Eco-Friendly Materials Obtained by Fly Ash Sulphuric Activation for Cadmium Ions Removal

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Adsorbent Synthesis

2.3. Experimental Procedure

3. Results

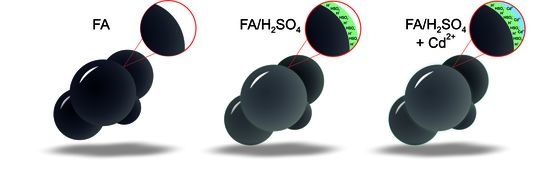

3.1. Characterization of Adsorbent

3.1.1. SEM Analysis

3.1.2. EDX Analysis

3.1.3. FTIR Analysis

3.1.4. XRD Analysis

3.1.5. BET Analysis

3.2. Effect of FA/H2SO4 Dose in Cd2+ Adsorption

3.3. Effect of Initial Concentration and Adsorption Isotherm

3.4. Effect of Contact Time and Kinetic Models

4. Conclusions

- The adsorbent dose had an effect on the adsorption process: A higher dose led to a decrease in adsorption capacity.

- Moreover, it was found that the adsorption process is dependent on the initial concentration.

- The adsorption equilibrium was reached after 60 min of contact time.

- The data fitted in the Langmuir model with a maximum adsorption capacity of 28.09 mg/g. The adsorption process could be explained through a pseudo-second-order kinetic model. This suggests the dominance of chemisorption and monolayer adsorption.

- The adsorption study demonstrated that the material is an effective adsorbent for the removal of cadmium ions from aqueous solutions.

Author Contributions

Funding

Conflicts of Interest

References

- Baby, R.; Hussein, M.Z. Ecofriendly approach for treatment of heavy-metal-contaminated water using activated carbon of kernel shell of oil Palm. Materials 2020, 13, 2627. [Google Scholar] [CrossRef]

- Huang, X.; Zhao, H.; Zhang, G.; Li, J.; Yang, Y.; Ji, P. Potential of removing Cd (II) and Pb (II) from contaminated water using a newly modified fly ash. Chemosphere 2020, 242, 125148. [Google Scholar] [CrossRef]

- Roman, T.; Asavei, R.L.; Karkalos, N.E.; Roman, C.; Virlan, C.; Cimpoesu, N.; Istrate, B.; Zaharia, M.; Markopoulos, A.P.; Kordatos, K.; et al. Synthesis and adsorption properties of nanocrystalline ferrites for kinetic modeling development. Int. J. Appl. Ceram. Technol. 2019, 16, 693–705. [Google Scholar] [CrossRef]

- Favier, L.; Harja, M. TiO2/fly ash nanocomposite for photodegradation of persistent organic pollutant. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Kharissova, O., Martínez, L., Kharisov, B., Eds.; Springer: Basel, Switzerland, 2020. [Google Scholar] [CrossRef]

- Harja, M.; Ciobanu, G. Ecofriendly nano-adsorbents for pollutant removal from wastewaters. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Kharissova, O., Martínez, L., Kharisov, B., Eds.; Springer: Basel, Switzerland, 2020. [Google Scholar]

- Kokkinos, E.; Chousein, C.; Simeonidis, K.; Coles, S.; Zouboulis, A.; Mitrakas, M. Improvement of manganese feroxyhyte’s surface charge with exchangeable Ca ions to maximize Cd and Pb uptake from water. Materials 2020, 13, 1762. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.; Wang, Q.; Li, R.; Lou, Z.; Li, Y. A novel phenolic foam-derived magnetic carbon foam treated as adsorbent for rhodamine B: Characterization and adsorption kinetics. Crystals 2020, 10, 159. [Google Scholar] [CrossRef] [Green Version]

- Noli, F.; Buema, G.; Misaelides, P.; Harja, M. New materials synthesized from ash under moderate conditions for removal of toxic and radioactive metals. J. Radioanal. Nucl. Chem. 2015, 303, 2303–2311. [Google Scholar] [CrossRef]

- Wang, Y.; Han, P.; Lu, Y.; Xiao, L.; Du, Y.; Liu, X.; Ye, S. Removal of arsenic and heavy metals from arsenic-containing acid wastewater with iron salt and lime. Environ. Eng. Manag. J. 2019, 18, 2655–2662. [Google Scholar] [CrossRef]

- Liu, S.; Yang, C.; Liu, W.; Yi, L.; Qin, W. A novel approach to preparing ultra-lightweight ceramsite with a large amount of fly ash. Front. Environ. Sci. Eng. 2020, 14, 62–73. [Google Scholar] [CrossRef]

- Harja, M.; Cimpeanu, S.M.; Dirja, M.; Bucur, D. Synthesis of zeolites from fly ash and their use as soil amendment. In Zeolites—Useful Minerals; IntechOpen: London, UK, 2016. [Google Scholar]

- Pivák, A.; Pavlíková, M.; Záleská, M.; Lojka, M.; Jankovský, O.; Pavlík, Z. Magnesium oxychloride cement composites with silica filler and coal fly ash admixture. Materials 2020, 13, 2537. [Google Scholar] [CrossRef]

- Risdanareni, P.; Villagran, Y.; Schollbach, K.; Wang, J.; De Belie, N. Properties of alkali activated lightweight aggregate generated from sidoarjo volcanic mud (lusi), fly ash, and municipal solid waste incineration bottom ash. Materials 2020, 13, 2528. [Google Scholar] [CrossRef]

- Lei, T.; Li, S.J.; Jiang, F.; Ren, Z.X.; Wang, L.L.; Yang, X.J.; Tang, L.H.; Wang, S.X. Adsorption of cadmium ions from an aqueous solution on a highly stable dopamine-modified magnetic nano adsorbent. Nanoscale Res. Lett. 2019, 14, 352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Supelano, G.I.; Cuaspud, J.G.; Moreno-Aldana, L.C.; Ortiz, C.; Trujillo, C.A.; Palacio, C.A. Synthesis of magnetic zeolites from recycled fly ash for adsorption of methylene blue. Fuel 2020, 263, 116800. [Google Scholar] [CrossRef]

- Buema, G.; Noli, F.; Misaelides, P.; Sutiman, D.M.; Cretescu, I.; Harja, M. Uranium removal from aqueous solutions by raw and modified thermal power plant ash. J. Radioanal. Nucl. Chem. 2014, 299, 381–386. [Google Scholar] [CrossRef]

- Noli, F.; Kapnisti, M.; Buema, G.; Harja, M. Retention of barium and europium radionuclides from aqueous solutions on ash-based sorbents by application of radiochemical techniques. Appl. Radiat. Isot. 2016, 116, 102–109. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Ye, J.; Liu, Z.; Qiu, Y.; Li, L.; Mao, S.; Wang, X.; Zhang, Q. Microwave digestion and alkali fusion assisted hydrothermal synthesis of zeolite from coal fly ash for enhanced adsorption of Cd(II) in aqueous solution. J. Cent. South Univ. 2018, 25, 9–20. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, L.; Chen, L.; Guo, Y.; Guo, F.; Wu, J.; Dai, B. Synthesis of zeolite Na-P1 from coal fly ash produced by gasification and its application as adsorbent for removal of Cr(VI) from water. Front. Chem. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Noli, F.; Buema, G.; Misaelides, P.; Harja, M. Retention of cesium from aqueous solutions using synthetic zeolites produced from power plant ash. J. Radioanal. Nucl. Chem. 2016, 309, 589–596. [Google Scholar] [CrossRef]

- Mor, S.; Chhavi, M.K.; Sushil, K.K.; Ravindra, K. Assessment of hydrothermally modified fly ash for the treatment of methylene blue dye in the textile industry wastewater. Environ. Dev. Sustain. 2018, 20, 625–639. [Google Scholar] [CrossRef]

- Styszko, K.; Szczurowski, J.; Czuma, N.; Makowska, D.; Kistler, M.; Uruski, L. Adsorptive removal of pharmaceuticals and personal care products from aqueous solutions by chemically treated fly ash. Int. J. Environ. Sci. Technol. 2018, 15, 493–506. [Google Scholar] [CrossRef]

- Ileri, B.; SanliyukselYucel, D. Metal removal from acid mine lake using ultrasound-assisted modified fly ash at different frequencies. Environ. Monit. Assess. 2020, 192, 185. [Google Scholar] [CrossRef]

- Harja, M.; Buema, G.; Sutiman, D.M.; Munteanu, C.; Bucur, D. Low cost adsorbents obtained from ash for copper removal. Korean J. Chem. Eng. 2012, 29, 1735–1744. [Google Scholar] [CrossRef]

- Harja, M.; Buema, G.; Bulgariu, L.; Bulgariu, D.; Sutiman, D.M.; Ciobanu, G. Removal of cadmium(II) from aqueous solution by adsorption onto modified algae and ash. Korean J. Chem. Eng. 2015, 32, 1804–1811. [Google Scholar] [CrossRef]

- Harja, M.; Buema, G.; Sutiman, D.M.; Cretescu, I. Removal of heavy metal ions from aqueous solutions using low-cost sorbents obtained from ash. Chem. Pap. 2013, 67, 497–508. [Google Scholar] [CrossRef]

- Nguyen, T.C.; Loganathan, P.; Nguyen, T.V.; Kandasamy, J.; Naidu, R.; Vigneswaran, S. Adsorptive removal of five heavy metals from water using blast furnace slag and fly ash. Environ. Sci. Pollut. Res. 2018, 25, 20430–20438. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, H.; Huang, X.; Zhang, G.; Li, J.; He, Z.; Ji, P.; Zhao, J. Possibility of removing cadmium pollution from the environment using a newly synthesized material coal fly ash. Environ. Sci. Pollut. Res. 2020, 27, 4997–5008. [Google Scholar] [CrossRef]

- Harja, M.; Bărbuţă, M.; Rusu, L.; Apostolescu, N. Utilization of coal fly ash from power plants I. Ash characterization. Environ. Eng. Manag. J. 2008, 7, 289–294. [Google Scholar] [CrossRef]

- Forminte (Litu), L.; Ciobanu, G.; Buema, G.; Lupu, N.; Chiriac, H.; Gomez de Castro, C.; Harja, M. New materials synthesized by sulfuric acid attack over power plant fly ash. Rev. Chim 2020, 71, 48–58. [Google Scholar] [CrossRef]

- Buema, G.; Lupu, N.; Chiriac, H.; Ciobanu, G.; Kotova, O.; Harja, M. Modeling of solid-fluid non-catalytic processes for nickel ion removal. Rev. Chim. 2020, 71, 4–15. [Google Scholar] [CrossRef]

- Harja, M.; Barbuta, M.; Gavrilescu, M. Study of morphology for geopolymer materials obtained from fly ash. Environ. Eng. Manag. J. 2009, 8, 1021–1027. [Google Scholar] [CrossRef]

- Ma, L.; Wei, Q.; Chen, Y.; Song, Q.; Sun, C.; Wang, Z.; Wu, G. Removal of cadmium from aqueous solutions using industrial coal fly ash-nZVI. R. Soc. Open Sci. 2018, 5, 171051. [Google Scholar] [CrossRef] [Green Version]

- Jorfi, S.; Shooshtarian, M.R.; Pourfadakari, S. Decontamination of cadmium from aqueous solutions using zeolite decorated by Fe3O4 nanoparticles: Adsorption modeling and thermodynamic studies. Int. J. Environ. Sci. Technol. 2020, 17, 273–286. [Google Scholar] [CrossRef]

- Treacy, M.M.; Higgins, J.B. Collection of Simulated XRD Powder Patterns for Zeolites, 5th ed.; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Wang, N.; Hao, L.; Chen, J.; Zhao, Q.; Xu, H. Adsorptive removal of organics from aqueous phase by acid-activated coal fly ash: Preparation, adsorption, and Fenton regenerative valorization of “spent” adsorbent. Environ. Sci. Pollut. Res. 2018, 25, 12481–12490. [Google Scholar] [CrossRef] [PubMed]

- Sukpreabprom, H.; Arqueropanyo, O.; Naksata, W.; Sooksamiti, P.; Janhom, S. Single and binary adsorption of Cd (II) and Zn (II) ions from aqueous solutions onto bottom ash. Korean J. Chem. Eng. 2015, 32, 896–902. [Google Scholar] [CrossRef]

- Gorzin, F.; Abadi, M.B.R. Adsorption of Cr(VI) from aqueous solution by adsorbent prepared from paper mill sludge: Kinetics and thermodynamics studies. Adsorp. Sci. Technol. 2018, 36, 149–169. [Google Scholar] [CrossRef]

- Yusuff, A.S.; Popoola, L.T.; Babatunde, E.O. Adsorption of cadmium ion from aqueous solutions by copper-based metal organic framework: Equilibrium modeling and kinetic studies. Appl. Water Sci. 2019, 9, 106. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Lou, Z.; Wang, C.; Wang, W.; Cai, J. Synthesis of porous Fe/C bio-char adsorbent for rhodamine B from waste wood: Characterization, kinetics and thermodynamics. Processes 2019, 7, 150. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Li, J.; Zhang, G.; Zhi, Y.; Yang, D.; Lai, X.; Ren, T. Characterization of acid-aged biochar and its ammonium adsorption in an aqueous solution. Materials 2020, 13, 2270. [Google Scholar] [CrossRef]

- Merrikhpour, H.; Jalali, M. Comparative and competitive adsorption of cadmium, copper, nickel, and lead ions by Iranian natural zeolite. Clean Technol. Environ. Policy 2013, 15, 303–316. [Google Scholar] [CrossRef]

- Olabemiwo, F.A.; Tawabini, B.S.; Patel, F.; Oyehan, T.A.; Mazen Khaled, M.; Laoui, T. Cadmium removal from contaminated water using polyelectrolyte-coated industrial waste fly ash. Bioinorg. Chem. Appl. 2017, 7298351. [Google Scholar] [CrossRef]

- Deng, Y.; Huang, S.; Laird, D.A.; Wang, X.; Dong, C. Quantitative mechanisms of cadmium adsorption on rice straw- and swine manure-derived biochars. Environ. Sci. Pollut. Res. 2018, 25, 32418–32432. [Google Scholar] [CrossRef]

- Gorimbo, J.; Taenzana, B.; Muleja, A.A.; Kuvarega, A.T.; Jewell, L.L. Adsorption of cadmium, nickel and lead ions: Equilibrium, kinetic and selectivity studies on modified clinoptilolites from the USA and RSA. Environ. Sci. Pollut. Res. 2018, 25, 30962–30978. [Google Scholar] [CrossRef] [PubMed]

- Yusof, M.S.M.; Othman, M.H.D.; Mustafa, A.; Rahman, M.A.; Jaafar, J.; Ismail, A.F. Feasibility study of cadmium adsorption by palm oil fuel ash (POFA)-based low-cost hollow fibre zeolitic membrane. Environ. Sci. Pollut. Res. 2018, 25, 21644–21655. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Liu, P.; Wang, F.; Hu, C.; Hu, S. Versatile surface modification of ceramsite via honeycomb calcium-aluminum-silicate-hydrate and its functionalization by 3-thiocyanatopropyltriethoxysilane for enhanced cadmium (II) removal. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2020, 35, 71–80. [Google Scholar] [CrossRef]

| Element | Mass, % |

|---|---|

| O | 59.82826 |

| Si | 20.07406 |

| Al | 8.967165 |

| Ca | 2.286939 |

| Fe | 1.500967 |

| K | 1.039111 |

| Mg | 0.872161 |

| Na | 0.638949 |

| Ti | 0.344842 |

| S | 4.447546 |

| Element | Mass, % |

|---|---|

| O | 53.8552 |

| Si | 26.6605 |

| Al | 10.7206 |

| Ca | 0.7185 |

| Fe | 1.8664 |

| K | 1.7000 |

| Mg | 0.5995 |

| Na | 0.5135 |

| Ti | 0.3448 |

| Cd | 3.0207 |

| Langmuir Model | Freundlich Model | ||||

|---|---|---|---|---|---|

| R2 | , | 1/n | R2 | ||

| 28.09 | 0.0110 | 0.9956 | 6.23 | 0.2101 | 0.9806 |

| Kinetic model | Parameters | Values |

|---|---|---|

| Pseudo-first order | , 1/min | 0.071 |

| R2 | 0.763 | |

| Pseudo-second order | qe cal, mg/g | 5.28 |

| , g/mg·min | 0.1308 | |

| R2 | 0.9999 | |

| Intraparticle diffusion | , mg/g·min0.5 | 0.114 |

| R2 | 0.693 |

| Adsorbent | qmax (mg/ g) | References |

|---|---|---|

| Iranian natural zeolite | 4.01 | [42] |

| Modified fly ash | 43.12 | [25] |

| Bottom ash | 13.70 | [37] |

| Coated Industrial Waste Fly Ash | 6.39 | [43] |

| NaOH modified ash | 31.79 | [28] |

| Swine manure biochar | 46.5 | [44] |

| USA clinoptilolite-K | 24.5 | [45] |

| RSA clinoptilolite-K | 20.73 | [45] |

| Palm Oil Fuel Ash | 10.56 | [46] |

| Fe3O4@PDA | 21.58 | [14] |

| Ceramsite/C-A-S-H/TCPS | 14.27 | [47] |

| Fe3O4@Z | 19.9 | [34] |

| FA/H2SO4 | 28.09 | This study |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buema, G.; Lupu, N.; Chiriac, H.; Roman, T.; Porcescu, M.; Ciobanu, G.; Burghila, D.V.; Harja, M. Eco-Friendly Materials Obtained by Fly Ash Sulphuric Activation for Cadmium Ions Removal. Materials 2020, 13, 3584. https://doi.org/10.3390/ma13163584

Buema G, Lupu N, Chiriac H, Roman T, Porcescu M, Ciobanu G, Burghila DV, Harja M. Eco-Friendly Materials Obtained by Fly Ash Sulphuric Activation for Cadmium Ions Removal. Materials. 2020; 13(16):3584. https://doi.org/10.3390/ma13163584

Chicago/Turabian StyleBuema, Gabriela, Nicoleta Lupu, Horia Chiriac, Tiberiu Roman, Marieta Porcescu, Gabriela Ciobanu, Daniela Vasilica Burghila, and Maria Harja. 2020. "Eco-Friendly Materials Obtained by Fly Ash Sulphuric Activation for Cadmium Ions Removal" Materials 13, no. 16: 3584. https://doi.org/10.3390/ma13163584