]

- Galiffi, E.; Pendry, J.; Huidobro, P. Broadband Tunable THz Absorption with Singular Graphene Metasurfaces. ACS Nano 2018, 12, 1006–1013. [Google Scholar] [CrossRef] [Green Version]

- Soukoulis, C.M.; Koschny, T.; Zhou, J.; Kafesaki, M.; Economou, E.N. Magnetic response of split ring resonators at terahertz frequencies. Phys. Status Solidi 2007, 244, 1181. [Google Scholar] [CrossRef]

- Gundogdu, T.F.; Gökkavas, M.; Güven, K.; Kafesaki, M.; Soukoulis, C.M.; Ozbay, E. Simulation and micro-fabrication of optically switchable split ring resonators. Photonics Nanostruct. Fundam. Appl. 2007, 5, 106. [Google Scholar] [CrossRef] [Green Version]

- Smith, D.R.; Pendry, J.B.; Wiltshire, M.C. Metamaterials and negative refractive index. Science 2004, 305, 788. [Google Scholar] [CrossRef] [Green Version]

- Pitilakis, A.; Tsilipakos, O.; Liu, F.; Kossifos, K.M.; Tasolamprou, A.C.; Kwon, D.; Mirmoosa, M.S.; Manessis, D.; Kantartzis, N.V.; Liaskos, C.; et al. A multi-functional reconfigurable metasurface: Electromagnetic design accounting for fabrication aspects. arXiv 2020, arXiv:2003.08654. [Google Scholar] [CrossRef]

- Gebhardt, A.; Hötter, J.S. Additive Manufacturing. In Additive Manufacturing; Hanser Publications: Cincinnati, OH, USA, 2016. [Google Scholar]

- Papadopoulos, A.; Skoulas, E.; Tsibidis, G.D.; Stratakis, E. Formation of periodic surface structures on dielectrics after irradiation with laser beams of spatially variant polarisation: A comparative study. Appl. Phys. A 2018, 124, 126. [Google Scholar] [CrossRef] [Green Version]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Kenanakis, G.; Romanitan, C.; Tutunaru, O.; Suchea, M.; Kechagias, J. The mechanical and physical properties of 3D-Printed materials composed of ABS-ZnO nanocomposites and ABS-ZnO microcomposites. Micromachines 2020, 11, 615. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Maniadi, A.; Petousis, M.; Vamvakaki, M.; Kenanakis, G.; Koudoumas, E. Mechanical and Electrical Properties Investigation of 3D-Printed Acrylonitrile–Butadiene–Styrene Graphene and Carbon Nanocomposites. J. Mater. Eng. Perform. 2020, 29, 1909–1918. [Google Scholar] [CrossRef]

- Kenanakis, G.; Vasilopoulos, K.; Viskadourakis, Z.; Barkoula, N.M.; Anastasiadis, S.; Kafesaki, M.; Economou, E.; Soukoulis, C. Electromagnetic shielding effectiveness and mechanical properties of graphite-based polymeric films. Appl. Phys. A 2016, 122, 802. [Google Scholar] [CrossRef]

- Vernardou, D.; Kenanakis, G. Electrochemistry studies of hydrothermally grown ZnO on 3D-printed graphene. Nanomaterials 2019, 9, 1056. [Google Scholar] [CrossRef] [Green Version]

- Viskadourakis, Z.; Sevastaki, M.; Kenanakis, G. 3D structured nanocomposites by FDM process: A novel approach for large-scale photocatalytic applications. Appl. Phys. A 2018, 124, 585. [Google Scholar] [CrossRef]

- Viskadourakis, Z.; Vasilopoulos, K.; Economou, E.; Soukoulis, C.; Kenanakis, G. Electromagnetic shielding effectiveness of 3D printed polymer composites. Appl. Phys. A 2017, 123, 736. [Google Scholar] [CrossRef] [Green Version]

- Vallecchi, A.; Cadman, D.; Whittow, W.G.; Vardaxoglou, J.; Shamonina, E.; Stevens, C.J. 3-D Printed Bandpass Filters With Coupled Vertically Extruded Split Ring Resonators. IEEE Trans. Microw. Theory Tech. 2019, 67, 4341–4352. [Google Scholar] [CrossRef] [Green Version]

- Rao, S.J.M.; Srivastava, Y.K.; Kumar, G.; Roy Chowdhury, D. Modulating Fundamental Resonance in Capacitive Coupled Asymmetric Terahertz Metamaterials. Sci. Rep. 2018, 8, 16773. [Google Scholar] [CrossRef]

- Chowdhury, D.R.; Singh, R.; Reiten, M.; Zhou, J.; Taylor, A.J.; O’Hara, J.F. Tailored resonator coupling for modifying the terahertz metamaterial response. Opt. Express 2011, 19, 10679. [Google Scholar] [CrossRef] [PubMed]

- Penciu, R.S.; Aydin, K.; Kafesaki, M.; Koschny, T.; Ozbay, E.; Economou, E.N.; Soukoulis, C.M. Multi-gap individual and coupled split-ring resonator structures. Opt. Express 2008, 16, 18131. [Google Scholar] [CrossRef] [PubMed]

- Pizarro, F.; Salazar, R.; Rajo-Iglesias, E.; Rodriguez, M.; Fingerhuth, S.; Hermosilla, G. Parametric Study of 3D Additive Printing Parameters Using Conductive Filaments on Microwave Topologies. IEEE Access 2019, 7, 106814–106823. [Google Scholar] [CrossRef]

- Massaccesi, A.; Dassano, G.; Pirinoli, P. Beam scanning capabilities of a 3d-printed perforated dielectric transmitarray. Electronics 2019, 8, 379. [Google Scholar] [CrossRef] [Green Version]

- Massaccesi, A.; Pirinoli, P.; Bertana, V.; Scordo, G.; Marasso, S.L.; Cocuzza, M.; Dassano, G. 3D-Printable Dielectric Transmitarray With Enhanced Bandwidth at Millimeter-Waves. IEEE Access 2018, 6, 46407–46418. [Google Scholar] [CrossRef]

- Poyanco, J.M.; Pizarro, F.; Rajo-Iglesias, E. 3D-Printing for Transformation Optics in Electromagnetic High-Frequency Lens Applications. Materials 2020, 13, 2700. [Google Scholar] [CrossRef]

- Stuardo, P.; Pizarro, F.; Rajo-Iglesias, E. 3D-Printed Sievenpiper Metasurface Using Conductive Filaments. Materials 2020, 13, 2614. [Google Scholar] [CrossRef]

- Xie, Y.; Ye, S.; Reyes, C.; Sithikong, P.; Popa, B.I.; Wiley, B.J.; Cummer, S.A. Microwave metamaterials made by fused deposition 3D printing of a highly conductive copper-based filament. Appl. Phys. Lett. 2017, 110, 181903. [Google Scholar] [CrossRef]

- Meisak, D.; Gurnevich, E.; Plyushch, A.; Bychanok, D.; Georgiev, V.; Kotsilkova, R.; Kuzhir, P. Robust design of compact microwave absorbers and waveguide matched loads based on DC-conductive 3D-printable filament. J. Phys. D 2020, 53, 30. [Google Scholar] [CrossRef]

- Ishikawa, A.; Kato, T.; Takeyasu, N.; Fujimori, K.; Tsuruta, K. Selective electroless plating of 3D-printed plastic structures for three-dimensional microwave metamaterials. Appl. Phys. Lett. 2017, 111, 183102. [Google Scholar] [CrossRef]

- Katsarakis, N.; Kafesaki, M.; Tsiapa, I.; Economou, E.N.; Soukoulis, C.M. High transmittance left-handed materials involving symmetric split-ring resonators. Photonics Nanostruct. Fundam. Appl. 2007, 5, 149. [Google Scholar] [CrossRef]

- Chen, Y.; Mao, J.; Zhu, Y.; Zhang, K.; Wu, G.; Wu, J.; Zhang, H. Structure and properties of microwave transparent crosslinked polystyrene prepared through 3D printing bulk polymerization. J. Appl. Polym. Sci. 2017, 134, 44865. [Google Scholar] [CrossRef]

| Printing Conditions | PLA | Electrifi |

|---|---|---|

| Filament Diameter | 1.75 mm | 1.75 mm |

| Filament Conductivity | 0 | S/m |

| Nozzle Diameter | 0.4 mm | 0.4 mm |

| Nozzle Temperature | °C | °C |

| Printing bed temperature | °C | Room temperature |

| Printing speed | 25 mm/s | 15 mm/s |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tasolamprou, A.C.; Mentzaki, D.; Viskadourakis, Z.; Economou, E.N.; Kafesaki, M.; Kenanakis, G. Flexible 3D Printed Conductive Metamaterial Units for Electromagnetic Applications in Microwaves. Materials 2020, 13, 3879. https://doi.org/10.3390/ma13173879

Tasolamprou AC, Mentzaki D, Viskadourakis Z, Economou EN, Kafesaki M, Kenanakis G. Flexible 3D Printed Conductive Metamaterial Units for Electromagnetic Applications in Microwaves. Materials. 2020; 13(17):3879. https://doi.org/10.3390/ma13173879

Chicago/Turabian StyleTasolamprou, Anna C., Despoina Mentzaki, Zacharias Viskadourakis, Eleftherios N. Economou, Maria Kafesaki, and George Kenanakis. 2020. "Flexible 3D Printed Conductive Metamaterial Units for Electromagnetic Applications in Microwaves" Materials 13, no. 17: 3879. https://doi.org/10.3390/ma13173879