Enhancing Mechanical Properties of the Spark Plasma Sintered Inconel 718 Alloy by Controlling the Nano-Scale Precipitations

Abstract

:1. Introduction

2. Experimental Procedures

3. Results

3.1. Microstructure of the IN718 Powder and the SPS IN718 Alloys

3.2. XRD Analysis

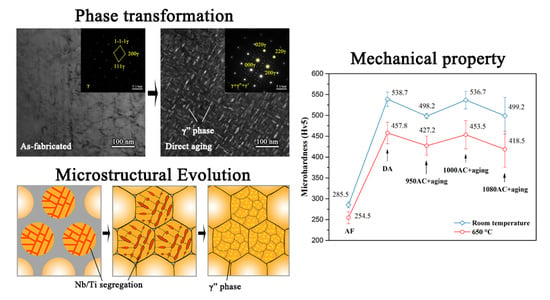

3.3. TEM Observation of the SPS IN718 Alloys

3.4. Mechanical Properties

3.4.1. Vickers Hardness

3.4.2. Compressive Properties

4. Discussion

4.1. The Precipitating Mechanisms of γ”/γ’ in the DA Condition

4.2. The Relations of the Microstructure and Mechanical Properties

4.3. Microstructural Evolution during SPS and Heat Treatment

5. Conclusions

- Direct aging promotes the full precipitation of γ”/γ’ phases and reduces the heat treatment steps, which is considered as the optimal heat treatment regime for the SPS-fabricated IN718 alloy. Compared with the samples heat-treated by the standard route of as-cast IN718, both hardness and compressive properties of the DA samples showed obvious enhancement.

- The microstructural evolution of the SPS IN718 was ascribed to the reduction of elemental segregation during SPS and heat treatment. The post-sintering heat treatment tailored the phase compositions in the alloy, and thus mechanical properties were enhanced by this method. The SPS IN718 alloys exhibited excellent high-temperature resistance at 650 °C.

- In addition, the method provided herein is an efficient and economic process for enhancing the mechanical properties of the SPS IN718 alloy, which was achieved by the direct aging regime. The DA samples have comparable strength with the best one of the solution-treated and aged samples. The approach can provide potential guidance for improving mechanical properties in other precipitation strengthening alloys by excluding the energy-intensive solution treatment.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, L.; Gong, X.; Ye, X.; Teng, J.; Nie, Y.; Li, Y.; Lei, Q. Influence of Building Direction on the Oxidation Behavior of Inconel 718 Alloy Fabricated by Additive Manufacture of Electron Beam Melting. Materials 2018, 11, 2549. [Google Scholar] [CrossRef] [PubMed]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef] [Green Version]

- Hua, Y.; Liu, Z. Experimental Investigation of Principal Residual Stress and Fatigue Performance for Turned Nickel-Based Superalloy Inconel 718. Materials 2018, 11, 879. [Google Scholar] [CrossRef] [PubMed]

- Calandri, M.; Manfredi, D.; Calignano, F.; Ambrosio, E.P.; Biamino, S.; Lupoi, R.; Ugues, D. Solution Treatment Study of Inconel 718 Produced by SLM Additive Technique in View of the Oxidation Resistance. Adv. Eng. Mater. 2018, 20, 1800351. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Guo, Q.; Li, H.; Liu, Y. Deformation Mechanism of L12-γ′ Phase in Bimodal γ″-γ′ Precipitation Hardened Inconel 718 Superalloy. Adv. Eng. Mater. 2018, 20, 1800652. [Google Scholar] [CrossRef]

- Ma, W.; Xie, Y.; Chen, C.; Fukanuma, H.; Wang, J.; Ren, Z.; Huang, R. Microstructural and mechanical properties of high-performance Inconel 718 alloy by cold spraying. J. Alloys Compd. 2019, 792, 456–467. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yin, L.-X.; Luo, S.-C.; He, D.-G.; Peng, X.-B. Effects of Initial δ Phase on Creep Behaviors and Fracture Characteristics of a Nickel-Based Superalloy. Adv. Eng. Mater. 2018, 20, 1700820. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Liu, Y.; Guo, Q.; Huang, Y.; Li, H.; Yu, J. Effect of hot deformation on γ″ and δ phase precipitation of Inconel 718 alloy during deformation&isothermal treatment. J. Alloys Compd. 2017, 716, 65–72. [Google Scholar]

- Sano, K.; Oono, N.; Ukai, S.; Hayashi, S.; Inoue, T.; Yamashita, S.; Yoshitake, T. γ″-Ni3Nb precipitate in Fe–Ni base alloy. J. Nucl. Mater. 2013, 442, 389–393. [Google Scholar] [CrossRef]

- Lyu, F.; Liu, F.; Hu, X.; Yang, X.; Huang, C.; Shi, D. The delta Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming. Materials 2019, 12, 2604. [Google Scholar] [CrossRef]

- Nunes, R.M.; Pereira, D.; Clarke, T.; Hirsch, T.K. Delta Phase Characterization in Inconel 718 Alloys Through X-ray Diffraction. ISIJ Int. 2015, 55, 2450–2454. [Google Scholar] [CrossRef] [Green Version]

- Deng, D.; Moverare, J.; Peng, R.L.; Söderberg, H. Microstructure and anisotropic mechanical properties of EBM manufactured Inconel 718 and effects of post heat treatments. Mater. Sci. Eng. A 2017, 693, 151–163. [Google Scholar] [CrossRef]

- Zhang, D.; Feng, Z.; Wang, C.; Wang, W.; Liu, Z.; Niu, W. Comparison of microstructures and mechanical properties of Inconel 718 alloy processed by selective laser melting and casting. Mater. Sci. Eng. A 2018, 724, 357–367. [Google Scholar] [CrossRef]

- Huang, W.; Yang, J.; Yang, H.; Jing, G.; Wang, Z.; Zeng, X. Heat treatment of Inconel 718 produced by selective laser melting: Microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 750, 98–107. [Google Scholar] [CrossRef]

- Yan, S.; Wang, Q.; Chen, X.; Zhang, C.; Cui, G. Fabrication of highly compact Inconel 718 alloy by spark plasma sintering and solution treatment followed by aging. Vacuum 2019, 163, 194–203. [Google Scholar] [CrossRef]

- Elissalde, C.; Chung, U.C.; Josse, M.; Goglio, G.; Suchomel, M.R.; Majimel, J.; Weibel, A.; Soubie, F.; Flaureau, A.; Fregeac, A.; et al. Single-step sintering of zirconia ceramics using hydroxide precursors and Spark Plasma Sintering below 400 °C. Scr. Mater. 2019, 168, 134–138. [Google Scholar] [CrossRef]

- Olevsky, E.A.; Froyen, L. Impact of Thermal Diffusion on Densification During SPS. J. Am. Ceram. Soc. 2009, 92, S122–S132. [Google Scholar] [CrossRef]

- Chang, L.; Sun, W.; Cui, Y.; Zhang, F.; Yang, R. Effect of heat treatment on microstructure and mechanical properties of the hot-isostatic-pressed Inconel 718 powder compact. J. Alloys Compd. 2014, 590, 227–232. [Google Scholar] [CrossRef]

- Wan, H.-Y.; Zhou, Z.-J.; Li, C.-P.; Chen, G.-F.; Zhang, G.-P. Enhancing Fatigue Strength of Selective Laser Melting-Fabricated Inconel 718 by Tailoring Heat Treatment Route. Adv. Eng. Mater. 2018, 20, 1800307. [Google Scholar] [CrossRef]

- Wang, L.Y.; Zhou, Z.J.; Li, C.P.; Chen, G.F.; Zhang, G.P. Comparative investigation of small punch creep resistance of Inconel 718 fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 745, 31–38. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.F.; Zhang, D.L.; Zhang, Y.S.; Lu, J.W.; Zhang, W.; Zhang, P.X. Fabrication of a powder metallurgy Ti2AlNb-based alloy by spark plasma sintering and associated microstructure optimization. Mater. Des. 2016, 89, 823–829. [Google Scholar] [CrossRef]

- Chua, A.S.; Brochu, M.; Bishop, D.P. Spark plasma sintering of prealloyed aluminium powders. Powder Metall. 2015, 58, 51–60. [Google Scholar] [CrossRef]

- Mahathaninwong, N.; Plookphol, T.; Wannasin, J.; Wisutmethangoon, S. T6 heat treatment of rheocasting 7075 Al alloy. Mater. Sci. Eng. A 2012, 532, 91–99. [Google Scholar] [CrossRef]

- Mondet, M.; Barraud, E.; Lemonnier, S.; Allain, N.; Grosdidier, T. Optimisation of the mechanical properties of a Spark Plasma Sintered (SPS) magnesium alloy through a post-sintering in-situ precipitation treatment. J. Alloys Compd. 2017, 698, 259–266. [Google Scholar] [CrossRef]

- Ma, S.; Yang, Y.; Li, A.; Zhou, S.; Shi, L.; Wang, S.; Liu, M. Effects of temperature on microstructure and mechanical properties of IN718 reinforced by reduced graphene oxide through spark plasma sintering. J. Alloys Compd. 2018, 767, 675–681. [Google Scholar] [CrossRef]

- AMS Standard 5663, Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, and Rings; SAE International Aerospace: New York, NY, USA, 2004.

- ASTM Standard E9-89a(2000), Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature; ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM Standard E112, Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 2012.

- Anderson, M.; Thielin, A.L.; Bridier, F.; Bocher, P.; Savoie, J. δ Phase precipitation in Inconel 718 and associated mechanical properties. Mater. Sci. Eng. A 2017, 679, 48–55. [Google Scholar] [CrossRef]

- Strondl, A.; Fischer, R.; Frommeyer, G.; Schneider, A. Investigations of MX and γ′/γ″ precipitates in the nickel-based superalloy 718 produced by electron beam melting. Mater. Sci. Eng. A 2008, 480, 138–147. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; pp. 55–65. [Google Scholar]

- PeakFit® 4.0 for Windows® User’s Manual; SPSS Inc.: Chicago, IL, USA, 1997.

- Özgün, Ö.; Gülsoy, H.Ö.; Findik, F.; Yilmaz, R. Microstructure and mechanical properties of injection moulded Nimonic-90 superalloy parts. Powder Metall. 2012, 55, 405–414. [Google Scholar] [CrossRef]

- Özgün, Ö.; Özkan Gülsoy, H.; Yilmaz, R.; Findik, F. Injection molding of nickel based 625 superalloy: Sintering, heat treatment, microstructure and mechanical properties. J. Alloys Compd. 2013, 546, 192–207. [Google Scholar] [CrossRef]

- Singh, S.S.; Williams, J.J.; Stannard, T.J.; Xiao, X.; Carlo, F.D.; Chawla, N. Measurement of localized corrosion rates at inclusion particles in AA7075 by in situ three dimensional (3D) X-ray synchrotron tomography. Corros. Sci. 2016, 104, 330–335. [Google Scholar] [CrossRef]

- Li, X.; Shi, J.J.; Wang, C.H.; Cao, G.H.; Russell, A.M.; Zhou, Z.J.; Li, C.P.; Chen, G.F. Effect of heat treatment on microstructure evolution of Inconel 718 alloy fabricated by selective laser melting. J. Alloys Compd. 2018, 764, 639–649. [Google Scholar] [CrossRef]

- Cao, G.H.; Sun, T.Y.; Wang, C.H.; Li, X.; Liu, M.; Zhang, Z.X.; Hu, P.F.; Russell, A.M.; Schneider, R.; Gerthsen, D.; et al. Investigations of γ′, γ″ and δ precipitates in heat-treated Inconel 718 alloy fabricated by selective laser melting. Mater. Charact. 2018, 136, 398–406. [Google Scholar] [CrossRef]

- Özgün, Ö.; Gülsoy, H.Ö.; Yılmaz, R.; Fındık, F. Microstructural and mechanical characterization of injection molded 718 superalloy powders. J. Alloys Compd. 2013, 576, 140–153. [Google Scholar] [CrossRef]

- You, X.; Tan, Y.; Zhao, L.; You, Q.; Wang, Y.; Ye, F.; Li, J. Effect of solution heat treatment on microstructure and electrochemical behavior of electron beam smelted Inconel 718 superalloy. J. Alloys Compd. 2018, 741, 792–803. [Google Scholar] [CrossRef]

- You, X.; Tan, Y.; Shi, S.; Yang, J.-M.; Wang, Y.; Li, J.; You, Q. Effect of solution heat treatment on the precipitation behavior and strengthening mechanisms of electron beam smelted Inconel 718 superalloy. Mater. Sci. Eng. A 2017, 689, 257–268. [Google Scholar] [CrossRef]

- Oradei-Basile, A.; Radavich, J.F. Superalloys 718, 625, 706 and Derivatives; The Minerals, Metals &Materials Society: Warrendale, PA, USA, 2005; p. 325. [Google Scholar]

- Chang, L.; Sun, W.; Cui, Y.; Yang, R. Influences of hot-isostatic-pressing temperature on microstructure, tensile properties and tensile fracture mode of Inconel 718 powder compact. Mater. Sci. Eng. A 2014, 599, 186–195. [Google Scholar] [CrossRef]

- Goel, S.; Sittiho, A.; Charit, I.; Klement, U.; Joshi, S. Effect of post-treatments under hot isostatic pressure on microstructural characteristics of EBM-built Alloy 718. Addit. Manuf. 2019, 28, 727–737. [Google Scholar] [CrossRef]

- Azadian, S.; Wei, L.-Y.; Warren, R. Delta phase precipitation in Inconel 718. Mater. Charact. 2004, 53, 7–16. [Google Scholar] [CrossRef]

- Raghavan, S.; Zhang, B.; Wang, P.; Sun, C.-N.; Nai, M.L.S.; Li, T.; Wei, J. Effect of different heat treatments on the microstructure and mechanical properties in selective laser melted INCONEL 718 alloy. Mater. Manuf. Processes 2017, 32, 1588–1595. [Google Scholar] [CrossRef]

- Liu, L.; Tanaka, K.; Hirose, A.; Kobayashi, K.F. Effects of precipitation phases on the hydrogen embrittlement sensitivity of Inconel 718. Sci. Technol. Adv. Mater. 2002, 3, 335–344. [Google Scholar] [CrossRef] [Green Version]

- Kuo, Y.-L.; Horikawa, S.; Kakehi, K. The effect of interdendritic δ phase on the mechanical properties of Alloy 718 built up by additive manufacturing. Mater. Des. 2017, 116, 411–418. [Google Scholar] [CrossRef]

- Strößner, J.; Terock, M.; Glatzel, U. Mechanical and Microstructural Investigation of Nickel-Based Superalloy IN718 Manufactured by Selective Laser Melting (SLM). Adv. Eng. Mater. 2015, 17, 1099–1105. [Google Scholar] [CrossRef]

- Chlebus, E.; Gruber, K.; Kuźnicka, B.; Kurzac, J.; Kurzynowski, T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A 2015, 639, 647–655. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Nb | Mo | Ti | Al | Co | Mn | Si | Cu | C | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 54.28 | 17.97 | 5.12 | 3.00 | 0.98 | 0.57 | 0.21 | 0.09 | 0.077 | 0.069 | 0.024 | Bal. |

| Heat Treatment | Direct aging | 950AC+aging | 1000AC+aging | 1080AC+aging |

|---|---|---|---|---|

| aγ | 0.35907 | 0.36019 | 0.36163 | 0.36166 |

| aγ’ | 0.35904 | 0.35899 | 0.36097 | 0.36044 |

| aγ’’ | 0.35761 | 0.35874 | 0.35877 | 0.35882 |

| cγ’’ | 0.71648 | 0.71834 | 0.71983 | 0.71821 |

| δγ/γ’ | 0.08412 | 0.33384 | 0.18254 | 0.33868 |

| δγ/γ’’ | 0.32121 | 0.34511 | 0.63827 | 0.75209 |

| Samples | σ0.2 (MPa) | σb (MPa) | Young’s Modulus (GPa) | Density (g·cm−3) | Relative Density (%) |

|---|---|---|---|---|---|

| As-fabricated | 419 | - | 13.83 | 7.66 | 93 |

| DA | 1454 | 3626 | 27.50 | 8.07 | 98 |

| 950AC+aging | 1349 | 3100 | 24.80 | 8.15 | 99 |

| 1000AC+aging | 1463 | 3666 | 26.55 | 8.16 | 99 |

| 1080AC+aging | 1350 | 3303 | 26.18 | 8.20 | 99 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, S.; Wang, Y.; Wang, Q.; Zhang, C.; Chen, D.; Cui, G. Enhancing Mechanical Properties of the Spark Plasma Sintered Inconel 718 Alloy by Controlling the Nano-Scale Precipitations. Materials 2019, 12, 3336. https://doi.org/10.3390/ma12203336

Yan S, Wang Y, Wang Q, Zhang C, Chen D, Cui G. Enhancing Mechanical Properties of the Spark Plasma Sintered Inconel 718 Alloy by Controlling the Nano-Scale Precipitations. Materials. 2019; 12(20):3336. https://doi.org/10.3390/ma12203336

Chicago/Turabian StyleYan, Shuaijiang, Yun Wang, Qingxiang Wang, Chengsong Zhang, Dazhi Chen, and Guodong Cui. 2019. "Enhancing Mechanical Properties of the Spark Plasma Sintered Inconel 718 Alloy by Controlling the Nano-Scale Precipitations" Materials 12, no. 20: 3336. https://doi.org/10.3390/ma12203336