1. Introduction

A smart grid is defined as a power grid integrated with a computerized and bidirectional communication network. Due to the rising importance and significance of smart grid applications in households, these topics have increased interest in academic and practical applications. A detailed review has been carried out in [

1], highlighting the critical challenges of involving demand-side management in optimization problems, providing information for developing different optimization algorithms. A mixed-integer linear programming (MILP) model for the cost-optimal operational scheduling of an individual end-user has been developed in [

2], including renewable energy sources (RES), an energy storage system (ESS), and an electric vehicle (EV). Apart from the main power grid, an energy trading platform is also modeled for energy exchanges. The end user’s energy demand is considered deterministic. A MILP model has been presented in the same context in [

3] for the cost-optimal smart home energy management system, including RES, ESS, and EV. The smart home’s consumption is considered deterministic except for two appliances: a washing machine and a dishwasher, modeled as shiftable load types. A similar MILP model has also been presented in [

4], in which the electricity consumption is considered deterministic. In addition to the load modeling, the main difference with [

3] refers to the incorporation of capability for energy exchanged between the flexibility providers (ESS, EV) and the power grid. Focusing on a microgrid level, the authors in [

5] developed a MILP model for a microgrid’s optimal energy scheduling, including photovoltaics, ESS, and a fleet of EVs. The microgrid’s energy requirements are fully inelastic. The impacts of photovoltaics’ uncertainty, stochasticity in the EVs’ driving schedules, and different selling energy prioritization approaches on end-user electricity costs have also been investigated.

By incorporating smart loads (schedulable and thermostatic), a MILP model has been formulated in [

6] to optimally determine a smart home’s energy schedule, including an ESS in the form of battery and RES (photovoltaics and micro wind turbine). EVs are not modeled as additional flexibility providers. A similar MILP model has been presented in [

7] for optimal home energy management to minimize the household’s electricity bill. Thermostatic and schedulable loads have been modeled, as well as an ESS and a photovoltaic panel. However, the work does not include EVs. The author in [

8] also dealt with the optimal home energy management problem. The model developed includes a solar photovoltaic panel and an ESS, and the load types modeled are both shiftable and non-shiftable. Coping with the same problem, the authors in [

9] modeled fixed and flexible types of loads and considered a photovoltaics panel without including additional load types, as well as ESS and EV. The authors in [

10] presented another MILP version of the same problem, taking into account smart loads, a photovoltaic system, and an ESS, but without including an EV. Additionally, in the MILP version of the same problem in [

11], a series of smart loads are modeled, and a photovoltaic panel is also available. However, the model does not consider any flexibility provision from ESS and EV. In [

12], a mixed-integer non-linear programming (MINLP) model for the smart home energy management problem has been developed, including smart loads and a photovoltaic panel. As in [

9,

10,

11], ESSs and EVs are not incorporated in the modeling approach.

Besides, a relevant MILP model has been presented in [

13] for the optimal dispatch optimizes the residential load’s dispatch considering various smart load types, ESSs, EVs, and implicitly solar power generation, since the model utilizes the residual load. Thus, there is no component in the model’s objective function representing potential revenues from electricity sold to the grid. In the same frame of reference, the authors in [

14] developed a MILP model for the optimal demand scheduling problem, incorporating a smart load type (thermostatic load), an ESS, an EV, and a photovoltaic panel. Other smart load types were not modeled in this work. The authors in [

15] developed another MILP model for the solution of the smart home’s energy scheduling problem, incorporating EVs, ESSs, wind, and photovoltaic power production, as well as smart load types (thermostatic and controllable). The model does not include other smart load types such as curtailable dependent and adjustable loads. The MILP-based model presented in [

16] deals with the same topic and is among few works covering the whole spectrum of the problem aspects, including ESSs, EVs, smart loads, and photovoltaic power generation. A multi-objective optimization algorithm has been developed in [

17] to optimally determine the smart homes’ energy of a residential microgrid.

Focusing on a larger scale, namely, a smart apartment building including several smart homes, a MILP model has been developed in [

18], including combined heat and power units, boiler, ESSs, thermal storage systems, as well as smart appliances. However, the model does not incorporate renewable energy sources and EVs. The authors in [

19] developed a robust-CVaR MILP model to minimize the energy cost’s risk value. Focusing on a utility scale, the authors in [

20] formulated a MILP model for minimizing the peak demand considering EVs as well as adjustable and constant power loads. RES and ESSs were not included in this modeling framework. Additionally, the authors in [

21] developed a MILP model for the optimal residential demand response scheduling of smart homes, in terms of shiftable load. EVs and ESSs were not considered. Furthermore, the authors in [

22] presented a MILP model for the cost-optimal dispatch of smart appliances without considering the supply side and flexibility providers. The authors in [

23] proposed a demand scheduling optimization approach to minimize the peak hourly load, including shiftable loads and EVs. In this work, ESSs and RES were not modeled. Finally, an incentive-based methodological framework has been developed in [

24] for scheduling various electric appliances of a residential community.

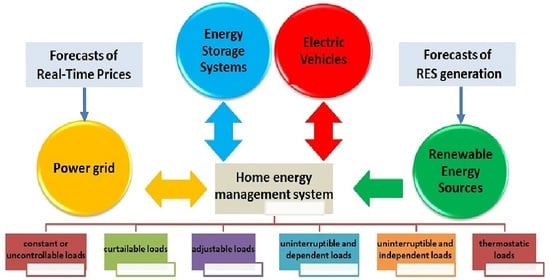

As it is clear from the provided literature review, several works deal with the smart home energy optimization problem from many perspectives, the majority of which cover all the aspects of the studied problem partially. This work is based on the development of an optimization approach, namely, a MILP model, for optimal smart home energy management, including all types of smart loads (uncontrollable loads, curtailable, adjustable, uninterruptible and independent loads, uninterruptible and dependent loads, and thermostatic ones), RES, in the form of wind and photovoltaic power contribution, ESS, EV, and energy exchanges with the power grid. This work comprises an extension of the work presented in [

25], on the grounds that it incorporates the following:

- i.

A forecasting approach is proposed combining clustering and neural network. The critical variables that affect the prosumer’s expenses are electricity prices. Photovoltaics (PV) generation and wind turbine (WT) generation are employed in the forecasting process. The clustering part of the forecasting model is utilized for the optimal selection of historical values of the target variable;

- ii.

A peak load constraint has been added in the mathematical formulation, exerting significant influence on the decision making;

- iii.

A more detailed temporal granularity has been employed, namely, 15 min time step instead of an hourly one in [

25];

- iv.

The case studies executed include both summer and winter days, providing the ability to capture the seasonal fluctuation in terms of RES generation and the operation of thermostatic loads.

Thus, the salient feature of the present work that is among few works in the literature integrates scheduling of both supply and demand sides, including the flexibility providers and all types of smart loads.

The developed modeling framework has been assessed on an illustrative case study, including a summer and a winter day, to demonstrate its applicability and effectiveness. It aims at capturing the time dynamics and interdependencies among the load scheduling, the flexibility provided by EVs and ESSs, the renewable energy contribution, and the interaction with the power grid. This systematic approach enhances decentralized energy generation, converting passive consumers into active prosumers, and is characterized by significant flexibility on the grounds that it can be easily adapted for large-scale case studies at a neighborhood and/or an urban level.

The main decision variables to be determined by the optimization approach are (i) RES generation scheduling (allocation of the energy generation and interactions with the grid), (ii) optimal load dispatch of the home’s smart appliances, and (iii) optimal operation of flexibility providers (ESS and EV).

Following the Introduction section, the work’s structure has the following form:

Section 2 presents the mathematical model formulation of the underlying problem and is followed by

Section 3, explaining the modeling approach of the forecasting processes whose outputs provide some of the required inputs to the optimization model. The assumptions and the input data of the employed case studies are described in

Section 4, and

Section 5 provides a detailed discussion of the model solution outputs. Last but not least,

Section 6 summarizes the key findings of the work.

3. Forecasting Processes

The scope of forecasting processes is the optimal strategic utilization of the prosumer resources in order to reach out in minimal energy costs. In this paper, a method of selecting the proposer inputs for the forecasting model is proposed. The prosumer model is applied to two test cases, namely, the summer day and the winter day.

Figure 2 shows the connection of the forecasting processes and the prosumer model. The latter receives inputs the forecasts and is executed every time step. The proposed forecasting model refers to a combination of unsupervised and supervised machine learning algorithms. The unsupervised machine learning part corresponds to clustering. The K-medoids algorithm is employed for proper selection of the training inputs [

26]. The supervised part refers to the Elman neural network (ENN) [

27]. The role of ENN is to perform the forecasts of the three variables.

Figure 3 displays the flowchart of the hybrid forecasting model. The same model is used for all variables. The difference lies on the types and number of inputs of the ENN. Let

be an input pattern of the ENN, where

denotes the

th component of the

feature vector

The data are normalized in the [0, 1] range by dividing each element of

with the maximum value among the

values. The normalization aids at the better exploitation of clustering results. In the clustering procedure, the scope is to group together patterns with similar characteristics. In the case of Real-Time Prices (RTP) and generation, the similarity lies on the similarity of the time series shapes. The pattern corresponds to the time series that cover a 24 h period. K-medoids is applied for the proper selection of historical data that will be used for the training of the ENN. Let

be the target day of forecasting, i.e., either the summer or winter day. The training input selection process is composed by the following steps:

Step#1: Conduct a correlation analysis between the current time instance (i.e., 15 min)

of day

with all previous hours from the start date of the available dataset. For example,

Figure 3 presents the Pearson correlation coefficient curves for the summer and winter days up to 196 h in the past [

28]. It can be noticed that day

is more corelated with day

.

Step#2: Apply K-medoids for number of clusters to all days up to .

Step#3: Locate the cluster that day belongs to.

Step#4: Calculate the Euclidean distances between all days in the same cluster of day and day .

Step#5: Sort the according distances in ascending order.

Step#6: Selected days on the top of the order and train ENN using this set.

The above process leads to the selection of the most similar days to day

, which refers to the target day. According to

Figure 3, external variables are utilized as inputs. For the RTP forecasting process, the RTPs of the two test days are predicted using only historical values. More specifically, it is regarded that the prosumer purchases electricity from a retailer. The RTP is the forecasted system marginal price (SMP) increased by 65%. This increase is necessary for the retailer to cover its operational expenses and witness profit. RES generation includes photovoltaics (PV) and small wind turbines (WT). Let

, and

be the RTP, PV generation, and WT generation of time instance

respectively. These variables refer to the outputs of the forecasting model.

Table 1 presents the outputs and the inputs of the model. The forecasts of PV and WT generations include external variables, namely, mean daily temperature of day,

, clearness sky index of day

and mean daily wind speed of day

The selected time lags

and

are selected via correlation analysis.

Figure 4 presents the correlation coefficient curves for the two test days.

K-medoids is a partitional clustering algorithm. Prior to its execution, the most significant parameters that needs to be defined are the number of training epochs, the objective function threshold improvement, and the selection of initial centroids method. These have been selected with a trial-and-error procedure. Specifically, the number of epochs is set to 500, the threshold to 10

−6 and the centroids are initialized randomly. Let

be the indicator denoting the number of clusters, and

is the number of clusters. Each cluster is presented by the medoid, which is the median of all patterns of the cluster. Let

be the medoid of the

-th cluster. Through a number of iterations, K-medoids aims at minimizing the sum of squared errors (SSE) between pattern

and each medoid of the clusters:

For ENN, the following structure is selected: one hidden layer, resilient back-propagation training algorithm, tangent sigmoid activation function for the neurons of the hidden and output layers, number of epochs 500, and objective function threshold improvement 10

−6 [

29]. The training error refers to mean absolute percentage error (MAPE) [

30].

In order to fully evaluate the performance of ENN, a comparison takes place between ENN and an auto-regressive integrated moving average (ARIMA) model [

31]. Prior to its implementation, the order of the model needs to be defined. Let

be the value of variable

in next hour

The ARIMA model treats future values of the variable as a linear combination of historical values. ARIMA is composed of the sum of auto-regressive (AR) and moving average (MA) components. The AR(

p) component is obtained by the following expression:

where

p is the order of the model,

are the factors of the AR components,

is a constant, and

is white noise. The moving average (MA) components consider part errors. The MA(

q) component is obtained by the following expression:

where

q is the order of the model,

are the factors of the AR components,

is a constant, and

is white noise. By combining Equations (63) and (64), the ARIMA model expression is obtained:

where

is white noise. The model is represented as ARIMA(

,

,

), where

is the number of differentiation needed for the time series to become stationary. In order to select the order of the model, the sample auto-correlation function (SAF) and sample partial auto-correlation function (SPAF) are checked.

Figure 5 presents the SPAF for the RTP, and

Figure 6,

Figure 7,

Figure 8 and

Figure 9 present the SAF and SPAF of PV and WT generation, respectively.

By checking

Figure 4a and

Figure 5, the RTP series presents a correlation with high order lags. This is not the case for PV and WT generation. In order to select the order of the model, Akaike’s information criterion (

AIC) and Bayesian information criterion (

BIC) are considered. They are given by the following equations, respectively:

where

is the log-likelihood estimate,

is the number of independent variables used, and

is the number of observations. Thus, a series of different structures are examined. Different combiations of

and

are take into account.

Table 2 and

Table 3 present the scores of the various examined models of ARIMA(

and ARIMA(

for RTP forecasting, respectively. The tables refer to the summer day. The scores are calculated using the same training set that the ENN has used. The selected structure should lead to lower values to AIC and BIC. It can be observed that, in general, ARIMA(

results in better scores compared to ARIMA(

The best scores are met at the ARIMA(

model.

Table 4 and

Table 5 show the scores of ARIMA(

and ARIMA(

for PV generation forecasting, respectively. Finally,

Table 6 and

Table 7 show the scores of ARIMA(

and ARIMA(

for WT generation forecasting, respectively. For the PV generation, model ARIMA(

is selected. For the WT generation, model ARIMA(

is selected.