Fabrication and Characterization of Sn-Based Babbitt Alloy Nanocomposite Reinforced with Al2O3 Nanoparticles/Carbon Steel Bimetallic Material

Abstract

:1. Introduction

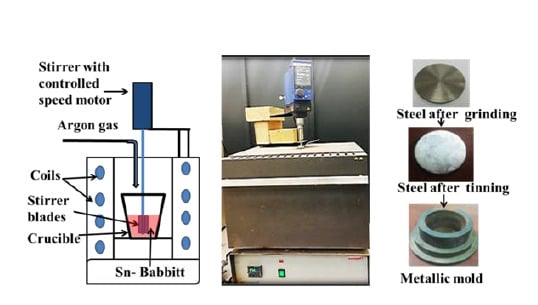

2. Materials and Methods

3. Results

3.1. Microstructure of Reinforced Sn-based Babbitt Alloy and Bimetal Interface

3.2. Mechanical Properties of Reinforced Sn-based Babbitt Alloy and Bimetal Interface

3.3. Wear Properties of Reinforced Sn-based Babbitt Alloy

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gebretsadik, D.W.; Hardell, J.; Prakash, B. Tribological performance of tin-based overlay plated engine bearing materials. Tribol. Int. 2015, 92, 281–289. [Google Scholar] [CrossRef]

- Ünlü, B. Determination of the tribological and mechanical properties of SnPbCuSb (white metal) bearings. Mater. Sci. 2011, 46, 478–485. [Google Scholar] [CrossRef]

- Leszczyńska-Madej, B.; Madej, M. The Tribological Properties and the Microstructure Investigations of Tin Babbit with Pb Addition after Heat Treatment. Arch. Metall. Mater. 2016, 61. [Google Scholar] [CrossRef]

- Khan, M.; Zulfaqar, M.; Ali, F.; Subhani, T. Microstructural and mechanical characterization of hybrid aluminum matrix composite containing boron carbide and Al-Cu-Fe quasicrystals. Met. Mater. Int. 2017, 23, 813–822. [Google Scholar] [CrossRef]

- Khan, M.; Amjad, M.; Khan, A.; Ud-Din, R.; Ahmad, I.; Subhani, T. Microstructural evolution, mechanical profile, and fracture morphology of aluminum matrix composites containing graphene nanoplatelets. J. Mater. Res. 2017, 32, 2055–2066. [Google Scholar] [CrossRef]

- Alghamdi, A.; Ramadan, M.; Abdel-Halim, K.; Fathy, N. Microscopical Characterization of Cast Hypereutectic Al-Si Alloys Reinforced with Graphene Nanosheets. Eng. Technol. Appl. Sci. Res. 2018, 8, 2514–2519. [Google Scholar]

- Khurram, A.A.; Khan, A.; Gul, I.H.; Subhani, T. Glass Fiber Epoxy Matrix Composites Containing Zero and Two Dimensional Carbonaceous Nanoreinforcements. Polym. Compos. 2018, 39, E2056–E2063. [Google Scholar] [CrossRef]

- Asghar, Z.; Latif, M.A.; Rafi ud, D.; Nazar, Z.; Ali, F.; Basit, A.; Badshah, S.; Subhani, T. Effect of distribution of B4C on the mechanical behaviour of Al-6061/B4C composite. Powder Metall. 2018, 61, 293–300. [Google Scholar] [CrossRef]

- Subhani, T.; Latif, M.; Ahmad, I.; Rakha, S.A.; Ali, N.; Khurram, A.A. Mechanical performance of epoxy matrix hybrid nanocomposites containing carbon nanotubes and nanodiamonds. Mater. Des. 2015, 87, 436–444. [Google Scholar] [CrossRef]

- Subhani, T.; Shaukat, B.; Ali, N.; Khurram, A.A. Toward improved mechanical performance of multiscale carbon fiber and carbon nanotube epoxy composites. Polym. Compos. 2017, 38, 1519–1528. [Google Scholar] [CrossRef]

- Ahmad, M.S.; Subhani, T. Thermal and ablative properties of binary carbon nanotube and nanodiamond reinforced carbon fibre epoxy matrix composites. Plast. Rubber Compos. 2015, 44, 397–404. [Google Scholar] [CrossRef]

- Ahmad, I.; Subhani, T.; Wang, N.; Zhu, Y. Thermophysical Properties of High-Frequency Induction Heat Sintered Graphene Nanoplatelets/Alumina Ceramic Functional Nanocomposites. J. Mater. Eng. Perform. 2018, 27, 2949–2959. [Google Scholar] [CrossRef]

- Khan, M.; Zulfaqar, M.; Ali, F.; Subhani, T. Hybrid aluminium matrix composites containing boron carbide and quasicrystals: Manufacturing and characterisation. Mater. Sci. Technol. 2017, 33, 1955–1963. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Aziz, T.; Shahzad, M.; Naveed, K.; Subhani, T. Effect of inter-cavity spacing in friction stir processed Al 5083 composites containing carbon nanotubes and boron carbide particles. J. Mater. Process. Technol. 2018, 253, 72–85. [Google Scholar] [CrossRef]

- Aleshin, N.; Kobernik, N.; Mikheev, R.; Vaganov, V.; Reshetniak, V.; Aborkin, A. Plasma–powder application of antifrictional babbitt coatings modified by carbon nanotubes. Russ. Eng. Res. 2016, 36, 46–52. [Google Scholar] [CrossRef]

- Ramadan, M.; Ayadi, B.; Rajhi, W.M.A.; Alghamdi, A. Influence of Tinning Material on Interfacial Microstructures and Mechanical Properties of Al-Sn /Carbon Steel Bimetallic Castings for Bearing Applications. Key Eng. Mater. 2020, 835, 108–114. [Google Scholar] [CrossRef]

- Koutský, J.; Veselá, J. Evaluation of white metal adhesion (conventional casting and thermal wire arc spraying) by ultrasonic non-destructive method. J. Mater. Process. Technol. 2004, 157–158, 724–728. [Google Scholar]

- Barykin, N.; Sadykov, F.; Aslanian, I. Wear and failure of babbit bushes in steam turbine sliding bearings. J. Mater. Eng. Perform. 2000, 9, 110–115. [Google Scholar] [CrossRef]

- Sadykov, F.A.; Barykin, N.P.; Valeev, I.S.; Danilenko, V.N. Influence of the structural state on mechanical behavior of tin babbit. J. Mater. Eng. Perform. 2003, 12, 29–36. [Google Scholar] [CrossRef]

- Dean, R.R.; Evans, C.J. Plain bearing materials: The role of tin. Tribol. Int. 1976, 9, 101–108. [Google Scholar] [CrossRef]

- Pratt, G.C. Materials for plain bearings. Int. Metall. Rev. 1973, 18, 62–88. [Google Scholar] [CrossRef]

- Moazami Goudarzi, M.; Jenabali Jahromi, S.A.; Nazarboland, A. Investigation of characteristics of tin-based white metals as a bearing material. Mater. Des. 2009, 30, 2283–2288. [Google Scholar] [CrossRef]

- Choi, H.; Konishi, H.; Li, X. Al2O3 nanoparticles induced simultaneous refinement and modification of primary and eutectic Si particles in hypereutectic Al–20Si alloy. Mater. Sci. Eng. A 2012, 541, 159–165. [Google Scholar] [CrossRef]

- Algarín, D.F.; Marrero, R.; Li, X.; Choi, H.; Suárez, O.M. Strengthening of aluminum wires treated with A206/alumina nanocomposites. Materials 2018, 11, 413. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dieringa, H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 2010, 46, 289–306. [Google Scholar] [CrossRef]

- El Mahallawi, I.; Shash, A.; Amer, A. Nanoreinforced cast Al-Si alloys with Al2O3, TiO2 and ZrO2 nanoparticles. J. Met. 2015, 2015, 802–821. [Google Scholar] [CrossRef] [Green Version]

- Scattergood, R.O.; Koch, C.C.; Murty, K.L.; Brenner, D. Strengthening mechanisms in nanocrystalline alloys. Mater. Sci. Eng. A 2008, 493, 3–11. [Google Scholar] [CrossRef]

| Materials | Chemical Compositions (wt.%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sb | Cu | Pb | C | Si | Mn | Cr | Sn | Fe | |

| Tin Babbitt Alloy | 6.5–7.5 | 2.5–3.5 | 0.35 | - | - | - | - | Bal. | |

| Carbon Steel | - | 0.20 | - | 0.14 | 0.30 | 0.48 | 0.14 | - | Bal. |

| S/N | Composition | Sn-Babbitt Zone | Interface Zone | |

|---|---|---|---|---|

| Tensile Strength, MPa | Hardness, HV | Shear Strength, MPa | ||

| 1 | Sn-Babbitt/steel bimetal | 56 ± 5.6 | 19.5 ± 1.08 | 27.2 ± 1.36 |

| 2 | Sn-Babbitt + 0.25% Al2O3 nanoparticles/steel bimetal | 65 ± 6.5 | 22.5 ± 1.13 | 29.9 ± 1.50 |

| 3 | Sn-Babbitt + 0.50% Al2O3 nanoparticles/steel bimetal | 68 ± 6.8 | 24.0 ± 1.13 | 30.6 ± 1.53 |

| 4 | Sn-Babbitt + 1.00% Al2O3 nanoparticles/steel bimetal | 63 ± 6.3 | 21.6 ± 1.08 | 27.7 ± 1.39 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramadan, M.; Alghamdi, A.S.; Subhani, T.; Halim, K.S.A. Fabrication and Characterization of Sn-Based Babbitt Alloy Nanocomposite Reinforced with Al2O3 Nanoparticles/Carbon Steel Bimetallic Material. Materials 2020, 13, 2759. https://doi.org/10.3390/ma13122759

Ramadan M, Alghamdi AS, Subhani T, Halim KSA. Fabrication and Characterization of Sn-Based Babbitt Alloy Nanocomposite Reinforced with Al2O3 Nanoparticles/Carbon Steel Bimetallic Material. Materials. 2020; 13(12):2759. https://doi.org/10.3390/ma13122759

Chicago/Turabian StyleRamadan, Mohamed, Abdulaziz S. Alghamdi, Tayyab Subhani, and K. S. Abdel Halim. 2020. "Fabrication and Characterization of Sn-Based Babbitt Alloy Nanocomposite Reinforced with Al2O3 Nanoparticles/Carbon Steel Bimetallic Material" Materials 13, no. 12: 2759. https://doi.org/10.3390/ma13122759