Parametric Optimization of Ferrite Structure Used for Dynamic Wireless Power Transfer for 3 kW Electric Vehicle

Abstract

:1. Introduction

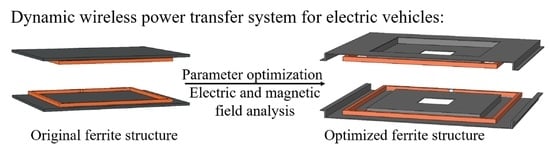

2. Dynamic Wireless Power Transfer System

2.1. General Description

2.2. Studied DWPT System

3. Ferrite Core Optimization

3.1. Variation of the External Dimensions of the Ferrite Plate

3.2. Thickness Variation of the Ferrite Plate

3.3. Hole in the Central Part of the Ferrite Plate

3.4. Inner Square Boss of the Ferrite Plate

3.5. Bosses at the Edge of the Ferrite Plate

3.6. Optimized Structure

4. Discussion

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Economic and Environmental Sustainability of Dynamic Wireless Power Transfer for Electric Vehicles Supporting Reduction of Local Air Pollutant Emissions—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S1364032120308212 (accessed on 7 July 2023).

- Kadem, K. Modélisation et Optimisation d’un Coupleur Magnétique Pour la Recharge par Induction Dynamique des Véhicules électriques. Ph.D. Thesis, Université Paris-Saclay, Paris, France, 2020. Available online: https://hal.science/view/index/identifiant/tel-03253967 (accessed on 16 July 2023).

- Coca, E. (Ed.) Wireless Power Transfer—Fundamentals and Technologies; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef]

- Mohamed, A.A.S.; Shaier, A.A.; Metwally, H.; Selem, S.I. An Overview of Dynamic Inductive Charging for Electric Vehicles. Energies 2022, 15, 5613. [Google Scholar] [CrossRef]

- Budhia, M.; Covic, G.; Boys, J. A New IPT Magnetic Coupler for Electric Vehicle Charging Systems. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 2487–2492. [Google Scholar]

- Budhia, M.; Boys, J.T.; Covic, G.A.; Huang, C.-Y. Development of a Single-Sided Flux Magnetic Coupler for Electric Vehicle IPT Charging Systems. IEEE Trans. Ind. Electron. 2013, 60, 318–328. [Google Scholar] [CrossRef]

- European Commission. Wireless Charging for Electic Vehicles. UNPLUGGED Project|FP7|CORDIS. Available online: https://cordis.europa.eu/project/id/314126 (accessed on 22 February 2021).

- Benders, B.; Vermaat, P.; Bludszuweit, H.B.; Theodoropoulos, T. Interoperability Considerations. Available online: http://www.fabric-project.eu/www.fabric-project.eu/images/Deliverables/FABRIC_D33.3_Interoperability_considerations_2017_update.pdf (accessed on 20 July 2020).

- Jayalath, S.; Khan, A. Design, Challenges, and Trends of Inductive Power Transfer Couplers for Electric Vehicles: A Review. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 6196–6218. [Google Scholar] [CrossRef]

- Ahmad, A.; Alam, M.S.; Chabaan, R. A Comprehensive Review of Wireless Charging Technologies for Electric Vehicles. IEEE Trans. Transp. Electrif. 2018, 4, 38–63. [Google Scholar] [CrossRef]

- Thai, V.X.; Choi, S.Y.; Choi, B.H.; Kim, J.H.; Rim, C.T. Coreless power supply rails compatible with both stationary and dynamic charging of electric vehicles. In Proceedings of the 2015 IEEE 2nd International Future Energy Electronics Conference (IFEEC), Taipei, Taiwan, 1–4 November 2015; pp. 1–5. [Google Scholar]

- Miller, J.M.; Scudiere, M.B.; McKeever, J.W.; White, C. Wireless power transfer. In Proceedings of the Oak Ridge National Laboratery’s Power Electronics Symposium, Singapore, 5–8 December 2011. [Google Scholar]

- COMSOL. Software for Simulating Static and Low-Frequency Electromagnetics. Available online: https://www.comsol.com/acdc-module (accessed on 29 January 2022).

- Ibrahim, M. Wireless Inductive Charging for Electrical Vehicles: Electromagnetic Modelling and Interoperability Analysis. Ph.D. Thesis, Université Paris Sud, Paris, France, 2014. Available online: https://theses.hal.science/tel-01127163/document (accessed on 12 July 2023).

- Kadem, K.; Cheriet, F.; Laboure, E.; Bensetti, M.; Le Bihan, Y.; Debbou, M. Sensorless Vehicle Detection for Dynamic Wireless Power Transfer. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications (EPE ’19 ECCE Europe), Genova, Italy, 2–5 September 2019; pp. 1–6. [Google Scholar]

- SAE International. Wireless Power Transfer for Light-Duty Plug-In/Electric Vehicles and Alignment Methodology; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- International Electrotechnical Commission. Electric Vehicle Wireless Power Transfer (WPT) Systems—Part 1: General Requirements; International Electrotechnical Commission: Geneva, Switzerland, 2019. [Google Scholar]

- International Organization for Standardization. Electrically Propelled Road Vehicles—Magnetic Field Wireless Power Transfer—Safety and Interoperability Requirements; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- International Electrotechnical Commission. Interoperability and Safety of Dynamic Wireless Power Transfer (WPT) for Electric Vehicles; International Electrotechnical Commission: Geneva, Switzerland, 2021. [Google Scholar]

- Debbou, M.; Colet, F.; Kadem, K. Wireless Inductive Power Transfer: Design and Control for an Optimal Operation. In Proceedings of the 2018 20th European Conference on Power Electronics and Applications (EPE’18 ECCE Europe), Riga, Latvia, 17–21 September 2018; pp. 1–8. [Google Scholar]

- Kadem, K.; Benyoubi, F.; Bensetti, M.; Bihan, Y.L.; Labouré, E.; Debbou, M. An Efficient Method for Dimensioning Magnetic Shielding for an Induction Electric Vehicle Charging System. Prog. Electromagn. Res. 2021, 170, 153–167. [Google Scholar] [CrossRef]

- Kadem, K.; Bensetti, M.; Le Bihan, Y.; Labouré, E.; Debbou, M. Optimal Coupler Topology for Dynamic Wireless Power Transfer for Electric Vehicle. Energies 2021, 14, 3983. [Google Scholar] [CrossRef]

- Robert, W.E.; Dragan, M. Fundamentals of Power Electronics, 2nd ed.; Springer: New York, NY, USA, 2001. [Google Scholar]

- Boys, J.T.; Covic, G.A. IPT Fact Sheet Series: No. 2 Magnetic Circuits for Powering Electric Vehicles. 2014. Available online: https://www.qualcomm.com/content/dam/qcomm-martech/dm-assets/documents/ipt_fact_sheet_2_-_uoa_2014.pdf (accessed on 16 July 2023).

- COMSOL. Documentation. Available online: https://doc.comsol.com/6.1/docserver/#!/com.comsol.help.acdc/acdc_ug_theory.05.51.html (accessed on 7 July 2023).

- FERROXCUBE. 3C95 Material Specification. Available online: https://www.ferroxcube.com/upload/media/product/file/MDS/3c95.pdf (accessed on 16 July 2023).

- TDK. N27 Ferrite Datasheet. Available online: https://www.tdk-electronics.tdk.com/download/528850/3a7f957d754f899aec42cd946598c5c4/pdf-n27.pdf (accessed on 16 July 2023).

- Elghanam, E.A.; Kabalan, H.H.; Hassan, M.S.; Osman, A. Design and Modeling of Ferrite Core Geometry for Inductive Wireless Chargers of Electric Vehicles. In Proceedings of the 2019 International Conference on Electrical and Computing Technologies and Applications (ICECTA), Ras Al Khaimah, United Arab Emirates, 19–21 November 2019; pp. 1–5. [Google Scholar]

- Hu, M.; Madawala, U.K.; Baguley, C. The Optimal Placement of Ferrite in Inductive Power Transfer Coupling Pads. In Proceedings of the 2021 IEEE 12th Energy Conversion Congress & Exposition—Asia (ECCE—Asia), Singapore, 24–27 May 2021; pp. 469–474. [Google Scholar]

- Carretero, C.; Lope, I.; Acero, J. Magnetizable Concrete Flux Concentrators for Wireless Inductive Power Transfer Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 2696–2706. [Google Scholar] [CrossRef]

- Choi, B.-G.; Kim, Y.-S. New Structure Design of Ferrite Cores for Wireless Electric Vehicle Charging by Machine Learning. IEEE Trans. Ind. Electron. 2021, 68, 12162–12172. [Google Scholar] [CrossRef]

- Debbou, M.; Kadem, K.; Labouré, E.; Le Bihan, Y.; Bensetti, M. Inductive Coupler and Magnetic Induction Charging System for Electric and Hybrid Vehicles. FR3094832A1, WO2020208313A1. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2020208313 (accessed on 5 June 2023).

- Tel Aviv University Station. Available online: https://electreon.com/projects/tel-aviv (accessed on 11 June 2023).

- McFadden, C. A New Wireless EV Charging Road Is Currently under Construction in Germany. Available online: https://interestingengineering.com/innovation/germany-first-public-ev-charging (accessed on 11 June 2023).

- Zarazaga, S. Innovative Charging in Electric Vehicle Solutions to Be Tested in Europe; INCIT-EV Project. 2020. Available online: https://www.incit-ev.eu/news-title/ (accessed on 16 July 2023).

| Parameters | Values (Unit) |

|---|---|

| Air gap A | 150 (mm) |

| Ferrite thickness Deptf | 2 (mm) |

| Coil thickness Depc | 13 (mm) |

| Ferrite length Lf | 600 (mm) |

| Ferrite width Wf | 500 (mm) |

| Coil external length Lou | 468 (mm) |

| Coil internal length Lin | 442 (mm) |

| Ferrite Relative Permeability | Self-Inductance L (µH) | Mutual Inductance M (µH) | Coupling Coefficient K | Magnetic Flux Density on the Surface Center of the Secondary Pad (µT) |

|---|---|---|---|---|

| 0 (without ferrite) | 46.5 | 7.81 | 0.17 | 7.93 |

| 2000 | 63.7 | 13.4 | 0.21 | 3.18 |

| 3000 | 65.8 | 15.0 | 0.23 | 3.03 |

| Simulation | Self-Inductance L (µH) | Mutual Inductance M (µH) | Coupling Coefficient K |

|---|---|---|---|

| Original ferrite structure | 63.7 | 13.4 | 0.21 |

| Optimized ferrite structure | 72.5 | 18.9 | 0.26 |

| Experiment | Self-Inductance L (µH) | Mutual Inductance M (µH) | Coupling Coefficient K |

| Original ferrite structure | 58.5 | 12.1 | 0.20 |

| Optimized ferrite structure | 69.9 | 18.9 | 0.27 |

| Relative difference between the original and optimized ferrite structure | 16.3% | 36.0% | 25.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bensetti, M.; Kadem, K.; Pei, Y.; Le Bihan, Y.; Labouré, E.; Pichon, L. Parametric Optimization of Ferrite Structure Used for Dynamic Wireless Power Transfer for 3 kW Electric Vehicle. Energies 2023, 16, 5439. https://doi.org/10.3390/en16145439

Bensetti M, Kadem K, Pei Y, Le Bihan Y, Labouré E, Pichon L. Parametric Optimization of Ferrite Structure Used for Dynamic Wireless Power Transfer for 3 kW Electric Vehicle. Energies. 2023; 16(14):5439. https://doi.org/10.3390/en16145439

Chicago/Turabian StyleBensetti, Mohamed, Karim Kadem, Yao Pei, Yann Le Bihan, Eric Labouré, and Lionel Pichon. 2023. "Parametric Optimization of Ferrite Structure Used for Dynamic Wireless Power Transfer for 3 kW Electric Vehicle" Energies 16, no. 14: 5439. https://doi.org/10.3390/en16145439