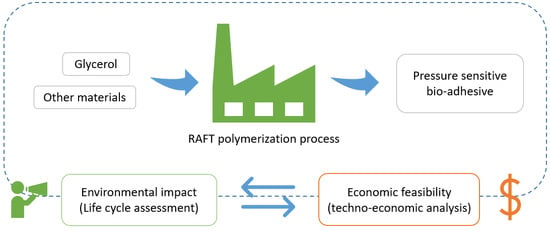

Life Cycle Assessment and Techno-Economic Analysis of Pressure Sensitive Bio-Adhesive Production

Abstract

:1. Introduction

2. Methods

2.1. Life Cycle Assessment

2.1.1. Goal and Scope Definition

2.1.2. Life Cycle Inventory Analysis

2.1.3. Life Cycle Impact Assessment

2.2. Techno-Economic Analysis

2.3. Total Capital Investment (CTCI) Analysis

2.4. Annual Operating Cost (CAOC) Analysis

2.5. Profitability Analysis

2.6. Discounted Cash Flow Analysis

2.7. Sensitivity Analyses

3. Results and Discussion

3.1. Life Cycle Assessment (LCA) Results

3.2. Techno-Economic Analysis (TEA) Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Nitzsche, R.; Budzinski, M.; Gröngröft, A. Techno-Economic Assessment of a Wood-Based Biorefinery Concept for the Production of Polymer-Grade Ethylene, Organosolv Lignin and Fuel. Bioresour. Technol. 2016, 200, 928–939. [Google Scholar] [CrossRef] [PubMed]

- U.S. EPA. Global Greenhouse Gas Emissions Data | Greenhouse Gas (GHG) Emissions | US EPA. Available online: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (accessed on 19 November 2019).

- Matar, S.; Hatch, L.F. Chemistry of Petrochemical Processes, 2nd ed.; Gulf Professional Publishing: London, UK, 2001. [Google Scholar] [CrossRef]

- Markets, R.; Global Adhesives Market. 2017–2022—$53.5 Billion Opportunity Analysis and Industry Forecasts. Available online: https://www.globenewswire.com/news-release/2017/10/17/1148538/0/en/Global-Adhesives-Market-2017-2022-53-5-Billion-Opportunity-Analysis-and-Industry-Forecasts.html (accessed on 19 November 2019).

- Doyle, J.S.; O’Quinn, R.C. Adhesives Types, Mechanics and Applications; Nova Science Publishers: New York, NY, USA, 2011. [Google Scholar]

- Mohammed, I.K.; Charalambides, M.N.; Kinloch, A.J. Modelling the Interfacial Peeling of Pressure-Sensitive Adhesives. J. Nonnewton. Fluid Mech. 2015, 222, 141–150. [Google Scholar] [CrossRef]

- Reuters. Pressure Sensitive Adhesives Market Size, Share, Report, Analysis, Trends. Available online: https://www.reuters.com/brandfeatures/venture-capital/article?id=13015 (accessed on 19 November 2019).

- Moad, G.; Rizzardo, E.; Thang, S.H. Radical Addition-Fragmentation Chemistry in Polymer Synthesis. Polymer 2008, 49, 1079–1131. [Google Scholar] [CrossRef]

- Lowe, A.B.; McCormick, C.L. Reversible Addition-Fragmentation Chain Transfer (RAFT) Radical Polymerization and the Synthesis of Water-Soluble (Co) Polymers under Homogeneous Conditions in Organic and Aqueous Media. Prog. Polym. Sci. 2007, 32, 283–351. [Google Scholar] [CrossRef]

- Chakraborty, S.; Jähnichen, K.; Komber, H.; Basfar, A.A.; Voit, B. Synthesis of Magnetic Polystyrene Nanoparticles Using Amphiphilic Ionic Liquid Stabilized RAFT Mediated Miniemulsion Polymerization. Macromolecules 2014, 47, 4186–4198. [Google Scholar] [CrossRef]

- Boyer, C.; Bulmus, V.; Davis, T.P.; Ladmiral, V.; Liu, J.; Perrier, S. Bioapplications of RAFT Polymerization. Chem. Rev. 2009, 109, 5402–5436. [Google Scholar] [CrossRef]

- Cochran, E.W.; Williams, R.C.; Hernandez, N.; Cascione, A. Thermoplastic Elastomers via Atom Transfer Radical Polymerization of Plant Oil. US Patent US20180237571A1, 2013. [Google Scholar]

- Gallagher, J.J.; Hillmyer, M.A.; Reineke, T.M. Acrylic Triblock Copolymers Incorporating Isosorbide for Pressure Sensitive Adhesives. ACS Sustain. Chem. Eng. 2016, 4, 3379–3387. [Google Scholar] [CrossRef]

- Forrester, M.J. Glycerol-Based Polymers and Their Pathway to Industrial Relevance. Ph.D. Dissertation, Iowa State University, Ames, IA, USA, 2018. [Google Scholar]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; de Bruijn, H.; et al. Life Cycle Assessment: An Operational Guide to the ISO Standards, Final Report; Leiden University: Leiden, The Netherlands, 2001. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Lahr, F.A.R.; Varanda, L.D.; Christoforo, A.L.; Ometto, A.R. Environmental Performance Assessment of the Melamine-Urea-Formaldehyde (MUF) Resin Manufacture: A Case Study in Brazil. J. Clean. Prod. 2015, 96, 299–307. [Google Scholar] [CrossRef]

- Kim, S. Environment-Friendly Adhesives for Surface Bonding of Wood-Based Flooring Using Natural Tannin to Reduce Formaldehyde and TVOC Emission. Bioresour. Technol. 2009, 100, 744–748. [Google Scholar] [CrossRef]

- Wilson, J.B. Life-Cycle Inventory of Particleboard in Terms of Resources, Emissions, Energy and Carbon. Wood Fiber Sci. 2010, 42, 90–106. [Google Scholar]

- Chau, J.; Sowlati, T.; Sokhansanj, S.; Preto, F.; Melin, S.; Bi, X. Techno-Economic Analysis of Wood Biomass Boilers for the Greenhouse Industry. Appl. Energy 2009, 86, 364–371. [Google Scholar] [CrossRef]

- Ou, L.; Li, B.; Dang, Q.; Jones, S.; Brown, R.; Wright, M.M. Understanding Uncertainties in the Economic Feasibility of Transportation Fuel Production Using Biomass Gasification and Mixed Alcohol Synthesis. Energy Technol. 2016, 4, 441–448. [Google Scholar] [CrossRef]

- Xu, F.; Sun, J.; Konda, N.V.S.N.M.; Shi, J.; Dutta, T.; Scown, C.D.; Simmons, B.A.; Singh, S. Transforming Biomass Conversion with Ionic Liquids: Process Intensification and the Development of a High-Gravity, One-Pot Process for the Production of Cellulosic Ethanol. Energy Environ. Sci. 2016, 9, 1042–1049. [Google Scholar] [CrossRef]

- Shen, R.; Tao, L.; Yang, B. Techno-economic Analysis of Jet-fuel Production from Biorefinery Waste Lignin. Biofuels, Bioprod. Biorefining 2019, 13, 486–501. [Google Scholar] [CrossRef]

- Yang, M.; Rosentrater, K.A. Techno-Economic Analysis (TEA) of Low-Moisture Anhydrous Ammonia (LMAA) Pretreatment Method for Corn Stover. Ind. Crops Prod. 2015, 76, 55–61. [Google Scholar] [CrossRef]

- Yang, M.; Rosentrater, K.A. Techno-Economic Analysis of the Production Process of Structural Bio-Adhesive Derived from Glycerol. J. Clean. Prod. 2019, 228, 388–398. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. Electric Power Monthly with Data for June 2018; EIA: Washington, DC, USA, 2018.

- Sheehan, J.; Camobreco, V.; Duffield, J.; Graboski, M.; Shapouri, H. Life Cycle Inventory of Biodiesel and Petroleum Diesel for Use in an Urban Bus; National Renewable Energy Lab.(NREL): Washington, DC, USA, 1998. [Google Scholar]

- Bare, J.C.; Hofstetter, P.; Pennington, D.W.; de Haes, H.A.U. Midpoints versus Endpoints: The Sacrifices and Benefits. Int. J. Life Cycle Assess. 2000, 5, 319–326. [Google Scholar] [CrossRef]

- Bare, J. Tool for the Reduction and Assessment of Chemical and O Ther Environmental Impacts (TRACI), TRACI Version 2.1, User’s Guide; TRACI-EPA: Cincinnati, OH, USA, 2012. [Google Scholar]

- Dreyer, L.C.; Niemann, A.L.; Hauschild, M.Z. Comparison of Three Different LCIA Methods: EDIP97, CML2001 and Eco-Indicator 99. Int. J. Life Cycle Assess. 2003, 8, 191–200. [Google Scholar] [CrossRef]

- Phoenix Equipment Corporation. Formaldehyde Resins Plant—15,000 TPY. Available online: https://www.phxequip.com/plant.104/formaldehyde-resin-plant-15-000-tpy.aspx (accessed on 6 September 2018).

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2013. [Google Scholar]

- Ulrich, G.D. A Guide to Chemical Engineering Process Design and Economics; John Wiley & Sons: New York, NY, USA, 1984. [Google Scholar]

- Humphreys, K.K. Project and Cost Engineers’ Handbook, 4th ed.; Humphreys, K.K., Ed.; CRC Press: New York, NY, USA, 2004. [Google Scholar]

- Landress, L. ICIS Pricing, Glycerine (US Gulf). Available online: https://www.icis.com/globalassets/global/icis/pdfs/sample-reports/chemicals-glycerine.pdf (accessed on 9 April 2019).

- Ronald, H. Electric Power Monthly with Data for September 2017; US EIA: Washington, DC, USA, 2017.

- IRS. Publication 946: How to Depreciate Property. 2018. Available online: https://www.irs.gov/publications/p946 (accessed on 19 November 2019).

- Turton, R.; Baille, R.C.; Whiting, W.B.; Shaeiwitz, J.A. Analysis, Synthesis, and Design of Chemical Processes, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- Hayes, A. Gross Profit Definition. Available online: https://www.investopedia.com/terms/g/grossprofit.asp (accessed on 10 April 2019).

- Kenton, W. Net Present Value (NPV). Available online: https://www.investopedia.com/terms/n/npv.asp (accessed on 10 April 2019).

- Humbird, D.; Davis, R.; Tao, L.; Kinchin, C.; Hsu, D.; Aden, A. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol; National Renewable Energy Laboratory: Golden, CO, USA, 2011. [Google Scholar]

- Swanson, R.M.; Platon, A.; Satrio, J.A.; Brown, R.C. Techno-Economic Analysis of Biomass-to-Liquids Production Based on Gasification. Fuel 2010, 89 (Suppl. 1), S11–S19. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Hu, G. Techno-Economic Analysis of Advanced Biofuel Production Based on Bio-Oil Gasification. Bioresour. Technol. 2015, 191, 88–96. [Google Scholar] [CrossRef] [PubMed]

- SmartAsset. Free Income Tax Calculator. Available online: https://smartasset.com/taxes/income-taxes (accessed on 10 April 2019).

- Saltelli, A.; Ratto, M.; Andres, T.; Campolongo, F.; Cariboni, J.; Gatelli, D.; Saisana, M.; Tarantola, S. Global Sensitivity Analysis; John Wiley & Sons: Hoboken, NY, USA, 2008. [Google Scholar]

- Olukoya, I.A.; Bellmer, D.; Whiteley, J.R.; Aichele, C.P. Evaluation of the Environmental Impacts of Ethanol Production from Sweet Sorghum. Energy Sustain. Dev. 2015, 24, 1–8. [Google Scholar] [CrossRef]

- Dysert, L.R.; Christesen, P. AACE International Recommended Practice No. 18R-97, Cost Estimate Classification System—As Applied in Engineering, Procurement, and Construction for the Process Industries; Inc.: New York, NY, USA, 2016. [Google Scholar]

- Wernet, G.; Conradt, S.; Isenring, H.P.; Jiménez-González, C.; Hungerbühler, K. Life Cycle Assessment of Fine Chemical Production: A Case Study of Pharmaceutical Synthesis. Int. J. Life Cycle Assess. 2010, 15, 294–303. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Life Cycle Assessment Study of Biopolymers (Polyhydroxyalkanoates) Derived from No-Tilled Corn. Int. J. Life Cycle Assess. 2005, 10, 200–210. [Google Scholar] [CrossRef]

- McDevitt, J.E.; Grigsby, W.J. Life Cycle Assessment of Bio- and Petro-Chemical Adhesives Used in Fiberboard Production. J. Polym. Environ. 2014, 22, 537–544. [Google Scholar] [CrossRef]

- Arrington, K.J.; Radzinski, S.C.; Drummey, K.J.; Long, T.E.; Matson, J.B. Reversibly Cross-Linkable Bottlebrush Polymers as Pressure-Sensitive Adhesives. ACS Appl. Mater. Interfaces 2018, 10, 26662–26668. [Google Scholar] [CrossRef] [PubMed]

- Heinzle, E.; Biwer, A.P.; Cooney, C.L. Development of Sustaiable Bioprocesses: Modelling and Assessment; John Wiley & Sons: Chichester, UK, 2006. [Google Scholar]

- Molbase. Chemical B2B E-commerce Platform. Available online: http://www.molbase.com/ (accessed on 9 April 2019).

| Parameter | Unit | Data | GHG Emission Factor |

|---|---|---|---|

| Input | |||

| Glycerol | kg | 0.63 | 1.28 kg CO2-eq/kg |

| Acrylic acid | kg | 0.49 | 1.37 kg CO2-eq/kg |

| Acetone | kg | 0.10 | 1.61 kg CO2-eq/kg |

| Ethanethiol | kg | 0.13 | 2.35 kg CO2-eq/kg |

| Carbon disulfide | kg | 0.31 | 1.47 kg CO2-eq/kg |

| 3-Chloro-2-butanone | kg | 0.43 | 0.97 kg CO2-eq/kg |

| Potassium hydroxide | kg | 0.13 | 1.68 kg CO2-eq/kg |

| AIBN | kg | 2.46 × 10−5 | 4.79 kg CO2-eq/kg |

| Succinic hydride | kg | 0.02 | 0.45 kg CO2-eq/kg |

| Isosorbide | kg | 0.01 | 3.01 kg CO2-eq/kg |

| Transportation distance | km | 80.5 | 3.20 × 10−5 kg CO2-eq/(kg × km) |

| Output | |||

| PSA | kg | 1 | |

| Potassium chloride | kg | 0.286 | |

| Impact Category | Bio-Glycerol Scenario | Petro-Glycerol Scenario |

|---|---|---|

| TRACI global warming (kg CO2-eq./FUa) | 3.8 | 6.1 |

| TRACI acidification (kg H+ moles-eq./FU) | 1.3 | 1.3 |

| TRACI eutrophication (kg N-eq./FU) | 1.4 × 10−3 | 1.1 × 10−3 |

| TRACI ozone depletion (kg CFC 11-eq./FU) | 2.0 × 10−11 | 8.9 × 10−11 |

| TRACI smog air (kg O3-eq./FU) | 0.2 | 0.3 |

| TRACI human health particulate air (kg PM 2.5-eq./FU) | 1.2 × 10−3 | 1.4 × 10−3 |

| TRACI human health, cancer air (CTUb/FU) | 1.1 × 10−9 | 1.1 × 10−9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Rosentrater, K.A. Life Cycle Assessment and Techno-Economic Analysis of Pressure Sensitive Bio-Adhesive Production. Energies 2019, 12, 4502. https://doi.org/10.3390/en12234502

Yang M, Rosentrater KA. Life Cycle Assessment and Techno-Economic Analysis of Pressure Sensitive Bio-Adhesive Production. Energies. 2019; 12(23):4502. https://doi.org/10.3390/en12234502

Chicago/Turabian StyleYang, Minliang, and Kurt A. Rosentrater. 2019. "Life Cycle Assessment and Techno-Economic Analysis of Pressure Sensitive Bio-Adhesive Production" Energies 12, no. 23: 4502. https://doi.org/10.3390/en12234502