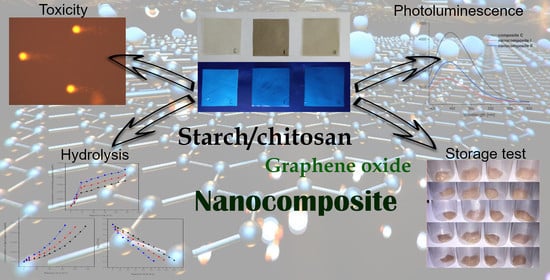

The Functional and Application Possibilities of Starch/Chitosan Polymer Composites Modified by Graphene Oxide

Abstract

:1. Introduction

2. Results and Discussion

2.1. Water Vapour Transmission Rate

2.2. Enzymatic and Acid Hydrolysis of Composites

2.3. Toxicity Profile

2.3.1. Cell Viability Assessment Test

2.3.2. Comet Test

2.4. Storage Studies

2.5. Photoluminescence Spectroscopy

3. Materials and Methods

3.1. Materials

3.2. Water Vapour Transmision Rate

3.3. Enzymatic Hydrolysis

3.4. Acid Hydrolysis

3.5. Toxicity Profile

3.5.1. Isolation of Whole Peripheral Blood Lymphocytes for Analysis

3.5.2. Viability Assessment

3.5.3. Alkaline Variant Comet Test

3.6. Storage Test

3.7. Photoluminescence Spectroscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, H.; Chen, L.; McClements, D.J.; Yang, T.; Zhang, Z.; Ren, F.; Miao, M.; Tian, Y.; Jin, Z. Starch-based biodegradable packaging materials: A review of their preparation, characterization and diverse applications in the food industry. Trends Food Sci. Technol. 2021, 114, 70–82. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions The European Green Deal—The European Green Deal, COM (2019) 640 Final, Document 52019DC0640. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1576150542719&uri=COM%3A2019%3A640%3AFIN (accessed on 11 December 2019).

- Krystyjan, M.; Khachatryan, G.; Ciesielski, W.; Buksa, K.; Sikora, M. Preparation and characteristics of mechanical and functional properties of starch/Plantago psyllium seeds mucilage films. Starch-Starke 2017, 69, 1700014. [Google Scholar] [CrossRef]

- Khachatryan, G.; Khachatryan, K. Starch based nanocomposites as sensors for heavy metals–detection of Cu2+ and Pb2+ ions. Int. Agrophys. 2019, 33, 121–126. [Google Scholar] [CrossRef]

- Krystyjan, M.; Khachatryan, G.; Khachatryan, K.; Krzan, M.; Ciesielski, W.; Zarska, S.; Szczepankowska, J. Polysaccharides Composite Materials as Carbon Nanoparticles Carrier. Polymers 2022, 14, 948. [Google Scholar] [CrossRef] [PubMed]

- Krystyjan, M.; Khachatryan, G.; Grabacka, M.; Krzan, M.; Witczak, M.; Grzyb, J.; Woszczak, L. Physicochemical, Bacteriostatic, and Biological Properties of Starch/Chitosan Polymer Composites Modified by Graphene Oxide, Designed as New Bionanomaterials. Polymers 2021, 13, 2327. [Google Scholar] [CrossRef]

- Nowak, N.; Grzebieniarz, W.; Khachatryan, G.; Khachatryan, K.; Konieczna-Molenda, A.; Krzan, M.; Grzyb, J. Synthesis of Silver and Gold Nanoparticles in Sodium Alginate Matrix Enriched with Graphene Oxide and Investigation of Properties of the Obtained Thin Films. Appl. Sci. 2021, 11, 3857. [Google Scholar] [CrossRef]

- Grzebieniarz, W.; Nowak, N.; Khachatryan, G.; Krzan, M.; Krystyjan, M.; Kosiński, J.; Khachatryan, K. The Preparation and Characterization of Quantum Dots in Polysaccharide Carriers (Starch/Chitosan) as Elements of Smart Packaging and Their Impact on the Growth of Microorganisms in Food. Materials 2021, 14, 7732. [Google Scholar] [CrossRef]

- Jamróz, E.; Khachatryan, G.; Kopel, P.; Juszczak, L.; Kawecka, A.; Krzyściak, P.; Kucharek, M.; Bębenek, Z.; Zimowska, M. Furcellaran nanocomposite films: The effect of nanofillers on the structural, thermal, mechanical and antimicrobial properties of biopolymer films. Carbohydr. Polym. 2020, 240, 116244. [Google Scholar] [CrossRef]

- Khachatryan, K.; Khachatryan, L.; Krzan, M.; Krystyjan, M.; Krzemińska-Fiedorowicz, L.; Lenart-Boroń, A.; Koronowicz, A.; Drozdowska, M.; Khachatryan, G. Formation and Investigation of Physicochemical, Biological and Bacteriostatic Properties of Nanocomposite Foils Containing Silver Nanoparticles and Graphene Oxide in Hyaluronic Acid Matrix. Materials 2021, 14, 3377. [Google Scholar] [CrossRef]

- Barreto, J.A.; O’Malley, W.; Kubeil, M.; Graham, B.; Stephan, H.; Spiccia, L. Nanomaterials: Applications in cancer imaging and therapy. Adv. Mater. 2011, 23, H18–H40. [Google Scholar] [CrossRef]

- Falco, A.; Mallavia, R. Electrospun nanomaterials: Applications in food, environmental remediation, and bioengineering. Nanomaterials 2020, 10, 1714. [Google Scholar] [CrossRef] [PubMed]

- Fernando, I.P.S.; Lee, W.; Han, E.J.; Ahn, G. Alginate-based nanomaterials: Fabrication techniques, properties, and applications. Chem. Eng. J. 2020, 391, 123823. [Google Scholar] [CrossRef]

- Krystyjan, M.; Dobosz-Kobędza, A.; Sikora, M.; Baranowska, H.M. Influence of Xanthan Gum Addition on the Short-and Long-Term Retrogradation of Corn Starches of Various Amylose Content. Polymers 2022, 14, 452. [Google Scholar] [CrossRef] [PubMed]

- Głąb, M.; Drabczyk, A.; Kudłacik-Kramarczyk, S.; Krzan, M.; Tyliszczak, B. Physicochemical Characteristics of Chitosan-Based Hydrogels Modified with Equisetum arvense L.(Horsetail) Extract in View of Their Usefulness as Innovative Dressing Materials. Materials 2021, 14, 7533. [Google Scholar] [CrossRef] [PubMed]

- Othman, N.H.; Ismail, M.C.; Mustapha, M.; Sallih, N.; Kee, K.E.; Jaal, R.A. Graphene-based polymer nanocomposites as barrier coatings for corrosion protection. Prog. Org. Coat. 2019, 135, 82–99. [Google Scholar] [CrossRef]

- Wróblewska-Krepsztul, J.; Rydzkowski, T.; Borowski, G.; Szczypiński, M.; Klepka, T.; Thakur, V.K. Recent progress in biodegradable polymers and nanocomposite-based packaging materials for sustainable environment. Int. J. Polym. Anal. Charact. 2018, 23, 383–395. [Google Scholar] [CrossRef]

- Taghizadeh, M.; Taghizadeh, A.; Yazdi, M.K.; Zarrintaj, P.; Stadler, F.J.; Ramsey, J.D.; Habibzadeh, S.; Rad, S.H.; Naderi, G.; Saeb, M.R.; et al. Chitosan-based inks for 3D printing and bioprinting. Green Chem. 2022, 24, 62–101. [Google Scholar] [CrossRef]

- Khachatryan, G.; Khachatryan, K.; Krystyjan, M.; Krzan, M.; Khachatryan, L. Functional properties of composites containing silver nanoparticles embedded in hyaluronan and hyaluronan-lecithin matrix. Int. J. Biol. Macromol. 2020, 149, 417–423. [Google Scholar] [CrossRef]

- Krystyjan, M.; Ciesielski, W.; Khachatryan, G.; Sikora, M.; Tomasik, P. Structure, rheological, textural and thermal properties of potato starch–Inulin gels. LWT—Food Sci. Technol. 2015, 60, 131–136. [Google Scholar] [CrossRef]

- Wu, X.; Dai, H.; Xu, C.; Liu, L.; Li, S. Citric acid modification of a polymer exhibits antioxidant and anti-inflammatory properties in stem cells and tissues. J. Biomed. Mater. Res. Part A 2019, 107, 2414–2424. [Google Scholar] [CrossRef]

- Güler, Ö.; Bağcı, N. A short review on mechanical properties of graphene reinforced metal matrix composites. J. Mater. Res. Technol. 2020, 9, 6808–6833. [Google Scholar] [CrossRef]

- Gaidukevič, J.; Barkauskas, J.; Malaika, A.; Jasulaitienė, V.; Kozłowski, M. Preparation and characterization of basic graphene-based catalysts and their application in biodiesel synthesis. Appl. Surf. Sci. 2021, 554, 149588. [Google Scholar] [CrossRef]

- Pandit, S.; Gaska, K.; Kádár, R.; Mijakovic, I. Graphene-Based Antimicrobial Biomedical Surfaces. ChemPhysChem 2021, 22, 250–263. [Google Scholar] [CrossRef]

- Janczarek, M.; Endo-Kimura, M.; Wei, Z.; Bielan, Z.; Mogan, T.R.; Khedr, T.M.; Wang, K.; Markowska-Szczupak, A.; Kowalska, E. Novel Structures and Applications of Graphene-Based Semiconductor Photocatalysts: Faceted Particles, Photonic Crystals, Antimicrobial and Magnetic Properties. Appl. Sci. 2021, 11, 1982. [Google Scholar] [CrossRef]

- Olabi, A.G.; Abdelkareem, M.A.; Wilberforce, T.; Sayed, E.T. Application of graphene in energy storage device—A review. Renew. Sustain. Energy Rev. 2021, 135, 110026. [Google Scholar] [CrossRef]

- Syama, S.; Mohanan, P.V. Comprehensive application of graphene: Emphasis on biomedical concerns. Nano-Micro Lett. 2019, 11, 6. [Google Scholar] [CrossRef] [Green Version]

- Gomes, B.F.M.L.; de Araújo, C.M.B.; do Nascimento, B.F.; Freire, E.M.P.D.L.; Da Motta Sobrinho, M.A.; Carvalho, M.N. Synthesis and application of graphene oxide as a nanoadsorbent to remove Cd (II) and Pb (II) from water: Adsorption equilibrium, kinetics, and regeneration. Environ. Sci. Pollut. Res. 2022, 29, 17358–17372. [Google Scholar] [CrossRef]

- Vivaldi, F.M.; Dallinger, A.; Bonini, A.; Poma, N.; Sembranti, L.; Biagini, D.; Salvo, P.; Greco, F.; Di Francesco, F. Three-dimensional (3D) laser-induced graphene: Structure, properties, and application to chemical sensing. ACS Appl. Mater. Interfaces 2021, 13, 30245–30260. [Google Scholar] [CrossRef]

- Almomani, F.; Vasseghian, Y.; Vilas–Boas, J.A.; Dragoi, E.N. Graphene-based nanomaterial for desalination of water: A systematic review and meta-analysis. Food Chem. Toxicol. 2021, 148, 111964. [Google Scholar] [CrossRef]

- Santos, N.F.; Pereira, S.O.; Moreira, A.; Girão, A.V.; Carvalho, A.F.; Fernandes, A.J.; Costa, F.M. IR and UV Laser-Induced Graphene: Application as Dopamine Electrochemical Sensors. Adv. Mater. Technol. 2021, 6, 2100007. [Google Scholar] [CrossRef]

- Morse, J.R.; Zugell, D.A.; Patterson, E.; Baldwin, J.W.; Willauer, H.D. Hydrogenated graphene: Important material properties regarding its application for hydrogen storage. J. Power Sources 2021, 494, 229734. [Google Scholar] [CrossRef]

- Dos Santos, F.A.; Vieira, N.C.; Zambianco, N.A.; Janegitz, B.C.; Zucolotto, V. The layer-by-layer assembly of reduced graphene oxide films and their application as solution-gated field-effect transistors. Appl. Surf. Sci. 2021, 543, 148698. [Google Scholar] [CrossRef]

- Yousef, S.; Kalpokaitė-Dičkuvienė, R.; Baltušnikas, A.; Pitak, I.; Lukošiūtė, S.I. A new strategy for functionalization of char derived from pyrolysis of textile waste and its application as hybrid fillers (CNTs/char and graphene/char) in cement industry. J. Clean. Prod. 2021, 314, 128058. [Google Scholar] [CrossRef]

- Chen, Y.; Dai, G.; Gao, Q. Starch nanoparticles–graphene aerogels with high supercapacitor performance and efficient adsorption. ACS Sustain. Chem. Eng. 2019, 7, 14064–14073. [Google Scholar] [CrossRef]

- Solati, M.; Saeidi, A.; Ghasemi, I. The effect of graphene nanoplatelets on dynamic properties, crystallization, and morphology of a biodegradable blend of poly (lactic acid)/thermoplastic starch. Iran. Polym. J. 2019, 28, 649–658. [Google Scholar] [CrossRef]

- Gabris, M.A.; Rezania, S.; Rafieizonooz, M.; Khankhaje, E.; Devanesan, S.; AlSalhi, M.S.; Aljaafreh, M.J.; Shadravan, A. Chitosan magnetic graphene grafted polyaniline doped with cobalt oxide for removal of arsenic (V) from water. Environ. Res. 2022, 207, 112209. [Google Scholar] [CrossRef]

- Wrońska, N.; Anouar, A.; El Achaby, M.; Zawadzka, K.; Kędzierska, M.; Miłowska, K.; Katir, N.; Draoui, K.; Różalska, S.; Piwoński, I.; et al. Chitosan-functionalized graphene nanocomposite films: Interfacial interplay and biological activity. Materials 2020, 13, 998. [Google Scholar] [CrossRef] [Green Version]

- Kosowska, K.; Domalik-Pyzik, P.; Nocuń, M.; Chłopek, J. Chitosan and graphene oxide/reduced graphene oxide hybrid nanocomposites—Evaluation of physicochemical properties. Mater. Chem. Phys. 2018, 216, 28–36. [Google Scholar] [CrossRef]

- Kosowska, K.; Domalik-Pyzik, P.; Sekuła-Stryjewska, M.; Noga, S.; Jagiełło, J.; Baran, M.; Lipińska, L.; Zuba-Surma, E.; Chłopek, J. Gradient chitosan hydrogels modified with graphene derivatives and hydroxyapatite: Physiochemical properties and initial cytocompatibility evaluation. Int. J. Mol. Sci. 2020, 21, 4888. [Google Scholar] [CrossRef] [PubMed]

- Mahmodi, G.; Zarrintaj, P.; Taghizadeh, A.; Taghizadeh, M.; Manouchehri, S.; Dangwal, S.; Ronte, A.; Ganjali, M.R.; Ramsey, J.D.; Kim, S.J.; et al. From microporous to mesoporous mineral frameworks: An alliance between zeolite and chitosan. Carbohydr. Res. 2020, 489, 107930. [Google Scholar] [CrossRef]

- DeLassus, P. Barrier Polymers. In Kirk-Othmer Encyclopedia of Chemical Technology; Wiley: New York, NY, USA, 2002. [Google Scholar] [CrossRef]

- Shogren, R. Water vapor permeability of biodegradable polymers. J. Environ. Polym. Degr. 1997, 5, 91–95. [Google Scholar] [CrossRef]

- Nguyen, G.T.; Sopade, P.A. Modeling Starch Digestograms: Computational Characteristics of Kinetic Models for in vitro Starch Digestion in Food Research. Compr. Rev. Food. Sci. Food Saf. 2018, 17, 1422–1445. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Poshina, D.N.; Raik, S.V.; Poshin, A.N.; Skorik, Y.A. Accessibility of chitin and chitosan in enzymatic hydrolysis: A review. Polym. Degrad. Stab. 2018, 156, 269–278. [Google Scholar] [CrossRef]

- Castillo, L.E.V.; Leite, M.A.; Ditchfield, C.; Amaral, J.P.S.; Moraes, I.C.F. Quinoa starch nanocrystals production by acid hydrolysis: Kinetics and properties. Int. J. Biol. Macromol. 2020, 143, 93–101. [Google Scholar] [CrossRef] [PubMed]

- Bakshi, P.S.; Selvakumar, D.; Kadirvelu, K.; Kumar, N.S. Chitosan as an environment friendly biomaterial—A review on recent modifications and applications. Int. J. Biol. Macromol. 2020, 150, 1072–1083. [Google Scholar] [CrossRef] [PubMed]

- Aljbour, N.D.; Beg, M.D.H.; Gimbun, J. Acid Hydrolysis of Chitosan to Oligomers Using Hydrochloric Acid. Chem. Eng. Technol. 2019, 42, 1741–1746. [Google Scholar] [CrossRef]

- Concha, B.B.S.; Agama-Acevedo, E.; Nuñez-Santiago, M.C.; Bello-Perez, L.A.; Garcia, H.S.; Alvarez-Ramirez, J. Acid hydrolysis of waxy starches with different granule size for nanocrystal production. J. Cereal Sci. 2018, 79, 193–200. [Google Scholar] [CrossRef]

- Zhao, Y.; Saldaña, M.D.A. Hydrolysis of cassava starch, chitosan and their mixtures in pressurized hot water media. J. Supercrit. Fluids 2019, 147, 293–301. [Google Scholar] [CrossRef]

- Rhazouani, A.; Gamrani, H.; El Achaby, M.; Aziz, K.; Gebrati, L.; Uddin, M.S.; Aziz, F. Synthesis and Toxicity of Graphene Oxide Nanoparticles: A Literature Review of In Vutro and In Vivo studies. BioMed Res. Int. 2021, 2021, 5518999. [Google Scholar] [CrossRef]

- Ibrahim, H.M.; El-Zairy, E.M.R. Chapter 4: Chitosan as a Biomaterial-Structure, Properties, and Electrostpun Nanofibers. In Concepts, Compounds and the Alternatives of Antibacterials; Bobborala, V., Ed.; IntechOpen: London, UK, 2015; pp. 81–102. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Lou, Y.; Wu, J.; Wang, Y.; Yang, X.; Yang, R.; Wang, B.; Yang, J.; Zhang, N. Graphene oxide can induce in vitro and in vivo mutagenesis. Sci. Rep. 2013, 3, 3469. [Google Scholar] [CrossRef] [Green Version]

- Lu, C.-J.; Jiang, X.-F.; Junaid, M.; Ma, Y.-B.; Jia, P.-P.; Wang, H.-B.; Pei, D.-S. Graphene oxide nanosheets induce DNA and activate the base excision repair (BER) signaling pathway both in vitro and in vivo. Chepesphere 2017, 184, 795–805. [Google Scholar] [CrossRef] [PubMed]

- Fujita, K.; Take, S.; Tani, R.; Maru, J.; Obara, S.; Endoh, S. Assessment of cytotoxicity and mutagenicity of exfoliated graphene. Toxicol. Vitr. 2018, 52, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Wojcik, E.; Andraszek, K.; Ciszewska, M.; Smalec, E. Sister chromatid exchange as an index of chromosome instability in chondrodystrophic chickens (Gallus domesticus). Poult. Sci. 2013, 92, 84–89. [Google Scholar] [CrossRef]

- Kuchta-Gładysz, M.; Wójcik, E.; Słonina, D.; Grzesiakowska, A.; Otwinowska-Mindur, A.; Szeleszczuk, O.; Niebała, P. Determination of cytogenetic markers for biological monitoring in coypu (Myocastor coypu). Anim. Sci. J. 2021, 91, e13440. [Google Scholar] [CrossRef] [PubMed]

- Grzesiakowska, A.; Kasprowicz, J.M.; Kuchta-Gładysz, M.; Rymuza, K.; Szeleszczuk, O. Genotoxicity of physical silver nanoparticles, produced by the HVAD method, for Chinchilla lanigera genome. Sci. Rep. 2021, 11, 18473. [Google Scholar] [CrossRef] [PubMed]

- Awad, W.A.; Ghareeb, K.; Dadak, A.; Hess, M.; Boehm, J. Single and combined effects of deoxynivalenol mycotoxin and a microbial feed additive on lymphocyte DNA damage and oxidative stress in broiler chickens. PLoS ONE 2014, 9, e88028. [Google Scholar] [CrossRef] [PubMed]

- Hossain, K.; Rafatullah, M.; Abbas, S.Z.; Ahmad, A.; Ismail, N.; Maruthi, A.Y. Antimicrobial activity of graphene-based nanomaterials: Current development and challenges. In Graphene-Based Nanotechnologies for Energy and Environmental Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 293–314. [Google Scholar]

- Goy, R.C.; Britto, D.D.; Assis, O.B. A review of the antimicrobial activity of chitosan. Polímeros 2009, 19, 241–247. [Google Scholar] [CrossRef]

- Perinelli, D.R.; Fagioli, L.; Campana, R.; Lam, J.K.; Baffone, W.; Palmieri, G.F.; Casettari, L.; Bonacucina, G. Chitosan-based nanosystems and their exploited antimicrobial activity. Eur. J. Pharm. Sci. 2018, 117, 8–20. [Google Scholar] [CrossRef]

- Confederat, L.G.; Tuchilus, C.G.; Dragan, M.; Sha’at, M.; Dragostin, O.M. Preparation and Antimicrobial Activity of Chitosan and Its Derivatives: A Concise Review. Molecules 2021, 26, 3694. [Google Scholar] [CrossRef]

- Abdel-Razek, N. Antimicrobial activities of chitosan nanoparticles against pathogenic microorganisms in Nile tilapia, Oreochromis niloticus. Aquac. Int. 2019, 27, 1315–1330. [Google Scholar] [CrossRef]

- Bykkam, S.; Narsingam, S.; Ahmadipour, M.; Dayakar, T.; Rao, K.V.; Chakra, C.S.; Kalakotla, S. Few layered graphene sheet decorated by ZnO nanoparticles for anti-bacterial application. Superlattices Microstruct. 2015, 83, 776–784. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E. Toxicity of graphene and graphene oxide nanowalls against bacteria. ACS Nano 2010, 4, 5731–5736. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.Y.; Park, S.; Kim, H.; Park, S.; Ruoff, R.S.; Hwang, S.J. Strongly-Coupled Freestanding Hybrid Films of Graphene and Layered Titanate Nanosheets: An Effective Way to Tailor the Physicochemical and Antibacterial Properties of Graphene Film. Adv. Funct. Mater. 2014, 24, 2288–2294. [Google Scholar] [CrossRef]

- Lee, H.M.; Kim, M.H.; Yoon, Y.I.; Park, W.H. Fluorescent Property of Chitosan Oligomer and Its Application as a Metal Ion Sensor. Mar. Drugs 2017, 15, 105. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, L.; Zhu, C.; Fan, M.; Chen, C.; Huang, Y.; Hao, Q.; Yang, J.; Wang, H.; Sun, D. Oxidation and degradation of graphitic materials by naphthalene-degrading bacteria. Nanoscale 2015, 7, 13619–13628. [Google Scholar] [CrossRef]

- ISO 2528:2017; Standard Gravimetric (Dish) Method. ISO: Geneva, Switzerland, 2017.

- Southgate, D.A.T. Determination of Food Carbohydrate; Elsevier Science Publishing Co., Inc.: New York, NY, USA, 1991; pp. 57–63. [Google Scholar]

- Konieczna-Molenda, A.; Fiedorowicz, M.; Zhong, W.; Tomasik, P. Polarized light-stimulated enzymatic hydrolysis of chitin and chitosan. Carbohydr. Res. 2008, 343, 3117–3119. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.P.; McCoy, M.T.; Tice, R.R.; Schneider, E.I. A sample technique for quantitation of low levels of DNA damage in individual cells. Exp. Cell Res. 1988, 175, 184–191. [Google Scholar] [CrossRef] [Green Version]

- PN-EN ISO 4833-2:2013-12+AC:2014-04; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 2: Colony Count at 30 Degrees C by the Surface Plating Technique. ISO: Geneva, Switzerland, 2014.

- PN-EN ISO 21528-2:2017-08; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Enterobacteriaceae—Part 2: Colony-Count Technique. ISO: Geneva, Switzerland, 2017.

- PN-EN ISO 6888-2:2001+A1:2004; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Coagulase-Positive Staphylococci (Staphylococcus aureus and other species)—Part 2: Technique Using Rabbit Plasma Fibrinogen Agar Medium. ISO: Geneva, Switzerland, 2001.

- PN-EN ISO 11290-1:2017-07; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Listeria monocytogenes and of Listeria spp.—Part 1: Detection Method. ISO: Geneva, Switzerland, 2017.

- PN-EN ISO 10272-2:2017-10; Microbiology of the Food Chain—Horizontal Method for Detection and Enumeration of Campylobacter spp.—Part 1: Detection Method. ISO: Geneva, Switzerland, 2017.

- PN-ISO 16649-2:2004; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Beta-Glucuronidase-Positive Escherichia coli—Part 2: Colony-Count Technique at 44 Degrees C Using 5-bromo-4-chloro-3-indolyl beta-D-glucuronide. ISO: Geneva, Switzerland, 2004.

| Composites | WVTR (g/m2·d) | |

|---|---|---|

| Composite C | Thin | 742.9 ± 11.6 a |

| Nanocomposite I | Thin | 740.8 ± 8.5 a |

| Nanocomposite II | Thin | 734.7 ± 11.4 a |

| Composite C | Thick | 824.8 ±16.8 b |

| Nanocomposite I | Thick | 813.0 ± 26.3 b |

| Nanocomposite II | Thick | 787.4 ± 37.4 b |

| Sample | Type of Hydrolysis | |||

|---|---|---|---|---|

| Enzymatic Hydrolysis of Chitosan | Enzymatic Hydrolysis of Starch | Acid Hydrolysis of Starch | ||

| k × 10−3 (min−1) | k1 × 10−6 (mg∙mL−1∙min−1) | k2 × 10−6 (mg∙mL−1∙min−1) | ka × 10−4 (mg∙mL−1∙min−1) | |

| Composite C | 2.72 ± 0.03 | 8.4 ± 0.7 | 1.59 ± 0.02 | 1.88 ± 0.06 |

| Nanocomposite I | 4.00 ± 0.08 | 14.6 ± 0.5 | 1.92 ± 0.05 | 1.67 ± 0.04 |

| Nanocomposite II | 3.17 ± 0.06 | 11.7 ± 0.6 | 1.70 ± 0.03 | 1.58 ± 0.04 |

| Sample | % of Viable Cells (Average ± sd) |

|---|---|

| Non-exposed cells 0 h | 95 ± 4 |

| Non-exposed cells stored for 24 h | 95 ± 4 |

| Control composite | 99 ± 2 |

| Nanocomposite I | 95 ± 6 |

| Nanocomposite II | 97 ± 2 |

| Sample | % Tail DNA (Average ± sd) |

|---|---|

| Non-exposed cells 0 h | 23.43 ± 8.76 |

| Non-exposed cells stored for 24 h | 25.81 ± 14.31 |

| Control composite | 16.26 ± 12.14 |

| Nanocomposite I | 6.48 ± 8.63 |

| Nanocomposite II | 9.39 ± 10.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krystyjan, M.; Khachatryan, G.; Khachatryan, K.; Konieczna-Molenda, A.; Grzesiakowska, A.; Kuchta-Gładysz, M.; Kawecka, A.; Grzebieniarz, W.; Nowak, N. The Functional and Application Possibilities of Starch/Chitosan Polymer Composites Modified by Graphene Oxide. Int. J. Mol. Sci. 2022, 23, 5956. https://doi.org/10.3390/ijms23115956

Krystyjan M, Khachatryan G, Khachatryan K, Konieczna-Molenda A, Grzesiakowska A, Kuchta-Gładysz M, Kawecka A, Grzebieniarz W, Nowak N. The Functional and Application Possibilities of Starch/Chitosan Polymer Composites Modified by Graphene Oxide. International Journal of Molecular Sciences. 2022; 23(11):5956. https://doi.org/10.3390/ijms23115956

Chicago/Turabian StyleKrystyjan, Magdalena, Gohar Khachatryan, Karen Khachatryan, Anna Konieczna-Molenda, Anna Grzesiakowska, Marta Kuchta-Gładysz, Agnieszka Kawecka, Wiktoria Grzebieniarz, and Nikola Nowak. 2022. "The Functional and Application Possibilities of Starch/Chitosan Polymer Composites Modified by Graphene Oxide" International Journal of Molecular Sciences 23, no. 11: 5956. https://doi.org/10.3390/ijms23115956