Enhancing the Performance of Textured Silicon Solar Cells by Combining Up-Conversion with Plasmonic Scattering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation and Characterization of Up-Conversion and Plasmonic Scattering Layers

2.1.1. Up-Conversion Layer Comprising Yb/Er-Doped Yttrium Oxide-Based Phosphors

2.1.2. Plasmonic Scattering Layer of SiO2 with Indium Nanoparticles

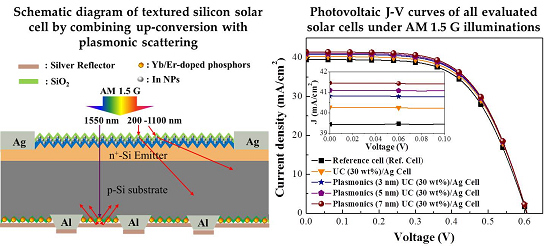

2.2. Fabrication and Characterization of Textured Silicon Solar Cells with Back Matrix Grooves

2.3. Fabrication and Characterization of Cells Coated with Up-Conversion and Plasmonic Scattering Layers

2.3.1. Cells Coated with an Up-Conversion Layer

2.3.2. Up-Conversion Combined with Plasmonic Scattering

3. Results and Discussion

3.1. Up-Conversion Layer: Characterization

3.2. Plasmonic Effects of Indium Nanoparticles Imbedded in SiO2 Layer

3.3. Reference Textured Silicon Solar Cell and Up-Conversion Solar Cells

3.4. Textured Silicon Solar Cells with Up-Conversion and Plasmonic Scattering Layers

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mennucci, C.; Muhammad, M.H.; Hameed, M.F.O.; Mohamed, S.A.; Abdelkhalik, M.S.; Obayya, S.S.A.; de Mongeot, F.B. Broadband light trapping in nanotextured thin film photovoltaic devices. Appl. Surf. Sci. 2018, 446, 74–82. [Google Scholar] [CrossRef]

- Green, M.A.; Bremner, S.P. Energy conversion approaches and materials for high-efficiency photovoltaics. Nat. Mater. 2017, 16, 23–34. [Google Scholar] [CrossRef]

- Lu, P.; Xu, J.; Cao, Y.Q.; Lai, J.W.; Xu, L.; Chen, K.J. Preparation of nano-patterned Si structures for hetero-junction solar cells. Appl. Surf. Sci. 2015, 334, 123–128. [Google Scholar] [CrossRef]

- Zhang, D.; Ren, W.N.; Zhu, Z.C.; Zhang, H.F.; Liu, B.; Shi, W.Z.; Qin, X.M.; Cheng, C.W. Highly-ordered silicon inverted nanocone arrays with broadband light antireflectance. Nanoscale Res. Lett. 2015, 10, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.M.; Wang, Q.K.; Wang, Q. Transfer the multiscale texture of crystalline Si onto thin-film micromorph cell by UV nanoimprint for light trapping. Appl. Surf. Sci. 2018, 439, 168–175. [Google Scholar] [CrossRef]

- Araújo, A.; Mendes, M.J.; Mateus, T.; Costa, J.; Nunes, D.; Fortunato, E.; Águas, H.; Martins, R. Ultra-fast plasmonic back reflectors production for light trapping in thin Si solar cells. Sol. Energy 2018, 174, 786–792. [Google Scholar] [CrossRef]

- Rao, L.; Ji, C.L.; Li, M. Broadband light absorption of silicon nanowires embedded in Ag nano-hole arrays. AIP Adv. 2016, 6, 095216. [Google Scholar] [CrossRef] [Green Version]

- Veenkamp, R.J.; Ye, W.N. Plasmonic metal nanocubes for broadband light absorption enhancement in thin-film a-Si solar cells. J. Appl. Phys. 2014, 115, 124317. [Google Scholar] [CrossRef]

- Atwater, H.A.; Polman, A. Plasmonics for improved photovoltaic devices. Nat. Mater. 2010, 9, 205–213. [Google Scholar] [CrossRef]

- Garcia, M.A. Surface plasmons in metallic nanoparticles: Fundamentals and applications. J. Phys. D Appl. Phys. 2011, 44, 283001. [Google Scholar] [CrossRef]

- Kelly, K.L.; Coronado, E.; Zhao, L.L.; Schatz, G.C. The optical properties of metal nanoparticles: The influence of size, shape, and dielectric environment. J. Phys. Chem. B 2003, 107, 668–677. [Google Scholar] [CrossRef]

- Derkacs, D.; Lim, S.H.; Matheu, P.; Mar, W.; Yu, E.T. Improved performance of amorphous silicon solar cells via scattering from surface plasmon polaritons in nearby metallic nanoparticles. Appl. Phys. Lett. 2006, 89, 093103. [Google Scholar] [CrossRef] [Green Version]

- Pedrueza, E.; Sancho-Parramon, J.; Bosch, S.; Valdés, J.L.; Martinez-Pastor, J.P. Plasmonic layers based on Au-nanoparticle-doped TiO2 for optoelectronics: Structural and optical properties. Nanotechnology 2013, 24, 065202. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.K.; Tan, C.L.; Lee, Y.T. Light trapping enhancement induced by bimetallic non-alloyed nanoparticles on a disordered subwavelength flexible thin film crystalline silicon substrate using metal-assisted chemical etching. Opt. Lett. 2017, 42, 431–434. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.; Santbergen, R.; Yang, G.; Smets, A.H.M.; Zeman, M. Combined optical and electrical design of plasmonic back reflector for high-efficiency thin-film silicon solar cells. IEEE J. Photovolt. 2013, 3, 53–58. [Google Scholar] [CrossRef]

- Tong, C.; Yun, J.; Song, H.; Gan, Q.; Anderson, W.A. Plasmonic-enhanced Si schottky barrier solar cells. Sol. Energy Mater. Sol. Cells 2014, 120, 591–595. [Google Scholar] [CrossRef]

- Lesina, A.C.; Paternoster, G.; Mattedi, F.; Ferrario, L.; Berini, P.; Ramunno, L.; Paris, A.; Vaccari, A.; Calliari, L. Modeling and characterization of antireflection coatings with embedded silver nanoparticles for silicon solar cells. Plasmonics 2015, 10, 1525–1536. [Google Scholar] [CrossRef]

- Manai, L.; Rezgui, B.D.; Zaghouani, R.B.; Barakel, D.; Torchio, P.; Palais, O.; Bessais, B. Tuning of light trapping and surface plasmon resonance in silver nanoparticles/c-Si structures for solar cells. Plasmonics 2016, 11, 1273–1277. [Google Scholar] [CrossRef]

- Araújo, A.; Mendes, M.J.; Mateus, T.; Vicente, A.; Nunes, D.; Calmeiro, T.; Fortunato, E.; Águas, H.; Martins, R. Influence of the substrate on the morphology of self-assembled silver nanoparticles by rapid thermal annealing. J. Phys. Chem. C 2016, 120, 18235–18242. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Chen, X.; Ouyang, Z.; Lu, H.Y.; Jia, B.H.; Shi, Z.R.; Gu, M. Improved multicrystalline Si solar cells by light trapping from Al nanoparticle enhanced antireflection coating. Opt. Mater. Express 2013, 3, 489–495. [Google Scholar] [CrossRef]

- Temple, T.L.; Bagnall, D.M. Optical properties of gold and aluminium nanoparticles for silicon solar cell applications. J. Appl. Phys. 2011, 109, 084343. [Google Scholar] [CrossRef] [Green Version]

- Parashar, P.K.; Sharma, R.P.; Komarala, V.K. Mediating broad band light trapping in silicon solar cell by aluminum nanoparticles with native oxide shell. Mater. Today Proc. 2017, 4, 12708–12715. [Google Scholar] [CrossRef]

- Couderc, R.; Amara, M.; Lemiti, M. In-depth analysis of heat generation in silicon solar cells. IEEE J. Photovolt. 2016, 6, 1123–1131. [Google Scholar] [CrossRef]

- Shockley, W.; Queisser, H.J. Detailed balance limit of efficiency of p-n junction solar cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Tayebjee, M.J.Y.; Rao, A.; Schmidt, T.W. All-optical augmentation of solar cells using a combination of up- and downconversion. J. Photonics Energy 2018, 8, 022007. [Google Scholar] [CrossRef]

- Ho, W.J.; Shen, Y.T.; Liu, J.J.; You, B.J.; Ho, C.H. Enhancing photovoltaic performance using broadband luminescent down-shifting by combining multiple species of Eu-doped silicate phosphors. Nanomaterials 2017, 7, 340. [Google Scholar] [CrossRef]

- Tahhan, A.; Dehouche, Z.; Fern, G.R.; Haverkamp, E. Photovoltaic cells energy performance enhancement with down-converting photoluminescence phosphors. Int. J. Energy Res. 2015, 39, 1616–1622. [Google Scholar] [CrossRef] [Green Version]

- Ho, W.J.; Yang, G.C.; Shen, Y.T.; Deng, Y.J. Improving efficiency of silicon solar cells using europium-doped silicate-phosphor layer by spin-on film coating. Appl. Surf. Sci. 2016, 365, 120–124. [Google Scholar] [CrossRef]

- Huang, X.; Liu, J.M.; Pan, H.; Tian, C.C.; Zhang, H.; Chen, X.J.; Huang, A.P.; Xiao, Z.S. Temperature-dependent upconversion luminescence and spectra characteristic of Er3+/Yb3+ co-doped fluorotellurite glasses. J. Lumines. 2019, 207, 41–47. [Google Scholar] [CrossRef]

- Castro, T.; Manzani, D.; Ribeiro, S.J.L. Up-conversion mechanisms in Er3+-doped fluoroindate glasses under 1550 nm excitation for enhancing photocurrent of crystalline silicon solar cell. J. Lumines. 2018, 200, 260–264. [Google Scholar] [CrossRef]

- Takeda, Y.; Luitel, H.N.; Mizuno, S. Competing effects of sensitization and energy dissipation by Ni2+ incorporation in La(Ga0.5Sc0.5)O3:Er,Ni,Nb upconverters. J. Lumines. 2018, 194, 778–784. [Google Scholar] [CrossRef]

- Luitel, H.N.; Mizuno, S.; Tani, T.; Takeda, Y. Broadband-sensitized upconversion of ATiO3:Er,Ni (A = Mg, Ca, Sr, Ba). J. Ceram. Soc. Jpn. 2017, 125, 821–828. [Google Scholar] [CrossRef]

- van Sark, W.G.; de Wild, J.; Rath, J.K.; Meijerink, A.; Schropp, R.E. Upconversion in solar cells. Nanoscale Res. Lett. 2013, 8, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.Y.; Han, S.Y.; Huang, W.; Liu, X.G. Enhancing solar cell efficiency: The search for luminescent materials as spectral converters. Chem. Soc. Rev. 2013, 42, 173–201. [Google Scholar] [CrossRef] [PubMed]

- Richards, B.S.; Shalav, A. Enhancing the near-infrared spectral response of silicon optoelectronic devices via up-conversion. IEEE Trans. Electron Devices 2007, 54, 2679–2684. [Google Scholar] [CrossRef]

- Ho, W.J.; Liu, J.J.; Yang, Y.C.; Ho, C.H. Enhancing output power of textured silicon solar cells by embedding indium plasmonic nanoparticles in layers within antireflective coating. Nanomaterials 2018, 8, 1003. [Google Scholar] [CrossRef]

- Ho, W.J.; Lin, J.C.; Liu, J.J.; Yeh, C.W.; Syu, H.J.; Lin, C.F. Plasmonic light scattering in textured silicon solar cells with indium nanoparticles from normal to non-normal light incidence. Materials 2017, 7, 737. [Google Scholar] [CrossRef]

- Ho, W.J.; Wei, C.Y.; Liu, J.J.; Lin, W.C.; Ho, C.H. Performance characterization of planar silicon solar cells using NIR up-conversion layer comprising YF3:Yb3+/Er3+ phosphors. Vacuum 2019, 166, 1–5. [Google Scholar] [CrossRef]

- Das, R.; Soni, R.K. Indium nanoparticles for ultraviolet surface-enhanced Raman spectroscopy. AIP Conf. Proc. 2018, 1953, 030123. [Google Scholar] [CrossRef]

| Silicon Solar Cell | Ideality Factor (n) | Reverse Saturation Current Density (J0, A/cm2) | RW (%) @ 350–1000 nm | EQEW (%) @ 350–1000 nm |

|---|---|---|---|---|

| Reference Cell (Ref. Cell) | 2.38 | 8.62 × 10–7 | 3.73 | 87.27 |

| UC (10 wt%) Cell | 2.31 | 5.51 × 10–7 | 3.73 | 87.41 |

| UC (20 wt%) Cell | 2.32 | 5.47 × 10–7 | 3.73 | 87.50 |

| UC (30 wt%) Cell | 2.30 | 4.23 × 10–7 | 3.73 | 87.63 |

| UC (10 wt%)/Ag Cell | 2.37 | 7.08 × 10–7 | 3.73 | 87.46 |

| UC (20 wt%)/Ag Cell | 2.37 | 8.04 × 10–7 | 3.73 | 87.71 |

| UC (30 wt%)/Ag Cell | 2.36 | 6.76 × 10–7 | 3.73 | 87.86 |

| Plasmonic (7 nm) UC/Ag Cell | 2.26 | 5.36 × 10–7 | 3.62 | 88.94 |

| For UC Comparison | Voc (mV) | JSC (mA/cm2) | F.F. (%) | η (%) | ΔJSC (%) | Δη (%) |

|---|---|---|---|---|---|---|

| Reference Cell (Ref. Cell) | 604.7 | 39.43 | 60.6 | 14.45 | -- | -- |

| UC (30 wt%) Cell | 608.6 | 40.08 | 60.7 | 14.82 | 1.65 | 2.56 |

| UC (30 wt%)/Ag Cell | 608.0 | 40.29 | 61.0 | 14.94 | 2.18 | 3.39 |

| Comparison of plasmonic effects | -- | -- | -- | -- | -- | -- |

| UC (30 wt%)/Ag Cell | 608.0 | 40.29 | 61.0 | 14.94 | -- | -- |

| Plasmonic (3 nm) UC/Ag Cell | 608.2 | 40.82 | 61.2 | 15.19 | 1.32 | 1.67 |

| Plasmonic (5 nm) UC/Ag Cell | 608.1 | 41.11 | 61.3 | 15.32 | 2.04 | 2.54 |

| Plasmonic (7 nm) UC/Ag Cell | 608.3 | 41.46 | 61.2 | 15.43 | 2.90 | 3.28 |

| Comparison of UC and Plasmonic Effects | -- | -- | -- | -- | -- | -- |

| Reference Cell (Ref. Cell) | 604.7 | 39.43 | 60.6 | 14.45 | -- | -- |

| UC (30 wt%) Cell | 608.6 | 40.08 | 60.7 | 14.82 | 1.65 | 2.56 |

| UC (30 wt%)/Ag Cell | 608.0 | 40.29 | 61.0 | 14.94 | 2.18 | 3.39 |

| Plasmonic (3 nm) UC/Ag Cell | 608.2 | 40.82 | 61.2 | 15.19 | 3.53 | 5.12 |

| Plasmonic (5 nm) UC/Ag Cell | 608.1 | 41.11 | 61.3 | 15.32 | 4.26 | 6.02 |

| Plasmonic (7 nm) UC/Ag Cell | 608.3 | 41.46 | 61.2 | 15.43 | 5.15 | 6.78 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, W.-J.; Lin, W.-C.; Liu, J.-J.; Syu, H.-J.; Lin, C.-F. Enhancing the Performance of Textured Silicon Solar Cells by Combining Up-Conversion with Plasmonic Scattering. Energies 2019, 12, 4119. https://doi.org/10.3390/en12214119

Ho W-J, Lin W-C, Liu J-J, Syu H-J, Lin C-F. Enhancing the Performance of Textured Silicon Solar Cells by Combining Up-Conversion with Plasmonic Scattering. Energies. 2019; 12(21):4119. https://doi.org/10.3390/en12214119

Chicago/Turabian StyleHo, Wen-Jeng, Wei-Chen Lin, Jheng-Jie Liu, Hong-Jhang Syu, and Ching-Fuh Lin. 2019. "Enhancing the Performance of Textured Silicon Solar Cells by Combining Up-Conversion with Plasmonic Scattering" Energies 12, no. 21: 4119. https://doi.org/10.3390/en12214119