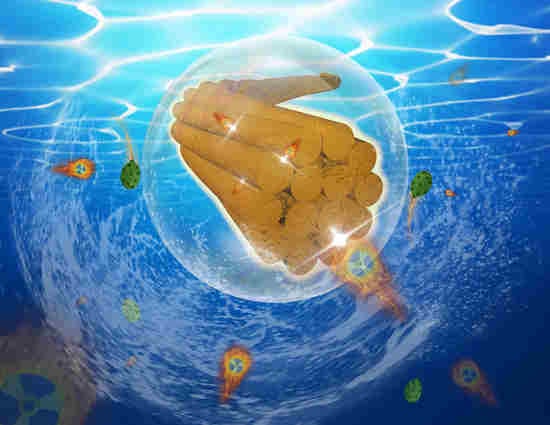

Theory-Guided Design of a Method to Obtain Competitive Balance between U(VI) Adsorption and Swaying Zwitterion-Induced Fouling Resistance on Natural Hemp Fibers

Abstract

:1. Introduction

2. Results and Discussion

2.1. MD Simulation of AOSB0, AOSB1, and AOSB2

2.2. Characterization of HFAO, HFAC, and HFAS

2.3. Batch U(VI) Adsorption Experiments with HFAO, HFAC, and HFAS

2.4. The Adsorption Performance of HF-Based Materials in Ion Competition Solution, U(VI)-Spiked Nitzschia closterium Solution, and Seawater

2.5. Analysis of U(VI) Adsorption on HFAS

3. Materials and Methods

3.1. Amidoxime-Modified Hemp Fibers (HFAO)

3.2. Zwitterion-Modified Hemp Fibers (HFAC and HFAS)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schiermeier, Q.; Tollefson, J.; Scully, T.; Witze, A.; Morton, O. Energy alternatives: Electricity without carbon. Nature 2008, 454, 816–823. [Google Scholar] [CrossRef]

- Wang, X.; Chen, L.; Wang, L.; Fan, Q.; Pan, D.; Li, J.; Chi, F.; Xie, Y.; Yu, S.; Xiao, C.; et al. Synthesis of novel nanomaterials and their application in efficient removal of radionuclides. Sci. China Ser. B Chem. 2019, 62, 933–967. [Google Scholar] [CrossRef]

- Liu, Y.; Huo, Y.; Wang, X.; Yu, S.; Ai, Y.; Chen, Z.; Zhang, P.; Chen, L.; Song, G.; Alharbi, N.S.; et al. Impact of metal ions and organic ligands on uranium removal properties by zeolitic imidazolate framework materials. J. Clean. Prod. 2021, 278. [Google Scholar] [CrossRef]

- Luo, W.; Xiao, G.; Tian, F.; Richardson, J.J.; Wang, Y.; Zhou, J.; Guo, J.; Liao, X.; Shi, B. Engineering robust metal–phenolic network membranes for uranium extraction from seawater. Energy Environ. Sci. 2019, 12, 607–614. [Google Scholar] [CrossRef]

- Abney, C.W.; Mayes, R.T.; Saito, T.; Dai, S. Materials for the Recovery of Uranium from Seawater. Chem. Rev. 2017, 117, 13935–14013. [Google Scholar] [CrossRef]

- Guo, X.; Yang, H.; Liu, Q.; Liu, J.; Chen, R.; Zhang, H.; Yu, J.; Zhang, M.; Li, R.; Wang, J. A chitosan-graphene oxide/ZIF foam with anti-biofouling ability for uranium recovery from seawater. Chem. Eng. J. 2020, 382, 122850. [Google Scholar] [CrossRef]

- Couzon, N.; Ferreira, M.; Duval, S.; El-Achari, A.; Campagne, C.; Loiseau, T.; Volkringer, C. Microwave-Assisted Synthesis of Porous Composites MOF–Textile for the Protection against Chemical and Nuclear Hazards. ACS Appl. Mater. Interfaces 2022, 14, 21497–21508. [Google Scholar] [CrossRef]

- Zhang, C.; Cui, W.; Niu, C.; Yi, S.; Liang, R.; Qi, J.; Chen, X.; Jiang, W.; Zhang, L.; Qiu, J. rGO-based covalent organic framework hydrogel for synergistically enhance uranium capture capacity through photothermal desalination. Chem. Eng. J. 2022, 428, 131178. [Google Scholar] [CrossRef]

- Song, Y.; Sun, Q.; Aguila, B.; Ma, S. Opportunities of covalent organic frameworks for advanced applications. Adv. Sci. 2019, 6, 1801410. [Google Scholar] [CrossRef]

- Guilhen, S.N.; Rovani, S.; de Araujo, L.G.; Tenório, J.A.; Mašek, O. Uranium removal from aqueous solution using macauba endocarp-derived biochar: Effect of physical activation. Environ. Pollut. 2020, 272, 116022. [Google Scholar] [CrossRef]

- Yu, Q.; Yuan, Y.; Feng, L.; Feng, T.; Sun, W.; Wang, N. Spidroin-inspired, high-strength, loofah-shaped protein fiber for capturing uranium from seawater. Angew. Chem. Int. Ed. 2020, 59, 15997–16001. [Google Scholar] [CrossRef] [PubMed]

- Ma, F.; Gui, Y.; Liu, P.; Xue, Y.; Song, W. Functional fibrous materials-based adsorbents for uranium adsorption and environmental remediation. Chem. Eng. J. 2020, 390, 124597. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, H.; Liu, Q.; Liu, J.; Chen, R.; Yu, J.; Zhu, J.; Li, R.; Wang, J. Surface hybridization of π-conjugate structure cyclized polyacrylonitrile and radial microsphere shaped TiO2 for reducing U(VI) to U(IV). J. Hazard. Mater. 2021, 416, 125812. [Google Scholar] [CrossRef]

- Pacaphol, K.; Aht-Ong, D. Preparation of hemp nanofibers from agricultural waste by mechanical defibrillation in water. J. Clean. Prod. 2017, 142, 1283–1295. [Google Scholar] [CrossRef]

- Schumacher, A.G.D.; Pequito, S.; Pazour, J. Industrial hemp fiber: A sustainable and economical alternative to cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Morin-Crini, N.; Loiacono, S.; Placet, V.; Torri, G.; Bradu, C.; Kostić, M.; Cosentino, C.; Chanet, G.; Martel, B.; Lichtfouse, E.; et al. Hemp-based adsorbents for sequestration of metals: A review. Environ. Chem. Lett. 2019, 17, 393–408. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, Y.; Ma, X.; Meng, Q.; Wang, L.; Zhao, S.; Zhu, G. Molecularly Imprinted Porous Aromatic Frameworks and Their Composite Components for Selective Extraction of Uranium Ions. Adv. Mater. 2018, 30, e1706507. [Google Scholar] [CrossRef]

- Aguila, B.; Sun, Q.; Cassady, H.; Abney, C.W.; Li, B.; Ma, S. Design Strategies to Enhance Amidoxime Chelators for Uranium Recovery. ACS Appl. Mater. Interfaces 2019, 11, 30919–30926. [Google Scholar] [CrossRef]

- Wang, D.; Song, J.; Lin, S.; Wen, J.; Ma, C.; Yuan, Y.; Lei, M.; Wang, X.; Wang, N.; Wu, H. A Marine-Inspired Hybrid Sponge for Highly Efficient Uranium Extraction from Seawater. Adv. Funct. Mater. 2019, 29, 1901009. [Google Scholar] [CrossRef]

- Yan, B.; Ma, C.; Gao, J.; Yuan, Y.; Wang, N. An Ion-Crosslinked Supramolecular Hydrogel for Ultrahigh and Fast Uranium Recovery from Seawater. Adv. Mater. 2020, 32, e1906615. [Google Scholar] [CrossRef]

- Yuan, Y.; Yu, Q.; Yang, S.; Wen, J.; Guo, Z.; Wang, X.; Wang, N. Ultrafast Recovery of Uranium from Seawater by Bacillus velezensis Strain UUS-1 with Innate Anti-Biofouling Activity. Adv. Sci. 2019, 6, 1900961. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.; Aguila, B.; Perman, J.; Ivanov, A.S.; Bryantsev, V.S.; Earl, L.D.; Abney, C.W.; Wojtas, L.; Ma, S. Bio-inspired nano-traps for uranium extraction from seawater and recovery from nuclear waste. Nat. Commun. 2018, 9, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Abney, C.W.; Liu, S.; Lin, W. Tuning Amidoximate to Enhance Uranyl Binding: A Density Functional Theory Study. J. Phys. Chem. A 2013, 117, 11558–11565. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-Z.; Lan, J.-H.; Wu, Q.-Y.; Luo, Q.; Zhao, Y.-L.; Wang, X.-K.; Chai, Z.-F.; Shi, W.-Q. Theoretical Insights on the Interaction of Uranium with Amidoxime and Carboxyl Groups. Inorg. Chem. 2014, 53, 9466–9476. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Han, X.; Hua, D. Polyoxime-functionalized magnetic nanoparticles for uranium adsorption with high selectivity over vanadium. J. Mater. Chem. A 2017, 5, 12278–12284. [Google Scholar] [CrossRef]

- Ma, C.; Gao, J.; Wang, D.; Yuan, Y.; Wen, J.; Yan, B.; Zhao, S.; Zhao, X.; Sun, Y.; Wang, X.; et al. Sunlight Polymerization of Poly(amidoxime) Hydrogel Membrane for Enhanced Uranium Extraction from Seawater. Adv. Sci. 2019, 6, 1900085. [Google Scholar] [CrossRef] [PubMed]

- Vukovic, S.; Watson, L.A.; Kang, S.O.; Custelcean, R.; Hay, B.P. How Amidoximate Binds the Uranyl Cation. Inorg. Chem. 2012, 51, 3855–3859. [Google Scholar] [CrossRef]

- Yu, Q.; Yuan, Y.; Wen, J.; Zhao, X.; Zhao, S.; Wang, D.; Li, C.; Wang, X.; Wang, N. A Universally Applicable Strategy for Construction of Anti-Biofouling Adsorbents for Enhanced Uranium Recovery from Seawater. Adv. Sci. 2019, 6, 1900002. [Google Scholar] [CrossRef]

- Yang, S.; Cao, Y.; Wang, T.; Cai, S.; Xu, M.; Lu, W.; Hua, D. Positively charged conjugated microporous polymers with antibiofouling activity for ultrafast and highly selective uranium extraction from seawater. Environ. Res. 2020, 183, 109214. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L.; Han, X.; Kuang, L.; Hua, D. Guanidine and Amidoxime Cofunctionalized Polypropylene Nonwoven Fabric for Potential Uranium Seawater Extraction with Antifouling Property. Ind. Eng. Chem. Res. 2018, 57, 1662–1670. [Google Scholar] [CrossRef]

- Ao, J.; Han, J.; Xu, X.; Qi, S.; Ma, L.; Wang, Z.; Zhang, L.; Li, Q.; Xu, L.; Ma, H. Enhanced Performance in Uranium Extraction by Quaternary Ammonium-Functionalized Amidoxime-Based Fibers. Ind. Eng. Chem. Res. 2020, 59, 5828–5837. [Google Scholar] [CrossRef]

- Huang, Z.; Dong, H.; Yang, N.; Li, H.; He, N.; Lu, X.; Wen, J.; Wang, X.; Ningning, H. Bifunctional Phosphorylcholine-Modified Adsorbent with Enhanced Selectivity and Antibacterial Property for Recovering Uranium from Seawater. ACS Appl. Mater. Interfaces 2020, 12, 16959–16968. [Google Scholar] [CrossRef] [PubMed]

- Blackman, L.D.; Gunatillake, P.A.; Cass, P.; Locock, K.E.S. An introduction to zwitterionic polymer behavior and applications in solution and at surfaces. Chem. Soc. Rev. 2019, 48, 757–770. [Google Scholar] [CrossRef]

- Qing, S.; Shaoyi, J. Molecular understanding and design of zwitterionic materials. Adv. Mater. 2015, 27, 15–26. [Google Scholar]

- Zhu, J.; Su, Y.; Zhao, X.; Li, Y.; Zhao, J.; Fan, X.; Jiang, Z. Improved Antifouling Properties of Poly(vinyl chloride) Ultrafiltration Membranes via Surface Zwitterionicalization. Ind. Eng. Chem. Res. 2014, 53, 14046–14055. [Google Scholar] [CrossRef]

- Lejars, M.; Margaillan, A.; Bressy, C. Fouling Release Coatings: A Nontoxic Alternative to Biocidal Antifouling Coatings. Chem. Rev. 2012, 112, 4347–4390. [Google Scholar] [CrossRef] [PubMed]

- Kardela, J.H.; Millichamp, I.S.; Ferguson, J.; Parry, A.L.; Reynolds, K.J.; Aldred, N.; Clare, A.S. Nonfreezable Water and Polymer Swelling Control the Marine Antifouling Performance of Polymers with Limited Hydrophilic Content. ACS Appl. Mater. Interfaces 2019, 11, 29477–29489. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, G.; Hein, R.; Liu, N.; Luo, X.; Davis, J.J. Antifouling Strategies for Selective In Vitro and In Vivo Sensing. Chem. Rev. 2020, 120, 3852–3889. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, C.; Crisci, R.; Lu, T.; Hung, H.-C.; Sajib, S.J.; Sarker, P.; Ma, J.; Wei, T.; Jiang, S.; et al. Strong Surface Hydration and Salt Resistant Mechanism of a New Nonfouling Zwitterionic Polymer Based on Protein Stabilizer TMAO. J. Am. Chem. Soc. 2021, 143, 16786–16795. [Google Scholar] [CrossRef]

- Wu, J.; Lin, W.; Wang, Z.; Chen, S.; Chang, Y. Investigation of the Hydration of Nonfouling Material Poly(sulfobetaine methacrylate) by Low-Field Nuclear Magnetic Resonance. Langmuir 2012, 28, 7436–7441. [Google Scholar] [CrossRef]

- Shao, Q.; He, Y.; White, A.D.; Jiang, S. Difference in Hydration between Carboxybetaine and Sulfobetaine. J. Phys. Chem. B 2010, 114, 16625–16631. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Zhang, H.; Liu, Q.; Chen, R.; Liu, J.; Zhu, J.; Yu, J.; Zhao, X.; Wang, J. The microstructure and properties of GO hydration layers and the effects on the adsorption of UO22+. Chem. Phys. Lett. 2021, 771, 138494. [Google Scholar] [CrossRef]

- Gunathilake, C.; Górka, J.; Dai, S.; Jaroniec, M. Amidoxime-modified mesoporous silica for uranium adsorption under seawater conditions. J. Mater. Chem. A 2015, 3, 11650–11659. [Google Scholar] [CrossRef]

- Yuan, J.; Zhang, J.; Zang, X.; Shen, J.; Lin, S. Improvement of blood compatibility on cellulose membrane surface by grafting betaines. Colloids Surfaces B Biointerfaces 2003, 30, 147–155. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, X.; Tang, B.; Yuan, L.; Wang, K.; Liu, X.; Zhu, X.; Li, J.; Ge, Z.; Chen, S. New insights into synergistic antimicrobial and antifouling cotton fabrics via dually finished with quaternary ammonium salt and zwitterionic sulfobetaine. Chem. Eng. J. 2018, 336, 123–132. [Google Scholar] [CrossRef]

- Chen, S.; Mo, F.; Yang, Y.; Stadler, F.J.; Chen, S.; Yang, H.; Ge, Z. Development of zwitterionic polyurethanes with multi-shape memory effects and self-healing properties. J. Mater. Chem. A 2015, 3, 2924–2933. [Google Scholar] [CrossRef]

- Ju, P.; Liu, Q.; Zhang, H.; Chen, R.; Liu, J.; Yu, J.; Liu, P.; Zhang, M.; Wang, J. Hyperbranched topological swollen-layer constructs of multi-active sites polyacrylonitrile (PAN) adsorbent for uranium(VI) extraction from seawater. Chem. Eng. J. 2019, 374, 1204–1213. [Google Scholar] [CrossRef]

- Ho, Y.S.; McKay, G. Pseudo-second order model for sorption processes. Process Biochem. 1999, 34, 451–465. [Google Scholar] [CrossRef]

- Song, W.; Wang, X.; Wang, Q.; Shao, D.; Wang, X. Plasma-induced grafting of polyacrylamide on graphene oxide nanosheets for simultaneous removal of radionuclides. Phys. Chem. Chem. Phys. 2015, 17, 398–406. [Google Scholar] [CrossRef]

- Zeng, J.; Zhang, H.; Sui, Y.; Hu, N.; Ding, D.; Wang, F.; Xue, J.; Wang, Y. New Amidoxime-Based Material TMP-g-AO for Uranium Adsorption under Seawater Conditions. Ind. Eng. Chem. Res. 2017, 56, 5021–5032. [Google Scholar] [CrossRef]

- Sitko, R.; Turek, E.; Zawisza, B.; Malicka, E.; Talik, E.; Heimann, J.; Gagor, A.; Feist, B.; Wrzalik, R. Adsorption of divalent metal ions from aqueous solutions using graphene oxide. Dalton Trans. 2013, 42, 5682–5689. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.; Chu, J.; Yin, X.; Wang, J.; Tian, W.; Huang, Q.; Jia, Z.; Wu, X.; Guo, H.; Qin, Z. Synthesis of amidoximated polyacrylonitrile nanoparticle/graphene composite hydrogel for selective uranium sorption from saline lake brine. Chem. Eng. J. 2020, 391, 123553. [Google Scholar] [CrossRef]

- Sun, Q.; Song, Y.; Aguila, B.; Ivanov, A.S.; Bryantsev, V.S.; Ma, S. Spatial Engineering Direct Cooperativity between Binding Sites for Uranium Sequestration. Adv. Sci. 2021, 8, 2001573. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, Z.; Zhang, H.; Liu, Q.; Yu, J.; Liu, J.; Chen, R.; Zhu, J.; Wang, J. Anti-bacterial and super-hydrophilic bamboo charcoal with amidoxime modified for efficient and selective uranium extraction from seawater. J. Colloid Interface Sci. 2021, 598, 455–463. [Google Scholar] [CrossRef]

- Gu, H.; Liu, Q.; Sun, G.; Liu, J.; Chen, R.; Yu, J.; Zhu, J.; Wang, J. Comprehensive biocompatible hemp fibers improved by phosphate zwitterion with high U(VI) affinity in the marine conditions. Chem. Eng. J. 2022, 430, 132742. [Google Scholar] [CrossRef]

- Yang, J.; Chen, H.; Xiao, S.; Shen, M.; Chen, F.; Fan, P.; Zhong, M.; Zheng, J. Salt-Responsive Zwitterionic Polymer Brushes with Tunable Friction and Antifouling Properties. Langmuir 2015, 31, 9125–9133. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, H.; Yu, J.; Zhang, H.; Sun, G.; Li, R.; Liu, P.; Li, Y.; Wang, J. Theory-Guided Design of a Method to Obtain Competitive Balance between U(VI) Adsorption and Swaying Zwitterion-Induced Fouling Resistance on Natural Hemp Fibers. Int. J. Mol. Sci. 2022, 23, 6517. https://doi.org/10.3390/ijms23126517

Gu H, Yu J, Zhang H, Sun G, Li R, Liu P, Li Y, Wang J. Theory-Guided Design of a Method to Obtain Competitive Balance between U(VI) Adsorption and Swaying Zwitterion-Induced Fouling Resistance on Natural Hemp Fibers. International Journal of Molecular Sciences. 2022; 23(12):6517. https://doi.org/10.3390/ijms23126517

Chicago/Turabian StyleGu, Huiquan, Jing Yu, Hongsen Zhang, Gaohui Sun, Rumin Li, Peili Liu, Ying Li, and Jun Wang. 2022. "Theory-Guided Design of a Method to Obtain Competitive Balance between U(VI) Adsorption and Swaying Zwitterion-Induced Fouling Resistance on Natural Hemp Fibers" International Journal of Molecular Sciences 23, no. 12: 6517. https://doi.org/10.3390/ijms23126517