A New Device Hypothesis for Water Extraction from Air and Basic Air Condition System in Developing Countries

Abstract

:1. Introduction

Objective and Novelty of the Project

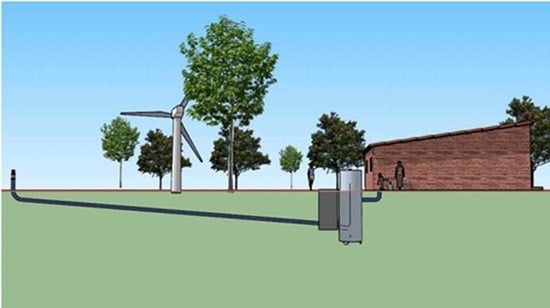

2. The Proposed System

2.1. Peltier Cells

2.2. Horizontal Earth-to-Air Heat Exchanger

3. Calculation

- (1)

- Calculation of the geothermal heat transfer and determination of the thermohygrometric conditions at the outlet of the geothermal probe;

- (2)

- Calculation of the thermal power exchanged on the cold and hot sides with the Peltier cell array;

- (3)

- Calculation of the indoor air intake conditions with or without adiabatic mixing.

3.1. The Geothermal System

3.2. The Peltier Cell Array

3.3. Adiabatic Mixture

4. Results

4.1. Monthly Trends of Temperatures Along the Length of the Pipe

4.2. Thermohygrometric Analysis and Calculation of Collected Water

- ●

- m is the mass flow value of the only cooling section (m3/h),

- ●

- is the title corresponding to the output values from the geothermal system (g/kg),

- ●

- is the title corresponding to the output values of the section Peltier (g/kg).

4.3. Optimization by Changing the Number of Peltier Cells

4.4. System Electrical Consumption

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Baglivo, C. Dynamic Evaluation of the Effects of Climate Change on the Energy Renovation of a School in a Mediterranean Climate. Sustainability 2021, 13, 6375. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, X.; Sun, S.; Tang, Y.; Yuan, X.; Tang, Q. Global assessment of future sectoral water scarcity under adaptive inner-basin water allocation measures. Sci. Total Environ. 2021, 783, 146973. [Google Scholar] [CrossRef]

- Vörösmarty, J.; McIntyre, P.B.; Gessner, M.O.; Dudgeon, D.; Prusevich, A.; Green, P.; Glidden, S.; Bunn, S.E.; Sullivan, C.A.; Liermann, C.R.; et al. Global threats to human water security and river biodiversity. Nature 2010, 467, 555. [Google Scholar] [CrossRef] [PubMed]

- Gerten, D.; Heinke, J.; Hoff, H.; Biemans, H.; Fader, M.; Waha, K. Global water availability and requirements for future food production. J. Hydrometeorol. 2011, 12, 885–899. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Q.; Yang, H. Assessing water scarcity by simultaneously considering environmental flow requirements, water quantity, and water quality. Ecol. Indic. 2016, 60, 434–441. [Google Scholar] [CrossRef] [Green Version]

- Hejazi, M.I.; Edmonds, J.; Clarke, L.; Kyle, P.; Davies, E.; Chaturvedi, V.; Wise, M.; Patel, P.; Eom, J.; Calvin, K. Integrated assessment of global water scarcity over the 21st century under multiple climate change mitigation policies. Hydrol. Earth Syst. Sci. 2014, 18, 2859–2883. [Google Scholar] [CrossRef] [Green Version]

- Congedo, P.M.; Baglivo, C. Implementation hypothesis of the Apulia ITACA Protocol at district level—part I: The model. Sustain. Cities Soc. 2021, 70, 102931. [Google Scholar] [CrossRef]

- Congedo, P.M.; Baglivo, C.; Toscano, A.M. Implementation Hypothesis of the Apulia ITACA Protocol at District Level—Part II: The Case Study. Sustain. Cities Soc. 2021, 70, 102927. [Google Scholar] [CrossRef]

- Van Blommestein, K.C.; Daim, T.U. Residential energy efficient device adoption in South Africa. Sustain. Energy Technol. Assess. 2013, 1, 13–27. [Google Scholar] [CrossRef]

- Weaver, M.; O’Keeffe, J.; Hamer, N.; Palmer, C. A civil society organisation response to water service delivery issues in South Africa drives transformative praxis. Part 2: Knowledge building, learning and active citizenship. Geoforum 2019, 107, 14–23. [Google Scholar] [CrossRef]

- Habiyaremye, A. Water innovation in South Africa: Mapping innovation successes and diffusion constraints. Environ. Sci. Policy 2020, 114, 217–229. [Google Scholar] [CrossRef]

- Zorić, A.; Heusinkveld, H. Developing Mobile Water Operator Technology for Africa. Environ. Sci. Policy 2020, 112, 314–317. [Google Scholar] [CrossRef]

- Zhuwakinyu, M. A Review of South Africa’s Water Sector; Creamer Media Research Channel: Johannesburg, South Africa, 2012. [Google Scholar]

- Salehi, A.A.; Ghannadi-Maragheh, M.; Torab-Mostaedi, M.; Torkaman, R.; Asadollahzadeh, M. A review on the water-energy nexus for drinking water production from humid air. Renew. Sustain. Energy Rev. 2020, 120, 109627. [Google Scholar] [CrossRef]

- Lundqvist, J.; Andersson, A.; Johannisson, A.; Lavonen, E.; Mandava, G.; Kylin, H.; Bastviken, D.; Oskarsson, A. Innovative drinking water treatment techniques reduce the disinfection-induced oxidative stress and genotoxic activity. Water Res. 2019, 155, 182–192. [Google Scholar] [CrossRef] [PubMed]

- Srithar, K.; Rajaseenivasan, T. Recent fresh water augmentation techniques in solar still and HDH desalination—A review. Renew. Sustain. Energy Rev. 2018, 82, 629–644. [Google Scholar] [CrossRef]

- Vakilifard, N.; Anda, M.; Bahri, P.A.; Ho, G. The role of water-energy nexus in optimising water supply systems—Review of techniques and approaches. Renew. Sustain. Energy Rev. 2018, 82, 1424–1432. [Google Scholar] [CrossRef]

- Wahlgren, R.V. Atmospheric water vapour processor designs for potable water production: A review. Water Res. 2001, 35, 1–22. [Google Scholar] [CrossRef]

- Shourideh, A.H.; Ajram, W.B.; Al Lami, J.; Haggag, S.; Mansouri, A. A comprehensive study of an atmospheric water generator using Peltier effect. Therm. Sci. Eng. Prog. 2018, 6, 14–26. [Google Scholar] [CrossRef]

- Liu, S.; He, W.; Hu, D.; Lv, S.; Chen, D.; Wu, X.; Xu, F.; Li, S. Experimental analysis of a portable atmospheric water generator by thermoelectric cooling method. Energy Procedia 2017, 142, 1609–1614. [Google Scholar] [CrossRef]

- Yıldırım, C.; Soylu, S.K.; Atmaca, İ.; Solmuş, İ. Experimental investigation of a portable desalination unit configured by a thermoelectric cooler. Energy Convers. Manag. 2014, 85, 140–145. [Google Scholar] [CrossRef]

- Milani, D.; Qadir, A.; Vassallo, A.; Chiesa, M.; Abbas, A. Experimentally validated model for atmospheric water generation using a solar assisted desiccant dehumidification system. Energy Build. 2014, 77, 236–246. [Google Scholar] [CrossRef]

- Lindblom, J.; Nordell, B. Underground condensation of humid air for drinking water production and subsurface irrigation. Desalination 2007, 203, 417–434. [Google Scholar] [CrossRef]

- Lindblom, J.; Nordell, B. Water production by underground condensation of humid air. Desalination 2006, 189, 248–260. [Google Scholar] [CrossRef]

- Bonuso, S.; Panico, S.; Baglivo, C.; Mazzeo, D.; Matera, N.; Congedo, P.M.; Oliveti, G. Dynamic Analysis of the Natural and Mechanical Ventilation of a Solar Greenhouse by Coupling Controlled Mechanical Ventilation (CMV) with an Earth-to-Air Heat Exchanger (EAHX). Energies 2020, 13, 3676. [Google Scholar] [CrossRef]

- Croce, D.; Giuliano, F.; Bonomolo, M.; Leone, G.; Musca, R.; Tinnirello, I. A decentralized load control architecture for smart energy consumption in small islands. Sustain. Cities Soc. 2020, 53, 101902. [Google Scholar] [CrossRef]

- Mazzeo, D.; Matera, N.; De Luca, P.; Baglivo, C.; Congedo, P.M.; Oliveti, G. A literature review and statistical analysis of photovoltaic-wind hybrid renewable system research by considering the most relevant 550 articles: An upgradable matrix literature database. J. Clean. Prod. 2021, 295, 126070. [Google Scholar] [CrossRef]

- Cannistraro, M.; Trancossi, M. Enhancement of indoor comfort in the presence of large glazed radiant surfaces by a local heat pump system based on Peltier cells. Therm. Sci. Eng. Prog. 2019, 14, 100388. [Google Scholar] [CrossRef]

- Congedo, P.M.; Baglivo, C.; Bonuso, S.; D’Agostino, D. Numerical and experimental analysis of the energy performance of an air-source heat pump (ASHP) coupled with a horizontal earth-to-air heat exchanger (EAHX) in different climates. Geothermics 2020, 87, 101845. [Google Scholar] [CrossRef]

- Baglivo, C.; D’Agostino, D.; Congedo, P.M. Design of a Ventilation System Coupled with a Horizontal Air-Ground Heat Exchanger (HAGHE) for a Residential Building in a Warm Climate. Energies 2018, 11, 2122. [Google Scholar] [CrossRef] [Green Version]

- Agrawal, K.K.; Agrawal, G.D.; Misra, R.; Bhardwaj, M.; Jamuwa, D.K. A review on effect of geometrical, flow and soil properties on the performance of Earth air tunnel heat exchanger. Energy Build. 2018, 176, 120–138. [Google Scholar] [CrossRef]

- Lund, J.W.; Freeston, D.H.; Boyd, T.L. Direct application of geothermal energy: 2005 Worldwide review. Geothermics 2005, 34, 691–727. [Google Scholar] [CrossRef]

- Wu, Y.; Gan, G.; Verhoef, A.; Vidale, P.L.; Gonzalez, R.G. Experimental measurement and numerical simulation of horizontal-coupled slinky ground source heat exchangers. Appl. Therm. Eng. 2010, 30, 2574–2583. [Google Scholar] [CrossRef] [Green Version]

- Congedo, P.M.; Lorusso, C.; Baglivo, C.; Milanese, M.; Raimondo, L. Experimental validation of horizontal air-ground heat exchangers (HAGHE) for ventilation systems. Geothermics 2019, 80, 78–85. [Google Scholar] [CrossRef]

- Choi, J.C.; Lee, S.R.; Lee, D.S. Numerical simulation of vertical ground heat exchangers: Intermittent operation in unsaturated soil conditions. Comput. Geotech. 2011, 38, 949–958. [Google Scholar] [CrossRef]

- Vaz, J.; Sattler, M.A.; Brum, R.D.S.; dos Santos, E.D.; Isoldi, L. An experimental study on the use of Earth-Air Heat Exchangers (EAHE). Energy Build. 2014, 72, 122–131. [Google Scholar] [CrossRef]

- Li, A.; Xu, X.; Sun, Y. A study on pipe-embedded wall integrated with ground source-coupled heat exchanger for enhanced building energy efficiency in diverse climate regions. Energy Build. 2016, 121, 139–151. [Google Scholar] [CrossRef] [Green Version]

- Benkert, S.; Heidt, F.D.; Scholer, D. Calculation Tool for Earth Heat Exchangers GAEA; Siegen University: Siegen, Gernany, 2011. [Google Scholar]

- Chiesa, G.; Simonetti, M.; Grosso, M. A 3-field earth-heat-exchange system for a school building in Imola, Italy: Monitoring results. Renew. Energy 2014, 62, 563–570. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.H.; Strand, R.K. The cooling and heating potential of an earth tube system in buildings. Energy Build. 2008, 40, 486–494. [Google Scholar] [CrossRef]

- Darkwa, J.; Kokogiannakis, G.; Magadzire, C.; Yuan, K. Theoretical and practical evaluation of an earth-tube (E-tube) ventilation system. Energy Build. 2011, 43, 728–736. [Google Scholar] [CrossRef]

- Mihalakakou, G.; Santamouris, M.; Asimakopoulos, D.; Tselepidaki, I. Parametric prediction of the buried pipes cooling potential for passive cooling applications. Sol. Energy 1995, 55, 163–173. [Google Scholar] [CrossRef]

- St. Benkert, F.D. Heid, Chapter 380—Designing Earth Heat Exchangers—Validation of the Software GAEA. In Proceedings of the Energy for the 21st Century World Renewable Energy Congress VI, Brighton, UK, 1–7 July 2000; pp. 1818–1821, ISBN 9780080438658. [Google Scholar] [CrossRef]

- Mazzeo, D.; Matera, N.; De Luca, P.; Baglivo, C.; Congedo, P.M.; Oliveti, G. Worldwide geographical mapping and optimization of stand-alone and grid-connected hybrid renewable system techno-economic performance across Köppen-Geiger climates. Appl. Energy 2020, 276, 115507. [Google Scholar] [CrossRef]

- Chen, D.; Chen, H.W. Using the Köppen classification to quantify climate variation and change: An example for 1901–2010. Environ. Dev. 2013, 6, 69–79. [Google Scholar] [CrossRef]

- Available online: https://docs.rs-online.com/9cff/0900766b8144aa0d.pdf (accessed on 1 June 2021).

| System Components | |

| 1 | Air intake system |

| 2 | Filter |

| 3 | Fan |

| 4 | EAHX |

| 5 | Curved connecting element |

| 6 | Pipe extension with Peltier cell placement |

| 7 | Septum |

| 8 | Peltier cell |

| 9 | Hot side of Peltier cell |

| 10 | Fan |

| 11 | Cold side of Peltier cell |

| 12 | Grille |

| 13 | Tank |

| 14 | Tank inspection chamber |

| 15 | Extension of the pipe for supplying air treated in the environment |

| Moist air states | |

| A | External air entering the geothermal pipe |

| B | Air exiting the geothermal before meeting the Peltier cells |

| C | Air exiting from cold side of Peltier cell |

| D | Air exiting from hot side of Peltier cell |

| E | Adiabatic mixing of hot and cold air flows |

| Elements | Descriptions | Values |

|---|---|---|

| Pipe | Number of pipes | 1 |

| Length of pipes | 20 m | |

| Diameter of pipes | 200 mm | |

| Burial depth | 1.2 m | |

| Soil | Type of soil | Clay |

| Density | 1500 kg/m3 | |

| Heat capacity | 0.88 kJ/kgK | |

| Thermal conductivity | 1.28 W/mK | |

| Soil water level | 20 m | |

| External temperature | Max. monthly value | 32.4 °C |

| Yearly mean temperature | 20.9 °C | |

| Min. monthly value | 9.4 °C | |

| Building | Volume | 100 m3 |

| Air change rate | 2.34 1/h | |

| Ventilation flow | 234 m3/h | |

| System control | Set point temperature | 20 °C |

| Boundary value for heating | 18 °C | |

| Boundary value for cooling | 25 °C | |

| Flow | Constant pressure drops | 50 Pa |

| Pressure drops in pipes | 0.47 Pa/m | |

| Total pressure drops | 59.43 Pa | |

| Fan efficiency | 0.4 | |

| Fan power | 9.66 W | |

| Specific energy consumption | 0.041 Wh/m3 | |

| Geothermal parameters | Heat gain | 678.6 kWh |

| Hear loss | 675.3 | |

| Yearly max. inlet air temperature | 38.4 °C | |

| Yearly max. outlet air temperature | 33.6 °C | |

| Yearly min. inlet air temperature | 3.4 °C | |

| Yearly min. outlet air temperature | 8.0 °C | |

| Efficiency factor heating | 2.65 | |

| Efficiency factor cooling | 5.86 |

| Technical Data | Values |

|---|---|

| Power (𝑃𝐶𝑒𝑙𝑙 𝑃𝑒𝑙𝑡𝑖𝑒𝑟) | 0.340 kW |

| Voltage | ≈25 V |

| Maximum absorbed current | 15.4 A |

| Maximum differential between hot and cold side temperatures | 68 °C |

| Maximum supply voltage | 35.9 V |

| Max hot side temperature | 90 °C |

| Size | 52 mm × 52 mm × 3.5 mm |

| Max mounting pressure | 1.5 MPa |

| Month | TA (°C) | RHA (%) | XA (g/kg) | TB (°C) | RHB (%) | ΔRH (%) | XB (g/kg) | (g/h) | HB (kJ/kg) |

|---|---|---|---|---|---|---|---|---|---|

| 15 January | 34.3 | 83.5 | 29.28 | 30.2 | 100.0 | 16.5 | 27.50 | 510.2 | 100.69 |

| 15 February | 36.6 | 73.5 | 29.48 | 32.3 | 94.1 | 20.6 | 29.48 | 0 | 107.38 |

| 15 March | 35.9 | 87.5 | 33.7 | 32 | 100.0 | 12.5 | 30.62 | 882.8 | 110.58 |

| 15 April | 32.3 | 71.5 | 22.28 | 29.6 | 82.9 | 11.4 | 22.28 | 0 | 85.57 |

| 15 May | 27.0 | 79.0 | 17.91 | 25.6 | 93.5 | 14.5 | 17.91 | 0 | 75.22 |

| 15 June | 20.9 | 80.0 | 12.43 | 20.9 | 80.0 | 0 | 12.43 | 0 | 52.42 |

| 15 July | 16.2 | 88.5 | 10.18 | 17.1 | 84.2 | −4.3 | 10.18 | 0 | 43.10 |

| 15 August | 13.8 | 64.5 | 6.34 | 14.9 | 59.2 | −5.3 | 6.34 | 0 | 30.68 |

| 15 September | 14.5 | 72.0 | 7.41 | 15.2 | 68.2 | −3.8 | 7.41 | 0 | 33.76 |

| 15 October | 18.0 | 92.0 | 11.89 | 17.7 | 94.5 | 2.5 | 11.89 | 0 | 48.09 |

| 15 November | 23.6 | 84.0 | 15.46 | 21.9 | 94.3 | 10.3 | 15.46 | 0 | 61.60 |

| 15 December | 29.4 | 87.5 | 22.94 | 26.4 | 100.0 | 12.5 | 21.86 | 309.5 | 82.28 |

| Month | Cooling Power (kJ/kg) | HC (kJ/kg) | XC (g/kg) | (g/h) | (g/h) | TC (°C) | RHC (%) | TD (°C) | RHD (%) | TE (°C) | RHE (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 January | 6.706 | 93.98 | 25 | 358.3 | 868.5 | 29.84 | 93.2 | 44.33 | 46.55 | 37.085 | 65.18 |

| 15 February | 6.706 | 100.67 | 27 | 355.4 | 355.4 | 31.33 | 92.2 | 45.83 | 45.9 | 38.58 | 64.45 |

| 15 March | 6.706 | 103.87 | 28.4 | 318.2 | 1201.1 | 30.96 | 98.79 | 46.06 | 47.04 | 38.51 | 67.39 |

| 15 April | 6.706 | 78.86 | 20.8 | 212.1 | 212.1 | 25.67 | 99.59 | 42.82 | 41.68 | 34.245 | 62.98 |

| 15 May | 6.706 | 68.51 | 17.7 | 30.1 | 30.1 | 23.32 | 98 | 43.73 | 31.62 | 33.525 | 54.5 |

| 15 June | 6.706 | 45.71 | 11.5 | 133.3 | 133.3 | 16.5 | 98.13 | 35.36 | 33.82 | 25.93 | 57.23 |

| 15 July | 6.706 | 36.39 | 9.26 | 131.9 | 131.9 | 12.93 | 99.8 | 31.91 | 34.52 | 22.42 | 57.6 |

| 15 August | 6.706 | 23.97 | 6.48 | 0 | 0 | 7.63 | 99.99 | 29.38 | 25.14 | 18.505 | 48.6 |

| 15 September | 6.706 | 27.05 | 7.13 | 40.1 | 40.1 | 9.05 | 99.82 | 29.72 | 28.61 | 19.385 | 52.1 |

| 15 October | 6.706 | 41.38 | 10.4 | 213.6 | 213.6 | 15 | 97.89 | 32.5 | 38.89 | 23.75 | 60.79 |

| 15 November | 6.706 | 54.89 | 13.9 | 223.6 | 223.6 | 19.51 | 97.84 | 36.71 | 39.83 | 28.11 | 61.51 |

| 15 December | 6.706 | 75.57 | 19 | 409.9 | 719.5 | 26.92 | 84.75 | 40.72 | 44.92 | 33.82 | 61.28 |

| Month | Cooling Power (kJ/kg) | h3 (kJ/kg) | X3 (g/kg) | (g/h) | (g/h) | TC (°C) | RHC (%) | TD (°C) | RHD (%) | TE (°C) | RHE (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 January | 20.119 | 80.57 | 21.0 | 931.6 | 1441.8 | 26.82 | 93.94 | 72.78 | 12.23 | 49.8 | 31.23 |

| 15 February | 20.119 | 87.26 | 23.3 | 885.7 | 885.7 | 27.59 | 99.23 | 74.15 | 12.34 | 50.87 | 32.12 |

| 15 March | 20.119 | 90.46 | 24.3 | 905.8 | 1788.7 | 28.21 | 99.71 | 75.86 | 12.7 | 52.035 | 31.18 |

| 15 April | 20.119 | 65.45 | 16.9 | 771.1 | 771.1 | 22.34 | 99.45 | 71.54 | 10.53 | 46.94 | 29.34 |

| 15 May | 20.119 | 55.10 | 14.0 | 560.4 | 560.4 | 19.46 | 98.77 | 72.69 | 8.11 | 46.075 | 25.12 |

| 15 June | 20.119 | 32.30 | 8.3 | 591.9 | 591.9 | 11.31 | 99.74 | 64.62 | 8.08 | 37.965 | 25.25 |

| 15 July | 20.119 | 22.98 | 6.2 | 570.4 | 570.4 | 7.36 | 97.57 | 61.31 | 7.72 | 34.335 | 24.45 |

| 15 August | 20.119 | 10.56 | 3.9 | 349.7 | 349.7 | 0.8 | 97.62 | 59 | 8.64 | 29.9 | 19.75 |

| 15 September | 20.119 | 13.64 | 4.5 | 419.9 | 419.9 | 3.59 | 82.02 | 59.27 | 6.2 | 31.43 | 20.17 |

| 15 October | 20.119 | 27.97 | 7.3 | 657.9 | 657.9 | 9.54 | 98.91 | 61.8 | 8.79 | 35.67 | 26.54 |

| 15 November | 20.119 | 41.48 | 10.5 | 710.9 | 710.9 | 14.85 | 99.77 | 65.8 | 9.48 | 40.325 | 27.73 |

| 15 December | 20.119 | 62.16 | 15.9 | 854.2 | 1163.8 | 21.62 | 97.91 | 69.46 | 11.31 | 45.54 | 30.41 |

| Month | Cooling Power (kJ/kg) | h3 (kJ/kg) | X3 (g/kg) | (g/h) | (g/h) | TC (°C) | RHC (%) | TD (°C) | RHD (%) | TE (°C) | RHE (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 January | 33.532 | 67.16 | 17.4 | 1447.6 | 1957.8 | 22.76 | 99.72 | 80 | 9 | 51.38 | 31.82 |

| 15 February | 33.532 | 73.85 | 19.3 | 1459.0 | 1459.0 | 24.54 | 99.09 | 80 | 9.69 | 52.27 | 32.85 |

| 15 March | 33.532 | 77.05 | 19.1 | 1651.1 | 2534.0 | 28.09 | 99.53 | 80 | 10.05 | 54.045 | 30.63 |

| 15 April | 33.532 | 52.04 | 13.2 | 1301.4 | 1301.4 | 18.46 | 99.24 | 80 | 7.4 | 49.23 | 29.1 |

| 15 May | 33.532 | 41.69 | 10 | 1133.7 | 1133.7 | 16.29 | 86.72 | 80 | 5.99 | 48.145 | 25.9 |

| 15 June | 33.532 | 18.89 | 5.45 | 1000.4 | 1000.4 | 5.18 | 99.74 | 80 | 4.19 | 42.59 | 22.35 |

| 15 July | 33.532 | 9.57 | 3.79 | 915.8 | 915.8 | 0.32 | 99.86 | 80 | 3.44 | 40.16 | 19.8 |

| 15 August | 33.532 | −2.85 | 2.72 | 629.2 | 629.2 | −7.65 | 99.28 | 80 | 2.16 | 36.175 | 13.5 |

| 15 September | 33.532 | 0.23 | 2.33 | 728.1 | 728.1 | −5.54 | 99.52 | 80 | 2.52 | 37.23 | 17.02 |

| 15 October | 33.532 | 14.56 | 4.65 | 1037.7 | 1037.7 | 3.02 | 98.15 | 80 | 4.02 | 41.51 | 21.2 |

| 15 November | 33.532 | 28.07 | 7.35 | 1162.4 | 1162.4 | 9.51 | 99.74 | 80 | 5.19 | 44.755 | 24.42 |

| 15 December | 33.532 | 48.75 | 12.3 | 1370.2 | 1679.8 | 17.49 | 98.48 | 80 | 7.27 | 48.745 | 28.42 |

| Month | Cooling Power (kJ/kg) | h3 (kJ/kg) | X3 (g/kg) | (g/h) | (g/h) | TC (°C) | RHC (%) | TD (°C) | RHD (%) | TE (°C) | RHE (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 January | 46.945 | 53.74 | 13.6 | 1992.2 | 2502.5 | 19.13 | 98.03 | 80 | 9.07 | 49.565 | 39.68 |

| 15 February | 46.945 | 60.43 | 15.5 | 2003.7 | 2003.7 | 20.93 | 99.62 | 80 | 9.81 | 50.465 | 40.52 |

| 15 March | 46.945 | 63.63 | 16.4 | 2038.1 | 2921.0 | 21.81 | 99.74 | 80 | 10.05 | 50.905 | 40.85 |

| 15 April | 46.945 | 38.62 | 9.8 | 1788.7 | 1788.7 | 13.78 | 99.86 | 80 | 7.4 | 46.89 | 38.71 |

| 15 May | 46.945 | 28.27 | 7.4 | 1506.3 | 1506.3 | 9.58 | 99.92 | 80 | 5.99 | 44.79 | 38.1 |

| 15 June | 46.945 | 5.47 | 3.11 | 1335.8 | 1335.8 | −2.28 | 99.9 | 80 | 4.19 | 38.86 | 37.86 |

| 15 July | 46.945 | −3.85 | 2.86 | 1196.8 | 1196.8 | −8.35 | 100 | 80 | 3.44 | 35.825 | 27.03 |

| 15 August | 46.945 | −16.27 | 1.55 | 794.0 | 794.0 | −17.5 | 100 | 80 | 2.16 | 31.25 | 16.72 |

| 15 September | 46.945 | −13.19 | 1.32 | 918.7 | 918.7 | −15.1 | 100 | 80 | 2.52 | 32.45 | 19.29 |

| 15 October | 46.945 | 1.14 | 2.46 | 1351.6 | 1351.6 | −4.96 | 99.45 | 80 | 4.02 | 37.52 | 37.96 |

| 15 November | 46.945 | 14.65 | 4.66 | 1547.9 | 1547.9 | 2.96 | 99.84 | 80 | 5.19 | 41.48 | 37.76 |

| 15 December | 46.945 | 35.33 | 9.01 | 1841.7 | 2151.3 | 12.52 | 99.84 | 80 | 7.27 | 46.26 | 38.48 |

| Configuration | Peltier Cell Absorbed Power (W) (220 W Each One) | Total Power Consumption of Two Fans (W) (9.2 W Each One) | Total Power Consumption (W) |

|---|---|---|---|

| Only Geothermal system | 0 | 18.4 | 18.4 |

| 1 Peltier cell | 220 | 18.4 | 238.4 |

| 3 Peltier cells | 660 | 18.4 | 678.4 |

| 5 Peltier cells | 1100 | 18.4 | 1118.4 |

| 7 Peltier cells | 1540 | 18.4 | 1558.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Congedo, P.M.; Baglivo, C.; Negro, G. A New Device Hypothesis for Water Extraction from Air and Basic Air Condition System in Developing Countries. Energies 2021, 14, 4507. https://doi.org/10.3390/en14154507

Congedo PM, Baglivo C, Negro G. A New Device Hypothesis for Water Extraction from Air and Basic Air Condition System in Developing Countries. Energies. 2021; 14(15):4507. https://doi.org/10.3390/en14154507

Chicago/Turabian StyleCongedo, Paolo Maria, Cristina Baglivo, and Giulia Negro. 2021. "A New Device Hypothesis for Water Extraction from Air and Basic Air Condition System in Developing Countries" Energies 14, no. 15: 4507. https://doi.org/10.3390/en14154507