Tunability of the Superconductivity of NbSe2 Films Grown by Two-Step Vapor Deposition

Abstract

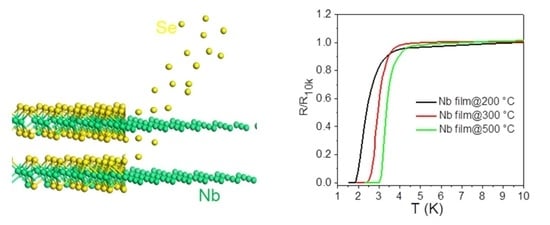

:1. Introduction

2. Results and Discussion

2.1. Optimization of the Crystalline Quality of Nb Films

2.2. Tunability of Superconductivity in Bilayer NbSe2 Films

2.3. Extending the Two-Step Vapor Deposition Method to Grow Monolayer NbSe2

3. Materials and Methods

3.1. Growth of NbSe2 Films and Monolayer NbSe2 Crystals

3.2. Characterizations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Geim, A.K.; Grigorieva, I.V. Van der Waals heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.; Duan, X.; Huang, Y.; Duan, X. Two-dimensional transistors beyond graphene and TMDCs. Chem. Soc. Rev. 2018, 47, 6388–6409. [Google Scholar] [CrossRef] [PubMed]

- Chhowalla, M.; Liu, Z.; Zhang, H. Two-dimensional transition metal dichalcogenide (TMD) nanosheets. Chem. Soc. Rev. 2015, 44, 2584–2586. [Google Scholar] [CrossRef]

- Bhimanapati, G.R.; Lin, Z.; Meunier, V.; Jung, Y.; Cha, J.; Das, S.; Xiao, D.; Son, Y.; Strano, M.S.; Cooper, V.R. Recent advances in two-dimensional materials beyond graphene. ACS Nano. 2015, 9, 11509–11539. [Google Scholar] [CrossRef] [PubMed]

- Joe, Y.I.; Chen, X.; Ghaemi, P.; Finkelstein, K.; de La Peña, G.; Gan, Y.; Lee, J.; Yuan, S.; Geck, J.; MacDougall, G. Emergence of charge density wave domain walls above the superconducting dome in 1T-TiSe2. Nat. Phys. 2014, 10, 421–425. [Google Scholar] [CrossRef]

- Xi, X.; Zhao, L.; Wang, Z.; Berger, H.; Forró, L.; Shan, J.; Mak, K.F. Strongly enhanced charge-density-wave order in monolayer NbSe2. Nat. Nanotechnol. 2015, 10, 765–769. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; O’Farrell, E.; Loh, K.; Eda, G.; Özyilmaz, B.; Castro Neto, A. Controlling many-body states by the electric-field effect in a two-dimensional material. Nature 2016, 529, 185–189. [Google Scholar] [CrossRef] [Green Version]

- Calandra, M.; Mazin, I.; Mauri, F. Effect of dimensionality on the charge-density wave in few-layer 2H-NbSe2. Phys. Rev. B 2009, 80, 241108. [Google Scholar] [CrossRef] [Green Version]

- Zheng, F.; Zhou, Z.; Liu, X.; Feng, J. First-principles study of charge and magnetic ordering in monolayer NbSe2. Phys. Rev. B 2018, 97, 081101. [Google Scholar] [CrossRef] [Green Version]

- Silva-Guillén, J.Á.; Ordejón, P.; Guinea, F.; Canadell, E. Electronic structure of 2H-NbSe2 single-layers in the CDW state. 2D Mater. 2016, 3, 035028. [Google Scholar] [CrossRef]

- El-Bana, M.S.; Wolverson, D.; Russo, S.; Balakrishnan, G.; Paul, D.M.; Bending, S.J. Superconductivity in two-dimensional NbSe2 field effect transistors. Supercon. Sci. Technol. 2013, 26, 125020. [Google Scholar] [CrossRef] [Green Version]

- Hamill, A.; Heischmidt, B.; Sohn, E.; Shaffer, D.; Tsai, K.-T.; Zhang, X.; Xi, X.; Suslov, A.; Berger, H.; Forró, L. Two-fold symmetric superconductivity in few-layer NbSe2. Nat. Phys. 2021, 17, 949–954. [Google Scholar] [CrossRef]

- Dreher, P.; Wan, W.; Chikina, A.; Bianchi, M.; Guo, H.; Harsh, R.; Mañas-Valero, S.; Coronado, E.; Martínez-Galera, A.J.; Hofmann, P. Proximity Effects on the Charge Density Wave Order and Superconductivity in Single-Layer NbSe2. ACS Nano. 2021, 15, 19430–19438. [Google Scholar] [CrossRef] [PubMed]

- Xi, X.; Wang, Z.; Zhao, W.; Park, J.-H.; Law, K.T.; Berger, H.; Forró, L.; Shan, J.; Mak, K.F. Ising pairing in superconducting NbSe2 atomic layers. Nat. Phys. 2016, 12, 139–143. [Google Scholar] [CrossRef] [Green Version]

- Dvir, T.; Massee, F.; Attias, L.; Khodas, M.; Aprili, M.; Quay, C.H.; Steinberg, H. Spectroscopy of bulk and few-layer superconducting NbSe2 with van der Waals tunnel junctions. Nat. Commun. 2018, 9, 598. [Google Scholar] [CrossRef] [Green Version]

- Ye, J.; Zhang, Y.J.; Akashi, R.; Bahramy, M.S.; Arita, R.; Iwasa, Y. Superconducting dome in a gate-tuned band insulator. Science 2012, 338, 1193–1196. [Google Scholar] [CrossRef]

- Marezio, M.; Dernier, P.; Menth, A.; Hull, G., Jr. The crystal structure of NbSe2 at 15 K. J. Solid State Chem. 1972, 4, 425–429. [Google Scholar] [CrossRef]

- Lee, H.; Garcia, M.; McKinzie, H.; Wold, A. The low-temperature electrical and magnetic properties of TaSe2 and NbSe2. J. Solid State Chem. 1970, 1, 190–194. [Google Scholar] [CrossRef]

- Sekar, P.; Greyson, E.C.; Barton, J.E.; Odom, T.W. Synthesis of nanoscale NbSe2 materials from molecular precursors. J. Am. Chem. Soc. 2005, 127, 2054–2055. [Google Scholar] [CrossRef] [PubMed]

- Xing, Y.; Zhao, K.; Shan, P.; Zheng, F.; Zhang, Y.; Fu, H.; Liu, Y.; Tian, M.; Xi, C.; Liu, H. Ising superconductivity and quantum phase transition in macro-size monolayer NbSe2. Nano Lett. 2017, 17, 6802–6807. [Google Scholar] [CrossRef]

- Xu, C.; Wang, L.; Liu, Z.; Chen, L.; Guo, J.; Kang, N.; Ma, X.-L.; Cheng, H.-M.; Ren, W. Large-area high-quality 2D ultrathin Mo2C superconducting crystals. Nat. Mater. 2015, 14, 1135–1141. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Huang, X.; Lin, J.; Cui, J.; Chen, Y.; Zhu, C.; Liu, F.; Zeng, Q.; Zhou, J.; Yu, P. High-quality monolayer superconductor NbSe2 grown by chemical vapour deposition. Nat. Commun. 2017, 8, 394. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Zhu, Q.; Shu, D.; Lin, D.; Xu, J.; Huang, X.; Shi, W.; Xi, X.; Wang, J.; Gao, L. Growth of environmentally stable transition metal selenide films. Nat. Mater. 2019, 18, 602–607. [Google Scholar] [CrossRef]

- Hong, J.; Hu, Z.; Probert, M.; Li, K.; Lv, D.; Yang, X.; Gu, L.; Mao, N.; Feng, Q.; Xie, L. Exploring atomic defects in molybdenum disulphide monolayers. Nat. Commun. 2015, 6, 6293. [Google Scholar] [CrossRef] [Green Version]

- Zeng, Z.; Sun, T.; Zhu, J.; Huang, X.; Yin, Z.; Lu, G.; Fan, Z.; Yan, Q.; Hng, H.H.; Zhang, H. An effective method for the fabrication of few-layer-thick inorganic nanosheets. Angew. Chem. Int. Ed. 2012, 51, 9052–9056. [Google Scholar] [CrossRef]

- Hitz, E.; Wan, J.; Patel, A.; Xu, Y.; Meshi, L.; Dai, J.; Chen, Y.; Lu, A.; Davydov, A.V.; Hu, L. Electrochemical intercalation of lithium ions into NbSe2 nanosheets. ACS Appl. Mater. Inter. 2016, 8, 11390–11395. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Song, P.; Zhao, J.; Vaklinova, K.; Zhao, X.; Li, Z.; Qiu, Z.; Wang, Z.; Lin, L.; Zhao, M. Printable two-dimensional superconducting monolayers. Nat. Mater. 2021, 20, 181–187. [Google Scholar] [CrossRef]

- Zhao, M.; Li, J.; Sebek, M.; Yang, L.; Liu, Y.J.; Bosman, M.; Wang, Q.; Zheng, X.; Lu, J.; Teng, J. Electrostatically Tunable Near-Infrared Plasmonic Resonances in Solution-Processed Atomically Thin NbSe2. Adv. Mater. 2021, 33, 2101950. [Google Scholar] [CrossRef]

- Ahmad, H.M.; Ghosh, S.; Dutta, G.; Maddaus, A.G.; Tsavalas, J.G.; Hollen, S.; Song, E. Effects of Impurities on the Electrochemical Characterization of Liquid-Phase Exfoliated Niobium Diselenide Nanosheets. J. Phys. Chem. C 2019, 123, 8671–8680. [Google Scholar] [CrossRef]

- Li, S.; Wang, S.; Tang, D.-M.; Zhao, W.; Xu, H.; Chu, L.; Bando, Y.; Golberg, D.; Eda, G. Halide-assisted atmospheric pressure growth of large WSe2 and WS2 monolayer crystals. Appl. Mater. Today 2015, 1, 60–66. [Google Scholar] [CrossRef]

- Zhou, J.; Lin, J.; Huang, X.; Zhou, Y.; Chen, Y.; Xia, J.; Wang, H.; Xie, Y.; Yu, H.; Lei, J. A library of atomically thin metal chalcogenides. Nature 2018, 556, 355–359. [Google Scholar] [CrossRef] [PubMed]

- Hotta, T.; Tokuda, T.; Zhao, S.; Watanabe, K.; Taniguchi, T.; Shinohara, H.; Kitaura, R. Molecular beam epitaxy growth of monolayer niobium diselenide flakes. Appl. Phys. Lett. 2016, 109, 133101. [Google Scholar] [CrossRef]

- Ugeda, M.M.; Bradley, A.J.; Zhang, Y.; Onishi, S.; Chen, Y.; Ruan, W.; Ojeda-Aristizabal, C.; Ryu, H.; Edmonds, M.T.; Tsai, H.-Z. Characterization of collective ground states in single-layer NbSe2. Nat. Phys. 2016, 12, 92–97. [Google Scholar] [CrossRef]

- Duan, X.; Wang, C.; Shaw, J.C.; Cheng, R.; Chen, Y.; Li, H.; Wu, X.; Tang, Y.; Zhang, Q.; Pan, A. Lateral epitaxial growth of two-dimensional layered semiconductor heterojunctions. Nat. Nanotechnol. 2014, 9, 1024–1030. [Google Scholar] [CrossRef] [PubMed]

- Tinkham, M. Introduction to Superconductivity; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Chandrasekhar, B. A note on the maximum critical field of high-field superconductors. Appl. Phys. Lett. 1962, 1, 7–8. [Google Scholar] [CrossRef]

- Clogston, A.M. Upper limit for the critical field in hard superconductors. Phys. Rev. Lett. 1962, 9, 266. [Google Scholar] [CrossRef]

- Reyren, N.; Thiel, S.; Caviglia, A.D.; Kourkoutis, L.F.; Hammerl, G.; Richter, C.; Schneider, C.W.; Kopp, T.; Ruetschi, A.S.; Jaccard, D.; et al. Superconducting interfaces between insulating oxides. Science 2007, 317, 1196–1199. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, H.; Chang, M.; Fu, X.; Li, P.; Chen, M.; Wu, L.; Yang, F.; Zhang, Q. Tunability of the Superconductivity of NbSe2 Films Grown by Two-Step Vapor Deposition. Molecules 2023, 28, 1059. https://doi.org/10.3390/molecules28031059

Lin H, Chang M, Fu X, Li P, Chen M, Wu L, Yang F, Zhang Q. Tunability of the Superconductivity of NbSe2 Films Grown by Two-Step Vapor Deposition. Molecules. 2023; 28(3):1059. https://doi.org/10.3390/molecules28031059

Chicago/Turabian StyleLin, Huihui, Meijuan Chang, Xingjie Fu, Pengfei Li, Maoxin Chen, Luyan Wu, Fangqi Yang, and Quan Zhang. 2023. "Tunability of the Superconductivity of NbSe2 Films Grown by Two-Step Vapor Deposition" Molecules 28, no. 3: 1059. https://doi.org/10.3390/molecules28031059