1. Introduction

One of the best solutions for compensating for power losses and voltage drop due to load growth is to operate with the optimal allocation of distributed generation (DG) systems [

1,

2,

3,

4]. Not only DG increases energy efficiency, but it also provides environmental benefits with lower emissions compared to coal- or oil-based central thermal power generation [

5,

6]. Therefore, regulatory agencies in several countries have imposed strict environmental protection regulations to encourage the switch to green energy sources, and several countries are working to reduce their dependence on fossil fuels and increase their production of renewable energy. For example, the Ministry of Trade and Industry in the Republic of Korea established a policy to increase power generation from renewable energy sources to 20% total generation by 2030 [

7]. For these reasons, the DG systems have recently started to be added to power grids with increasing worldwide penetration, and a typical example is a photovoltaic (PV) system. Over the past decade since 2000, solar power has grown at an average annual rate of 42%. On the other hand, installation costs are reduced by 70%, and prices in Q4 2020 are among the lowest in all market segments [

8].

DG systems typically use renewable energy resources, including PV, wind turbines, and fuel cells (FCs). Renewable energy is highly volatile, and DG systems and related energy storage systems have the challenge caused by injecting power into the grid (e.g., reverse power flow) [

9,

10]. Additionally, there is a problem that adding DG increases grid complexity. Therefore, it is necessary to properly allocate DG to effectively utilize it, and studies are needed to greatly increase energy efficiency by an optimal DG in energy hubs [

11,

12,

13]. Furthermore, studies should be conducted considering economic feasibility as well as reducing energy losses and emissions.

Many studies have analyzed DG system impacts on costs, emissions, reliability, and power quality, following several approaches:

Finding optimal energy consumption when including DG options using meta-heuristic algorithms (e.g., artificial bee colony, genetic algorithm (GA) and particle swarm optimization (PSO));

Various analysis software for DG systems in an integrated energy hub system (e.g., Engineering Equation Solver (EES) or HOMER), typically using case studies regarding energy consumption, cost savings, or emissions savings, and

Analyzing carbon dioxides (CO2) and nitrogen oxide (NOx) emission effects.

Regarding the first approach, many previous researchers have used meta-heuristic algorithms to study the optimal energy consumption of DG systems. For example, Abu-Mouti and El-Hawary used an artificial bee colony algorithm to determine optimal DG capacity and location to minimize power losses [

14]. Abou El-Ela, Allam, and Shatlab used GAs to determine the optimal DG location and capacity [

15]. They have been shown to have an impact for improving voltage profile improvement (VPI), spinning reserve increasing (SRI), power flow reduction (PFR), and line-loss reduction (LLR). Gomez-Gonzalez, López, and Jurado defined the optimal DG location and capacity for minimizing power loss and voltage profile through four simulations [

16]. They used PSO and compared the convergence curves of the objective function and the number of convergences, proving that it is a better solution than achieved using GA. However, in the case of studies such as the first approach, there is a limitation that an integrated energy hub system cannot be considered. Moreover, there is also a limitation that it is difficult to analyze the impact of energy consumption, cost savings, and emissions savings by DG.

To solve the limitations of the first approach, studies on the second approach have been conducted by many researchers. For example, Alam and Gao simulated hybrid system costs, electricity production, and emissions using HOMER, and examined feasibility for PV, wind, and diesel hybrid systems [

17]. They proposed a fuzzy logic power flow controller to provide sustainable power and simulation results verified that wind, PV, and FC hybrid power systems could be feasible solutions for standalone applications. Mirzaee, Zare, and Sadeghzadeh modeled energy efficiency for cogeneration systems, including gas turbines, absorption chillers (AbCs), boilers, and heat exchangers, using an EES software [

18]. For this, the values of energy efficiency (EE), energy used (UE), and utility fuel ratio (UFR) were calculated and analyzed. Nine scenarios were considered, and they confirmed that double-effect AbCs were more optimal than single-effect AbCs.

Previous studies optimized combined heat and power (CHP) systems and proposed the energy hub concept for power flow, reliability, system optimization, investment evaluation, and application [

19,

20]. Energy hubs including CHP systems have also been modeled [

21]. Continued DG developments for CHP systems have made increased urban electricity, water, and natural gas distribution network interconnectivity and complexity. For this reason, studies on energy hubs have been enhanced to studies involving the interconnectivity and complexity of networks. For example, Zhang, Karady, and Ariaratnam designed individual electric, water, and gas network models to analyze integrated system dispatch models [

22]. CHP systems based on DG were also included in the distribution systems. They considered multiple factors, including capacity bounds, power factors, gas supply, ambient temperatures, and nodal water pressures, and their mutual effects on CHP-based DG systems and distribution networks’ operational performances for optimal CHP-based DG systems’ allocations. Li and Wang studied optimizing a renewable energy integrated combined cooling heat and power (CCHP) system [

23]. They implemented a multi-objective (e.g., total annual cost, carbon dioxide emission, potential loss of energy supply) optimization model to characterize system reliability, system cost, and environmental sustainability. For these purposes, they considered the number of PV panels and wind turbines, the tilt angle of the PV panel, the height of the wind turbines, maximum fuel consumption, battery, and heat storage tanks as variables’ configuration. Kim, James and Crittenden used HOMER to simulate modern net-zero energy buildings with such CCHP, PV, and AbCs [

24]. They presented considering hosting only the CCHP system or CCHP and PV systems in an office building, and confirmed improved energy efficiency and economic sensitivity for CCHP and PV systems.

Although studies of the first approach focused on meta-heuristic algorithms (e.g., artificial bee colony, GA, and PSO) to achieve optimal DG location and capacity, the energy hubs were not considered in these studies. Moreover, energy consumptions, cost savings, and emissions savings by DG were not analyzed. Studies on the second approach were supplemented by considering the energy hubs, but the most cost-efficient of DG was not investigated in the CHP system for metropolitan resident customers. Furthermore, energy consumption and emissions savings from using the CHP system with AbCs have not been investigated for metropolitan residential customers. For example, AbCs can convert waste heat to cooling water or air, maximizing energy usage efficiency.

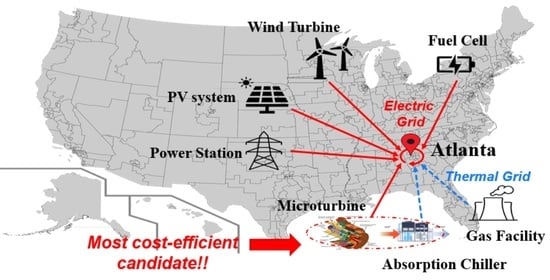

This paper developed an energy hub model for residential customers to determine the most cost-efficient DG type, considering PV, wind turbines, FCs, and microturbines (MTs) with AbCs. We selected a specific metropolitan area as a testbed (Atlanta, USA), and used MATLAB and HOMER to determine MTs with AbCs to be the most cost-effective candidate DG. Optimal scheduling for MTs and AbCs minimized DG and AbC life-cycle costs and electric and thermal energy purchasing costs from the external system. As an additional case study, electrical and thermal energy, costs, and emissions savings were compared by changing optimal DG operation modes (e.g., full or optimal-blast, with or without AbC in the CHP system, etc.).

The remainder of this paper is organized as follows.

Section 2 presents the problem statement and

Section 3 describes proposed mathematical DG and AbC models for energy systems.

Section 4 performs case studies and

Section 5 summarizes simulation results to verify the proposed methods. Finally,

Section 6 and

Section 7 discuss and conclude the paper.

4. Case Study

This study presents the methodology for selecting the most cost-efficient DG type for metropolitan residential customers (e.g., Atlanta). For this purpose, we considered Atlanta USA as a testbed for case studies to analyze DG impacts on metropolitan residential customers. Capital, replacement, operating and maintenance costs (OM), lifetime, search space, fuel consumption, and emissions are factors to be considered to determine the most cost-efficient DG type. In the first scenario, which will be presented in the following section (e.g.,

Section 5.1), we present a case study for metropolitan residential customers to find the most cost-efficient DG type in the CCHP system. In the second scenario (e.g.,

Section 5.2), it is necessary to extend the first scenario results (e.g.,

Section 5.1). The first scenario results did not take into account how the DG was operated and the presence or absence of AbCs. These factors affect energy consumption, cost savings, and emission reduction and need to be considered. For this purpose, in

Section 5.2, we compare the energy consumption, cost savings, and emissions reduction either with or without AbCs, and CCHP operational modes for full or optimal-blast scenarios. Moreover, to demonstrate these simulation results, the electric and thermal load profile data of the Atlanta area are applied as input to HOMER and MATLAB software. The detailed MT, FC, wind turbine, PV, and converter parameters are presented in the

Appendix A.

4.1. Electric and Thermal Load Profile

Since loads (or demands) vary momentarily depending on customer needs, we collected load data at hourly intervals for metropolitan residential customers (e.g., Atlanta) from open energy information (OpenEI) in the Atlanta area in 2013 [

34], summarized in

Table 1.

Figure 4 shows the electrical and thermal load profile for metropolitan residential customers in the Atlanta area [

24], where 1 unit represents the electrical (4.13 kW, 1 August) and thermal (13.28 kW, 12 February) peaks. Cooling demand was dominant for the summer electric peak day, whereas heating demand was dominant for the winter thermal peak day. Load factors, for electric and thermal demands = 0.36 and 0.09, respectively, are defined as the ratio of average to maximum load over a given period.

4.2. Case Study Input Data

The first scenario optimally scheduled all DG systems without AbCs. Since the CCHP system in Atlanta was unavailable, we examined the Masonic Village in Elizabethtown, Pennsylvania, USA, which recently installed six 65 kW Capstone MTs in metropolitan residential facilities [

35], and assumed the same MTs were available in Atlanta to identify the effect of AbCs for residential customers in a metropolitan area. For the feasibility of these simulation conditions, the energy use patterns (e.g., cooling, fans, heating, lighting, equipment, unknown) and load profiles of Masonic Village were investigated and compared to Atlanta for similarity. Since there is no energy observatory in Masonic Village, the data from the energy observatory in Harrisburg, which is closest to Masonic Village, were used.

Figure 5 shows energy usage patterns like

Figure 4a in

Section 4.1, and

Figure 6 and

Figure 7 show that the annual electric and thermal demands of Atlanta and Masonic Village are similar.

The Masonic Village serves 1700 residents, hence the number of households ≈669 assuming 2.54 people per household [

24,

36]. We scaled the total active power for the Atlanta community by multiplying this number of households by the mean load profile data for metropolitan residential customers collected from OpenEI [

34]. Load profile data have electrical peak = 2762 kW and thermal peak = 8884.94 kW, hence total penetration for the CCHP system comprising six 65 kW Capstone MTs for the proposed Atlanta area = 14.1% (65 kW × 6)/(4.13 kW × 669) from equation (1), corresponding to the recommended limit, or 15% peak load proposed in [

37].

Table 2 shows cost input data for the simulation model to analyze the CCHP system’s economic impacts on energy generation costs. Georgia Power Company (GPC) on-peak hours = 2–7 p.m. June to September with total cost 203.217

$/MWh [

38]. The remaining off-peak hours’ cost = 49.409

$/MWh [

38]. Natural gas prices for electric power in Georgia = 0.1155

$/m

3 in 2015 [

26].

The second scenario assumed MTs operated constantly, referred to as a full-blast scenario, and compares the optimally operating MT effects. As a difference from the first scenario, the AbCs were added. Metropolitan residential customers do not need energy for cooling, which often overlaps peak hours, using the most expensive fuel when AbCs produce chilled water or air from waste heat. Thus, optimally scheduling the AbCs can reduce energy costs, and cooling loads can be met by recovering chilled air or water from waste heat within capacity limits. We also examined energy consumption, costs, and emissions savings between MTs with or without AbCs and optimal or full-blast during on or off-peak hours.

6. Discussion

In this study, a case study was conducted to investigate the most cost-efficient DG type in an integrated energy hub model (e.g., the CCHP system) for metropolitan residential customers. For this purpose, we modeled various DG types and examined their impacts on the CCHP system including PV, wind turbines, FCs, and MTs with AbCs. We collected electrical and thermal load profile data for the Atlanta, USA area, and constructed a simulation model based on residential customers in Atlanta. After that, we optimally scheduled the annual operation of DG systems in hourly intervals using HOMER and determined the most cost-efficient DG type from the various feasible options by implementing MATLAB codes that read the HOMER simulation results and hence analyzed electrical and thermal energy and emissions savings effects.

Our simulation results suggest the following points. First, MTs have a life-cycle cost lower than all other DG systems and hence were the best candidate without considering AbCs. The indexes of

Table 3 and

Figure 8 show that MTs are the most cost-efficient compared to all other DG systems. Second, AbCs show a significant impact on energy efficiency, cost savings, and emission reduction. The indexes of

Table 4 show that full-blast MTs with AbCs are the most cost-efficient. In

Figure 12 and

Figure 13, full-blast MTs with AbCs show the highest reduction in energy consumed from the grid. In

Figure 15,

Figure 16,

Figure 17 and

Figure 18, full-blast MTs with AbCs show the highest reduction in emissions. The reason is that when full-blast MTs with AbCs reduce the energy supplied from the grid and reuse waste heat through AbCs.

Most of the previous studies examined in the literature review section have used meta-heuristic algorithms to estimate the optimal DG location or capacity or to build an energy hub model that analyzes energy consumption, cost savings, or emissions savings. The previous studies also did not consider the conditions (e.g., electric and thermal load profile data should be changed by the use of AbCs for metropolitan residential customers). However, the methodology of this paper not only considers an overall energy hub model that includes the CCHP system with PV, wind turbines, FCs, or MTs with AbCs but also allows the selection of the most cost-efficient DG candidates for the conditions of the corresponding metropolis. This methodology can be also applied to other large cities or rural area models.