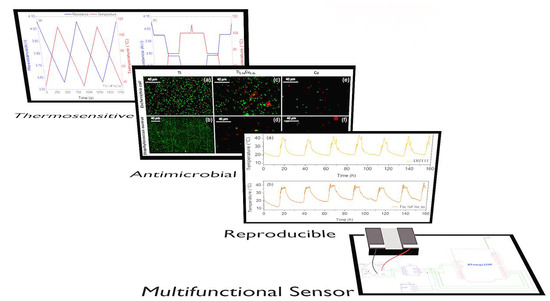

High Performance of Metallic Thin Films for Resistance Temperature Devices with Antimicrobial Properties

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, J.; Liu, H.; Li, X.; Jiang, S.; Zhang, B.; Song, Y.; Zhang, W. Fabrication and characterization of nickel thin film as resistance temperature detector. Vacuum 2020, 176, 109288. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, C.; Li, J.; Ding, G.; Duan, L. Fabrication and characterization of ITO thin film resistance temperature detector. Vacuum 2017, 140, 121–125. [Google Scholar] [CrossRef]

- Reverter, F. A Tutorial on Thermal Sensors in the 200th Anniversary of the Seebeck Effect. IEEE Sens. J. 2021, 21, 22122–22132. [Google Scholar] [CrossRef]

- Ferreira, A.; Borges, J.; Lopes, C.; Rodrigues, M.S.; Lanceros-Mendez, S.; Vaz, F. Relationship between nano-architectured Ti1xCux thin film and electrical resistivity for resistance temperature detectors. J. Mater. Sci. 2017, 52, 4878–4885. [Google Scholar] [CrossRef]

- Sim, J.K.; Hyun, J.; Doh, I.; Ahn, B.; Kim, Y.T. Thin-film resistance temperature detector array for the measurement of temperature distribution inside a phantom. Metrologia 2018, 55, L5–L11. [Google Scholar] [CrossRef] [Green Version]

- Yu, C.; Wang, Z.; Yu, H.; Jiang, H. A stretchable temperature sensor based on elastically buckled thin film devices on elastomeric substrates. Appl. Phys. Lett. 2009, 95, 141912. [Google Scholar] [CrossRef] [Green Version]

- Yan, W.; Li, H.; Liu, J.; Guo, J. EPMA and XRD study on nickel metal thin film for temperature sensor. Sens. Actuators A Phys. 2007, 136, 212–215. [Google Scholar] [CrossRef]

- Van Duy, N.; Thai, N.X.; Ngoc, T.M.; Thi Thanh Le, D.; Hung, C.M.; Nguyen, H.; Tonezzer, M.; Van Hieu, N.; Hoa, N.D. Design and fabrication of effective gradient temperature sensor array based on bilayer SnO2/Pt for gas classification. Sens. Actuators B Chem. 2022, 351, 130979. [Google Scholar] [CrossRef]

- Kilinc, N.; Sanduvac, S.; Erkovan, M. Platinum-Nickel alloy thin films for low concentration hydrogen sensor application. J. Alloys Compd. 2022, 892, 162237. [Google Scholar] [CrossRef]

- Rashid, S.; Vita, G.M.; Persichetti, L.; Iucci, G.; Battocchio, C.; Daniel, R.; Visaggio, D.; Marsotto, M.; Visca, P.; Bemporad, E.; et al. Biocompatibility and antibacterial properties of TiCu(Ag) thin films produced by physical vapor deposition magnetron sputtering. Appl. Surf. Sci. 2022, 573, 151604. [Google Scholar] [CrossRef]

- Efeoğlu, H.; Turut, A. A highly stable temperature sensor based on Au/Cu/n-Si Schottky barrier diodes dependent on the inner metal thickness. J. Phys. D Appl. Phys. 2022, 55, 185303. [Google Scholar] [CrossRef]

- Chung, G.S.; Kim, C.H. RTD characteristics for micro-thermal sensors. Microelectron. J. 2008, 39, 1560–1563. [Google Scholar] [CrossRef]

- Bourega, A.; Doumi, B.; Mokaddem, A.; Sayede, A.; Tadjer, A. Electronic structures and magnetic performance related to spintronics of Sr0.875Ti0.125S. Opt. Quantum Electron. 2019, 51, 385. [Google Scholar] [CrossRef]

- Lourenço, M.J.; Serra, J.M.; Nunes, M.R.; Vallêra, A.M.; Nieto de Castro, C.A. Thin-film characterization for high-temperature applications. Int. J. Thermophys. 1998, 19, 1253–1265. [Google Scholar] [CrossRef]

- Peng, C.; Zhao, Y.; Jin, S.; Wang, J.; Liu, R.; Liu, H.; Shi, W.; Kolawole, S.K.; Ren, L.; Yu, B.; et al. Antibacterial TiCu/TiCuN Multilayer Films with Good Corrosion Resistance Deposited by Axial Magnetic Field-Enhanced Arc Ion Plating. ACS Appl. Mater. Interfaces 2019, 11, 125–136. [Google Scholar] [CrossRef] [PubMed]

- Childs, P.R.; Greenwood, J.R.; Long, C.A. Review of temperature measurement. Rev. Sci. Instrum. 2000, 71, 2959–2978. [Google Scholar] [CrossRef] [Green Version]

- Santo, C.E.; Quaranta, D.; Grass, G. Antimicrobial metallic copper surfaces kill Staphylococcus haemolyticus via membrane damage. Microbiologyopen 2012, 1, 46–52. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, X.; Jiang, L.; Ma, Y.; Fan, A.; Tang, B. Surface microstructures and antimicrobial properties of copper plasma alloyed stainless steel. Appl. Surf. Sci. 2011, 258, 1399–1404. [Google Scholar] [CrossRef]

- Stranak, V.; Wulff, H.; Rebl, H.; Zietz, C.; Arndt, K.; Bogdanowicz, R.; Nebe, B.; Bader, R.; Podbielski, A.; Hubicka, Z.; et al. Deposition of thin titanium-copper films with antimicrobial effect by advanced magnetron sputtering methods. Mater. Sci. Eng. C 2011, 31, 1512–1519. [Google Scholar] [CrossRef]

- Heidenau, F.; Mittelmeier, W.; Detsch, R.; Haenle, M.; Stenzel, F.; Ziegler, G.; Gollwitzer, H. A novel antibacterial titania coating: Metal ion toxicity and in vitro surface colonization. J. Mater. Sci. Mater. Med. 2005, 16, 883–888. [Google Scholar] [CrossRef]

- Bao, M.; Wang, X.; Yang, L.; Qin, G.; Zhang, E. Tribocorrosion Behavior of Ti-Cu Alloy in Hank’s Solution for Biomedical Application. J. Bio- Tribo-Corros. 2018, 4, 29. [Google Scholar] [CrossRef]

- Ferreira, A.; Pedrosa, P.; Martin, N.; Yazdi, M.A.P.; Billard, A.; Lanceros-Méndez, S.; Vaz, F. Nanostructured Ti 1-xCux thin films with tailored electrical and morphological anisotropy. Thin Solid Films 2019, 672, 47–54. [Google Scholar] [CrossRef]

- Magina, S.; Santos, M.D.; Ferra, J.; Cruz, P.; Portugal, I.; Evtuguin, D. High Pressure Laminates with Antimicrobial Properties. Materials 2016, 9, 100. [Google Scholar] [CrossRef] [Green Version]

- Sousa, B.C.; Cote, D.L. Antimicrobial copper cold spray coatings and SARS-CoV-2 surface inactivation. MRS Adv. 2020, 5, 2873–2880. [Google Scholar] [CrossRef] [PubMed]

- Shum, R.L.; Liu, S.R.; Caschera, A.; Foucher, D.A. UV-curable surface-attached antimicrobial polymeric onium coatings: Designing effective, solvent-resistant coatings for plastic surfaces. ACS Appl. Bio Mater. 2020, 3, 4302–4315. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, A.; Fernandes, M.M.; Souza, A.L.; Correa, M.A.; Lanceros-Mendez, S.; Vaz, F. Flexible TiCux Thin Films with Dual Antimicrobial and Piezoresistive Characteristics. ACS Appl. Bio Mater. 2022, 5, 1267–1272. [Google Scholar] [CrossRef]

- Mayadas, A.F.; Shatzkes, M. Electrical-Resistivity Model for Polycrystalline Films: The Case of Arbitrary Reflection at External Surfaces. Phys. Rev. B 1970, 1, 1382–1389. [Google Scholar] [CrossRef]

- Warnes, S.L.; Caves, V.; Keevil, C.W. Mechanism of copper surface toxicity in Escherichia coli O157:H7 and Salmonella involves immediate membrane depolarization followed by slower rate of DNA destruction which differs from that observed for Gram-positive bacteria. Environ. Microbiol. 2012, 14, 1730–1743. [Google Scholar] [CrossRef]

- Siti Nur Hazwani, M.R.; Lim, L.X.; Lockman, Z.; Zuhailawati, H. Fabrication of titanium-based alloys with bioactive surface oxide layer as biomedical implants: Opportunity and challenges. Trans. Nonferrous Met. Soc. China 2022, 32, 1–44. [Google Scholar] [CrossRef]

- Fatoba, O.S.; Esezobor, D.E.; Akanji, O.L.; Fatoba, A.J.; Macgregor, D.; Etubor, J. The Study of the Antimicrobial Properties of Selected Engineering Materials’ Surfaces. J. Min. Mater. Charact. Eng. 2014, 02, 78–87. [Google Scholar] [CrossRef]

- Szymański, P.; Frączek, T.; Markowicz, M.; Mikiciuk-Olasik, E. Development of copper based drugs, radiopharmaceuticals and medical materials. Biometals 2012, 25, 1089–1112. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vincent, M.; Duval, R.; Hartemann, P.; Engels-Deutsch, M. Contact killing and antimicrobial properties of copper. J. Appl. Microbiol. 2018, 124, 1032–1046. [Google Scholar] [CrossRef] [Green Version]

- Montero, D.A.; Arellano, C.; Pardo, M.; Vera, R.; Gálvez, R.; Cifuentes, M.; Berasain, M.A.; Gómez, M.; Ramírez, C.; Vidal, R.M. Antimicrobial properties of a novel copper-based composite coating with potential for use in healthcare facilities. Antimicrob. Resist. Infect. Control 2019, 8, 3. [Google Scholar] [CrossRef] [PubMed]

- Grass, G.; Rensing, C.; Solioz, M. Metallic Copper as an Antimicrobial Surface. Appl. Environ. Microbiol. 2011, 77, 1541–1547. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lv, W.; Wang, Y.; Shi, W.; Cheng, W.; Huang, R.; Zhong, R.; Zeng, Z.; Fan, Y.; Zhang, B. Role of micro-nano fabrication process on the temperature coefficient of resistance of platinum thin films resistance temperature detector. Mater. Lett. 2022, 309, 131313. [Google Scholar] [CrossRef]

- Sarma, S.; Lee, J. Developing Efficient Thin Film Temperature Sensors Utilizing Layered Carbon Nanotube Films. Sensors 2018, 18, 3182. [Google Scholar] [CrossRef]

| Ti (mA) | Cu (mA) | Ti (at.%) | Cu (at.%) | TiCu | Thick. (nm) | Rough. (nm) |

|---|---|---|---|---|---|---|

| 200 | 5 | 0.74 | 0.26 | TiCu | 46.6 | 4.8 |

| 200 | 10 | 0.70 | 0.30 | TiCu | 39.4 | 8.0 |

| 200 | 15 | 0.54 | 0.46 | TiCu | 53.9 | 6.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Souza, A.L.R.; Correa, M.A.; Bohn, F.; Castro, H.; Fernandes, M.M.; Vaz, F.; Ferreira, A. High Performance of Metallic Thin Films for Resistance Temperature Devices with Antimicrobial Properties. Sensors 2022, 22, 7665. https://doi.org/10.3390/s22197665

Souza ALR, Correa MA, Bohn F, Castro H, Fernandes MM, Vaz F, Ferreira A. High Performance of Metallic Thin Films for Resistance Temperature Devices with Antimicrobial Properties. Sensors. 2022; 22(19):7665. https://doi.org/10.3390/s22197665

Chicago/Turabian StyleSouza, Arthur L. R., Marcio A. Correa, Felipe Bohn, Helder Castro, Margarida M. Fernandes, Filipe Vaz, and Armando Ferreira. 2022. "High Performance of Metallic Thin Films for Resistance Temperature Devices with Antimicrobial Properties" Sensors 22, no. 19: 7665. https://doi.org/10.3390/s22197665