1. Introduction

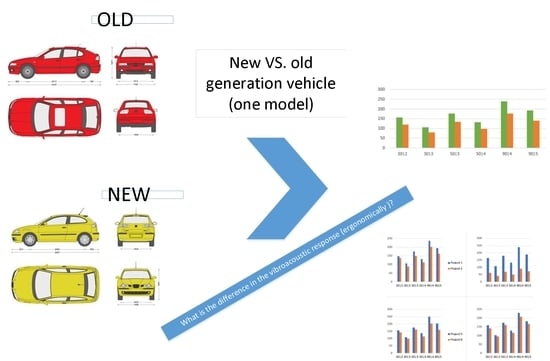

The purpose of this article is to present the results regarding the vibroacoustic response of the internal combustion engine in subsequent generations of vehicles. The research was preceded by the preparation of the measurement methodology for vibrations generated by an internal combustion engine and transmitted through the structure of a vehicle to the defined measuring points, in the significant ranges from the perspective of human health and comfort. The main objective of the research is to verify the thesis that the vibroacoustic response signal generated by an internal combustion engine in a downsized passenger vehicle possesses harmonic components in its frequency spectrum, with frequency values lower than those occurring in a vehicle powered by a naturally aspirated internal combustion engine, and is within the range which is harmful to the human body.

The subject of vibroacoustic response testing of passenger vehicles has been so far explored by research groups in Poland and in the world, but in the opinion of the author of this dissertation, the potential of this topic has not been exhausted in the least.

In Poland, it has been dealt with quite extensively by Burdzik and Konieczny [

1,

2,

3] as well as Burdzik et al. [

4,

5,

6]. Internationally, the ergonomic research in the direction of vibration effects on the human body has been discussed by Griffin in his numerous publications on vibrations and their effects on the human body [

7,

8,

9,

10,

11].

The authors of the paper [

1] present the results of research on vibrations and their distribution at selected points during laboratory and road tests. The vibration acceleration sensors were placed on the control arm, on the upper mounting of the shock absorber and on the floor at the potential foot contact point. The results showed values for vibration damping through the shock absorbers and that the differences in vibration values between sprung and unsprung masses were more than ten times. In addition, the differences in results for different locations on the vehicle floor were revealed.

Łazarz, Madej and Czech, in their paper [

12], investigated the damping properties of a seat transmitting vibrations to the driver while driving. The research was conducted on one Fiat Punto car for two speeds and two types of road surfaces. The measurement points were chosen: on the floorboard and on the passenger seat. The research was conducted in accordance with the Polish PN-91/N standards [

13,

14]. The most interesting conclusion for the author of this dissertation was the evidence that the dominant frequency range for the vertical component during driving on an asphalt road was 1–30 Hz and for the horizontal component—50–70 Hz. An increase in speed caused the ranges to shift to areas of lower frequencies—1–20 Hz and 45–65 Hz, respectively. This indicates that the more damaging frequency range lies in the vertical component.

A similar study was conducted by Kumaresh and Aladdin [

15]. A three-axis accelerometer was mounted on the driver’s seat where the driver would sit. In addition, a single-axis sensor was attached to the seat mount on the floor. The sensor attachment was carried out in accordance with ISO 10326-1 [

16]. The tests were performed in Malaysia on vehicles popular there: Perodua Myvi, Proton Saga and Perodua Alza. The authors focused on determining the weighted root mean square (RMS) of vibration accelerations for ISO standard and vibration dose value (VDV) for BS standard. The conclusion of the study was that, despite the good damping of the chair, with respect to health standards, the vibrations transmitted to the human body are not hazardous to health but are at a level that causes discomfort to the user with prolonged exposure to the vibrations.

Nahvi, Fouladi, and Nor, in their paper [

17], conducted frequency measurements for different types of roadways and driving surfaces: highway, sidewalk, suburban road and road with distinct bumps. A single-axis sensor was mounted on the backrest, measuring the normal axis to the backrest surface. A tri-axis sensor was mounted on the seat. Two single-axis sensors measuring accelerations in the vertical axis and in the axis normal to the backrest surface were mounted on the seat mount near the floor, as well as a single-axis sensor on the floor measuring in the vertical axis. The conclusions indicate that the study confirmed a directly proportional relationship of the vibration dose rate VDV with vehicle speed and the IRI (International Roughness Index) pavement roughness index on which the vehicle is traveling. Moreover, they indicate that the power spectral density is higher for lower frequencies in the vertical direction of the vibration measurements.

Griffin, in his paper [

8], describes a method for describing and evaluating how the human body senses vibrations while traveling in a vehicle. He points out that an important aspect is to take into account the individual sensitivity of different organisms to different vibration magnitudes, frequencies, directions and durations. He also talks about the imperfections in vibration testing standards related to people’s comfort and health, where their opinion depends on many factors beyond the vibrations in the vehicle itself. In addition, small and sudden changes may not be perceptible by a subjective assessment but have an impact on the whole in the long-term perspective.

In one of the articles [

18], Griffin and Lewis try to compare and evaluate the methods defined in three different standards: ISO 2631/1:1985, ISO 2631/1:1997 and BS 6841:1987. They point out the differences in the methods of correction and averaging the frequency and the final evaluation. Additionally, they point out that in one standard, there are different approaches to vibration measurement and evaluation listed. They measured vibration accelerations on the seats of nine different vehicles, such as a bus, a passenger vehicle, a port crane, a forklift, a tank, a four-wheel-drive ambulance, a motorboat, a pontoon motorboat and a bicycle. An important conclusion on their part was that there were significant differences in the assessment of the acceptable time limit to which a body can be exposed during exposure to vibration in each of the vehicles. The difference in the shape of the signal filtering correction led to differences in the acceptable time of up to 75% in the quoted modes of transport. In the case of using filtering that differed only in the phase, the differences were up to 50%. They also highlight the problem that the aforementioned standards do not indicate the situations in which the method is to be used.

There are big gaps in recent articles on the effects of vibration on human health. However, it seems very interesting, especially in light of the increasingly popular alternative power sources. In one of the recently published articles [

19], the authors emphasized (and proved) the necessity to develop the field (Delphi47 program) of examining the impact of vibrations on human health. Unfortunately, this field is not very widely developed towards ergonomics.

The above literature review shows that the existing research has been performed each time in a very similar way, based mainly on the standards describing vibration measurements. The advantage of this solution is the referentiality and the possibility of comparisons between individual cases. The literature does not contain items concerning comparative vibroacoustic response tests of successive generations of vehicles. The presented results concern the changes in the power spectral density of successive generations of vehicles in the ranges having an impact on human health.

2. Vibroacoustic Response

The acoustic signal, which is a component of the vibroacoustic signal, is characterized by the value which is formed under the influence of vibration-inducing disturbances, of energy causing acoustic wave propagation in an elastic medium and causing an auditory experience in humans [

20]. The internal combustion engine, due to the nature of its work, shows a repetitive series of sequences in vibration measurements. As it may be observed, the successive repetitions are the same; however, the repetition refers to the operation performed in pursuit of the primary objective [

21,

22,

23].

Associated with a cyclic process, such as vibration, is the phenomenon of synchronization, which indicates a time-ordered chain of event implications. The synchronization occurs due to strokes between moving parts [

23,

24,

25]. The motion is the cause; therefore, the process is kinetic in the deterministic sense. As the condition of the engine deteriorates, the appearance of additional degrees of freedom can have a significant effect on the occurring vibrations.

Since its inception, the utilitarian goal of vibroacoustics has been to reduce vibration and acoustic disturbances of machines, devices, installations and their environment. Furthermore, the diagnostic potential of vibroacoustic response signals as information on the condition of machines, devices, buildings and quality assessment of technological processes was recognized.

Vibroacoustic phenomena can be divided into those which are harmful, negatively affecting humans and machines, and those which are positive, intentionally introduced to implement technological and production processes.

One of the most important aspects of vibroacoustics is the description of the phenomenon of generation and transmission of oscillations onto humans, which in this aspect are called vibrations. These are cyclic oscillations with frequencies ranging from 0.5 to 120 Hz [

26]. Vibrations that can affect humans are divided into general (concerning vibrations transmitted from the ground or the seat to the lower limbs or pelvic bones) and local (the type of vibration coming from tools that are in direct contact with the operator’s hands) [

27].

The most common method of vibroacoustic object analysis is based on digital processing, FFT (Fast Fourier Transform) in particular. In this case, the processed signal is of stationary nature (because the phase information is lost during the operation). The Fourier transform is a complex function during which the real variable (frequency) is assigned to the function. The real signal is then given a characteristic function, which is called the kernel of the function [

28,

29]. One of the most important features of an FFT (digital version of a Fourier transform) is the shift theorem:

where:

—the signal after the shift,

—the signal before the shift.

The above theorem simplifies the measurement remarkably, as synchronization of the engine and the acquisition system are not required to obtain the desired diagnostic information.

3. Methodology

The conducted research aims to demonstrate the changes in the vibroacoustic response of an internal combustion engine as a function of its evolution. The authors studied successive generations of the same vehicle models regarding the vibroacoustic response. All of the vehicles were examined with regard to technical aspects. They had no mechanical, electromechanical or electronic defects. A gasoline engine with multi-point fuel injection was used in each vehicle. The engines were located above the front axle. The vehicles were front-wheel drive types.

The subjects of the study were 4 groups of vehicles. Each group contained the same vehicle model, yet different generations of it. The newer (N) versions in each group were equipped with a turbocharged and downsized engine as standard. Older (O) vehicles were not equipped with charged engines. The table below (

Table 1) presents the most important parameters of the vehicles.

Laboratory tests were performed on a chassis dynamometer for passenger cars, MAHA LPS 3000. The test stand is located in a room providing constant temperature conditions and isolation for vibroacoustic interference. Before starting the actual tests, the engine and oil temperatures were brought to operating values and checked with a dipstick thermometer. Fan cooling was not used during testing to avoid interference, which was detected during testing as additional vibration movement of the entire vehicle. The temperature in the laboratory was 18 °C. The cars were accelerated on the dynamometer to a specified speed at a specified gear ratio, and then the speed was maintained, with a tolerance of ±1 km/h, as read from the display unit of the computer controlling the operation of the chassis dynamometer. The driving resistance generated by the dynamometer, which mirrored the resistance generated during natural operation, was determined for each vehicle and for each measurement speed.

The measurements for each speed occurred at two gear ratios. Each measurement was taken three times for greater statistical reliability. The results were then averaged using the arithmetic mean.

The sequence of testing each vehicle at a particular speed was determined as follows:

- 1.

Bringing the engine and operating fluids to operating temperatures.

- 2.

Setting the resistance of the movement on the chassis dynamometer at 30 km/h.

- 3.

Vibration measurements at a speed of 30 km/h and setting the gearbox to 2nd gear.

- 4.

Vibration measurements at 30 km/h with the gearbox shifted to 3rd gear.

- 5.

Setting the resistance to motion on a chassis dynamometer at a speed of 50 km/h.

- 6.

Vibration measurements at 50 km/h with the gearbox in 3rd gear.

- 7.

Vibration measurements at 50 km/h with the gearbox shifted to 4th gear.

- 8.

Setting the resistance to motion on a chassis dynamometer at 90 km/h.

- 9.

Vibration measurements at 90 km/h with the gearbox in 4th gear.

- 10.

Vibration measurements at 90 km/h with the gearbox in 5th gear.

High-sensitivity, single-axis accelerometer sensors from PCB Piezotronics were used for the measurements: a general-purpose sensor, model 352C34; and a high-temperature sensor, model HT352C34. A National Instruments 4-channel measurement module, model NI-9234, was used for the signal acquisition. The first sensor, the high-temperature one, was mounted on the upper engine mount (

Figure 1), following the SAE standard [

30].

The second sensor was glued to a steel clamp which was attached to the steering wheel (

Figure 2). This location was chosen as important because of the constant hand contact with the steering wheel and the lack of damping elements.

The third sensor was glued to a steel clamp and attached to the driver’s headrest support (

Figure 3).

On each occasion, the measurements were made several times, and the frequency response was averaged. The sampling rate was set at 2048 Hz for 2 s time intervals, resulting in 1024 Hz for a 1 s time interval, which complies with the Whittaker–Nyquist–Kotelnikov–Shannon theorem [

28,

29].

4. Research Results

The first series of tests were conducted using a sensor mounted on the engine foot. A graphical presentation of all 4 groups is shown in

Figure 4.

The magnitude was averaged for older and newer generation vehicles at each test point to determine the trend. The resulting values (for vibrations measured at the engine) are presented in

Figure 5.

The second series of tests concerned vibration acceleration measurements taken at the steering wheel (and thus having a direct effect on the driver). The obtained results are shown in

Figure 6.

As in the analysis of the results (measured on the engine), here as well the Magnitude values for the older generation and newer vehicles at each test point were averaged to determine the trend. The obtained values (for vibrations measured at the steering wheel) are presented in

Figure 7.

The last series of tests focused on the sensor mounting on the seat (

Figure 3). In this case, the comparison was also performed in groups (older vehicle vs. newer vehicle). The results are presented in

Figure 8.

Here again, the Magnitude values for older and newer generation vehicles at each test point were averaged to determine the trend. The resulting values (for vibrations measured at the steering wheel) are presented in

Figure 9.

5. Conclusions

The research presented in this paper focused on the evaluation of the vibroacoustic response characteristics of a gasoline internal combustion engine as a function of the development of subsequent versions of the vehicle (downsizing). Particular attention was paid to the changes in frequency bands that may affect the human body. At the same time, it should be noted that this band (<500 Hz) also carries diagnostic information about the condition of the power unit.

The tests on the internal combustion engine vibroacoustic response characteristics at various measurement locations have succeeded in obtaining frequency values for each of the measured speeds and gear ratios, as well as in recognizing some recurring relationships and distinguishing those that may be significant from the point of view of passenger vehicle driving ergonomics.

For the measurement point on the engine mount:

- 1.

For each measurement pair, the frequency measured on the turbocharged vehicle was lower than that measured on the naturally aspirated vehicle.

- 2.

In each measurement case, a higher gear ratio for a given vehicle speed caused a decrease in the vibration frequency value.

For the measuring point on the steering wheel:

- 1.

Changing the gear ratio for a given vehicle speed has no or very little effect on the vibration frequency values occurring on the steering wheel.

- 2.

The lowest frequency values occur at the speed of 30 km/h, ranging from 7–10 Hz (they remain within the range of resonant vibrations for upper limbs).

For the measuring point on the headrest support:

- 1.

Changing the gear ratio for a given vehicle speed has no or very little effect on the values of the vibration frequencies occurring on the headrest support.

- 2.

The lowest frequency values are 7–10 Hz at 30 km/h (they remain within the range of resonance vibrations for the head).

The vibration values at 50 km/h are mostly 10–16 Hz, and they fall within the resonance vibration range for the head and larynx, trachea and bronchi.

The successive vehicle models equipped with charged engines generate spectra like those of naturally aspirated engines. In the case of charged engines, the magnitudes of the dominant harmonics are smaller, which should have a positive effect on driving comfort.

The charged engines have lower average values in the bands (and therefore lower energy spectral density values). This implies that the introduction of additional high-speed components (turbocharger) has no negative effect on the vibroacoustic response of the engine.

Thus, it can be confirmed that modern engines extend the spectral density of the engine’s vibroacoustic response. At the same time, the size of the dominant harmonics is reduced. This means that they can potentially affect the functioning of other human organs than was the case with older models. The reduction of the above-mentioned dominant harmonics should translate into a longer possibility of exposure of the human body to vibrations and thus also a longer time of safe driving.

Author Contributions

Conceptualization, R.W. and Ł.Ł.; methodology, L.S.; software, M.A.-Z.; validation, R.W., L.S. and Ł.Ł.; formal analysis, R.W.; investigation, M.A.-Z.; resources, R.D.; data curation, V.M.; data curation R.D.; writing—original draft preparation, Ł.Ł.; writing—review and editing, M.A.-Z.; visualization, R.W. and M.A.-Z.; supervision, L.S.; project administration, R.W.; funding acquisition, L.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Wroclaw Univeristy of Science and Tachnology, grant number N_PODST_BAD_EXP_BAM - 8211104160.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The measurement values themselves are generally available after contact with the authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Burdzik, R.; Konieczny, Ł. Vibrations issues in passenger car. Transp. Probl. 2014, 9, 83–90. [Google Scholar]

- Burdzik, R.; Konieczny, Ł. Application of vibroacoustic methods for monitoring and control of comfort and safety of passenger cars. In Solid State Phenomena; Trans Tech Publications Ltd: Bach, Switzerland, 2014; Volume 210, pp. 20–25. [Google Scholar]

- Burdzik, R.; Konieczny, Ł. Research on structure, propagation and exposure to general vibration in passenger car for different damping parameters. J. Vibroeng. 2011, 2, 42–49. [Google Scholar]

- Burdzik, R. Research on the influence of engine rotational speed to the vibration penetration into the driver via feet—Multidimensional analysis. J. Vibroeng. 2013, 15, 2114–2123. [Google Scholar]

- Burdzik, R. Material vibration propagation in floor pan. Arch. Mater. Sci. Eng. 2013, 59, 22–27. [Google Scholar]

- Burdzik, R.; Dolecek, R. Research of vibration distribution in vehicle constructive. Perner’s Contact 2012, 7, 16–25. [Google Scholar]

- Griffin, M.J. Handbook of Human Vibrations; Academic Press: London, UK, 1990. [Google Scholar]

- Griffin, M.J. Discomfort from feeling vehicle vibration. Int. J. Veh. Mech. Mobil. 2007, 45, 679–698. [Google Scholar] [CrossRef] [Green Version]

- Griffin, M.J.; Paddan, G.S. Evaluation of whole-body vibration in vehicles. J. Sound Vib. 2002, 253, 195–213. [Google Scholar]

- Griffin, M.J.; Paddan, G.S. Effects of seating on exposures to whole-body vibrations in vehicle. J. Sound Vib. 2002, 253, 215–241. [Google Scholar]

- Griffin, M.J.; Wyllie, I.H. Discomfort from sinusoidal oscillation in the pitch and fore-and-aft axes at frequencies between 0.2 and 1.6 Hz. J. Sound Vib. 2009, 324, 453–467. [Google Scholar]

- Łazarz, B.; Madej, H.; Czech, P. Fotel kierowcy jako element układu tłumienia drgań. Transport 2009, 65, 39–44. [Google Scholar]

- PN-91/N-01352 Drgania. Zasady wykonywania pomiarów na stanowiskach pracy. Standard of the Polish Standsisation Committee, KT 157, Physical Hazards in the Work Environment. Warszawa, Poland, 1991.

- PN-91/N-01354 Drgania. Dupszczalne wartości przyspieszeń drgań o oddziaływaniu ogólnym na organizm człowieka. Wymagania i badania., Standard of the Polish Standsisation Committee, KT 157, Physical Hazards in the Work Environment. Warszawa, Poland, 1991.

- Kumaresh, S.A.; Aladdin, M.F. A study of vibration transmission on seated person in passenger vehicle. AIP Conf. Proc. 2019, 2137, 040001. [Google Scholar]

- ISO 10326-1. Mechanical Vibration—Laboratory Method for Evaluating Vehicle Seat Vibration—Part 1: Basic Requirements; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Nahvi, H.; Fouladi, M.H.; Nor, M.J. Evaluation of whole-body vibration and ride comfort in a passenger car. Int. J. Acoust. Vib. 2009, 14, 143–149. [Google Scholar]

- Griffin, M.J.; Lewis, C.H. A comparison of evaluations and assessment obtained using alternative standards for predicting the hazards of whole-body vibrations and repeated schocks. J. Sound Vib. 1998, 215, 915–926. [Google Scholar] [CrossRef]

- Oroszi, T.; Van Heuvelen, M.J.G.; Nyakas, C.; Van der Zee, E.A. Vibration detection: Its function and recent advances in medical applications. F1000Research 2020, 9. [Google Scholar] [CrossRef] [PubMed]

- Singiresu, S. Mechanical Vibrations; Prentice Hall: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- Cempel, C.; Tomaszewski, F. Diagnostyka Maszyn; Wydawnictwo Techniczne: Radom, Poland, 1992. [Google Scholar]

- Krzyworzeka, P.; Adamczyk, J.; Łopacz, H. Systemy Synchronicznego Przetwarzania Sygnałów Diagnostycznych; Collegium Columbinum: Kraków, Poland, 1999. [Google Scholar]

- Cempel, C. Diagnostyka Wibroakustyczna Maszyn; Wydawnictwo Politechniki Poznańskiej: Poznań, Poland, 1985. [Google Scholar]

- Żółtkowski, B. Podstawy Diagnostyki Maszyn; Wydawnictwo Techniczne: Bydgoszcz, Poland, 1996. [Google Scholar]

- Bolton, W. Mechatronics: Electronic Control System in Mechanical and Electrical Engineering; Longman: Harlow, UK, 1999. [Google Scholar]

- Więckowski, D. An attempt to estimate natural frequencies of parts of the child’s body. Arch. Automot. Eng. 2012, 55, 61–74. [Google Scholar]

- Helbin, J. Wybrane Problemy Higieny i Ekologii Człowieka—Środowiskowe Czynniki Fizyczne Wpływające na Organizm Człowieka; Wydawnictwo Uniwersytetu Jagielońskiego: Kraków, Poland, 2008. [Google Scholar]

- Zieliński, T.P. Cyfrowe Przetwarzanie Sygnałów od Teorii do Zastosowań; Wydawnictwo Komunikacji i Łącznośći: Warszawa, Poland, 2005. [Google Scholar]

- Szabatin, J. Podstawy Teorii Sygnałów; Wydawnictwo Komunikacji i Łączności: Warszawa, Poland, 2004. [Google Scholar]

- SAE J1211. Handbook for Robustness Validation of Automotive Electrical/Electronic Modules; ZVEI: Frankfurt, Germany, 2008. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).