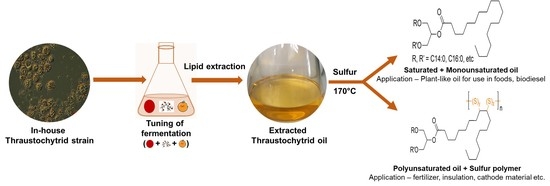

Integration of the Exogenous Tuning of Thraustochytrid Fermentation and Sulfur Polymerization of Single-Cell Oil for Developing Plant-like Oils

Abstract

:1. Introduction

2. Results and Discussion

2.1. Exogenous Addition of Vitamin B12, Tween 80 and Limonene in Fermentation Medium

2.2. Downstream Processing: Hydrogenation of Thraustochytrid Oil

2.3. Copolymerization of Thraustochytrid Oil with Sulfur

2.4. Fatty Acid Profile of the Oil Samples after Hydrogenation and Sulfur Polymerization

2.5. Characterisation of the Thraustochytrid Oil and the Oil-Sulfur Polymer

3. Materials and Methods

3.1. Medium Components and Chemicals

3.2. Thraustochytrid Strain and Inoculum Preparation

3.3. Exogenous Supplementation of Chemical Modulators in the Fermentation Medium

3.4. Biomass Production

3.5. Lipid Extraction, FAMEs Preparation and GC Analysis

3.6. Hydrogenation of Thraustochytrid Oil

3.7. Copolymerization of Thraustochytrid Oil with Sulfur

3.8. Analysis of Thraustochytrid Oil Recovered after Hydrogenation or after Copolymerization with Sulfur

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Y.; Mu, D.; Xue, Z.; Xu, P.; Li, Y.; Xiang, W.; Burnett, J.; Bryant, K.; Zhou, W. Life cycle assessment of industrial production of microalgal oil from heterotrophic fermentation. Algal Res. 2021, 58, 102404. [Google Scholar] [CrossRef]

- Gupta, A.; Barrow, C.J.; Puri, M. Multiproduct biorefinery from marine thraustochytrids towards a circular bioeconomy. Trends Biotechnol. 2022, 40, 448–462. [Google Scholar] [CrossRef] [PubMed]

- Xiang, X.; Ozkan, A.; Chiriboga, O.; Chotyakul, N.; Kelly, C. Techno-economic analysis of glucosamine and lipid production from marine diatom Cyclotella sp. Bioresour. Technol. 2017, 244, 1480–1488. [Google Scholar] [CrossRef]

- Zirnheld, K.H.; Warner, D.R.; Warner, J.B.; Hardesty, J.E.; McClain, C.J.; Kirpich, I.A. Dietary fatty acids and bioactive fatty acid metabolites in alcoholic liver disease. Liver Res. 2019, 3, 206–217. [Google Scholar] [CrossRef]

- Ghazani, S.M.; Marangoni, A.G. Microbial lipids for foods. Trends Food Sci. Technol. 2022, 119, 593–607. [Google Scholar] [CrossRef]

- Gupta, A.; Singh, D.; Byreddy, A.R.; Thyagarajan, T.; Sonkar, S.P.; Mathur, A.S.; Tuli, D.K.; Barrow, C.J.; Puri, M. Exploring omega-3 fatty acids, enzymes and biodiesel producing thraustochytrids from Australian and Indian marine biodiversity. Biotechnol. J. 2016, 11, 345–355. [Google Scholar] [CrossRef] [PubMed]

- Singh, D.; Mathur, A.S.; Tuli, D.K.; Puri, M.; Barrow, C.J. Propyl gallate and butylated hydroxytoluene influence the accumulation of saturated fatty acids, omega-3 fatty acid and carotenoids in thraustochytrids. J. Funct. Foods 2015, 15, 186–192. [Google Scholar] [CrossRef]

- Fedorova-Dahms, I.; Marone, P.A.; Bauter, M.; Ryan, A.S. Safety evaluation of DHA-rich Algal Oil from Schizochytrium sp. Food Chem. Toxicol. 2011, 49, 3310–3318. [Google Scholar] [CrossRef]

- EFSA Panel on Nutrition, Novel Foods and Food Allergens (NDA); Turck, D.; Castenmiller, J.; De Henauw, S.; Hirsch-Ernst, K.I.; Kearney, J.; Maciuk, A.; Mangelsdorf, I.; McArdle, H.J.; Naska, A.; et al. Safety of Schizochytrium sp. oil as a novel food pursuant to Regulation (EU) 2015/2283(a). EFSA J. 2020, 18, e06242. [Google Scholar]

- Puri, M.; Gupta, A.; McKinnon, R.A.; Abraham, R.E. Marine bioactives: From energy to nutrition. Trends Biotechnol. 2022, 40, 271–280. [Google Scholar] [CrossRef]

- Wang, S.; Wan, W.; Wang, Z.; Zhang, H.; Liu, H.; Arunakumara, K.K.I.U.; Cui, Q.; Song, X. A Two-Stage Adaptive Laboratory Evolution Strategy to Enhance Docosahexaenoic Acid Synthesis in Oleaginous Thraustochytrid. Front. Nutr. 2021, 8, 795491. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Sun, T.; Cui, J.; Liu, L.; Bi, Y.; Pei, G.; Chen, L.; Zhang, W. Screening of chemical modulators for lipid accumulation in Schizochytrium sp. S31. Bioresour. Technol. 2018, 260, 124–129. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, K.; Chen, L.; Liu, J.; Gao, F.; He, R.; Chen, W.; Guo, W.; Chen, S.; Li, D. Effects of butanol on high value product production in Schizochytrium limacinum B4D1. Enzym. Microb. Technol. 2017, 102, 9–15. [Google Scholar] [CrossRef] [PubMed]

- Ren, L.-J.; Sun, X.-M.; Ji, X.-J.; Chen, S.-L.; Guo, D.-S.; Huang, H. Enhancement of docosahexaenoic acid synthesis by manipulation of antioxidant capacity and prevention of oxidative damage in Schizochytrium sp. Bioresour. Technol. 2017, 223, 141–148. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nazir, Y.; Halim, H.; Prabhakaran, P.; Ren, X.; Naz, T.; Mohamed, H.; Nosheen, S.; Mustafa, K.; Yang, W.; Abdul Hamid, A.; et al. Different Classes of Phytohormones Act Synergistically to Enhance the Growth, Lipid and DHA Biosynthetic Capacity of Aurantiochytrium sp. SW1. Biomolecules 2020, 10, 755. [Google Scholar] [CrossRef]

- Bao, Z.; Zhu, Y.; Feng, Y.; Zhang, K.; Zhang, M.; Wang, Z.; Yu, L. Enhancement of lipid accumulation and docosahexaenoic acid synthesis in Schizochytrium sp. H016 by exogenous supplementation of sesamol. Bioresour. Technol. 2022, 345, 126527. [Google Scholar] [CrossRef]

- Santin, A.; Russo, M.T.; Ferrante, M.I.; Balzano, S.; Orefice, I.; Sardo, A. Highly Valuable Polyunsaturated Fatty Acids from Microalgae: Strategies to Improve Their Yields and Their Potential Exploitation in Aquaculture. Molecules 2021, 26, 7697. [Google Scholar] [CrossRef]

- Gupta, A.; Worthington, M.J.H.; Patel, H.D.; Johnston, M.R.; Puri, M.; Chalker, J.M. Reaction of Sulfur and Sustainable Algae Oil for Polymer Synthesis and Enrichment of Saturated Triglycerides. ACS Sustain. Chem. Eng. 2022, 10, 9022–9028. [Google Scholar] [CrossRef]

- Laverdura, U.P.; Rossi, L.; Ferella, F.; Courson, C.; Zarli, A.; Alhajyoussef, R.; Gallucci, K. Selective Catalytic Hydrogenation of Vegetable Oils on Lindlar Catalyst. ACS Omega 2020, 5, 22901–22913. [Google Scholar] [CrossRef]

- Shirasaka, N.; Hirai, Y.; Nakabayashi, H.; Yoshizumi, H. Effect of cyanocobalamin and p-toluic acid on the fatty acid composition of Schizochytrium limacinum (Thraustochytriaceae, Labyrinthulomycota). Mycoscience 2005, 46, 358–363. [Google Scholar] [CrossRef]

- Byreddy, A.R.; Rao, N.M.; Barrow, C.J.; Puri, M. Tween 80 influences the production of intracellular lipase by Schizochytrium S31 in a stirred tank reactor. Process. Biochem. 2017, 53, 30–35. [Google Scholar] [CrossRef]

- Papanikolaou, S.; Gortzi, O.; Margeli, E.; Chinou, I.; Galiotou-Panayotou, M.; Lalas, S. Effect of Citrus essential oil addition upon growth and cellular lipids of Yarrowia lipolytica yeast. Eur. J. Lipid Sci. Technol. 2008, 110, 997–1006. [Google Scholar] [CrossRef]

- Uprety, B.K.; Rakshit, S.K. Compositional Shift in Fatty Acid Profiles of Lipids Obtained from Oleaginous Yeasts upon the Addition of Essential Oil from Citrus sinensis L. Appl. Biochem. Biotechnol. 2017, 183, 1158–1172. [Google Scholar] [CrossRef] [PubMed]

- Lligadas, G.; Ronda, J.C.; Galià, M.; Cádiz, V. Renewable polymeric materials from vegetable oils: A perspective. Mater. Today 2013, 16, 337–343. [Google Scholar] [CrossRef]

- Worthington, M.J.H.; Kucera, R.L.; Albuquerque, I.S.; Gibson, C.T.; Sibley, A.; Slattery, A.D.; Campbell, J.A.; Alboaiji, S.F.K.; Muller, K.A.; Young, J.; et al. Laying Waste to Mercury: Inexpensive Sorbents Made from Sulfur and Recycled Cooking Oils. Chem. A Eur. J. 2017, 23, 16219–16230. [Google Scholar] [CrossRef] [Green Version]

- Worthington, M.J.H.; Shearer, C.J.; Esdaile, L.J.; Campbell, J.A.; Gibson, C.T.; Legg, S.K.; Yin, Y.; Lundquist, N.A.; Gascooke, J.R.; Albuquerque, I.S.; et al. Sustainable Polysulfides for Oil Spill Remediation: Repurposing Industrial Waste for Environmental Benefit. Adv. Sustain. Syst. 2018, 2, 1800024. [Google Scholar] [CrossRef] [Green Version]

- Hoefling, A.; Lee, Y.J.; Theato, P. Sulfur-Based Polymer Composites from Vegetable Oils and Elemental Sulfur: A Sustainable Active Material for Li–S Batteries. Macromol. Chem. Phys. 2017, 218, 1600303. [Google Scholar] [CrossRef]

- Mann, M.; Kruger, J.E.; Andari, F.; McErlean, J.; Gascooke, J.R.; Smith, J.A.; Worthington, M.J.H.; McKinley, C.C.C.; Campbell, J.A.; Lewis, D.A.; et al. Sulfur polymer composites as controlled-release fertilisers. Org. Biomol. Chem. 2019, 17, 1929–1936. [Google Scholar] [CrossRef]

- Lundquist, N.A.; Tikoalu, A.D.; Worthington, M.J.H.; Shapter, R.; Tonkin, S.J.; Stojcevski, F.; Mann, M.; Gibson, C.T.; Gascooke, J.R.; Karton, A.; et al. Reactive Compression Molding Post-Inverse Vulcanization: A Method to Assemble, Recycle, and Repurpose Sulfur Polymers and Composites. Chem. A Eur. J. 2020, 26, 10035–10044. [Google Scholar] [CrossRef]

- Bu Najmah, I.; Lundquist, N.A.; Stanfield, M.K.; Stojcevski, F.; Campbell, J.A.; Esdaile, L.J.; Gibson, C.T.; Lewis, D.A.; Henderson, L.C.; Hasell, T.; et al. Insulating Composites Made from Sulfur, Canola Oil, and Wool. ChemSusChem 2021, 14, 2352–2359. [Google Scholar] [CrossRef]

- Stojcevski, F.; Stanfield, M.K.; Hayne, D.J.; Mann, M.; Lundquist, N.A.; Chalker, J.M.; Henderson, L.C. Inverse Vulcanisation of canola oil as a route to recyclable chopped carbon fibre composites. Sustain. Mater. Technol. 2022, 32, e00400. [Google Scholar] [CrossRef]

- Tommasi, E.; Cravotto, G.; Galletti, P.; Grillo, G.; Mazzotti, M.; Sacchetti, G.; Samorì, C.; Tabasso, S.; Tacchini, M.; Tagliavini, E. Enhanced and Selective Lipid Extraction from the Microalga P. tricornutum by Dimethyl Carbonate and Supercritical CO2 Using Deep Eutectic Solvents and Microwaves as Pretreatment. ACS Sustain. Chem. Eng. 2017, 5, 8316–8322. [Google Scholar] [CrossRef]

- Li, X.; Liu, J.; Chen, G.; Zhang, J.; Wang, C.; Liu, B. Extraction and purification of eicosapentaenoic acid and docosahexaenoic acid from microalgae: A critical review. Algal Res. 2019, 43, 101619. [Google Scholar] [CrossRef]

- Popescu, R.; Costinel, D.; Dinca, O.R.; Marinescu, A.; Stefanescu, I.; Ionete, R.E. Discrimination of vegetable oils using NMR spectroscopy and chemometrics. Food Control 2015, 48, 84–90. [Google Scholar] [CrossRef]

- Tikoalu, A.D.; Lundquist, N.A.; Chalker, J.M. Mercury Sorbents Made By Inverse Vulcanization of Sustainable Triglycerides: The Plant Oil Structure Influences the Rate of Mercury Removal from Water. Adv. Sustain. Syst. 2020, 4, 1900111. [Google Scholar] [CrossRef]

- Lundquist, N.A.; Sweetman, M.J.; Scroggie, K.R.; Worthington, M.J.H.; Esdaile, L.J.; Alboaiji, S.F.K.; Plush, S.E.; Hayball, J.D.; Chalker, J.M. Polymer Supported Carbon for Safe and Effective Remediation of PFOA- and PFOS-Contaminated Water. ACS Sustain. Chem. Eng. 2019, 7, 11044–11049. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, A.; Worthington, M.J.H.; Chalker, J.M.; Puri, M. Integration of the Exogenous Tuning of Thraustochytrid Fermentation and Sulfur Polymerization of Single-Cell Oil for Developing Plant-like Oils. Mar. Drugs 2022, 20, 655. https://doi.org/10.3390/md20100655

Gupta A, Worthington MJH, Chalker JM, Puri M. Integration of the Exogenous Tuning of Thraustochytrid Fermentation and Sulfur Polymerization of Single-Cell Oil for Developing Plant-like Oils. Marine Drugs. 2022; 20(10):655. https://doi.org/10.3390/md20100655

Chicago/Turabian StyleGupta, Adarsha, Max J. H. Worthington, Justin M. Chalker, and Munish Puri. 2022. "Integration of the Exogenous Tuning of Thraustochytrid Fermentation and Sulfur Polymerization of Single-Cell Oil for Developing Plant-like Oils" Marine Drugs 20, no. 10: 655. https://doi.org/10.3390/md20100655