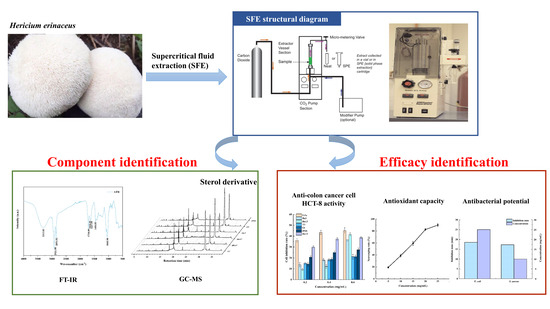

2.2. Effects of HE Crude Extracts on the Inhibition of the HCT-8 Cell

To assess the potential anti-colorectal cancer activity of the crude extracts derived from HE, we conducted an MTT assay to evaluate their effect on the proliferation of HCT-8 cells.

Figure 4 illustrates the administration of the various concentrations of HE crude extracts to HCT-8 cells for 24, 48, and 72 h. The results demonstrated a dose-dependent and time-dependent inhibitory effect of the crude extracts on HCT-8 cell growth, with a gradual increase in the inhibitory effect over time. Notably, at a concentration of 1.0 mg/mL, the cell growth inhibition rate reached 57.70%. These promising preliminary results prompted the selection of an appropriate concentration for further investigation into the anticancer activity of the crude extracts from six different varieties of HE.

Accordingly, concentrations of 0.5, 1, 2, 5, and 10 mg/mL, combined with a culture time of 24 h, were chosen.

Figure 5 presents the assessment of the inhibitory effect of these crude extracts on HCT-8 cells. The resulting IC

50 values were determined as follows: the positive control 5-Fu had an IC

50 of 0.528 mg/mL, He13 had an IC

50 of 2.224 mg/mL, He12 had an IC

50 of 2.255 mg/mL, 4916 had an IC

50 of 2.709 mg/mL, T3 had an IC

50 of 2.971 mg/mL, Gutian (Gt) had an IC

50 of 1.356 mg/mL, and He3 had an IC

50 of 1.315 mg/mL. Notably, at a concentration of 2 mg/mL, the cell inhibition rates were 61.75% for 5-Fu, 59.54% for He3, and 59.17% for Gt. These findings confirm the existence of a certain inhibitory effect that is caused by the HE crude extracts on HCT-8 cells.

2.4. Effects of HE Fractional Alcohol Extracts on the Inhibition of HCT-8 Cells

Coarse-graded alcohol extraction was utilized to fractionate the supercritical crude extracts of HE into four fractions: 100% alcohol precipitate, 70% alcohol precipitate, 40% alcohol precipitate, and 40% alcohol supernatant. The anticancer activity of the fractionated alcoholic extracts derived from HE He12 crude was assessed, as shown in

Figure 7A–C. Varying concentrations of the isolated and fractionated alcoholic extracts were applied to HCT-8 cells for 24, 48, and 72 h. The growth inhibitory effect of the HCT-8 cells exhibited a dose-dependent and time-dependent relationship, except for the 40% alcohol supernatant, which exhibited no anticancer activity and was thus omitted from the figure. These findings suggest that the primary components with anticancer activity in the crude extracts of HE are concentrated in the 70% alcohol precipitate and higher fractions.

Based on the results obtained from the coarse fractional alcohol extraction, a secondary fractional alcohol extraction was conducted to partition the supercritical crude extracts of HE into three fractions: 90% alcohol precipitate, 80% alcohol precipitate, and 70% alcohol precipitate. The anticancer activity of the HE He12 secondary fractionation ethanol extracts was evaluated and is depicted in

Figure 7D–F. Various concentrations of the isolated and secondary fractionated alcohol extracts were applied to the HCT-8 cells for 24, 48, and 72 h. The results demonstrated a dose-dependent inhibitory effect that was caused by the crude extracts of HE on the growth of HCT-8 cells. Specifically, the 90% alcohol precipitate exhibited lower anticancer activity when compared to the 80% and 70% alcohol precipitates. Further comparison revealed similar anticancer activity between the 80% and 70% alcohol precipitates. As a result, the 70% alcohol precipitate was chosen for subsequent experiments.

In accordance with the findings obtained from graded alcohol extraction, the growth inhibitory effect of the 70% alcohol precipitates that were induced by the six different varieties of HE on HCT-8 cells was examined, as presented in

Figure 8. The HCT-8 cells were individually exposed to various 70% alcohol precipitate concentrations and varieties of the HE cells for 24 and 48 h. The results demonstrated a dose-dependent inhibition of HCT-8 cell growth by the 70% alcohol precipitates from the six HE varieties. Notably, when the concentration of the 70% alcohol precipitate from the HE He12 variety was 1.0 mg/mL, the rate of the cell growth inhibition reached 51.56%. Under the same concentration conditions, the positive control 5-Fu exhibited a cell growth inhibition rate of 60.98%. These findings highlight the successful separation of the active components in the crude extracts of HE through fractional alcohol extraction.

2.5. Functional Groups in HE Crude Extracts

The functional groups present in the crude extracts of HE were determined using FT-IR, a widely employed technique for evaluating substance quality and for conducting chemical analysis [

5].

The main functional groups in the HE crude extracts are identified in

Figure 9A (ATR) and

Figure 9B (transmission). Two detection methods (ATR and transmission) were employed within the wavenumber range of 4000 cm

−1 to 500 cm

−1.

Figure 9A,B clearly depicts broad peaks at 3313.83 cm

−1, indicating the presence of intermolecular hydroxyl (-OH) groups undergoing tensile vibrations. A sharp peak at 2921.90 cm

−1 was identified as dimer acid, while a medium sharp absorption band at 2851.92 cm

−1 indicated the presence of aldehydes, specifically carbonyl groups (C=O). The sharp absorption bands at 1710.09 cm

−1 were assigned to ketones, which could encompass six-membered ring ketones, seven-membered ring ketones, or larger ring ketones. Two weak peaks, observed between 1600 cm

–1 and 1700 cm

–1 (specifically at 1627.95 cm

−1 and 1654.45 cm

−1), were identified as nitrites. Furthermore, a weak absorption band at 1456.83 cm

−1 was identified as cis amides. Another sharp absorption band at 1045.98 cm

−1 in the HE extracts indicated the stretching vibration of the amine groups (C=N). The results derived from FT-IR established a theoretical basis for the subsequent experiments involving component analysis.

2.6. Component Analysis of the Extracts in Relation to Bioactivities

The peaks derived from the supercritical crude extracts of HE were subjected to GC-MS analysis (Agilent) by using the standard spectrum library to determine the composition of each peak. The chemical constituents, which were identified from a single variety of HE, are shown in

Appendix A Figure A1,

Figure A2 and

Figure A3. The GC-MS spectrum of the crude supercritical extracts of HE is presented in

Figure 10A. The main components identified in the 4916 crude extracts were palmitic acid, oleic acid, 9-octadecenamide, erucamide, dehydro-ergosterol, and ergosterol. In Gt, the primary components were palmitic acid, octadecadienoic acid, oleic acid, erucamide, isochoric acid ethyl ester, dehydro-ergosterol, and ergosterol. He3 contained pentadecanoic acid, palmitic acid, erucamide, and ergosterol as its main components, while He12 comprised pentadecanoic acid, palmitic acid, isochoric acid ethyl ester, erucamide, dehydro-ergosterol, and ergosterol. The main components of He13 were pentadecanoic acid, palmitic acid, erucamide, dehydro-ergosterol, and ergosterol, while T3 consisted of palmitic acid, octadecadienoic acid, 9-octadecenamide, erucamide, dehydro-ergosterol and ergosterol. Among the identified components, stearic acid esters were the most common, with stearic acid methyl esters being the predominant ones. Notably, this study detected erucamide in HE for the first time. Erucamide is commonly used as a slip agent and as an anti-adhesive agent in plastics; thus, this could indicate potential environmental pollution during the growth of the HE. Palmitic acid and oleic acid, which exhibited the highest relative content, are crucial components in the growth process of HE. As an octadecyl compound, oleic acid is widely distributed in organisms and possesses significant physiological activities.

To investigate further, a secondary detection was carried out with different methods and instruments (Shimadzu, Kyoto, Japan) on the supercritical extracts of the six HE varieties. Notably, significant variations were observed in the components of the supercritical crude extracts across the different HE varieties (see

Supplementary Materials, Tables S1–S6). Specifically, 4916 exhibited 47 components, Gt had 52 components, He3 contained 31 components, He12 contained 38 components, He13 contained 42 components, and T3 contained 38 components. Based on the GC-MS analysis of the chemical structure, the components were broadly categorized into three groups: hydrocarbons, oxygen-containing compounds, and nitrogen-containing compounds. The GC-MS spectrum of the supercritical crude extract of HE is shown in

Figure 10C. Analysis of the peak areas revealed that the five components with the highest concentrations of the six HE varieties were 9,12-octadecadienoic acid, oleic acid, stearic acid, palmitic acid, and pentadecanoic acid. Previous studies on the volatile oil components of HE have predominantly focused on fatty acids and esters, such as palmitic acid, stearic acid, oleic acid, etc.

The GC-MS spectrogram in

Figure 10B illustrates the HE isolates obtained through fractional alcohol extraction. The primary constituents of the 4916 isolates were caproic acid, trimethyl tetradecane, palmitic acid, dehydro-ergosterol, neo-ergosterol, and ergosterol. Similarly, Gt contains caproic acid, phenethyl-benzylamine, palmitic acid, octadecadienoic acid, dehydro-ergosterol, spiro sterane, ergosterol, neo-ergosterol, ergo-sterane, and anthracene tetra enol. He3 consists of caproic acid, palmitic acid, oleic acid, spiro sterane, dehydro-ergosterol, ergosterol, and neo-ergosterol. In addition, He12 includes caproic acid, stearic acid, palmitic acid, dehydro-ergosterol, ergosterol, ergo sterane, and γ-ergosterol, while He13 contains benzene, hexanoic acid, trimethyl tetradecane, palmitic acid, spiro sterane, dehydro-ergosterol, ergosterol, ergo-sterane, γ-ergosterol, and anthracene tetra enol. T3 consists of hexanoic acid, palmitic acid, octadecadienoic acid, spiro sterane, dehydro-ergosterol, ergosterol, neo-ergosterol, anthracene tetra enol, γ-ergosterol, and ergo sterane. Upon comparing the GC-MS spectrum of the crude extracts, erucamide was found to be absent in the HE isolates. However, various sterols and sterol derivatives were detected, including ergosterol, dehydro-ergosterol, neo-ergot sterols, γ-ergosterol, ergo-steranes, spiro sterane, and anthracene tetra enol. Due to the diverse chemical properties of these identified compounds, it remains unclear which specific compounds or combinations contribute to the inhibition of HCT-8 cell proliferation. Hence, further validation studies are necessary to determine the therapeutic potential of the active ingredients present in the supercritical extracts of HE.