Impact of Blow-By Gas and Endgap Ring Position on the Variations of Particle Emissions in Gasoline Engines

Abstract

:1. Introduction

- -

- Incomplete combustion. This occurs when the mixture is not under stoichiometric conditions but is rich in fuel. The combustion process stops when there is not enough air to oxidize it. Therefore, there are unburned gases after combustion. Similarly, the extinction of the combustion flame against the cylinder walls, or before reaching the walls, generates unburned gases.

- -

- The oil film on the cylinder wall. It absorbs unburned fuel, which can be released after combustion.

- -

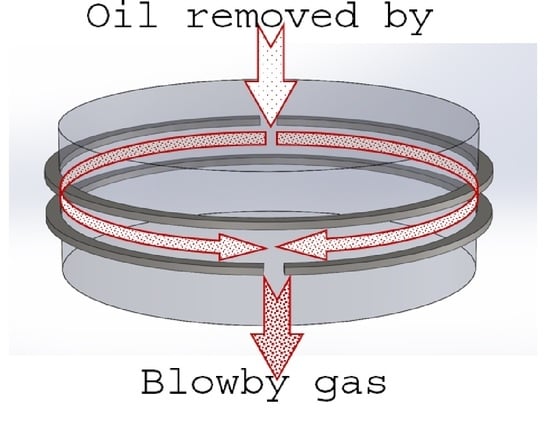

- The “crevices”. These are the areas close to the valve seats, the cylinder head gasket, the spark plug, and the piston rings, which are not in direct contact with the combustion flame and remain unburned. Cheng et al. [1] have also specified that, in a steady state, 0.6% of the total fuel injected would pass through the piston rings and the cylinder wall to end up in the oil pan. These are commonly called blow-by gases. If all of the blow-by gases are recycled, that is to say the oil is removed and the gases are reinjected at the intake for a new cycle, there would be only 1.8% of unburned fuel that would be emitted in the atmosphere in the form of soot particles [1].

2. Materials and Methods

2.1. Description of Engine Bench

2.2. Particles Measuring Device

2.3. Description of the Blow-By Circuit

2.4. Transient Tests

2.5. Similarity of the Tests

2.5.1. Thermal and Atmospheric Conditions

2.5.2. Motor Actuators

2.5.3. Engine Parameters

3. Results

3.1. Oil Pan Pressure

3.2. Particle Emissions for Cases 1 and 2

- If the emission level for case 1 is more important than case 2, this implies that the blowby gases are not completely free of oil and so that the engine oil separator is not 100% effective. Indeed, after the case 1 transients, the presence of oil is noticed in the blowby circuit from the engine oil separator to the intake manifold. Otherwise, there is no oil in the blowby circuit from the engine oil separator to the intake manifold for the case 2 transients.

- If the standard deviation is almost 33% lower without blowby gases, this implies that the oil concentration of blowby gases reinjected at the intake is variable.

4. Discussion

- -

- when is close to 180°, then Ioil-backflow () tends to 0

- -

- when is close to 0°, then Ioil-backflow () is maximal.

5. Conclusions

- -

- Indeed, even equipped with a two-way oil separator (Low pressure and High pressure), this engine emits 1.5 times more particles with a standard deviation that decreases by 33% compared to a configuration without blow-by gases. After analysis, it turns out that the oil separators are not effective enough to completely remove the oil from the blow-by gases.

- -

- Furthermore, the position of the “endgap” formed by the first two rings has a significant impact on the amount of oil transported by the blow-by gases toward the intake manifold and by the backflow gases towards the combustion chamber.

- -

- It turns out that for this engine and this transient, 57% of the particulate emissions are related to the equivalence ratio, while 31% are directly related to the blowby gases. Finally, 12% of the emissions come from the backflow.

- -

- Therefore, the endgap position is the main factor linked to the variation of particulate emissions and because the rings are not static, it makes sense to get some variation of particulate emissions of a gasoline engine. These variations are linked to the piston/rings design and the oil separator efficiency.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CA | Crank Angle (degree) |

| ECU | Electronic Control Unit |

| Endgap | Distance left between the ends of the ring when installed in the cylinder |

| EVC | Exhaust Valve Closing |

| GDI | Gasoline Direct Injection |

| HP | High Pressure |

| N | Particle number concentration (#/m3) |

| I | Current measured by the PPS and proportional to the particles number concentration |

| Imin | Smallest current value measured by the PPS for a series of 100 transients |

| Imax | Highest current value measured by the PPS for a series of 100 transients |

| Intensity | Measured current (pA) |

| IVO | Intake Valve Closing |

| LP | Low Pressure |

| OC | Oil Consumption |

| pA | Pico Ampère |

| PPS | Pegasor Particles Sensor |

| TGDI | Turbocharged Gasoline Direct Injection |

| Tq | Torque (nm) |

| TDC | Top Dead Center |

| Standard Deviation | |

| Equivalence ratio | |

| θ_rings | Angular position between two endgap of the first two rings (°) |

| v | Engine speed (rpm) |

References

- Cheng, W.K.; Hamrin, D.; Heywood, J.B.; Hochgreb, S.; Min, K.; Norris, M. An Overview of Hydrocarbon Emissions Mechanisms in Spark-Ignition Engines; SAE Technical Paper 932708; SAE International: Warrendale, PA, USA, 1993. [Google Scholar] [CrossRef]

- Kolbenshmidt. Piston Rings for Combustion Engine. Available online: https://www.ms-motorservice.com.tr/fileadmin/media/MAM/PDF_Assets/Piston-Rings-for-Combustion-Engines_53094.pdf (accessed on 5 March 2020).

- Delprete, C.; Selmani, E.; Bisha, A. Gas escape to crankcase: Impact of system parameters on sealing behavior of a piston cylinder ring pack. Int. J. Energy Environ. Eng. 2019, 10, 207–220. [Google Scholar] [CrossRef] [Green Version]

- Takiguchi, M.; Nakayama, K.; Furuhama, S.; Yoshida, H. Variation of Piston Ring Oil Film Thickness in an Internal Combustion Engine—Comparison Between Thrust and Anti-Thrust Sides; SAE Technical Paper 980563; SAE International: Warrendale, PA, USA, 1998. [Google Scholar] [CrossRef]

- Namazian, M.; Heywood, J.B. Flow in the Piston-Cylinder-Ring Crevices of a Spark-Ignition Engine: Effect on Hydrocarbon Emissions, Efficiency and Power; SAE Technical Paper 820088; SAE International: Warrendale, PA, USA, 1982. [Google Scholar] [CrossRef]

- Herbst, H.M.; Priebsch, H.H. Simulation of Piston Ring Dynamics and Their Effect on Oil Consumption; SAE Technical Paper 2000-01-0919; SAE International: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Rabute’, R.; Tian, T. Challenges Involved in Piston Top Ring Designs for Modern SI Engines. J. Eng. Gas. Turbines Power 2000, 123, 448–459. [Google Scholar] [CrossRef]

- Schneider, E.W.; Blossfeld, D.H.; Lechman, D.C.; Hill, R.F.; Reising, R.F.; Brevick, J.E. Effect of Cylinder Bore Out-of-Roundness on Piston Ring Rotation and Engine Oil Consumption; SAE Technical Paper 930796; SAE International: Warrendale, PA, USA, 1 March 1993. [Google Scholar] [CrossRef]

- Schneider, E.W.; Blossfeld, D.H. Method for Measurement of Piston Ring Rotation in an Operating Engine; SAE Technical Paper 900224; SAE International: Warrendale, PA, USA, 1990. [Google Scholar] [CrossRef]

- Uhlig, B.P.; Kirner, C.; Preuss, A.-C.; Wachtmeister, G. Real-Time Measurement of the Piston Ring Gap Positions and Their Effect on Exhaust Engine Oil Emission; SAE Technical Paper 2018-01-5006; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Usui, M.; Murayama, K.; Oogake, K.; Yoshida, H. Study of Oil Flow Surrounding Piston Rings and Visualization Observation; SAE Technical Paper 2008-01-0795; SAE Technical Paper 932708; SAE International: Warrendale, PA, USA, 2008. [Google Scholar] [CrossRef]

- Jung, S.; Jin, J. Monitoring of Rotational Movements of Two Piston Rings in a Cylinder Using Radioisotopes. J. Korean Nucl. Soc. 1999, 31, 423–431. [Google Scholar]

- Iijima, N.; Miyamoto, T.; Takiguchi, M.; Kai, R.; Sato, M. An Experimental Study on Phenomena of Piston Ring Collapse; SAE Technical Paper 2002-01-04832002; SAE International: Warrendale, PA, USA, 2002. [Google Scholar] [CrossRef]

- Tian, T. Dynamic behaviours of piston rings and their practical impact. Part 1: Ring flutter and ring collapse and their effects on gas flow and oil transport. Proc. Inst. Mech. Eng. Part. J. J. Eng. Tribol. 2002, 216, 209–228. [Google Scholar] [CrossRef]

- Cheng, C.; Schock, H.; Richardson, D. The Dynamics of Second Ring Flutter and Collapse in Modern Diesel Engines. J. Eng. Gas. Turbines Power 2015, 137, 111504. [Google Scholar] [CrossRef]

- Tian, T. Dynamic behaviours of piston rings and their practical impact. Part 2: Oil transport, friction and wear of ring/liner interface and the effects of piston and ring dynamics. Proc. Inst. Mech. Eng. Part. J. J. Eng. Tribol. 2002, 216, 229–248. [Google Scholar] [CrossRef]

- Kharazmi, A. Three Dimensional Analysis of the Gas Flow in Piston Ring Pack. Ph.D. Thesis, Michigan State University, Lansing, MI, USA, 2017. [Google Scholar]

- Wróblewski, P.; Koszalka, G. An Experimental Study on Frictional Losses of Coated Piston Rings with Symmetric and Asymmetric Geometry. SAE Int. J. Engines 2021, 14, 853–866. [Google Scholar] [CrossRef]

- Wróblewski, P.; Iskra, A. Problems of Reducing Friction Losses of a Piston-Ring-Cylinder Configuration in a Combustion Piston Engine with an Increased Isochoric Pressure Gain; SAE Technical Paper 2020-01-2227; SAE International: Warrendale, PA, USA, 15 September 2020. [Google Scholar] [CrossRef]

- Zarenbin, V.; Kolesnikova, T.; Sakno, O.; Ollo, V.; Klimenko, V. Impact Evaluation of Piston Rings Mobility on A Gas Passage in An Internal Combustion Engine (ICE). Sci. J. Sil. Univ. Technol. Ser. Transp. 2019, 104, 187–201. [Google Scholar] [CrossRef]

- Turnbull, R.; Dolatabadi, N.; Rahmani, R.; Rahnejat, H. An assessment of gas power leakage and frictional losses from the top compression ring of internal combustion engines. Tribol. Int. 2020, 142, 105991. [Google Scholar] [CrossRef]

- Jues, T. Modélisation et Simulation des gaz de Blow-by Dans un Décanteur Automobile. Ph.D. Thesis, L’Ecole Nationale Supérieure d’Arts et Métiers, Paris, France, 2010. [Google Scholar]

- Thawko, A.; Yadav, H.; Eyal, A.; Shapiro, M.; Tartakovsky, L. Particle emissions of direct injection internal combustion engine fed with a hydrogen-rich reformate. Int. J. Hydrogen Energy 2019, 44, 28342–28356. [Google Scholar] [CrossRef]

- Swanson, J.; Ragatz, A.; Watts, W.; Kittelson, D.; Winsor, R. Nanoparticle measurements used to detect an engine oil control ring failure. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2009, 223, 1071–1076. [Google Scholar] [CrossRef]

- Amirante, R.; Distaso, E.; Tamburrano, P.; Reitz, R.D. Measured and Predicted Soot Particle Emissions from Natural Gas Engines; SAE Technical Paper 2015-24-2518; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Berthome, V.; Chalet, D.; Hetet, J.-F. Characterization of Particle Emissions of Turbocharged Direct Injection Gasoline Engine in Transients and Hot Start Conditions. J. Therm. Sci. 2021, 30, 2056–2070. [Google Scholar] [CrossRef]

- Pegasor, PPS-Plotter; User Manual; Pegasor Ltd.: Tampere, Finland, 2014.

- The European Commission. Commission Regulation (EU) No 459/2012 of 29 May 2012 amending Regulation (EC) No 715/2007 of the European Parliament and of the Council and Commission Regulation (EC) No 692/2008 as regards emissions from light passenger and commercial vehicles (Euro 6). Off. J. Eur. Union 2012, 142, 16–24. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32012R0459&from=EN (accessed on 5 March 2020).

- Amanatidis, S.; Maricq, M.M.; Ntziachristos, L.; Samaras, Z. Measuring number, mass, and size of exhaust particles with diffusion chargers: The dual Pegasor Particle Sensor. J. Aerosol Sci. 2016, 92, 1–15. [Google Scholar] [CrossRef]

- Ntziachristos, L.; Amanatidis, S.; Samaras, Z.; Janka, K.; Tikkanen, J. Application of the Pegasor Particle Sensor for the Measurement of Mass and Particle Number Emissions. SAE Int. J. Fuels Lubr. 2013, 6, 521–531. [Google Scholar] [CrossRef]

- Manni, M.; Carriero, M.; Roselli, A. A Study of Oil Consumption on a Diesel Engine with Independently Lubricated Turbocharger; SAE Technical Paper 2002-01-2730; SAE International: Warrendale, PA, USA, 2002. [Google Scholar] [CrossRef]

- Delvigne, T. Oil Consumption Sources in a Modern Gasoline Engine Including Contribution of Blow-by Separator and Turbocharger: An Experimental Study Based on the Use of Radiotracers. SAE Int. J. Fuels Lubr. 2010, 3, 916–924. [Google Scholar] [CrossRef]

- Yilmaz, E.; Tian, T.; Wong, V.W.; Heywood, J.B. The Contribution of Different Oil Consumption Sources to Total Oil Consumption in a Spark Ignition Engine; SAE Technical Paper 2004-01-2909; SAE Technical Paper 932708; SAE International: Warrendale, PA, USA, 2004. [Google Scholar] [CrossRef]

- Gohl, M.; Matz, G.; Preuss, A.-C.; Pischinger, S.; Günther, M.; Ebert, T. Investigation of Oil Sources in the Combustion Chamber of Direct Injection Gasoline Engines; SAE Technical Paper 2018-01-1811; SAE Technical Paper 932708; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Min, B.-S.; Kim, J.-S.; Oh, D.-Y.; Choi, J.-K.; Jin, J.-H. Dynamic Characteristics of Oil Consumption—Relationship Between the Instantaneous Oil Consumption and the Location of Piston Ring Gap; SAE Technical Paper 982442; SAE International: Warrendale, PA, USA, 1998. [Google Scholar] [CrossRef]

- Icoz, T.; Dursunkaya, Z. Experimental Investigation of Oil Accumulation in Second Land of Internal Combustion Engines. J. Eng. Gas. Turbines Power 2005, 127, 206–212. [Google Scholar] [CrossRef]

- Thirouard, B.; Hart, D.P. Investigation of Oil Transport Mechanisms on the Piston Second Land of a Single Cylinder Diesel Engine, Using Two-Dimensional-Laser-Induzed Fluorescence. In Laser Techniques Applied to Fluid Mechanics, Proceedings of the 9th International Symposium, Lisbon, Portugal, 13–16 July 1998; Adrian, R.J., Durão, D.F.G., Durst, F., Heitor, M.V., Maeda, M., Whitelaw, J.H., Eds.; Springer: Berlin/Heidelberg, Germany, 2000; pp. 487–503. [Google Scholar]

- Thirouard, B.; Tian, T. Oil Transport in the Piston Ring Pack (Part I): Identification and Characterization of the Main Oil Transport Routes and Mechanisms; SAE Technical Paper 2003-01-1952; SAE International: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

| Engine Main Features | Main Parameters of Piston Rings | ||

|---|---|---|---|

| Engine | 4-stroke, TGDI, 3-cylinder | Piston diameter | 74.45 mm |

| Bore × Stroke | 75 mm × 90.48 mm | Ring 1 axial height | 1.2 mm |

| Displacement | 1199.9 cm3 | Ring 2 axial height | 1 mm |

| Valves | 12 | Ring 3 axial height | 2 mm |

| Compression ratio | 10.5:1 | Ring 1 end gap | 0.2 mm |

| Maximum Power | 96 kW @ 5500 rpm | Ring 2 end gap | 0.4 mm |

| Maximum Torque | 230 Nm @ 1750 rpm | Ring 3 end gap | 0.2 mm |

| Cases | Averaged Temperature (°C) | Pressure (mbars) | ||||||

|---|---|---|---|---|---|---|---|---|

| Engine cooling | Engine oil | Intake | Engine bench | Exhaust | Sample line PPS | Sample line PPS | Atmospheric | |

| 1 | 92.49 | 96.30 | 24.61 | 20.12 | 356.62 | 195.73 | 1531.73 | 1020.94 |

| 2 | 92.67 | 96.90 | 24.70 | 20.37 | 356.60 | 196.09 | 1529.12 | 1021.39 |

| Case Number | σ (%) | |

|---|---|---|

| 1 | 165 | 12 |

| 2 | 113 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berthome, V.; Chalet, D.; Hetet, J.-F. Impact of Blow-By Gas and Endgap Ring Position on the Variations of Particle Emissions in Gasoline Engines. Energies 2021, 14, 7492. https://doi.org/10.3390/en14227492

Berthome V, Chalet D, Hetet J-F. Impact of Blow-By Gas and Endgap Ring Position on the Variations of Particle Emissions in Gasoline Engines. Energies. 2021; 14(22):7492. https://doi.org/10.3390/en14227492

Chicago/Turabian StyleBerthome, Vincent, David Chalet, and Jean-François Hetet. 2021. "Impact of Blow-By Gas and Endgap Ring Position on the Variations of Particle Emissions in Gasoline Engines" Energies 14, no. 22: 7492. https://doi.org/10.3390/en14227492