The model developed in the previous section couples the analytical optical model (Equation (3)) to a simple conduction model that solves for the temperature distribution within the waveguide using commercial computational software. Verification of the analytical optical model predictions is critical to ensure model accuracy. To the authors’ knowledge, there is no investigation of the concept for concentrated solar thermal applications. Nevertheless, the optical model that was developed in this study was based on the methodology presented by Nithyanandam et al. [

22], which was verified through a comparison of the analytical results alongside the results that were obtained from the ray-tracing simulations performed using TracePro [

41]. In addition, the analytical solution obtained for

in Equation (3) is verified with physical consistency checks. For instance, if there is no volumetric absorption coefficient (

) in the waveguide, then it is expected that all of the incident irradiation (

) will be concentrated on the HCE, such that

. Starting from Equation (3) and defining

, it can be shown that the equation reduces to the following:

3.1. Parametric Analysis

Based on the models presented, the study first evaluates the influence of design parameters, namely, receiver radius

, absorption coefficient

, waveguide thickness

and waveguide length

, and operating parameters namely, incident irradiation

, HTF temperature

, on the steady-state temperature distribution. Further, the influence of HTF temperature

on net thermal power delivered

, maximum operating temperature

, and collection efficiency

are investigated at different values of

,

,

, and

. The gap between the waveguide and receiver (

) and the convective heat transfer coefficient of the HTF flow in the receiver (

) are considered to be 0.003 m and 500

, respectively. From the Dittus–Boelter equation [

30], the assumed convective heat transfer coefficient for thermal oil-based HTF flow in the receiver corresponds to a Reynolds number of ~15,000, which is typically observed in solar thermal systems [

42]. The value for absorptivity (

) of the receiver surface is considered as 0.95 [

21,

22]. The feasible design space for waveguide is dictated by the maximum allowable temperature in the waveguide due to irradiation absorption during operation. The maximum temperature in the waveguide will be observed when the convective heat transfer loss from the waveguide to the ambient is at its lowest. Hence, the value of forced convection heat transfer coefficient

from waveguide to ambient is assumed as 0 W/m

2-K to obtain a conservative design, as it represents the worst-case scenario in terms of the maximum temperature that occurs in the waveguide. The natural convection heat transfer coefficient from the planar horizontal waveguide to ambient (

) was obtained from the well-established correlation in the literature [

30] that evaluates to ~2.5 W/m

2-K. Further, the thermophysical properties of the two materials considered in the study, ZK7 and polycarbonate (PC), are given in

Table 1.

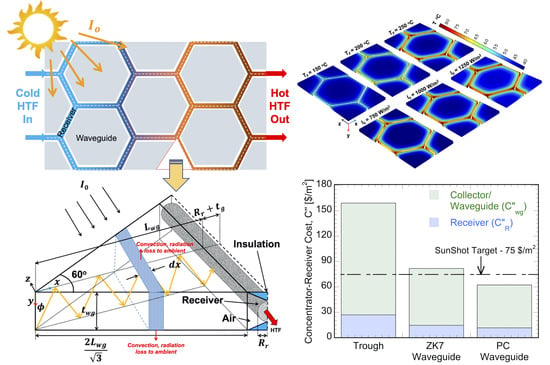

Figure 2 represents the temperature contours in a ZK7 hexagonal waveguide solar concentrator element at different

and

for

,

=

, and

. The maximum temperature within the waveguide is governed by volumetric heat generation rate, because of the incident solar irradiation absorption, HTF temperature that affects the heat exchange between the waveguide edge facing the HCE and the receiver pipe surface, and the heat loss to ambient in the form of convection and radiation (Equations (5) and (6)).

Figure 2a presents the temperature contour for

= 150

, 200

, and 250

at

. The temperature of the hexagonal waveguide solar concentrator is higher near the HTF tube as the HTF tube loses heat from its outer surface and transfers to the waveguide by convection and radiation. Consequently, the temperature of the waveguide increases with an increase in HTF temperature.

Figure 2b depicts the temperature contours of the waveguide at different

while considering

= 250

. The waveguide temperature increases with an increase in

, because higher incident solar irradiation leads to higher irradiation absorption and higher temperature excursion in the waveguide. The highest temperatures in the hexagonal waveguide (

) were observed at the corners, as seen in

Figure 2. These maximum values will limit the design of the optimal waveguide/receiver configurations as discussed later in this section.

Figure 3a–f present the effect of different operating and design factors on the spatial distribution of the temperature increase (

) inside the waveguide (ZK7 material). The non-dimensional distance is labeled as

, such that

= 0 represents the center and

represents the corner of the hexagonal waveguide, as sketched in

Figure 3e. The temperature increase is calculated at the mid-height (

) of the waveguide. The default values of

and

in

Figure 3 are 1000

, 250

, 0.02

, 1.4

, 0.025

, and 0.25

, respectively, unless specified otherwise. For all of the parameters, the temperature increase is the highest at the outer edge of the hexagon as compared to the center of the waveguide, because the waveguide is heated by the HTF receiver pipe.

Figure 3a demonstrates the effects of the incident solar irradiance on the temperature profile inside the waveguide concentrator. It is observed that an increase in the incident irradiation increases the magnitude of the steady-state temperature distribution in the waveguide solar concentrator, because the increase in ray absorption results in higher volumetric heat generation. The temperature rise for the solar radiation of 250 W/m

2 is nearly zero at the center of the waveguide because the heat generated due to irradiation absorption is compensated by the heat lost to the ambient.

Figure 3b presents the influence of HTF temperature on waveguide temperature rise. The temperature of the waveguide increases with an increase in HTF temperature, mirroring the trend shown in

Figure 2a. Further,

Figure 3c depicts the effects of the receiver radius on the temperature rise of the waveguide. The temperature of the waveguide rises with an increase in the receiver radius due to an increase in surface area that leads to enhanced heat transfer interaction between the HTF receiver pipe and waveguide. Further, the study has been conducted at five different absorption coefficient values, and

Figure 3d presents the obtained temperature rise. The increase in the absorption coefficient of waveguide materials leads to increased attenuation of rays and results in higher temperature rise, as contrasted with a lower absorption coefficient. For the absorption coefficient of 0.1

, the waveguide material absorbs a very small fraction of the incident radiation and, therefore, the temperature rise of the waveguide is negligible at the center of the waveguide. However, with an increase in the absorption coefficient, the operating temperature increases consistently. Furthermore, increase in waveguide thickness causes an increase in the temperature of the waveguide because of the increase in path length for the ray propagation that results in higher irradiation absorption, leading to higher operating temperature, as shown in

Figure 3e.

Figure 3f presents the influence of waveguide length on the temperature rise of the waveguide. The path length of solar rays to reach the receiver surface increases with an increase in waveguide length, which leads to increased absorption and results in a higher temperature rise within the waveguide (

Figure 3f). Although the temperature rise at the center of the waveguide for

m is higher than that obtained for

m, the maximum temperature rise that is observed at the corner for

m is higher than that observed for

(

Figure 3f).

Figure 3.

Influence of (a) incident solar radiation (), (b) HTF Temperature ( ), (c) Receiver radius (), (d) absorption coefficient (), (e) thickness of waveguide (), and (f) length of waveguide () on the spatial temperature rise distribution in a hexagonal waveguide solar concentrator.

Figure 3.

Influence of (a) incident solar radiation (), (b) HTF Temperature ( ), (c) Receiver radius (), (d) absorption coefficient (), (e) thickness of waveguide (), and (f) length of waveguide () on the spatial temperature rise distribution in a hexagonal waveguide solar concentrator.

Figure 4 presents the influence of HTF temperature on the net thermal power delivered and the maximum operating temperature of the waveguide for different parameters.

Figure 4a depicts the variation of net thermal power delivered and

with

for five different

. The maximum thermal power delivered (

) is obtained for the highest incident solar radiation i.e., 1250

because the total irradiation that reaches the end of the waveguide is directly proportional to

. The absorbed irradiation in the waveguide increases with an increase in

, resulting in higher volumetric heat generation and

in the waveguide. Further, the net thermal power delivered decreases with an increase in the HTF temperature because of higher heat loss from the HTF receiver pipe. In addition, the heat exchange between the HTF receiver pipe and waveguide also increases with an increase in

, which results in higher

. The increase in

with an increase in

can be observed in all of the plots depicted in

Figure 4.

Figure 4b presents the variation of net thermal power delivered and

with

for five different values of

. The net thermal power delivered decreases with an increase in both the HTF temperature and receiver radius. The increase in surface area with an increase in receiver pipe radius leads to higher heat loss from the receiver surface and subsequently, lower net thermal power delivery. Because part of the heat lost from the receiver surface interacts with the waveguide,

increases with an increase in receiver pipe radius (

Figure 4b). The difference in the temperature rise, as well as the net thermal power delivered between the different receiver radius, is small at a lower HTF temperature. This is explained by the decrease in temperature difference between the HTF receiver pipe, ambient air, and waveguide temperature, which limits the heat exchange. As expected, at higher HTF temperatures, the converse is observed, such that the differences in

and

are large (

Figure 4b).

Figure 4c presents the net thermal power delivered and

as functions of

for five different waveguide lengths. The smallest waveguide length delivered a very small amount of net thermal power to the HCE because of the smaller collection area for incident solar radiation. For

and

, a larger fraction of the collected irradiation in the waveguide is lost as heat to the ambient and, therefore, the net thermal power delivered is closer to zero, as shown in

Figure 4c. The maximum temperature of the waveguide increases with the length of the waveguide because of an increase in the path length of light rays in the waveguide that consequently increases the heat generation rate within the waveguide, owing to higher irradiation absorption.

Figure 4d shows the effect of waveguide thickness and HTF temperature on net thermal power delivered and the maximum waveguide temperature. The net thermal power delivered decreases while the maximum waveguide temperature increases with an increase in the waveguide thickness. This is attributed to the longer path length and higher absorption of total internally reflected light rays that result in lower thermal power output and higher waveguide temperature. Similar to that observed in

Figure 4c, at the lower HTF temperature, the difference between the net thermal power delivered for different waveguide thicknesses is minor; however, its value increases with an increase in the HTF temperature.

Figure 5 presents the variation in collection efficiency with the HTF temperature for different operating and geometrical parameters of the waveguide solar concentrator. The collection efficiency decreases with an increase in the HTF temperature for all parameters, because a higher HTF temperature results in higher heat loss from the receiver surface.

Figure 5a represents the variation of collection efficiency with HTF temperature for different incident solar radiation. The collection efficiency is higher for higher incident radiation as the thermal power transferred to the receiver from the waveguide increases with an increase in the intensity of incident solar radiation.

Figure 5b presents the effect of the receiver radius on collection efficiency. The collection efficiency is higher for a smaller radius of the waveguide because of lower conductive and radiative heat loss from the receiver surface.

Figure 5c presents the variation in collection efficiency with HTF temperature for different

. With an increase in the length of the waveguide from 0.25 m to 1 m, the collection efficiency decreases for all HTF temperature range due to an increase in ray absorption; however, this behavior is different for an increase in

from 0.1 m to 0.25 m. As expected, the collection efficiency is highest for

up to HTF temperature of 135

, however, beyond that, the collection efficiency decreases and reaches the lowest value at 250

HTF temperatures. At high temperatures, the heat loss from the receiver pipe increases and, since, for

, the solar collection area and the concentrated irradiation intensity are small, the net thermal power that is delivered to the HTF decreases drastically. For longer waveguides, the magnitude of the concentrated irradiation is much higher than the heat loss from the receiver that this phenomenon is not observed for the HTF temperature range studied here.

Figure 5d shows the effect of waveguide thickness on collection efficiency. The collection efficiency of the waveguide solar concentrator reduces with an increase in the waveguide thickness because of the higher absorption of incident solar radiation in the waveguide.

3.2. Design of Numerical Experiments

Figure 3,

Figure 4 and

Figure 5 present the effects of the different parameters on the waveguide temperature and thermal power delivered, by changing one parameter each time. It is of interest to understand the interactive effects of the different parameters on the power density and the maximum temperature waveguide, so as to design the waveguide concentrator for maximizing the power density while limiting the operating temperature to within acceptable values. To this end, an orthogonal array based design of experiments was conducted, from which a response surface was derived to obtain a functional relationship for the power density and the maximum temperature in terms of the governing parameters. For each waveguide material with its corresponding absorption coefficient (

) specified in

Table 1, a standard

orthogonal array constituting the design of numerical experiments that spans a range of

,

,

,

, and

was constructed, as presented in

Table 2. For each of the waveguide materials, numerical simulations were conducted to investigate the power density (

) and maximum operating temperature (

) in the waveguide for all of the experiments presented in the

orthogonal array. Here, the power density is the ratio of the thermal power delivered,

to the planar area of the waveguide in a unit cell identified by the dashed rectangle shown in

Figure 1a; i.e.,

.

Based on the results that were obtained for the power density (

) and the maximum temperature (

) from each experiment of the L16 orthogonal array, empirical correlations were developed for the performance metrics in terms of

,

,

,

and

, which are expressed in the following general form:

where

, are the coefficients for each of objective functions namely, power density,

, and maximum temperature,

, determined from the Taguchi orthogonal array analysis, as summarized in

Table 3 for the two different waveguide materials.

Figure 6 compares the accuracy of the correlations with the numerical simulation results on the power density (

Figure 6a) and the maximum temperature in the waveguide material (

Figure 6b). The presented results cover both materials PC and ZK7 depicted by the circle and the square markers, respectively. The developed correlations and the simulation results are in close agreement for both

(

Figure 6a) and

(

Figure 6b), where 85% of predicted power density and the maximum temperature fall within

10% (dashed lines) of the line of exact agreement (solid line diagonal to the plot frames) for both of the waveguide materials. The validated correlation is used to understand the effect of the various parameters on the power density and maximum temperature and to develop design windows, as discussed below.

Figure 7a depicts the variation in net thermal power density (

) delivered to the receiver as functions of both waveguide length and incident irradiation for the waveguide concentrator made of ZK7 glass for an application requiring HTF temperature at 100

, receiver radius of 0.01 m, and waveguide thickness of 0.02 m.

Figure 7a shows that the net thermal power density decreases with an increase in waveguide length due to an increase in path length of rays within the waveguide leading to higher attenuation, as explained earlier. The thermal power density that is collected at the receiver is directly proportional to the incident irradiation. The same trend is observed for the PC waveguide material in

Figure 7d. For a given incident irradiation, the intensity of rays propagated to the periphery of the waveguide is higher for PC (

Figure 7d) than ZK7 glass (

Figure 7a) due to its lower absorption coefficient. For higher application temperature requirements, the increase in thermal losses from the receiver decreases the power density concentration, as observed from comparing

Figure 7a,g. The temperature rise within the waveguide is dependent on the absorbed irradiation intensity and hence, the maximum temperature follows the inverse trend of power density (

Figure 7b,e,h). Specifically, the maximum temperature in the waveguide increases with an increase in waveguide length and an increase in incident irradiation. When comparing

Figure 7b,e,h, it is observed that the larger attenuation coefficient (

Figure 7b,e) and higher HTF temperature (

Figure 7b,h) increases the maximum temperature in the waveguide.

Table 3.

Values for the coefficients of Taguchi correlations expressed by Equation (16).

Table 3.

Values for the coefficients of Taguchi correlations expressed by Equation (16).

| Constants | | |

|---|

| ZK7 | PC | ZK7 | PC |

|---|

| −58.37 | −51.14 | 22.13 | 13.33 |

| 143.50 | 164.62 | 12.25 | 22.33 |

| −13,041 | 12,007 | −962.2 | −2432 |

| −22,116 | −20,196.5 | −1047.1 | −987 |

| 1.140 | 1.137 | 0.014 | 0.023 |

| 1.356 | 1.157 | 0.166 | 0.360 |

| 0.430 | −18.10 | 72.60 | 376 |

| −72,941 | −51,614 | −349 | −1302 |

| −501,458 | −397,740 | | |

| | | 94,082 | 163,405 |

| | | 0.0297 | 0.608 |

| −579 | −651.5 | 2.612 | 7.056 |

| −367 | −838.6 | 0.359 | 0.231 |

| −0.324 | −0.296 | −1.521 | −3.803 |

| 1,562,108 | 1,391,251 | | |

Figure 6.

Comparison of numerical simulation and Taguchi correlation predicted values for ZK7 and PC waveguide material: (a) power density and (b) maximum waveguide temperature.

Figure 6.

Comparison of numerical simulation and Taguchi correlation predicted values for ZK7 and PC waveguide material: (a) power density and (b) maximum waveguide temperature.

Figure 7c shows the cost of heat delivered (Equation (14)) as functions of ZK7 glass waveguide length and incident irradiation for application temperature requirement (

) of 100

. For a given waveguide thickness and receiver radius, the cost per unit area asymptotically decreases with an increase in the waveguide length (Equation (13)). For smaller waveguide lengths, the COH is high due to the high cost per unit aperture area of the waveguide-receiver system. The trade-off between the asymptotic decrease in cost power unit area and the decrease in power density with an increase in waveguide length results in a critical

(

Figure 7c), where COH is minimized. The COH decreases with an increase in incident irradiation as higher net thermal power is delivered to the receiver. Similar trends are observed in

Figure 7f, which shows the COH for PC. The low cost of PC polymer combined with their high net thermal power density (

Figure 7d) as a result of their low absorption coefficient leads to a lower COH than ZK7 glass. The COH decreases with an increase in

(compare

Figure 7c,i) due to a decrease in net thermal power density delivered. For conciseness, the trends that were observed for PC material at

are not shown here, but the optimal design for the complete HTF temperature spectrum is discussed in

Section 3.3.

Figure 7.

Variation of power density (), maximum waveguide temperature () and cost of heat (COH) with waveguide length () at different for (a–c) ZK7 at =100 °C, (d–f) PC at =100 °C, (g–i) ZK7 at = 250 °C. The receiver radius is 0.01 m and waveguide thickness is 0.02 m.

Figure 7.

Variation of power density (), maximum waveguide temperature () and cost of heat (COH) with waveguide length () at different for (a–c) ZK7 at =100 °C, (d–f) PC at =100 °C, (g–i) ZK7 at = 250 °C. The receiver radius is 0.01 m and waveguide thickness is 0.02 m.

Figure 8 represents the design windows for ZK7 and PC with maximum permissible temperature (

) as a constraint.

Figure 8a represents the design window for ZK7 waveguide material considering

= 1000 W/m

2,

= 0.01 m, and

= 0.025 m. For ZK7 glass, the tensile strength constrains the maximum recommended operating temperature to about 86

[

22], which is shown by the red line depicted in

Figure 8a. The solid lines represent the iso-contour lines for various power density values. The unshaded area is the feasible design and operation window, such that the operating temperature of the waveguide is below the critical threshold of about 86

for any combination of

and

. For

value of 250

, the maximum permissible waveguide length is around 0.68 m and, for larger values of

,

exceeds the maximum permissible operating temperature (

). Similarly, the design and operation envelope is plotted for PC waveguide material in

Figure 8b. The maximum permissible operating temperature (

) for PC waveguide materials is 120

(

Table 1). For the selected range of parameters, the maximum permissible HTF temperature is around 235

, and its value decreases with an increase in

. The waveguide lengths for achieving a specific power density can be determined while using the power density iso-contour lines for various application temperature (

) requirements. For a given design configuration and HTF temperature requirement, the power density with PC waveguide is higher when compared to ZK7 because of its lower absorption coefficient that transfers higher incident solar radiation to the receiver.

3.3. Optimal Design of Waveguide Concentrator

The empirical correlations obtained from the Taguchi

orthogonal array analysis were further used to determine the optimum design of the waveguide and receiver configuration for different application considerations. The objective is to establish the optimal parameters of the waveguide-receiver design for different operating conditions. In the present study, two different optimization objectives are considered: (1) maximizing power density (

) and (2) minimizing the cost of heat (COH) that is delivered for different combinations of application temperature requirements and incident irradiation. The optimization is subject to constraints on the maximum permissible temperature in the waveguide for fail-safe operation. Optimal values are sought for the receiver radius

, waveguide thickness

, and waveguide length

. The optimization problems can be mathematically expressed as:

where

is the maximum temperature in the waveguide that is obtained from the numerical model and

is the maximum permissible waveguide temperature that is constrained by either the tensile strength constraint or the maximum operating temperature constraint. The maximum continuous operating temperature limit constrains the maximum permissible temperature for PC to

, whereas the tensile strength constrains the maximum permissible temperature for ZK7 to

[

21,

43]. The optimization problem that is presented in Equation (17) was solved using MATLAB by means of sequential quadratic programming [

44], a nonlinear programming technique. The functional relationships in Equation (16) and the related coefficients in

Table 3 were used to develop an objective function. The convergence of the optimization was determined using the Karush–Kuhn–Tucker criterion [

44,

45,

46].

Figure 9 shows the optimal design configuration and corresponding performance metrics obtained from the numerical optimization for the objective of maximizing power density. The optimization runs were performed using 10 different arbitrarily selected initial parameter values to avoid solutions in local optima. For both of the objective functions, the optimal receiver radius and waveguide thickness values were obtained at the lower bound of 0.005 m and 0.01 m, respectively. Thinner waveguide incurs lower thermal energy loss due to absorption, while a smaller receiver radius results in lower thermal losses due to reduced surface area and, hence, the highest power density was obtained for lower values of

and

. For both of the investigated waveguide materials, the highest power density (

Figure 9a,d) was obtained for applications requiring low HTF temperature, due to a decrease in heat loss from the receiver. The maximum power density increases with an increase in incident irradiation, as noted in the previous section. For ZK7 and PC waveguides, the maximum power density was obtained for the lower bound of waveguide length value (

) used in the numerical optimizer (

Figure 9c,f), as a smaller waveguide reduces the absorption losses of the concentrated irradiation within the waveguide. Because the optimal design values for both ZK7 and PC waveguides were constant for varying

and

, the installed cost of the system,

(Equation (13)) was also constant at 96.1

and 79.6

for ZK7 and PC, respectively. Hence, the cost of heat trends shown in

Figure 9b,e are only influenced by the power density variations in

Figure 9a,d. The inverse dependence of COH on

(Equation (14)) is clearly observed in

Figure 9, in that the COH decreases with an increase in incident irradiation and the lowest COH value was obtained for applications requiring low HTF temperature. The highest power density was obtained for the PC waveguide as compared to ZK7 due to its low absorption coefficient.

Figure 10 shows the numerical optimization results for the objective of minimizing the cost of heat (COH) which represents a combined consideration of maximizing power density and minimizing cost. The optimal receiver radius and waveguide thickness values for least COH were obtained at the lower bound of 0.005 m and 0.01 m, respectively, since power density increases with decrease in

or

and the installed cost also decreases. In addition, lower

and

result in a lower temperature excursion in the waveguide (

Figure 4), which ensures the maximum temperature in the waveguide does not exceed the critical threshold for most of the design and operating parametric combinations. The optimal waveguide length values for ZK7 and PC glass that are shown in

Figure 10c,f are observed to decrease with increase in incident irradiation. The optimal waveguide length obtained for minimum COH is based on the trade-off between a decrease in installed cost (

) with an increase in

, which is sought to be minimized (Equation (13)), and a decrease in power density with an increase in

, which is sought to be maximized.

Because the power density decreases with decrease in

(

Figure 10b,e), the optimizer predicts higher waveguide length values to lower the installed cost and compensate for the decrease in power density. The corresponding cost of heat shown in

Figure 10a,d decreases with an increase in

due to higher power output in spite of the increase in installed cost due to the lower optimal

values predicted for higher

(

Figure 10c,f). For incident irradiation between 650–1250

, it is observed from

Figure 10c,f that the optimal waveguide length value reduces with an increasing

, owing to the increase in maximum waveguide temperature with increase in

that can extend beyond the maximum permissible temperature at higher

(compare

Figure 7b,h for ZK7). Hence, the numerical optimizer predicts a smaller optimal waveguide length for higher

to ensure the critical temperature constraint is satisfied, while the COH is minimized. Correspondingly, the COH for ZK7 and PC waveguide shown in

Figure 10a,d is observed to increase with an increase in

. The optimal waveguide length ranged between 0.5–1.0 m for ZK7 glass and 0.62–1.0 m for polycarbonate, depending on the incident irradiation and application temperature requirement (

Figure 10c,f). PC and ZK7 are both applicable for the entire temperature range studied here, and PC is superior in performance to ZK7 both in terms of cost and power density.

Figure 10.

Numerical optimization results obtained for the minimum cost of heat objective function: Optimal waveguide length and the corresponding performance metrics obtained from numerical optimization for (a–c) ZK7 and (d–f) PC waveguide for various incident irradiation and application temperature requirement represented by .

Figure 10.

Numerical optimization results obtained for the minimum cost of heat objective function: Optimal waveguide length and the corresponding performance metrics obtained from numerical optimization for (a–c) ZK7 and (d–f) PC waveguide for various incident irradiation and application temperature requirement represented by .

Figure 11 compares the total cost per unit aperture area that was optimized for the least cost of heat (

Figure 10) for the application temperature requirement of

against the state-of-the-art parabolic trough cost that was obtained from Ref. [

38]. Accordingly, the waveguide length,

used for the cost comparison are 0.49 m and 0.62 m for ZK7 and PC material, respectively. The waveguide thickness is 0.01 m for both the materials that represents a concentration ratio of 25 for ZK7 and 31 for PC waveguide. The breakdown of the receiver (

) and waveguide (

) cost per unit aperture area (Equation (13)) are also shown. It is observed that the major cost benefits of the waveguide-receiver system result from the reduction in cost that is associated with the solar collector component, which is very high for troughs due to massive and heavy form aspects of solar tracking mirrors and the associated structures to support them. Among the two waveguide materials investigated, the PC waveguide has a high potential to surpass the US DOE SunShot target of 75

[

1], due to the combination of the low cost of polymeric waveguide material and low absorption coefficient that leads to high thermal power density transport. Although the cost comparison is based on some ideal assumptions of the waveguide performance, as stated in

Section 2.1, the concept shows potential to be cost-competitive than conventional parabolic troughs, especially for low to medium temperature applications.

The results of this study establish the best realizable performance to guide practical system development. Future studies will focus on the experimental investigation of the proposed waveguide-receiver thermal and optical performance to validate the model predictions, and system level techno-economic analysis while considering both capital and operational expenses to optimize the overall design for different application requirements. Future work should also consider the long-term durability and stability of the waveguides.