Full-Scale Field Experimental Investigation on the Intended Irregularity of CWR Track in Vertical Plane

Abstract

:1. Introduction

2. Main Problems Arising in Railway Tracks during Operation

- Imperfections resulting from the railroad’s technical character (in consequence of the natural variable support of the railroad, e.g., the route in an excavation, on an embankment or on weak soils in the subgrade—shown in Figure 1b);

- Imperfections connected to human mistakes (mistakes during designing, improper building technology, improper diagnostic and repair of the track);

- Geometrical imperfections in the railway track [22] (e.g., vertical and horizontal irregularity and the track’s twist and width change);

- Imperfections of railway sleepers: in wooden sleepers, e.g., cracks, damages of sole-plates, dividers and screws; in concrete sleepers, e.g., scratches, cracks, breaks and dividers compressing;

- Imperfections and changes arising in the ballast and in the railway support (e.g., settlement of the granular layers and contact loss between the track and breakstone ballast) [5];

- Imperfections of a vehicle’s wheel [25]: a wheel’s tread, flange surface and ovalization;

- Other imperfections (e.g., mining damages).

- These different types of damage need to be analyzed in order to develop proper methods to reduce railway track degradation and maintenance costs (e.g., solutions for higher durability of the railway track structure). In this description, the track stiffness and irregularity of a jointless track in vertical plane should be considered in order to attain its long-term performance and the reduction in other forms of track degradation.

2.1. The Progressive Degradation of the Track

- The service life (durability) of railway track structure;

- The raveling of the ballast and cooperating protecting layers;

- Different settlement of the ballast layer and of the roadbed;

- Sleeper spacing;

- Stiffness variations (including track transition zones);

- Heterogeneities of the foundation;

- Sudden change of foundation elasticity;

- Dynamic interaction between cooperating elements in the railway track structure;

- Use of high performance (good quality) ballast particles [1];

- Use of new elements in the railway track structure (e.g., elastic sleeper);

- Increase in maintenance works frequency;

- Replacement of the granular material by stiff elements, leading to the successive development of slab tracks.

2.2. The Application of Elastic Elements in Railway Tracks

- Detecting and learning about unfavorable track phenomena (e.g., through direct track observations and routine measurements);

- Indicating the causes of the progressive degradation of the railway structure and preventive measures;

- Theoretical and computational analysis of unfavorable phenomena, taking into account the indicated factors;

- Field studies, measurements and simulations of unfavorable phenomena in the track (e.g., with known initial values of unfavorable parameters);

- Field tests and measurements of measures or elements used in the track to prevent unfavorable phenomena.

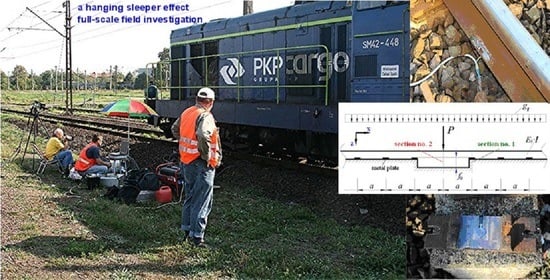

3. Methodology of the Field Investigation Carried out by the Author

- Description of the proposed method of generating the intended irregularity in the track (p. 4.1);

- Assumption of a scheme of induced irregularity in a railway track (Figure 3);

- Discussion about obtained effects (p. 5);

- Acquisition of the deflections of the rail and the railway sleeper results, obtained during field investigations;

- Acquisition of the results of stresses in the rail foot, obtained during field investigations;

- Analysis of the obtained measurement results for further engineering applications;

- Identification of the foundation parameters for engineering calculations;

- Theoretical calculations carried out for the chosen section of rail.

4. Experimental Research

4.1. A Description of the Proposed Method of Generating the Intended Irregularity in the Track

- f0—an irregularity induced in railway track (mm);

- ES·I—a track’s stiffness in vertical plane (MNm2) (ES—Young’s modulus; —moment of inertia);

- gt—the track’s weight (MN/m) (gt = 00022 MN/m);

- a—a sleeper’s spacing (m) (a = 0.60 m).

4.2. Pontos System Used for Measuring Deformation

5. Results and Discussion of Obtained Effects

5.1. The Results of Deflections of the Rail and the Railway Sleeper Obtained during Field Investigations

- The rail’s deflections under the moving locomotive;

- The rail’s stresses under the moving locomotive;

- The deflections of the concrete sleeper at its end;

- The force transferred from the rail to the railway sleeper.

- , calculated by the Levenberg–Marquardt’s method (a Levenberg–Marquardt method for minimization);

- (an exponential function),

- A rail’s deflection under a passing locomotive ();

- A deflection of the concrete sleeper at its end (),

- For the rail: ;

- For the sleeper: ;

- For the considered scheme in Figure 3, without the irregularity in the track (i.e., f0 = 0 mm), the rail’s deflection is about 2 mm (e.g., under the load of the second axle of the SM-42 locomotive, the value was 1996 mm). With f0 = 3 mm, the rail’s deflection increases to the value of 3537 mm, i.e., by 77.21%, while the sleeper’s deflection increases from 1437 mm to 2873 mm, i.e., up to 99.89%. The increase in the deflection of the rail and the sleeper is clearly visible in Figure 6.

5.2. Results of Stress Measurements in the Rail Foot Obtained during Field Investigations

- An exponential function: ;

- The third order polynomial function: ,

- This force is of a low value until the sleeper contacts with the co-operating foundation;

- Only the deflection of the rail with the sleeper after the sleeper made contact with the foundation causes the acting force from the rail to the sleeper.

5.3. An Analysis of the Obtained Measurement Results for an Engineering Consideration

- The rail as an Euler-Bernoulli beam of an infinite length placed on a one-parameter foundation (with being the parameter of the rail’s foundation);

- The sleeper as a beam of the finite length treated as the Euler–Bernoulli (E–B) elastic beam resting on a two-parameter modified Vlasov foundation (Table 1);

- The sleeper as the Euler–Bernoulli beam resting on an elastic one-parameter foundation (with being the parameter of the rail’s foundation);

- The sleeper as a short-length Timoshenko beam resting on a two-parameter analogue Vlasov foundation (defined by [MPa] and [MPa] coefficients) [36].

5.4. The Identification of the Foundation Parameters for the Engineering Calculations

| For a Rail | For a Sleeper | For a Sleeper | For a Sleeper |

|---|---|---|---|

| A one-parameter foundation: | A one-parameter foundation (1-par): | A two-parameter foundation (2-par): | A two-parameter foundation Timoshenko beam (an analogue Vlasov foundation): |

5.5. Theoretical Calculations Carried out for the Considered Section No. 2 of the Analyzed Rail

| A track Irregularity | (mm) | (mm) | (mm) | (Mpa) | (kN/mm) | (kN/mm) | (kN) | (kN) | (MPa) | (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 0 | 1.996 | - | 2.031 | 26.605 * | 45.089 | 44.309 | - | 90 | 58.474 | 63.392 |

| 1 | 2.887 | 1.887 | 2.722 | 17.526 | 31.172 | 33.068 | 16.68 | 73.32 | 71.949 | 69.016 |

| 2 | 3.054 | 1.054 | 3.237 | 14.181 | 29.469 | 27.803 | 34.51 | 55.49 | 78.367 | 71.881 |

| 3 | 3.537 | 0.537 | 3.689 | 12.099 | 25.445 | 24.391 | 54.19 | 35.81 | 75.561 | 74.064 |

| Measurement and Analysis for the Rail (Table 3) | ||||||

|---|---|---|---|---|---|---|

| A One-Parameter Foundation: | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Track irregularity (mm) | (mm) | (mm) | (kN) | (kN) | (MPa) | |

| 0 | 1.996 | - | 45.094 | 45.094 | 26.605 * | |

| 1 | 2.887 | 1.887 | 18.229 | 18.224 | 17.526 | |

| 2 | 3.054 | 1.054 | 6.810 | 6.845 | 14.181 | |

| 3 | 3.537 | 0.537 | 2.351 | 2.368 | 12.099 | |

| Measurement and Analysis for the Sleeper (with the Obtained Foundation Parameters (Table 1) | ||||||

| A sleeper’s deflection (mm) | A one-parameter foundation (1-par) | A two-parameter foundation (2-par) | A two-parameter foundation Timoshenko beam (TB 2-par) | |||

| 7 | 8 | 9 | 10 | 11 | 12 | 13 |

(mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 1.437 | 1.528 | - | 1.505 | - | 1.516 | - |

| 2.599 | 2.212 | 1.212 | 2.191 | 1.191 | 2.298 | 1.298 |

| 2.765 | 2.606 | 0.606 | 2.591 | 0.591 | 2.644 | 0.644 |

| 2.873 | 3.189 | 0.189 | 3.186 | 0.186 | 3.152 | 0.152 |

- f0—analyzed track irregularity along the length 2a (Figure 3);

- and —measured deflection of the rail and the sleeper (using the Pontos system);

- —calculated rail deflection (using the identified foundation parameters—Table 1);

- and —measured value of the acting force from the rail to the cooperating sleeper and: : measured value of the force assuming the theoretical “spring” in the considered section no. 2, where: kN/mm;

- , and , i.e., the theoretical deflection of the sleeper for the beam on the one-parameter, two-parameter and analogue Vlasov foundation, respectively;

- and —measured and theoretical (assumed ) stress in the rail foot.

- The differences in the obtained values of the sleeper deflection for different sleeper models, as a beam based on the foundation, are visible in Table 4, for example, the generated imperfection in the track equals f0 = 2 mm from Figure 3 (the value measured in the real railway track was 2.765 mm). The following values were obtained: for one-parameter foundations the theoretical deflection value was 2.606 mm, two-parameter foundations—2.591 mm, and Timoshenko’s beam on an analogue Vlasov foundation was 2.644 mm;

- On the basis of the obtained deflection values of the sleeper for one-parameter foundations, it can be concluded that the model is suitable for static theoretical–experimental analysis of the work of the sleeper under the conditions of small track imperfections.

6. Conclusions

- In the paper the author’s method, combining field research, measurements and simulation of an unfavorable phenomenon in the track (the effect of a hanging sleeper) and a computational analysis using the field research carried out, is presented.

- The simulated short irregularity in the railway track (Figure 3) causes a significant change in the work of its individual elements. On the basis of the performed investigations and analyses, experimental relationships are obtained to describe the changes in the values of deflections and stresses (in the rail and sleeper). Such relationships can be utilized for the engineering interpretations and applications.

- The influence of this irregularity (visible after the load is applied) was experimentally analyzed in the paper. It was observed that the induced irregularity, with an irregularity gap f0 in the track, significantly changes the work of the loaded elements of the railway track structure (increase in rail deflections was up to approximately 77% and the sleeper to 99%). A similar form of deformation in the track (vertical irregularities) arises during its operation.

- For the case of a track deformation caused by a non-homogeneous foundation of the sleepers, the author created the intended irregularity with the given initial values of the wavelength of irregularity and its gap (Figure 3)—the effect of the hanging sleeper. In addition, one can conclude that:

- –

- The influence of this irregularity is visible under the influence of the applied load (Figure 6);

- –

- The proposed method of generating irregularity in the railway track (by placing non-deformable distance plates on the railway track and placing measuring sensors in the rail pad) allows the creation of the intended form with known initial values of length l0, and, above all, the desired irregularity gap f0 (Figure 3);

- –

- It is a non-destructive method of causing irregularity, which does not damage the original contact between the rail and the sleeper with the foundation.

- The presented methods are particularly useful in examining changes in track support and may be appropriate tools for assessing the work of loaded track elements during operation.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abadi, T.; Le Pen, L.; Zervos, A.; Powrie, W. Improving the performance of railway tracks through ballast interventions. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 337–355. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Moreno-Navarro, F.; Rubio-Gámez, M.C. The use of elastic elements in railway tracks: A state of the art review. Constr. Build. Mater. 2015, 75, 293–305. [Google Scholar] [CrossRef]

- Abu Sayeed, M.; Shahin, M.A. Three-dimensional numerical modelling of ballasted railway track foundations for high-speed trains with special reference to critical speed. Transp. Geotech. 2016, 6, 55–65. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.; Li, P.; Wang, P.; Liu, J.; Xiao, J.; Chen, R.; Wei, X. Study on structural health monitoring of vertical vibration of ballasted track in high-speed railway. J. Civ. Struct. Health Monit. 2021, 11, 451–463. [Google Scholar] [CrossRef]

- Bednarek, W.A. Analysis of static forces generated in-track on a railway sleeper resting on an elastic foundation due to structural imperfections using the PONTOS system. In Proceedings of the MATEC Web of Conferences, Krynica-Zdrój, Poland, 16–20 September 2018; EDP Sciences: Les Ulis, France, 2019; Volume 262, p. 6. [Google Scholar] [CrossRef]

- Milne, D.; Le Pen, L.; Watson, G.; Thompson, D.; William Powrie, W.; Hayward, M.; Morley, S. Monitoring and repair of isolated trackbed defects on a ballasted railway. Transp. Geotech. 2018, 17, 61–68. [Google Scholar] [CrossRef]

- Guerrieri, M.; Parla, G. A new high-efficiency procedure for aggregate gradation determination of the railway ballast by means image recognition method. Arch. Civ. Eng. 2013, LIX, 469–482. [Google Scholar] [CrossRef] [Green Version]

- Bednarek, W.A. Analysis of continuous welded rail track stability in vertical plane. Arch. Civ. Eng. 2006, LII, 105–125. [Google Scholar]

- Lim, N.-H.; Park, N.-H.; Kang, Y.-J. Stability of continuous welded rail track. Comput. Struct. 2003, 81, 2219–2236. [Google Scholar] [CrossRef]

- Jing, G.; Luo, Q.; Wang, Z.; Shen, Y. Micro-analysis of hanging sleeper dynamic interactions with ballast bed. J. Vibroeng. 2015, 17, 444–454. [Google Scholar]

- Ishida, M. The progress mechanism of track geometrical irregularity focusing on hanging sleepers. Int. J. Railw. Res. 2015, 2, 15–23. [Google Scholar]

- Lundqvist, A.; Dahlberg, T. Load impact on railway track due to unsupported sleepers. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transp. 2005, 219, 67–77. [Google Scholar] [CrossRef]

- Augustin, S.; Gudehus, G.; Huber, G.; Schüunemann, A. Numerical model and laboratory tests on settlement of ballast track. In System Dynamics and Long-Term Behaviour of Railway Vehicles, Track and Subgrade; Popp, K., Schiehlen, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2003; pp. 317–336. [Google Scholar] [CrossRef]

- Grassie, S.L.; Cox, S.J. Dynamic response of railway track with unsupported sleepers. Proc. Inst. Mech. Eng. Part D Transp. Eng. 1985, 199, 123–135. [Google Scholar] [CrossRef]

- Yang, L.A.; Powrie, W.; Priest, J.A. Dynamic stress analysis of a ballasted railway track bed during train passage. J. Geotech. Geoenviron. Eng. 2009, 135, 680–689. [Google Scholar] [CrossRef]

- Egana, J.I.; Vinolas, J.; Seco, M. Investigation of the influence of rail pad stiffness on rail corrugation on a transit system. Wear 2006, 261, 216–224. [Google Scholar] [CrossRef]

- Arslan, M.A.; Kayabasi, O. 3-D Rail–Wheel contact analysis using FEA. Adv. Eng. Softw. 2012, 45, 325–331. [Google Scholar] [CrossRef]

- Karttunen, K. Influence of Rail, Wheel and Track Geometries on Wheel and Rail Degradation; Chalmers University of Technology: Göteborg, Sweden, 2015; ISBN 978-91-7597-203-9. ISSN 0346-718X. [Google Scholar]

- Larsson, D. A Study of the Track Degradation Process Related to Changes in Railway Traffic; Luleå University of Technology: Porsön, Sweden, 2004. [Google Scholar]

- Pombo, J.; Ambrósio, J.; Rereira, M.; Verardi, R.; Ariaudo, C.; Kuka, N. Influence of track conditions and wheel wear state on the loads imposed on the infrastructure by railway vehicles. Comput. Struct. 2011, 89, 1882–1894. [Google Scholar] [CrossRef]

- Remennikov, A.M.; Kaewunruen, S. A review of loading conditions for railway track structures due to train and track vertical interaction. Struct. Control Health Monit. 2007, 15, 207–234. [Google Scholar] [CrossRef]

- Bowe, C.J.; Mullarkey, T.P. Wheel-rail contact elements incorporating irregularities. Adv. Eng. Softw. 2005, 36, 827–837. [Google Scholar] [CrossRef]

- Grassie, S.L. Rail corrugation: Advances in measurement, understanding and treatment. Wear 2005, 258, 1224–1234. [Google Scholar] [CrossRef]

- Povilaitienė, I.; Laurinavičius, A. Reduction of external rail wearing on road curves. J. Civ. Eng. Manag. 2004, X, 123–130. [Google Scholar] [CrossRef]

- Iwnicki, S.D.; Bevan, A.J. Damage to Railway Wheels and Rails: A Review of the Causes, Prediction Methods, Reduction and Allocation of Costs. Int. J. Railw. Technol. 2012, 1, 121–146. [Google Scholar] [CrossRef]

- Dong, K.; Connolly, D.P.; Laghrouche, O.; Woodward, P.K.; Alves Costa, P. The stiffening of soft soils on railway line. Transp. Geotech. 2018, 17, 178–191. [Google Scholar] [CrossRef]

- Paixao, A.L.M. Transition Zones in Railway Tracks. An Expiremental and Numerical Study on the Structural Behaviour. Ph.D. Thesis, Faculdade de Engenharia Universidade do Porto (FEUP), Porto, Portugal, 2014. [Google Scholar]

- Varandas, J.N.; Hölscher, P.; Silva Manuel, A.G. Dynamic behaviour of railway tracks on transitions zones. Comput. Struct. 2011, 89, 1468–1479. [Google Scholar] [CrossRef]

- Dai, G.; Su, M. Full-scale field experimental investigation on the interfacial shear capacity of continuous slab track structure. Arch. Civ. Mech. Eng. 2016, 16, 485–493. [Google Scholar] [CrossRef]

- Kraśkiewicz, C.; Zbiciak, A.; Oleksiewicz, W.; Karwowski, W. Static and dynamic parameters of railway tracks retrofitted with under sleeper pads. Arch. Civ. Eng. 2018, LXIV, 187–201. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.M.; Yang, T.Y.; He, Z.; Li, J.Y. Analytical modeling of grinding process in rail profile correction considering grinding pattern. Arch. Civ. Mech. Eng. 2018, 18, 669–678. [Google Scholar] [CrossRef]

- Zaker, J.A.; Xia, H.; Fan, J.J. Dynamic response of train-track system to single rail irregularity. Lat. Am. J. Solids Struct. 2009, 6, 89–104. [Google Scholar]

- Available online: https://www.gom.com/en/products/high-precision-3d-metrology/pontos-live (accessed on 22 June 2021).

- Akas, A.Y.; Aksoydan, M. Transfer and stiffness matrix for Timoshenko beams on elastic foundations. ARI Bull. Istanb. Tech. Univ. 2004, 54, 1–15. [Google Scholar]

- Al-Azzawi, A.A.; Shaker, A.S. Finite difference analysis of curved deep beams on Winkler foundation. ARPN J. Eng. Appl. Sci. 2011, 6, 42–48. [Google Scholar]

- Dudzik, A.; Obara, P. Analiza Stateczności Belki Timoshenki Spoczywającej na Podłożu Sprężystym. Acta Sci. Pol. Archit. 2010, 9, 17–29. Available online: www.architectura.actapol.net/tom9/zeszyt1 (accessed on 26 April 2021).

- Kerr, A.D. On the vertical modulus in the standard railway track analyses. Rail Int. 1987, 11, 37–45. [Google Scholar]

- Vallabhan, C.V.G.; Das, Y.C. Parametric study of beams on elastic foundations. J. Eng. Mech. Div. 1988, 114, 2072–2082. [Google Scholar] [CrossRef]

- Eisenberger, M.; Bielak, J. Finite beams on infinite two-parameter elastic foundations. Comput. Struct. 1992, 42, 661–664. [Google Scholar] [CrossRef]

- Teodoru, I.-B.; Muşat, V. Beam Elements on Linear Variable Two-Parameter Elastic Foundation. Bul. Inst. Politeh. Din Iaşi Tomul. 2008, LIV(LVIII), 69–78. Available online: www.bipcons.ce.tuiasi.ro/Content/ArticleInformation.php?ArticleID=118 (accessed on 26 April 2021).

- Vlasov, V.Z.; Leont’ev, N.N. Beams, Plates, and Shells on Elastic Foundation; Israel Program for Scientific Translations: Jerusalem, Israel, 1966; pp. 1–94, (Translated from Russian). [Google Scholar]

- Teodoru, I.-B.; Muşat, V. The modified Vlasov foundation model: An attractive approach for beams resting on elastic supports. Electron. J. Geotech. Eng. 2010, 15, 1–13. Available online: www.ejge.com/2010/JourTOC15C.htm (accessed on 26 April 2021).

- Vallabhan, C.V.G.; Das, Y.C. Modified Vlasov model for beams on elastic foundations. J. Geotech. Eng. 1991, 117, 956–966. [Google Scholar] [CrossRef]

- Bednarek, W.A. Determination of foundation coefficients for a 2-parameter model on the basis of railway sleeper deflection. In Continuous Media with Microstructure 2; Springer International Publishing: Cham, Switzerland, 2016; pp. 325–341. ISBN 978-3-319-28239-8. [Google Scholar] [CrossRef]

- Eisenberger, M.; Yankelevsky, D.Z. Exact stiffness matrix for beams on elastic foundation. Comput. Struct. 1985, 21, 1355–1359. [Google Scholar] [CrossRef]

- Buczkowski, W. A solving of beams at variable stiffness by finite differences method. Architectura 2009, 8, 49–64. (In Polish) [Google Scholar]

| The Rail 49E1 of the Analyzed Railway Track Is Divided into Elements: | The Following Data is Used for the Railway Sleeper, Treated as a Timoshenko’s Beam: |

|---|---|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bednarek, W.A. Full-Scale Field Experimental Investigation on the Intended Irregularity of CWR Track in Vertical Plane. Energies 2021, 14, 7477. https://doi.org/10.3390/en14227477

Bednarek WA. Full-Scale Field Experimental Investigation on the Intended Irregularity of CWR Track in Vertical Plane. Energies. 2021; 14(22):7477. https://doi.org/10.3390/en14227477

Chicago/Turabian StyleBednarek, Włodzimierz Andrzej. 2021. "Full-Scale Field Experimental Investigation on the Intended Irregularity of CWR Track in Vertical Plane" Energies 14, no. 22: 7477. https://doi.org/10.3390/en14227477